Continuous coating material conveying device for linear metal coating evaporation source

A metal coating, linear technology, applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problems of increasing the difficulty of vacuum degree and cleanliness in the coating area, increasing the coating space, etc. Improved vacuum and cleanliness, reduced space, improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

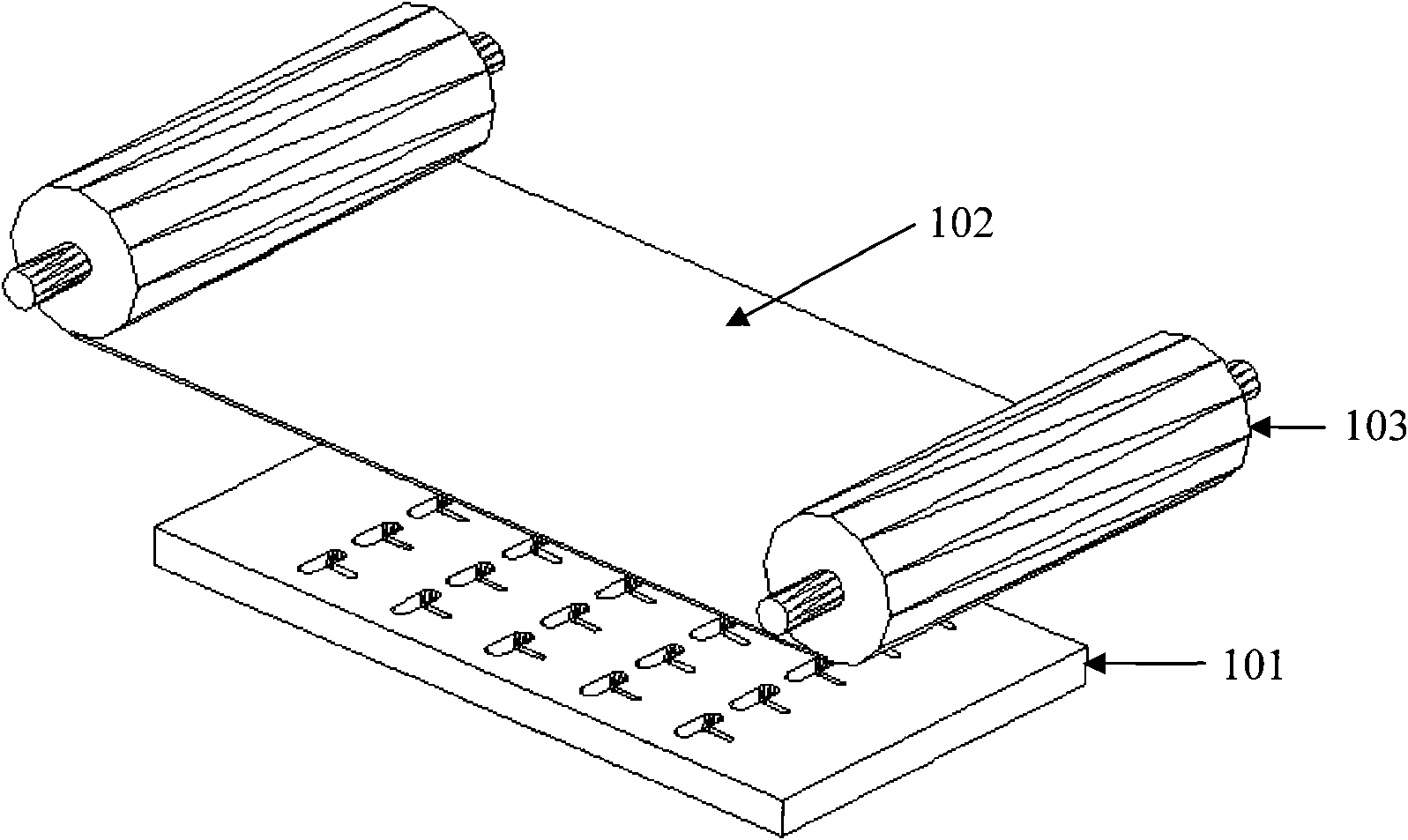

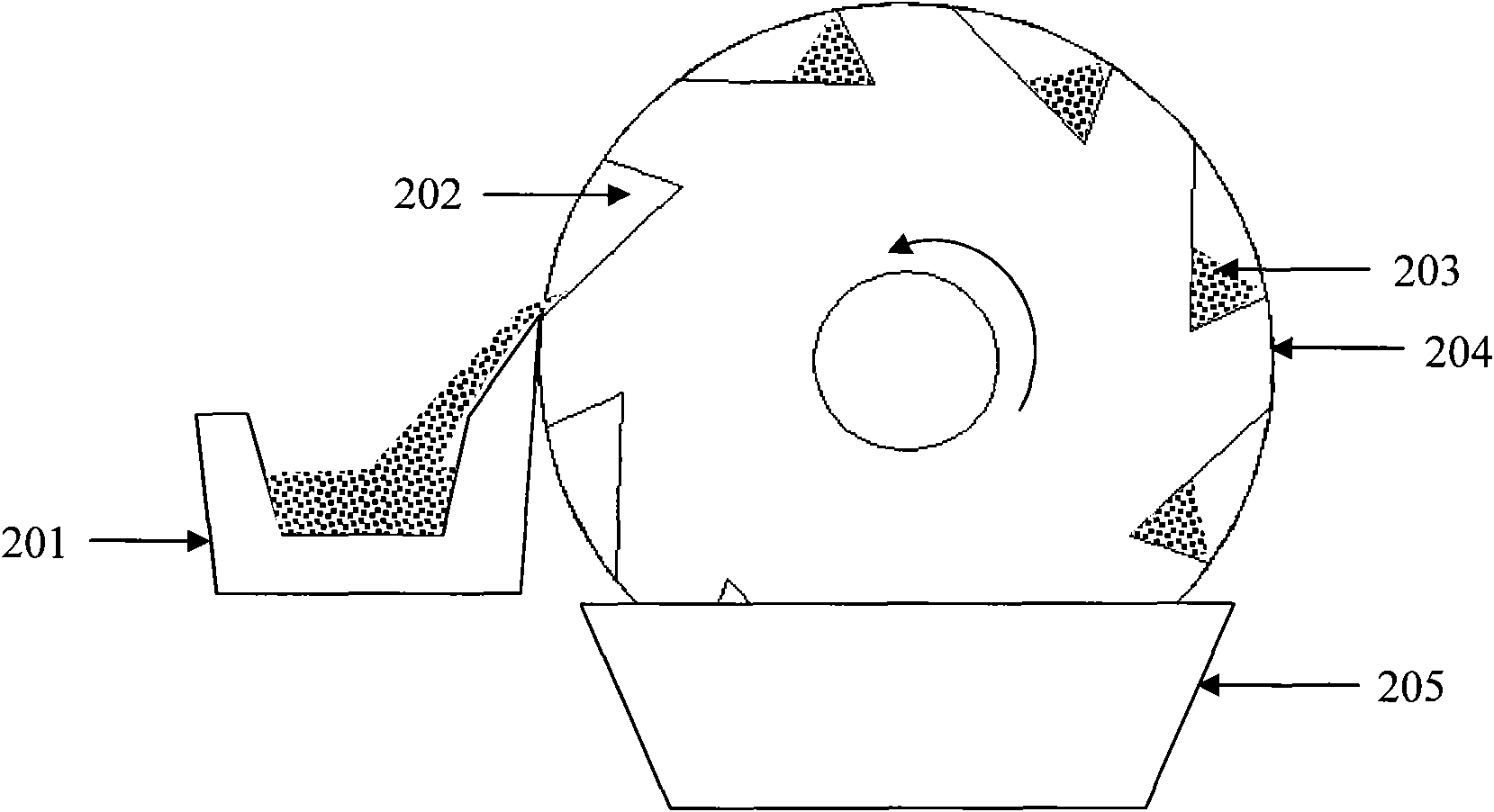

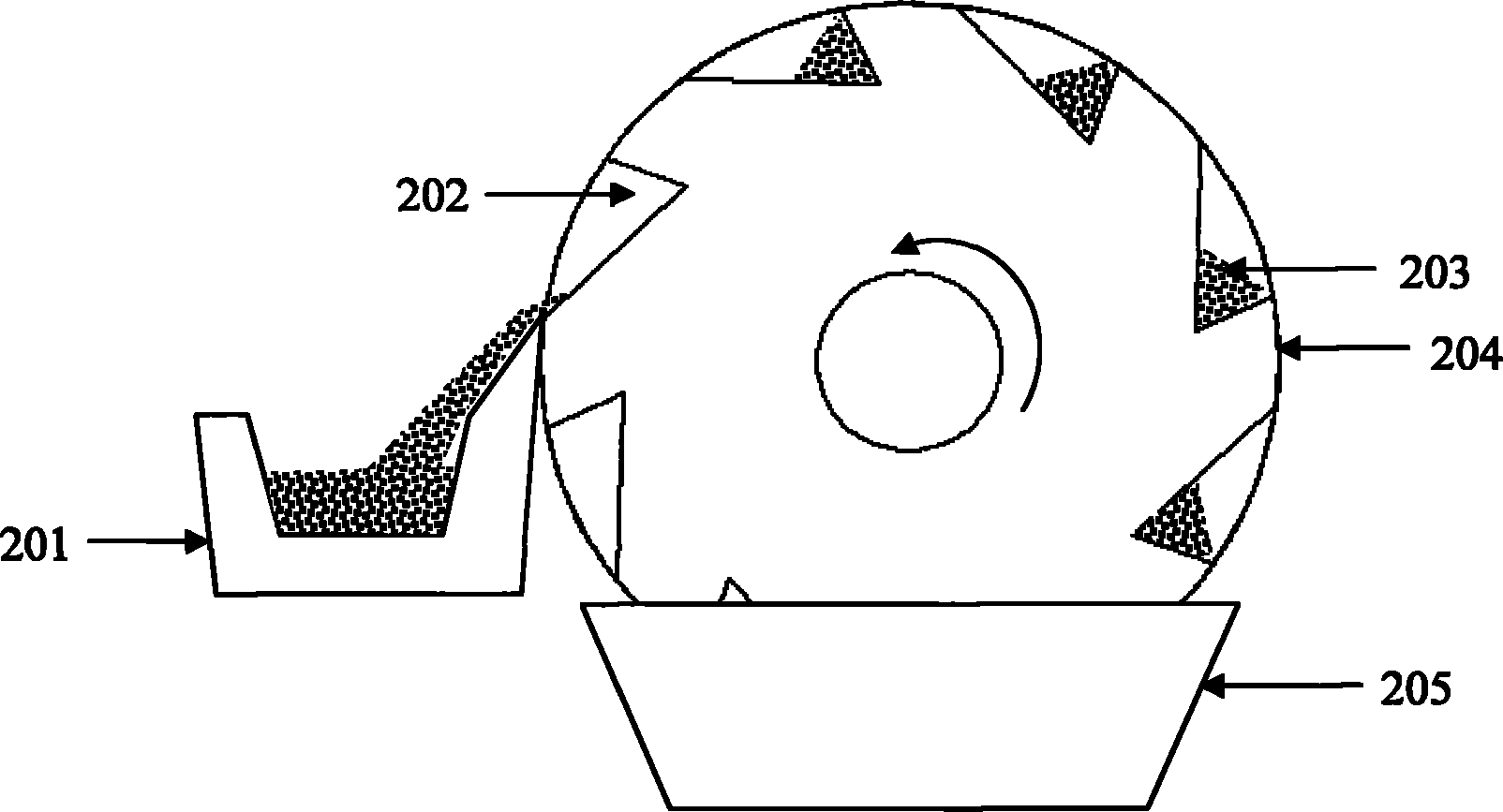

[0017] Such as figure 2 The cross-sectional structure of the metal thin film thermal evaporation system is shown. The present invention adopts a linear thermal evaporation source and a roller feeding device to cooperate with a substrate winding mechanism to realize large-area continuous technical coating.

[0018] The linear metal evaporation source is a strip-shaped open crucible 201, which reaches the melting evaporation temperature of the metal coating material through resistance heating or induction heating. And the length of the strip-shaped open crucible 201 matches the width of the base material, and is greater than or equal to the length of the roller feeding device 204 .

[0019] The rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com