A rotary automatic feeding mechanism for a stamping machine

An automatic feeding and punching machine technology, applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of low efficiency, laborious and time-consuming manual feeding, etc., achieve simple control, short intermediate feeding process, and improve feeding efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] as attached Figure 1-7 As shown, the blank 1 mentioned in the present invention refers to a circular metal sheet with two plane faces.

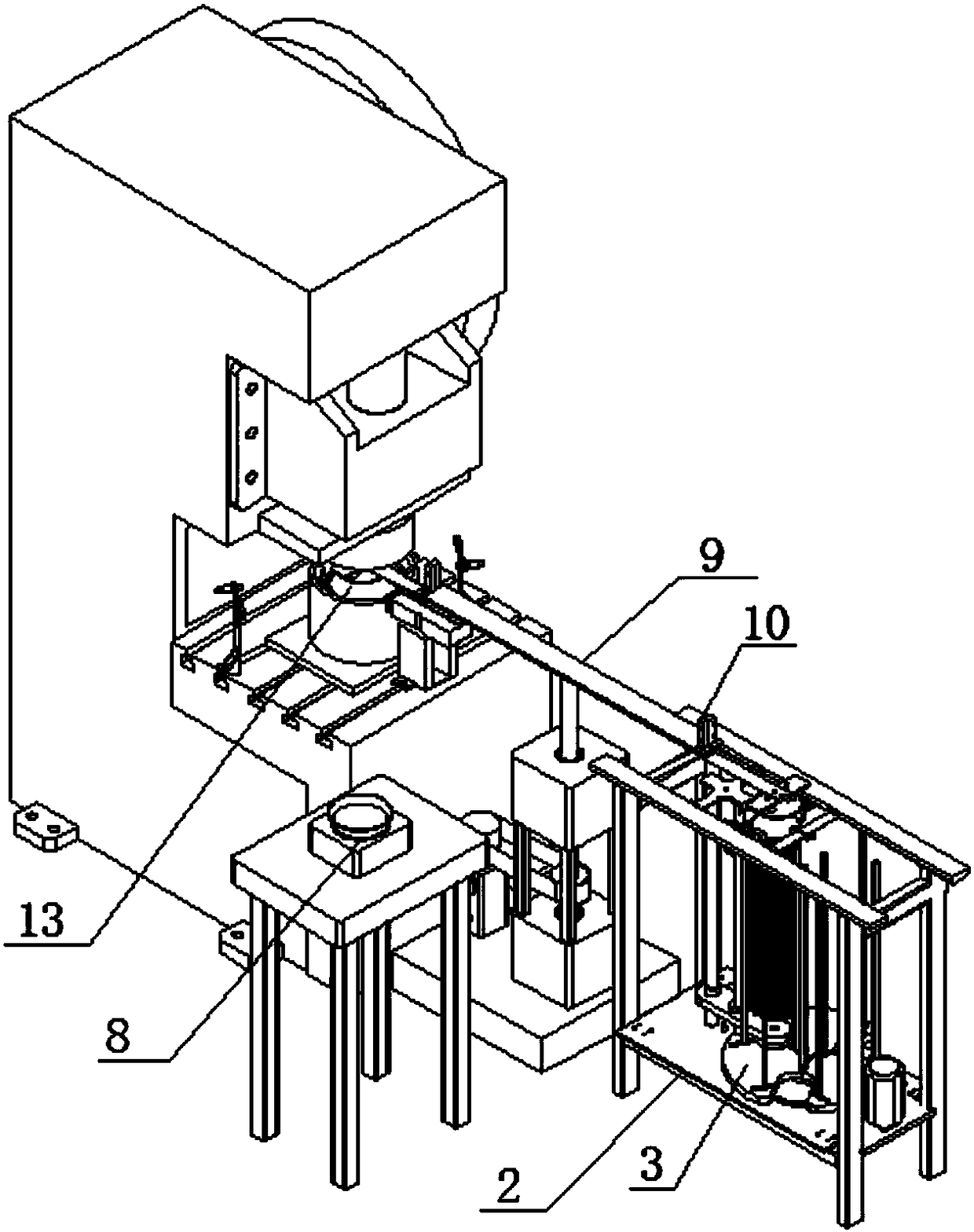

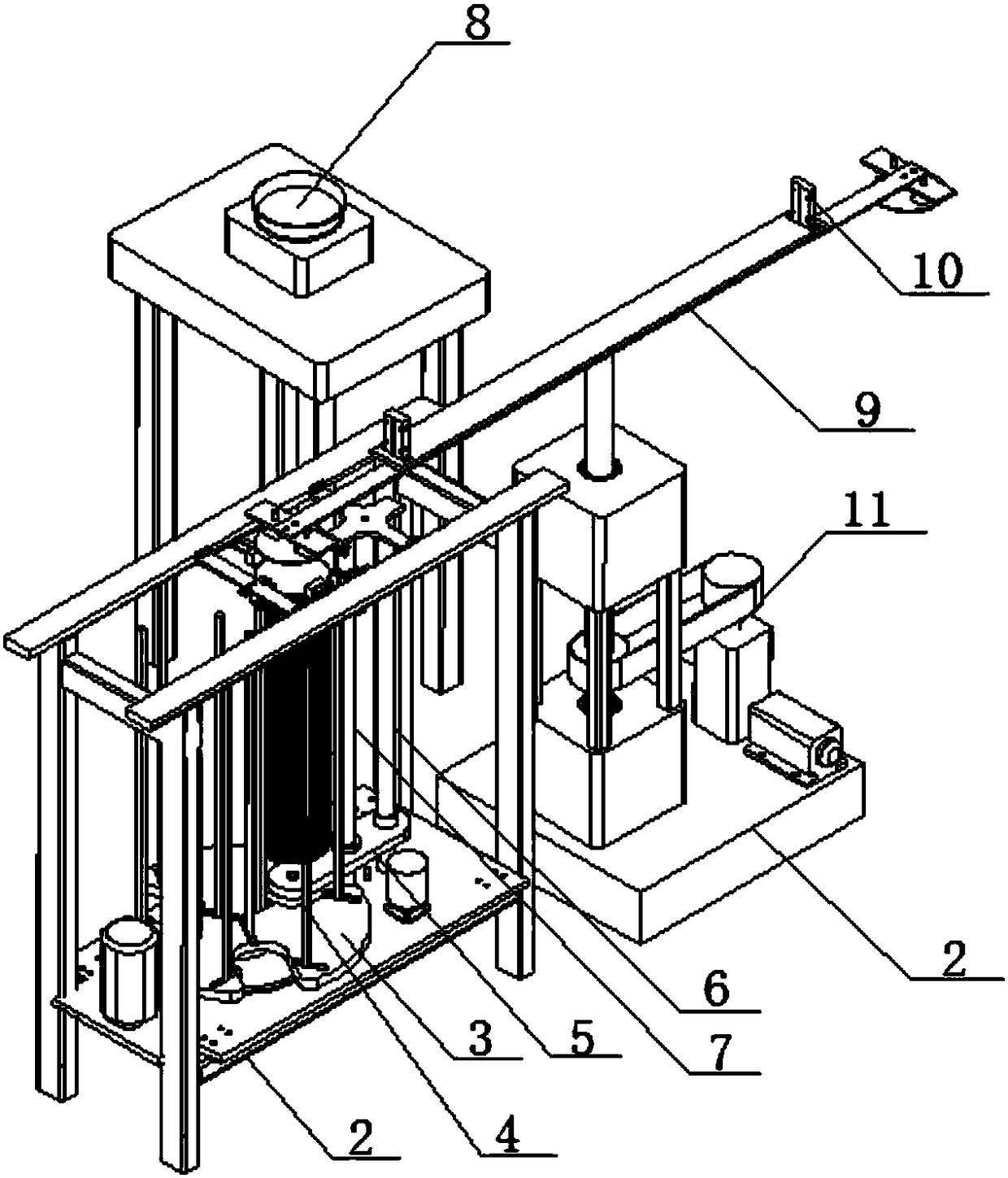

[0033] A rotary automatic feeding mechanism for a punching machine, comprising a frame 2, a feeding mechanism, a feeding mechanism, a punching machine 16, a detection disc 8, a blank detection and positioning mechanism and a main control machine.

[0034] The feeding mechanism, the retrieving mechanism, and the detection disc 8 are all fixed on the frame 2. According to the clockwise direction, the feeding mechanism, the detection disc 8 and the punching machine 16 are sequentially fixed around the retrieving mechanism, and the feeding mechanism, the detection disc 8 And stamping machine 16 is all equal from the distance of taking material mechanism.

[0035] The feeding mechanism includes a lifting pallet 5, a first drive motor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com