Multi-country specification uninterrupted feeding stock bin mechanism and feeding method

An instruction manual, country-specific technology, applied in the multi-country manual uninterrupted feeding silo mechanism and material supply field, it can solve the problems of wide area and low work efficiency, reduce the area, ensure production efficiency, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-6 The application is described in further detail.

[0042] The embodiment of the present application discloses a multi-country instructions uninterrupted feeding bin mechanism.

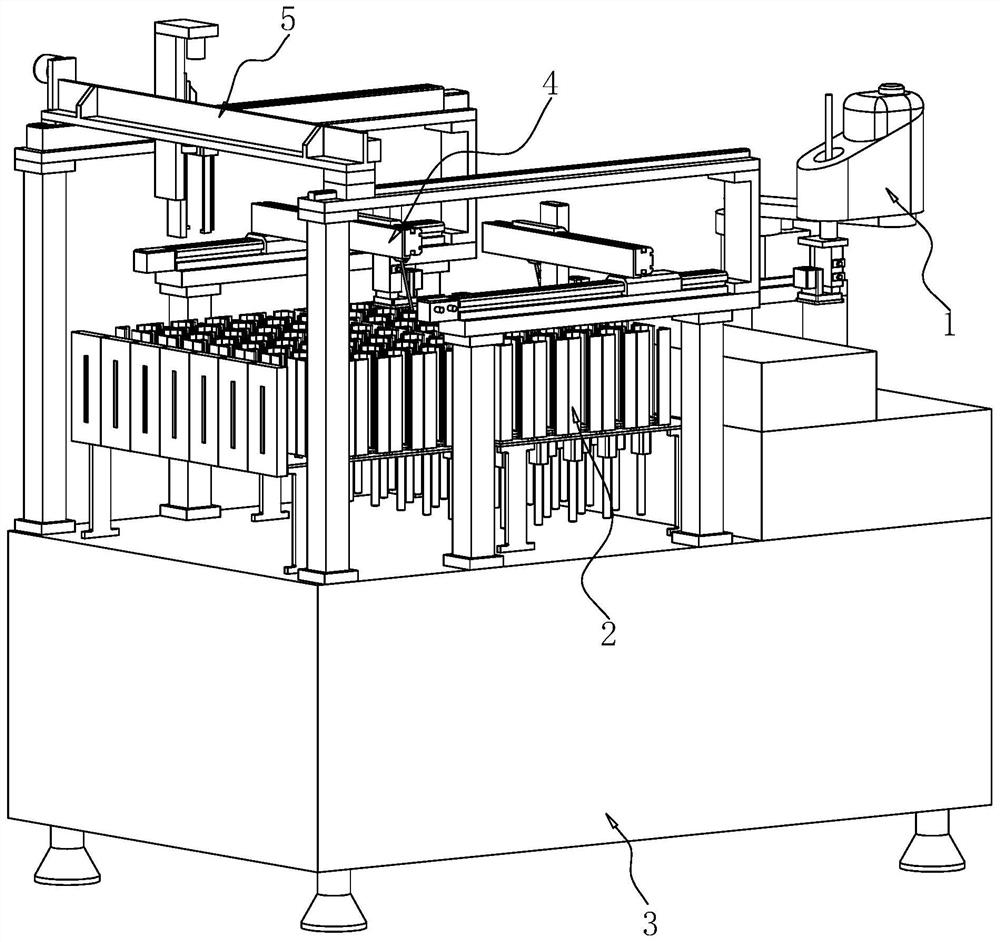

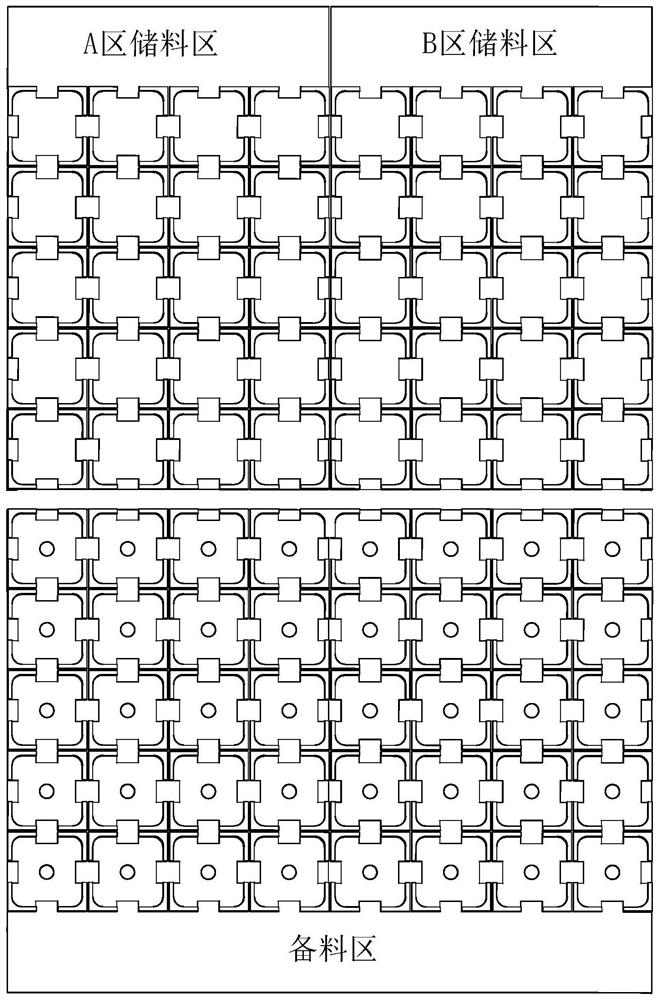

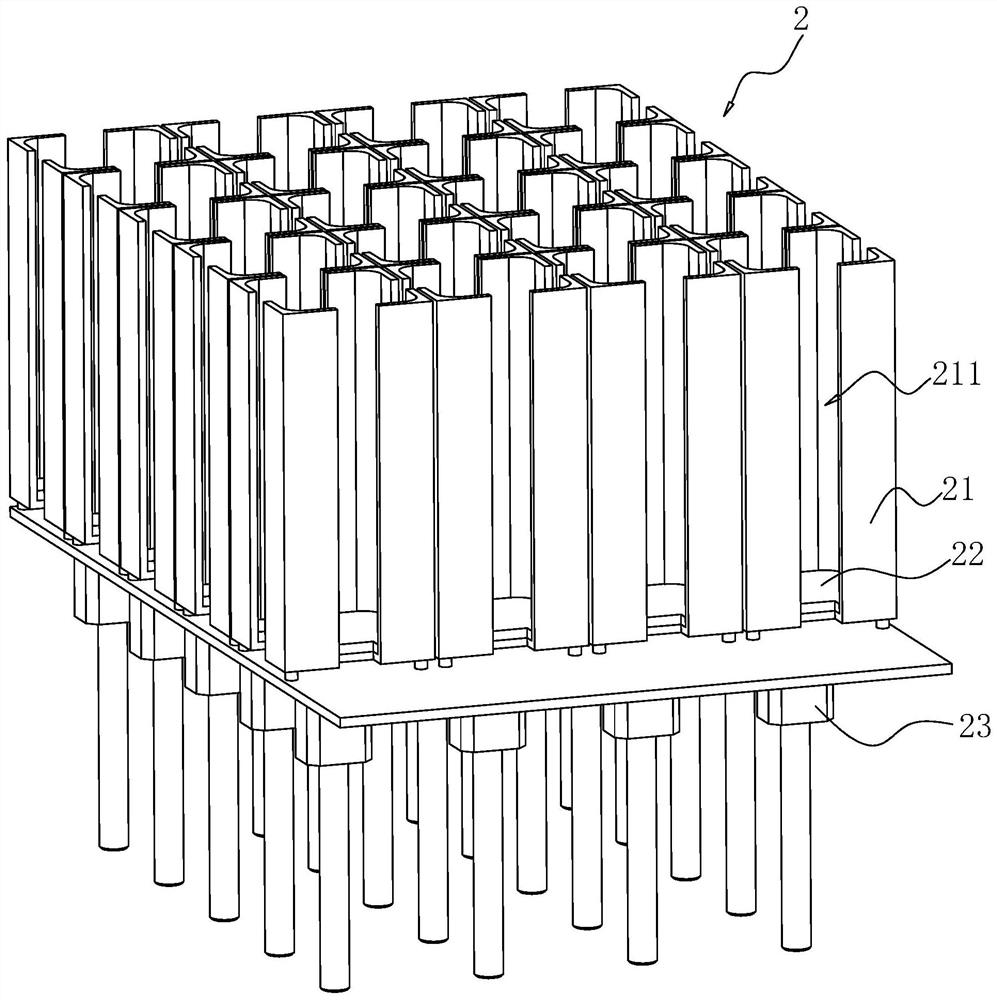

[0043] refer to figure 1 and figure 2 The multi-country manual uninterrupted feeding silo structure includes a pick-and-place instruction robot 1, a storage component 2, a chassis 3 and a retrieving component 4; the chassis 3 is a rectangular box, and the upper surface of the chassis 3 is divided into a storage area and a temporary storage area ; The temporary storage area is used to temporarily place a single manual for picking and placing the manual. The robot 1 places it in the packaging box; The material area is distributed along the width direction of the cabinet 3; the temporary storage area and the storage area are distributed along the length direction of the cabinet 3; Instructions for the area are placed in the box.

[0044] refer to figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com