Feeding system and feeding method for silicon chip quality sorting equipment

A silicon wafer and sorting technology, which is applied in the field of feeding systems, can solve the problems of labor-intensive, low yield of silicon wafers, etc., and achieve the effects of fast feeding speed, high reliability and simple control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

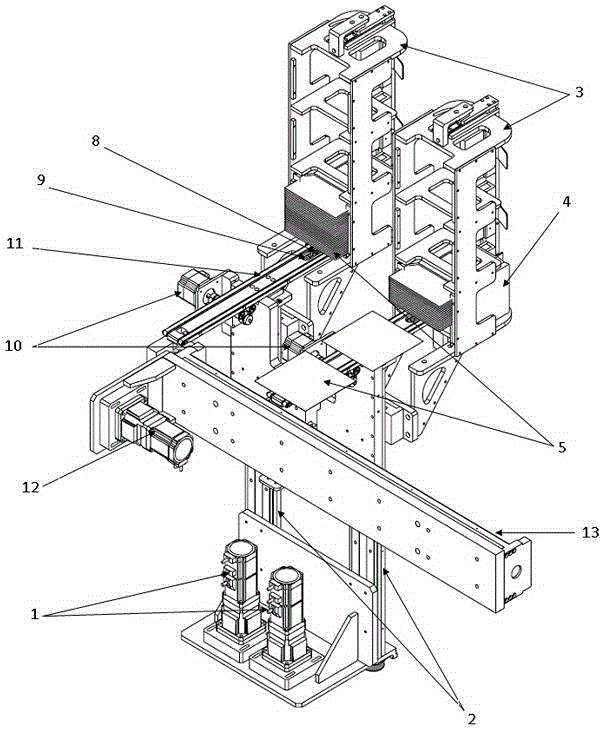

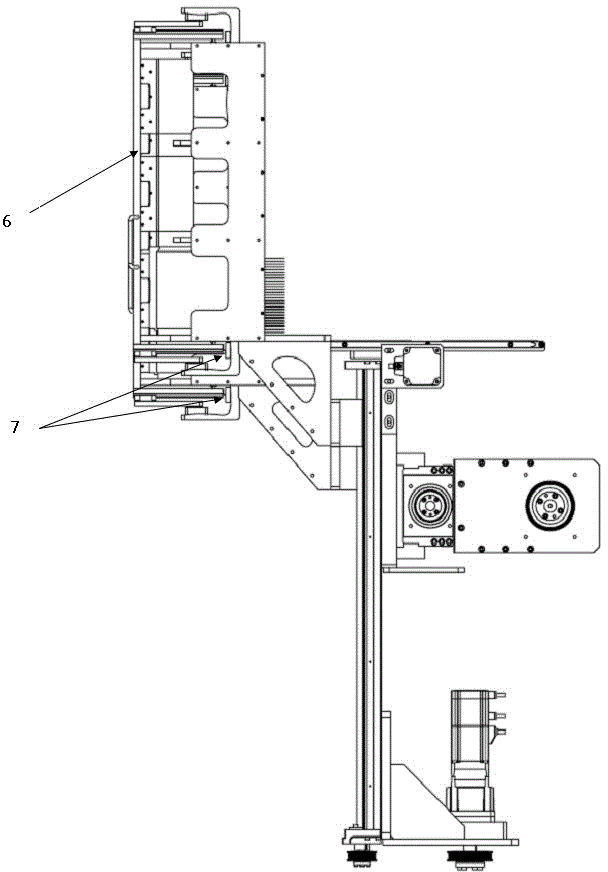

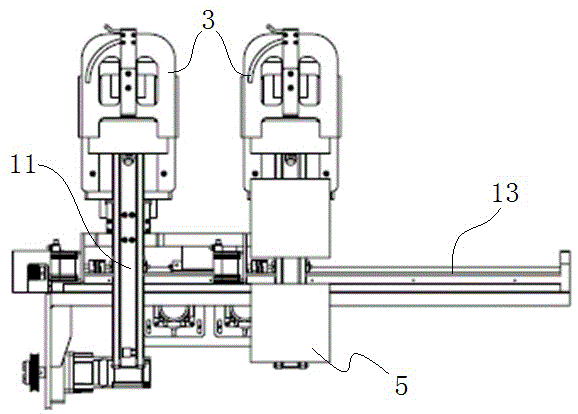

[0033] Attached below Figure 1-5 The present invention is further introduced, but not as a limitation to the present invention.

[0034] A feeding system suitable for silicon wafer quality sorting equipment, such as Figure 1-3 As shown, it includes lifting motor 1, high-precision vertical ball screw 2, loading box 3, flower basket box 4, silicon wafer 5, sliding door 6, loading sensor 7, sheet detection sensor 8, stop sensor 9, and transmission motor 10 , Conveyor belt 11, switching motor 12, high-precision horizontal ball screw 13. The lifting motor 1 is divided into two left and right ones, which respectively drive the corresponding high-precision ball screw 2 to move in the vertical direction. The high-precision vertical ball screw 2 is divided into two left and right parts, which are connected to the corresponding feeding box 9 in the vertical direction to realize the lifting operation of the feeding box. The feeding box 3 is divided into 2 left and right, and each lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com