Inner box forming machine

A forming machine and inner box technology, applied in container manufacturing machinery, box making operations, paper/cardboard containers, etc., can solve the problems of high production cost and low processing efficiency, achieve uninterrupted material feeding and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

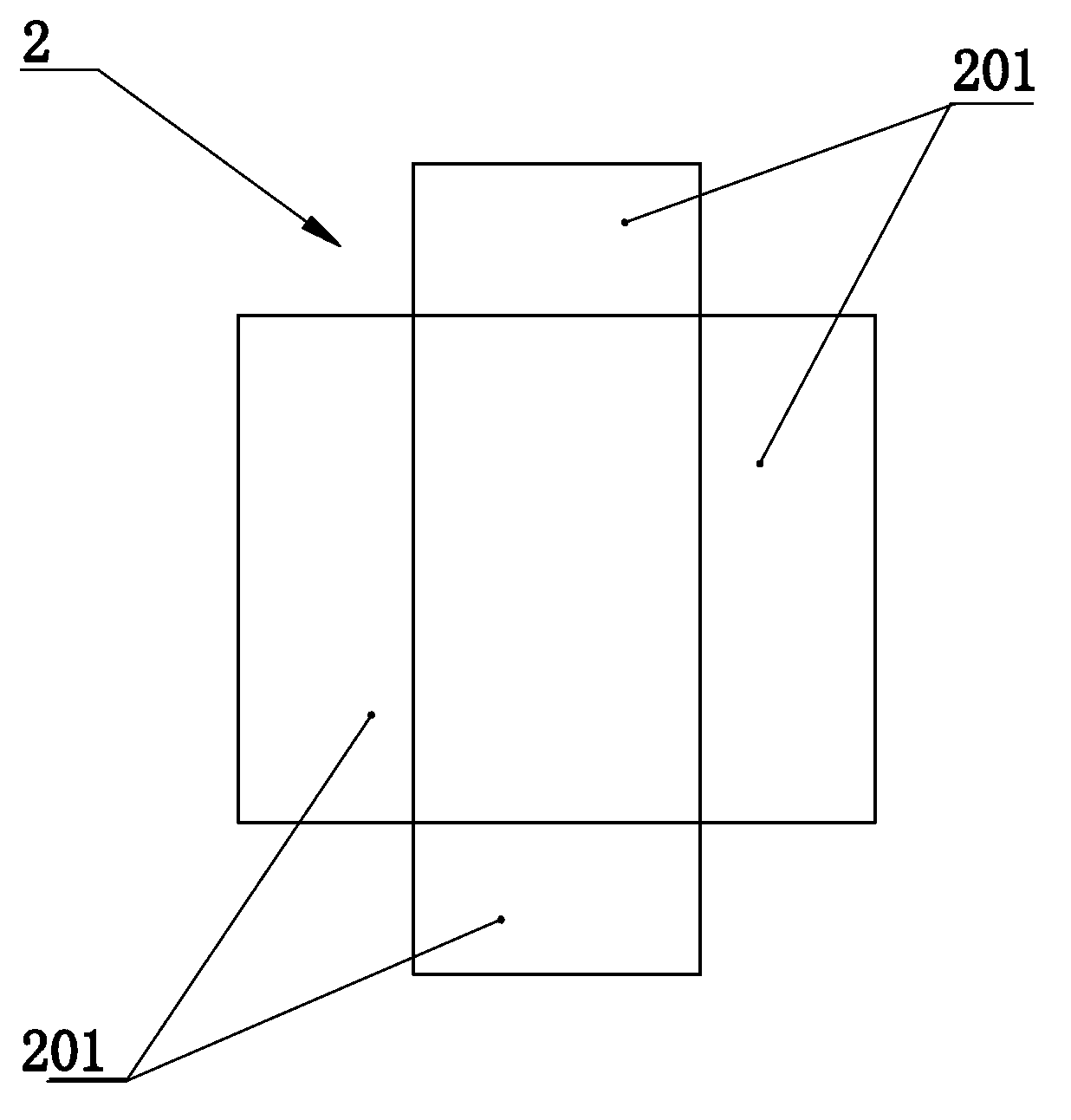

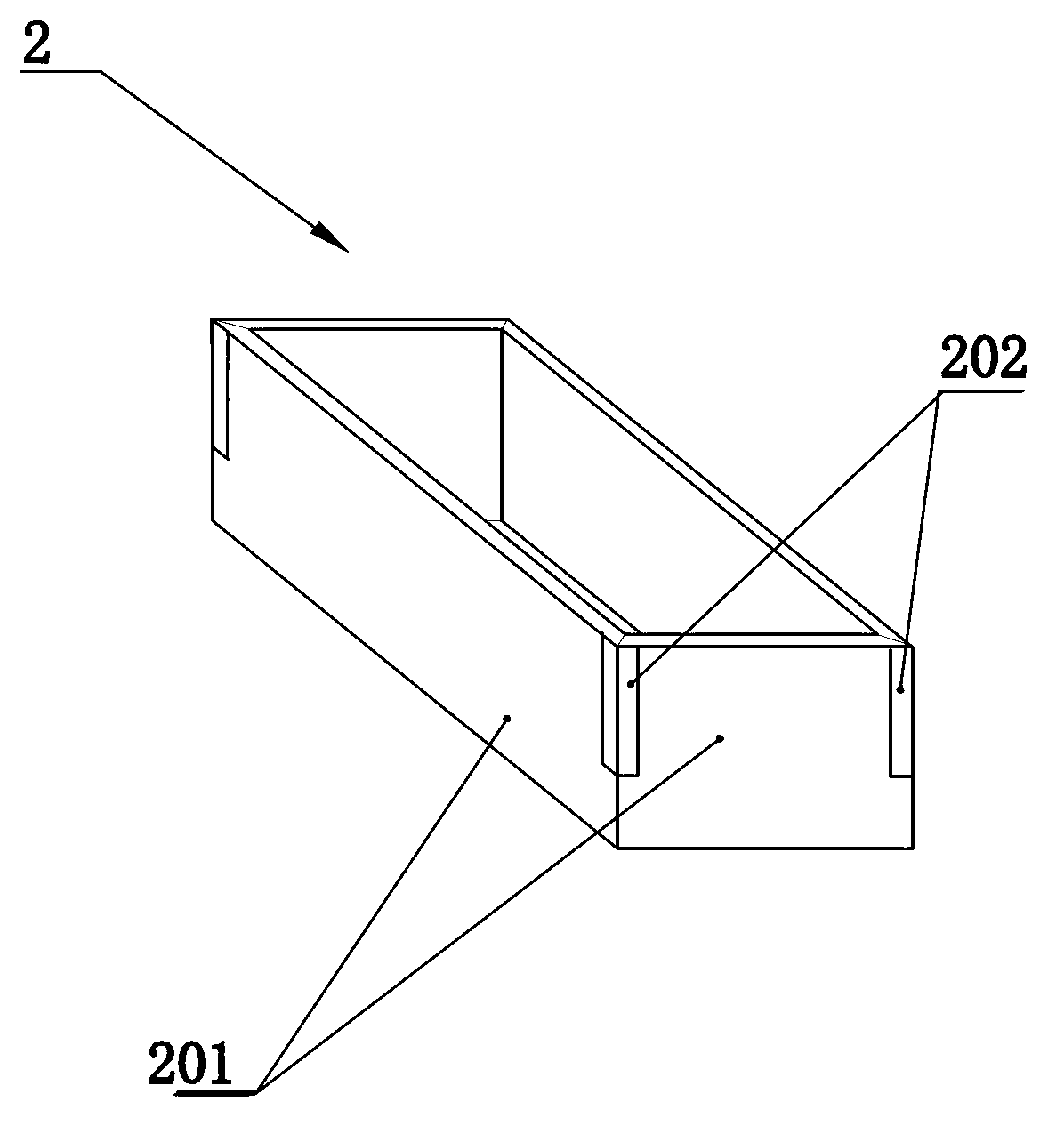

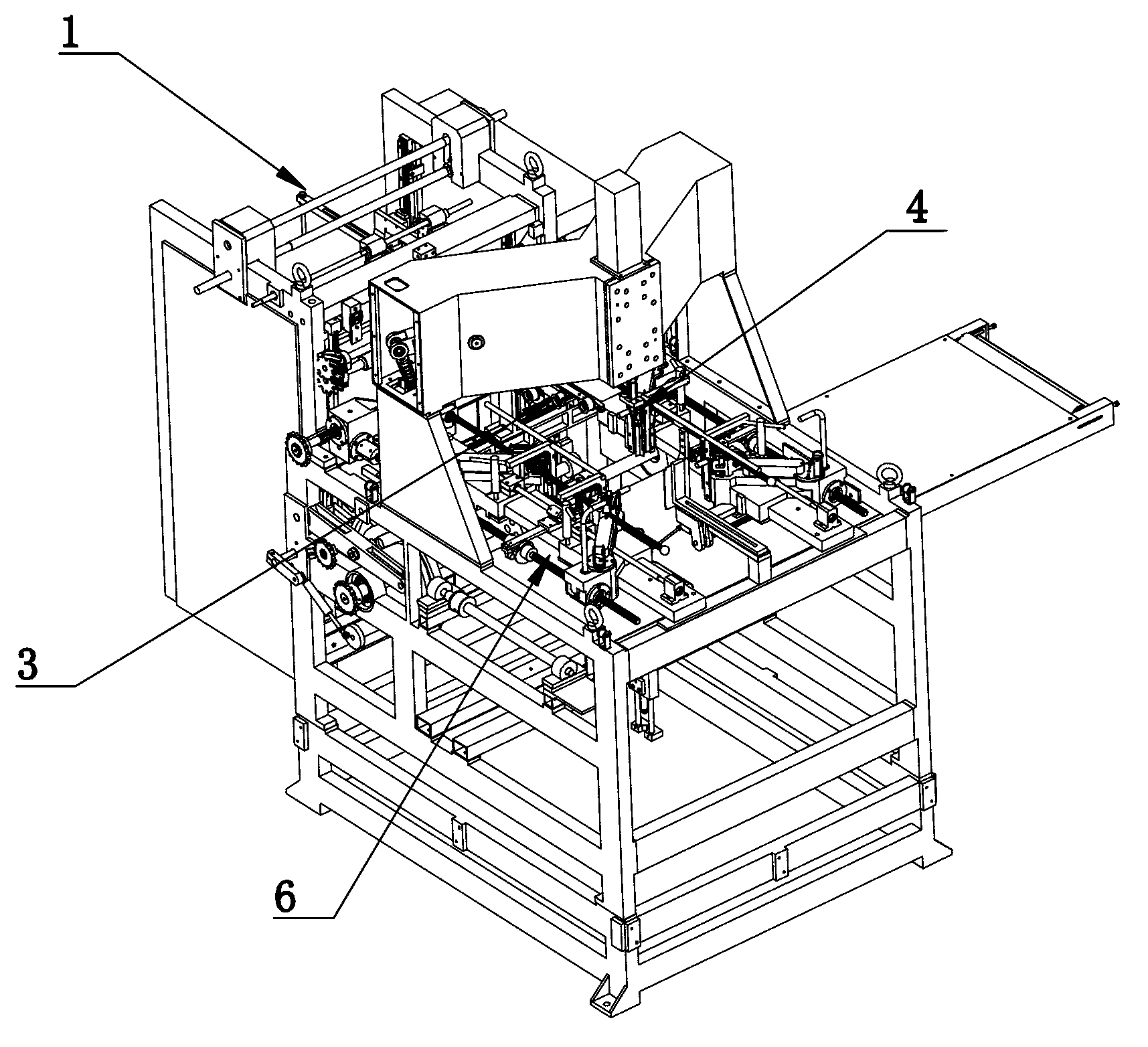

[0039] See attached figure 1 , the inner box forming machine disclosed by the present invention includes a discharging mechanism 1 for discharging the inner box cardboard one by one, a transmission mechanism 3 arranged on the rear side of the discharging mechanism 1 and used for transmitting the inner box cardboard 2, and the transmission mechanism 3 is relatively placed The other end of the material mechanism 1 is provided with a die head 4 that can move up and down, and the four ear sides 201 of the inner box cardboard 2 are provided with shaping parts 5 under the die head 4, and the corresponding inner box cardboard 2 is placed under the die head 4. A group of sticker mechanisms 6 are respectively provided at the four corners after being framed. By adopting the above technical scheme, during processing, the inner box cardboard 2 is discharged one by one by the discharging mechanism 1, and then conveyed by the conveying mechanism 3. When the inner box cardboard 2 is transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com