A casting cleaning line self-transfer system

A casting cleaning and casting technology, applied in foundry, casting equipment, conveyor objects, etc., can solve problems affecting work efficiency, wear, and large vehicles, and achieve the effect of improving production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

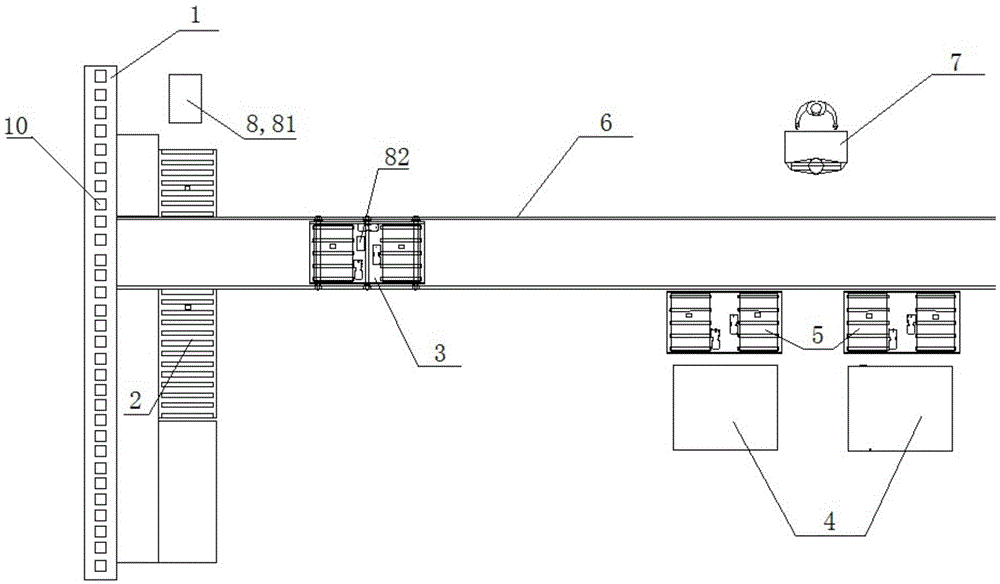

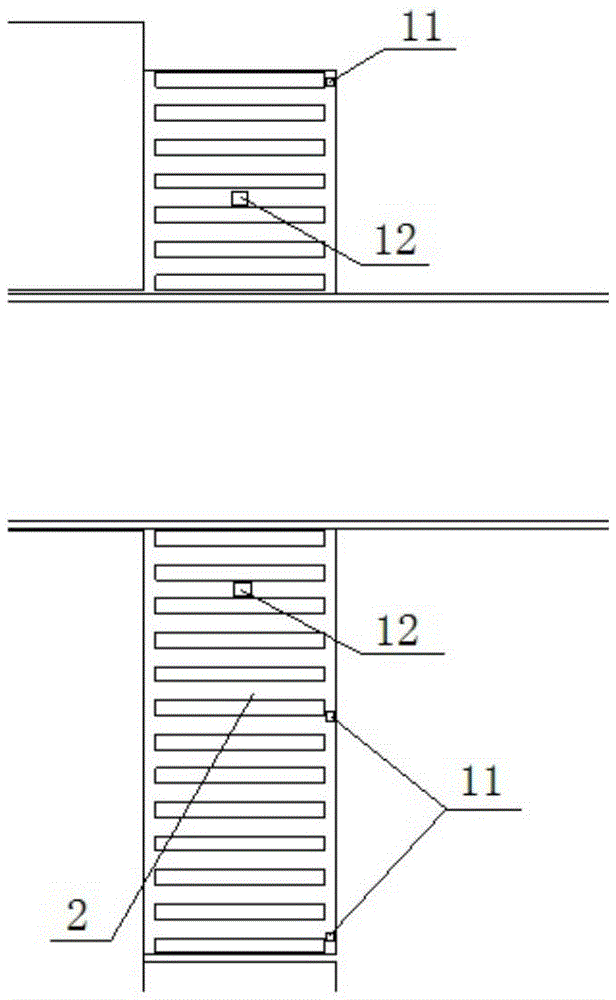

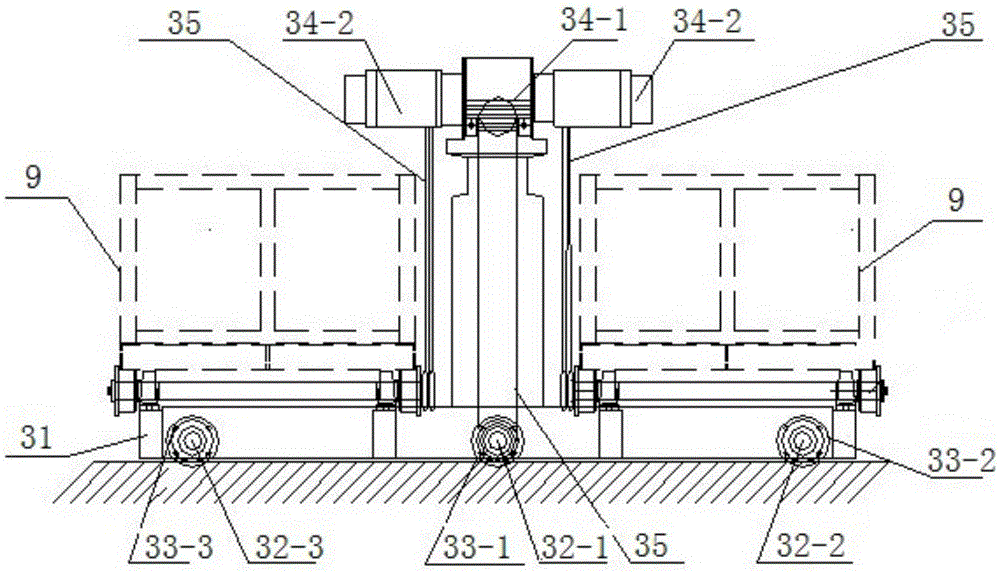

[0024] See Figure 1 to Figure 6 , the self-transfer system of the casting cleaning line of the present invention includes a shot blasting casting transportation line 1, a shot blasting machine rear roller table 2 arranged in parallel with the shot blasting casting transportation line 1, and a shot blasting casting transportation line 1 and a shot blasting casting rear roller table 2 The vertically arranged track 6 and the grinder 4 located on the outside of the end of the track 6 away from the rear roller table 2 of the shot blasting casting. There is also a front roller track 5 between the grinder 4 and the track 6; the upper part of the track 6 is provided with a track transfer The car 3 and the other side of the track 6 are also equipped with a main control console 7. When the automatic control system fails or is otherwise necessary, the transfer of the casting cleaning line can be realized through manual control of the self-transfer system, thereby ensuring the cleaning an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com