Automatic rotary feeding device

A technology of automatic rotation and rotation motor, which is applied in the direction of conveyor control device, transportation and packaging, conveyor objects, etc. It can solve the problems of low efficiency and inability to realize fully automated production, and achieve the effect of improving feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

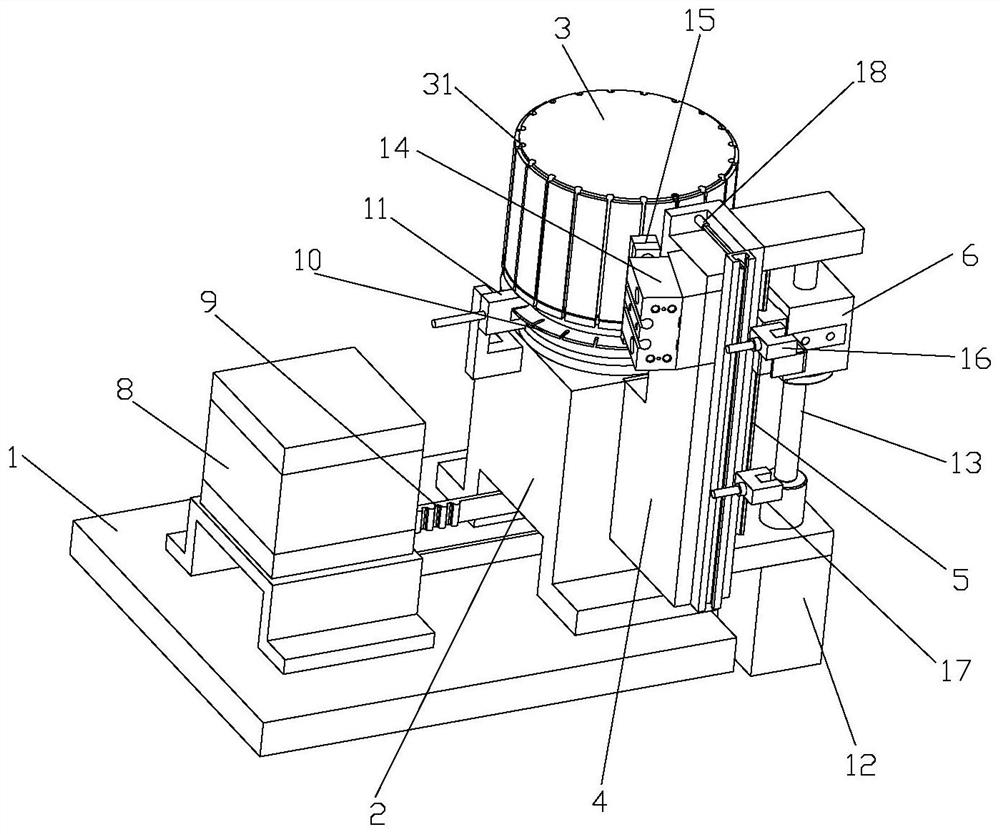

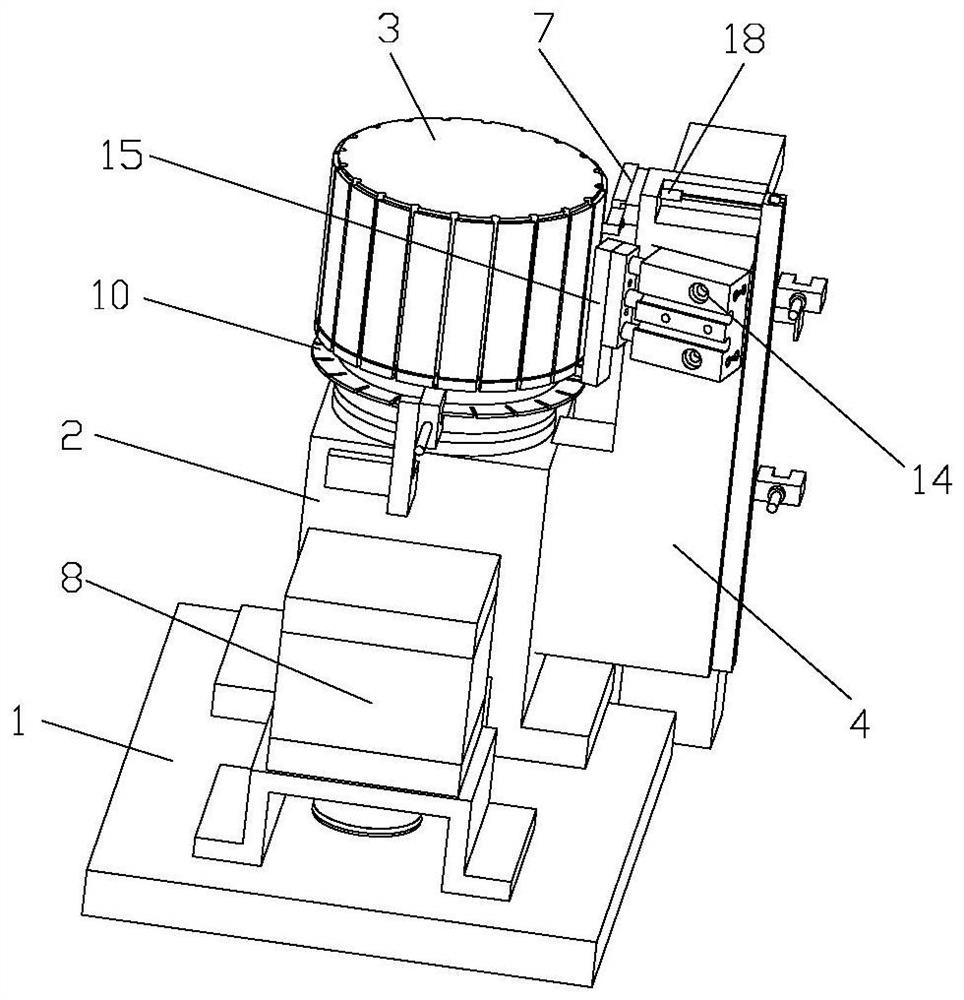

[0016] Such as Figure 1-2 As shown, an automatic rotary feeding device of the present invention comprises a bottom plate 1, a fixed frame 2 is fixed on one side of the upper end surface of the bottom plate 1, and a cylindrical feed bin 3 is rotatably connected to the fixed frame 2, and the feed bin 3 Driven by the rotary drive mechanism to rotate intermittently in the horizontal plane, the periphery of the silo 3 is provided with a plurality of troughs 31 arranged axially along the circumference; the side of the fixed frame 2 is fixed with a bracket 4, A guide rail 5 arranged vertically is fixed on the support 4, and a lifting seat 6 is slid on the guide rail 5, and the lifting seat 6 is driven by a lifting drive mechanism to perform intermittent lifting movements. There is a driving rod 7, and the end of the driving rod 7 extends into the material chute 31 at the upper material level, and the lifting seat 6 drives the driving rod 7 to rise intermittently, so that the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com