Flaky material stacking and conveying device

A technology of sheet material and conveying device, applied in the direction of handling coins or valuable banknotes, instruments, etc., can solve the problems of low production efficiency of the whole machine, shutdown of the input part, low efficiency, etc., and improve the efficiency of discharging and sorting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0025] The sheet material stack conveying device provided by the present invention is used for uninterruptedly conveying sheet material stacks from multiple discharge openings of the sheet material sorting equipment to the sorting equipment entrance.

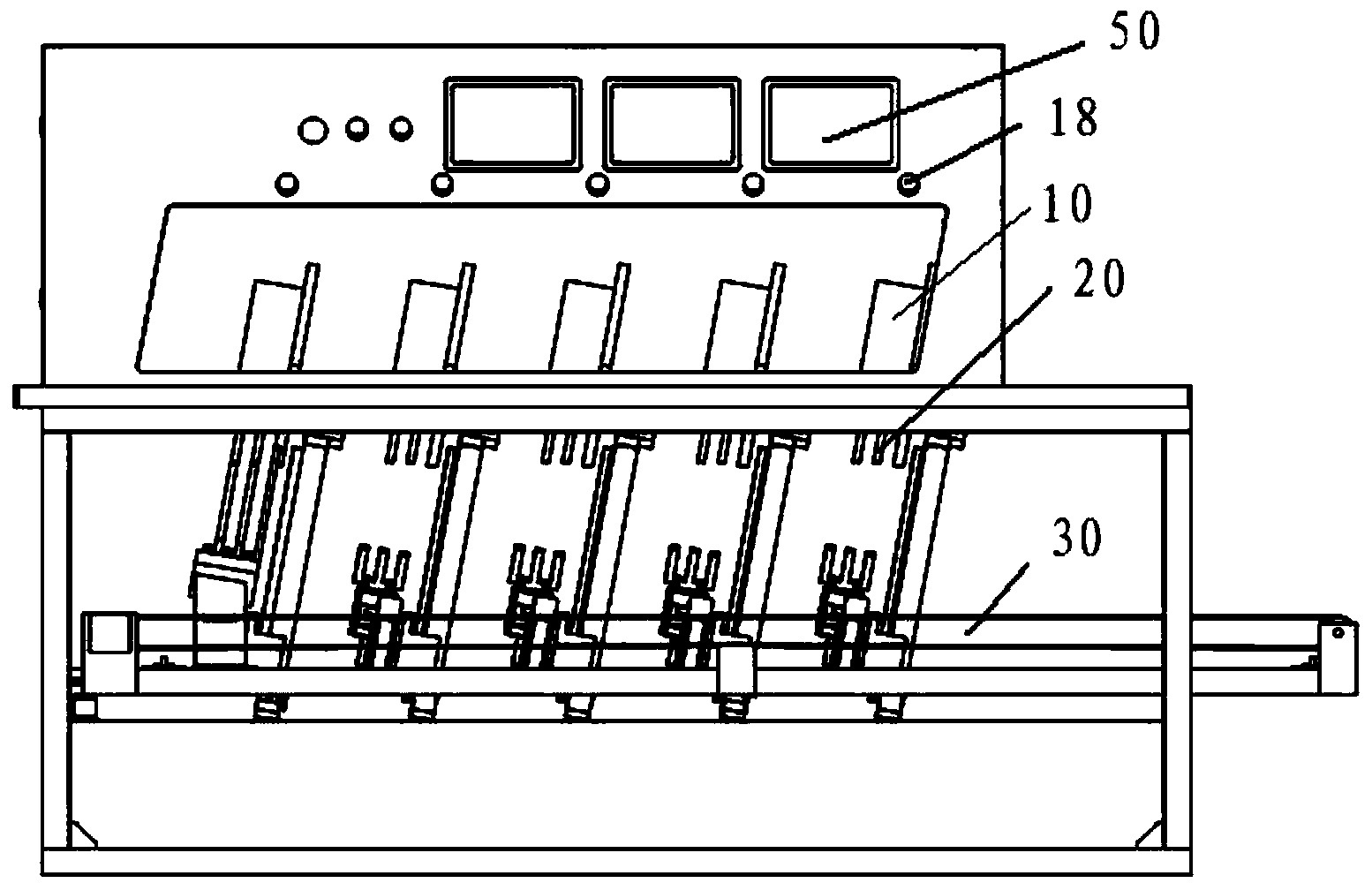

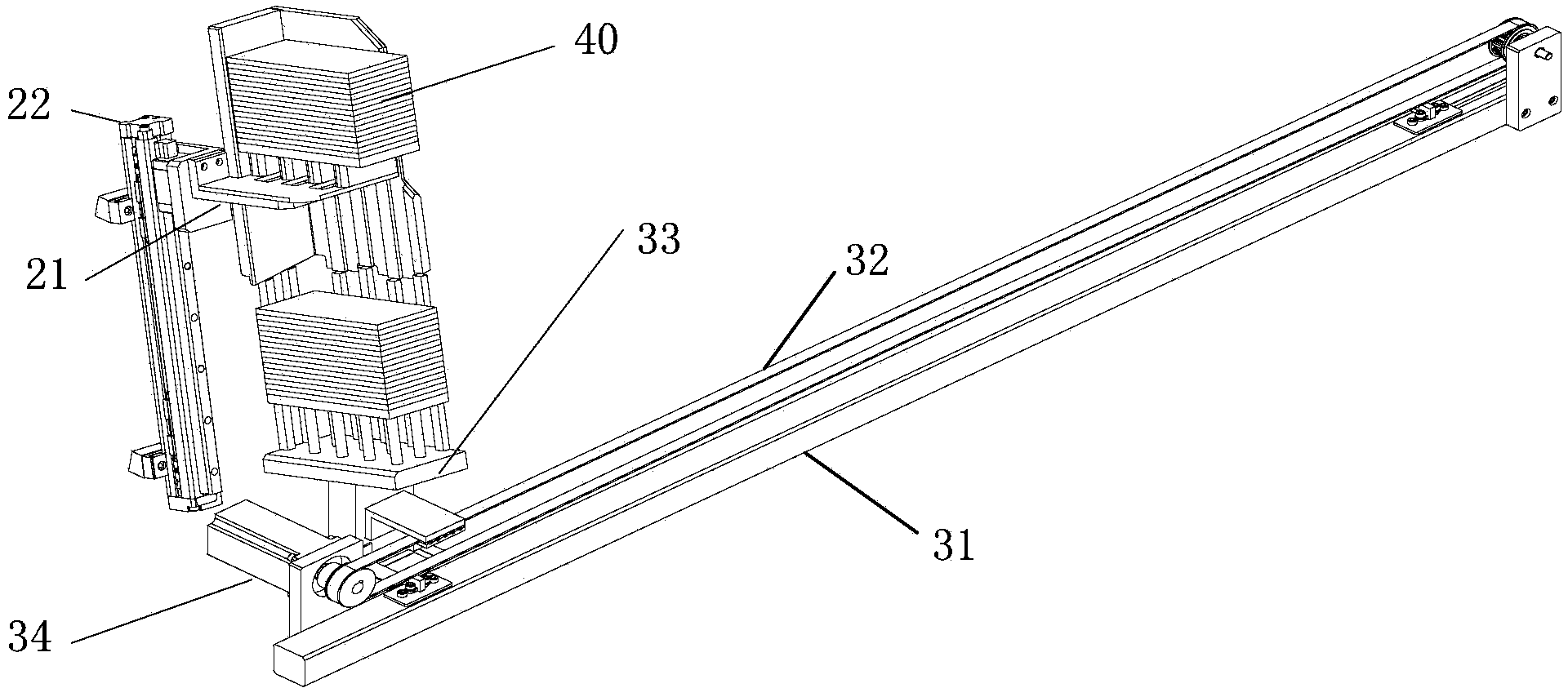

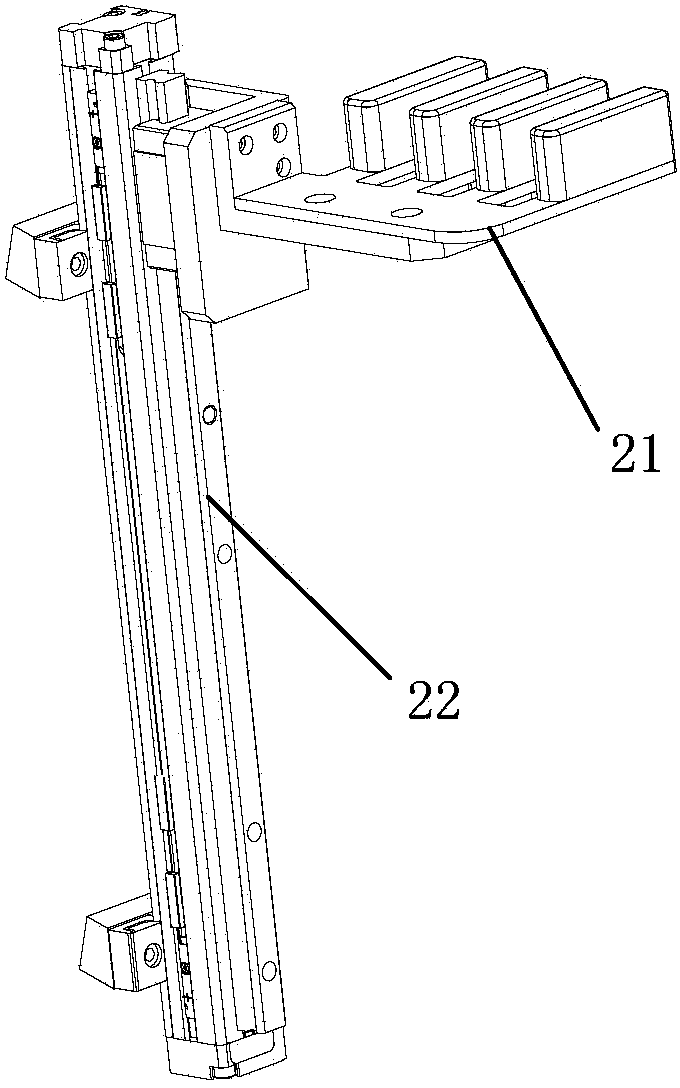

[0026] Such as figure 1 As shown, in the sheet material stacking conveying device, it includes a plurality of discharge ports 10, a lifting module 20 is arranged under each discharge port 10, and a conveying module is arranged under all the lifting modules 20 30; Wherein, the lifting module 20 is used to convey the sheet material stack 40 put in from the corresponding discharge port 10 downward to the conveying module 30; the conveying module 30 is used to continuously convey the sheet The material stacks are delivered to the target location in batches. The sheet mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com