A feeder tray grabbing mechanism for a multifunctional machine

A technology of grabbing mechanism and feeder, applied in the direction of electrical components, electrical components, etc., can solve the problems affecting the production efficiency of the feeder, and achieve the effect of simple structure, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

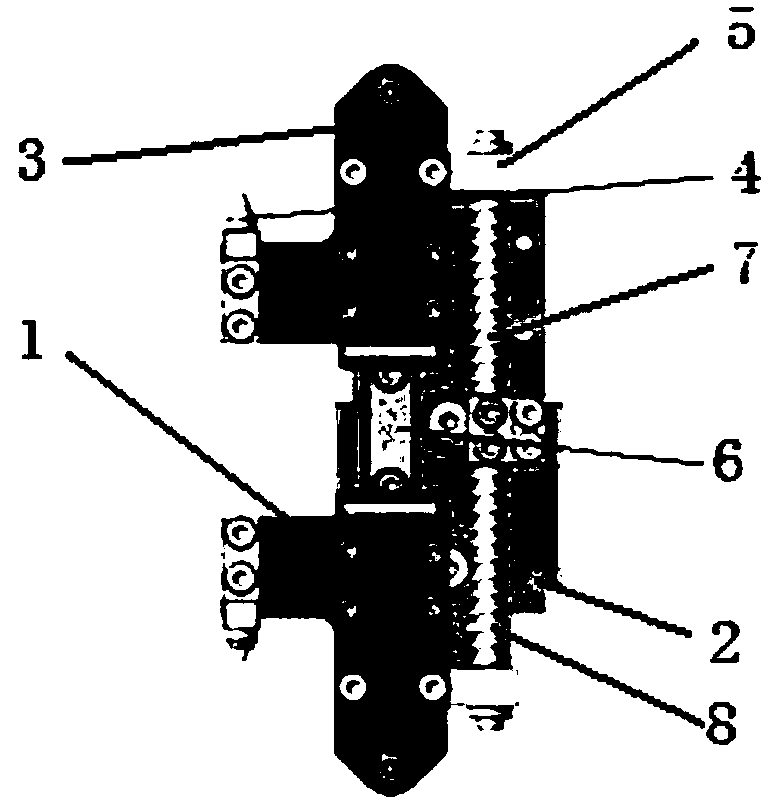

[0024] refer to figure 1 , a feeder tray grabbing mechanism for a chip mounter, the grabbing mechanism includes a pair of jaws 1 and a base 2 . The jaw 1 includes a slider 3, a positioning pin 4 and a sliding sleeve 5 fixed on the slider 3, and the base 2 is provided with two jaw guide rails 6, two guide posts 7 and two clamping jaws. The spring 8, the two jaw guide rails 6, the two guide posts 7 and the two clamping springs 8 are arranged end to end opposite to each other. When the base 2 is combined with a pair of jaws 1, the slider 3 is matched with the jaw guide rail 6, the sliding sleeve 5 is matched with the guide post 7, and the clamping spring 8 is set on the guide post 7 and press it tightly so that the pair of jaws 1 are separated from each other.

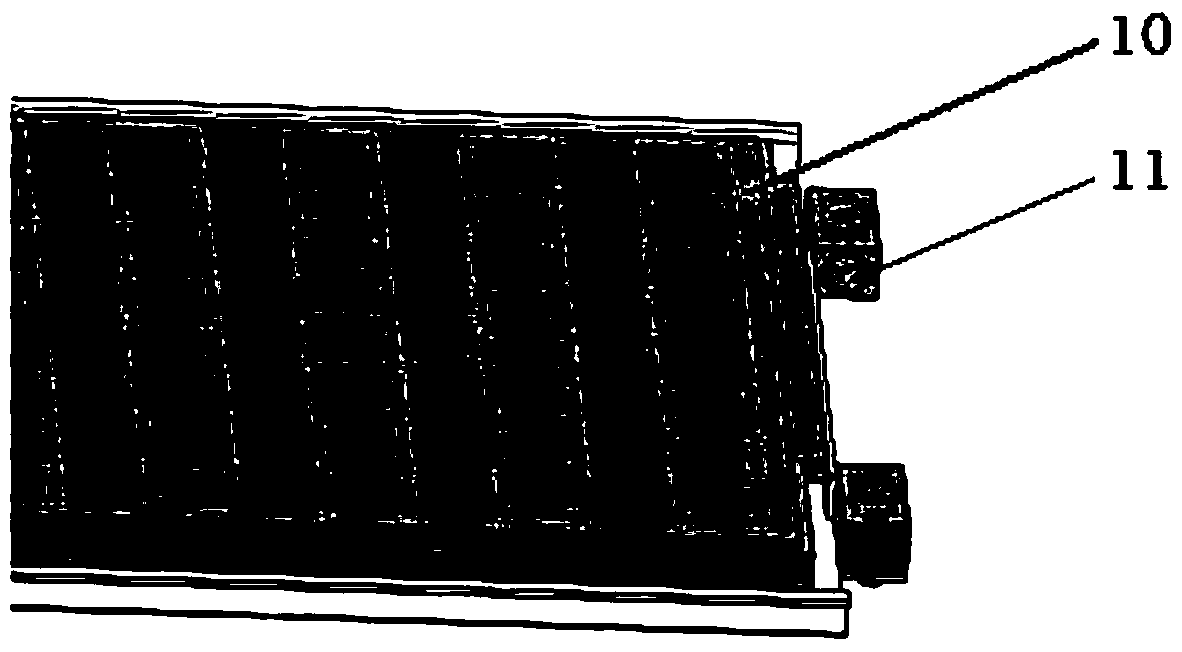

[0025] refer to figure 2 , the tray 10 matched with the tray grabbing mechanism is provided with a tray grabbing positioning hole 11 at a corresponding position.

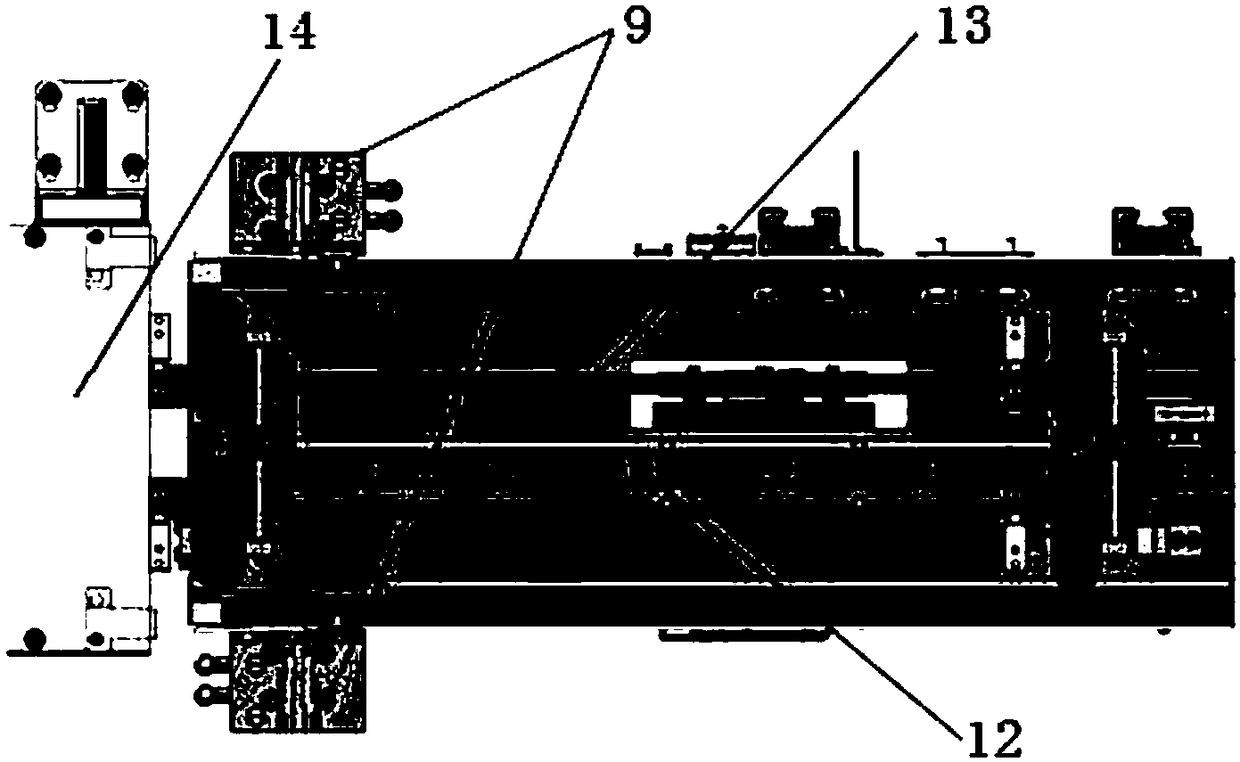

[0026] refer to image 3 , the relative movement of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com