Grouting trolley

A trolley and pulping technology, which is applied in the direction of control devices, clay preparation devices, cement mixing devices, etc., can solve the situation that is not suitable for moving, the space occupied by the mixing pulper and the pumping system is large, and the installation process is cumbersome. and other problems, to achieve the effect of improving production efficiency, facilitating movement, and eliminating the disassembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The core of the present invention is to provide a grouting trolley so as to meet the requirements of grouting and grouting under mobile occasions.

[0039] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

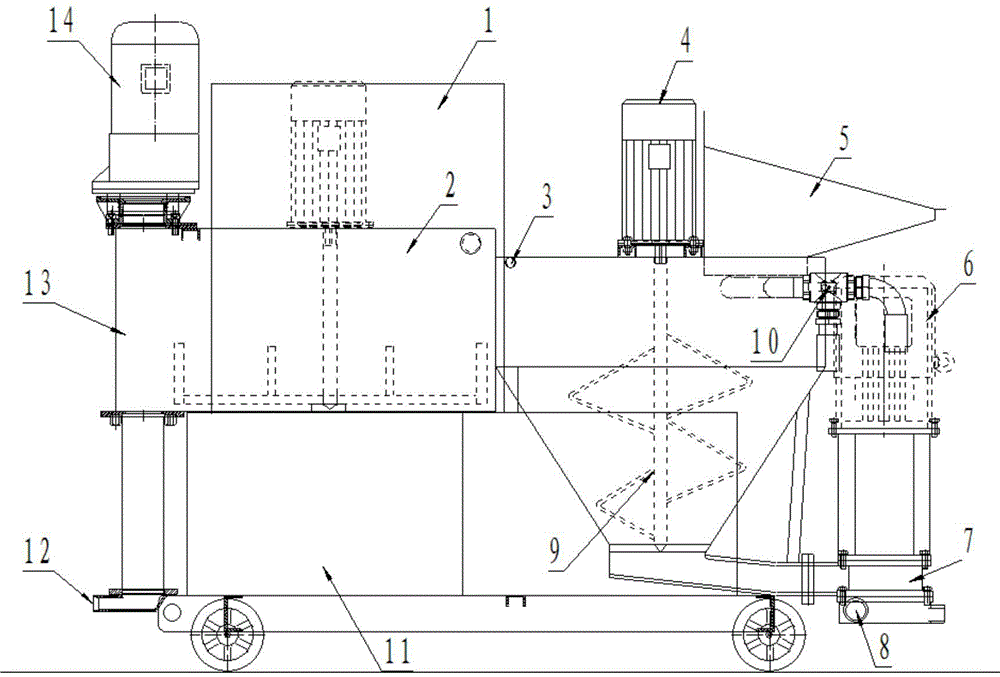

[0040] Please refer to figure 1 , figure 1 It is a schematic structural diagram of a grouting trolley provided in an embodiment of the present invention.

[0041] The grouting trolley provided by the present invention includes a frame, a pulping system and a slurry pumping system, wherein the bottom of the frame is provided with walking wheels to meet the requirements of the mobility of the grouting trolley when working in mobile situations. Requirements, the slurry system is used to prepare the cement slurry that meets the requirements, and the slurry pumping system is used to pump the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com