Full-automatic calcium carbide or iron alloy production line

A ferroalloy, fully automatic technology, applied in electric furnace heating, waste heat treatment, chemical industry, etc., can solve problems such as partial damage of electrodes, decreased production efficiency of submerged arc furnaces, and decreased electric heating efficiency of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

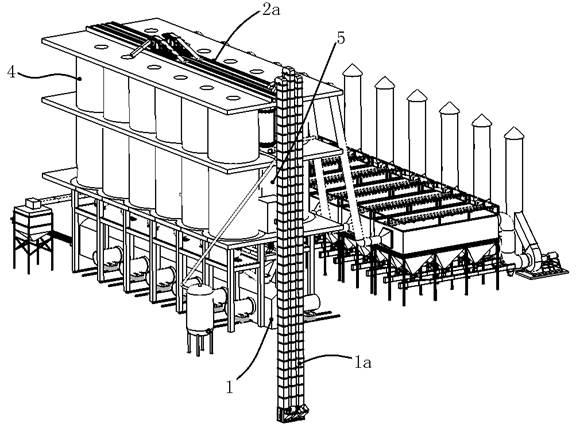

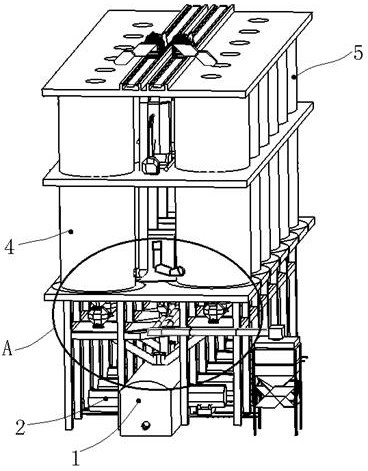

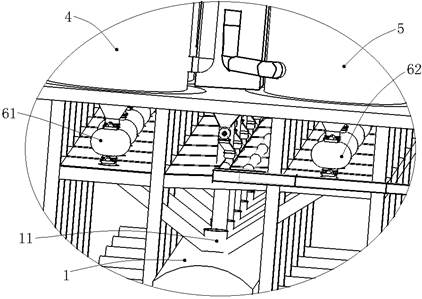

[0067] A fully automatic calcium carbide or ferroalloy production line, combined with Figure 1 to Figure 5As shown, it includes a submerged arc furnace, a feed inlet 11 is provided on the top of the submerged arc furnace, a first feed furnace and a second feed furnace are arranged above the feed inlet 11, and the first feed furnace The discharge port of the feeding furnace communicates with the feed port 11 through the high temperature resistant pipeline through the first meter 61, and the discharge port of the second feeding furnace passes through the second meter 62 through the high temperature resistant pipeline. After that, communicate with the feed port 11; wherein, on the inlet and outlet of the first meter 61 and on the inlet and outlet of the second meter 62, switch control valves are installed, and the switch control valve It is a plug-in valve; the first meter 61 and the second meter 62 are high-temperature-resistant meter; the switch control valve includes a baffle...

no. 2 example

[0089] Other technical features In the same situation as the first embodiment, the electrodes 2 are provided on the left and right side walls of the furnace body 1, and the electrodes 2 on the left and right side walls are arranged alternately. ; There is one feed port corresponding to the positions directly above the positions between the adjacent electrodes.

no. 3 example

[0091] combine Figure 16As shown, other technical features are the same as the first embodiment or the second embodiment, the clamping plate is set as a split opening structure, the lower part of the clamping hole 316 is an arc-shaped groove 315, A first clamping plate 311 and a second clamping plate 312 are sequentially hinged on both sides of the arc-shaped groove 315, and the arc-shaped groove 315, the first clamping plate 311 and the second clamping plate 312 forms the cylindrical clamping hole 316, on the outer wall of the first clamping plate 311 there are hinged plates 313, between the second clamping plate 312 and the hinged plate 313 and between the clamping A telescoping device 31 is hinged between the lower part of the holder 31 and the hinge plate 313 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com