Warehouse storage location allocation method and system based on big data

A technology of big data and big data platform, applied in the field of warehouse management, can solve problems such as unreasonable allocation of warehouse storage space and low picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

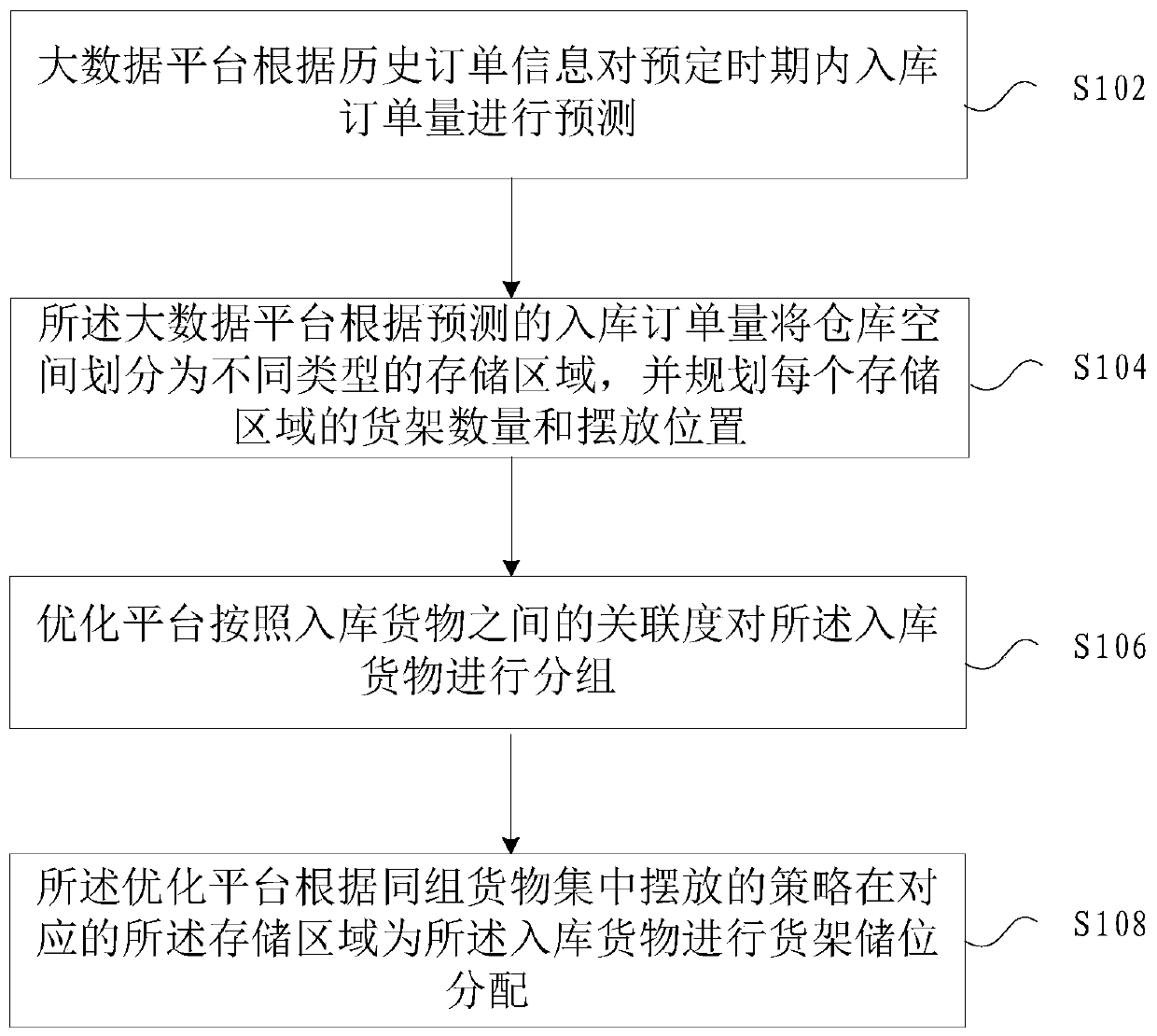

[0025] In this embodiment, a warehouse storage location allocation method based on big data is provided, figure 1 is a flow chart of a method according to an embodiment of the present invention, such as figure 1 As shown, the process includes the following steps:

[0026] Step S102, the big data platform predicts the quantity of incoming orders within a predetermined period according to historical order information;

[0027] Step S104, the big data platform divides the warehouse space into different types of storage areas according to the predicted quantity of incoming orders, and plans the number and placement of shelves in each storage area;

[0028] Step S106, the optimization platform groups the inbound goods according to the degree of correlation between the inbound goods;

[0029] Step S108, the optimization platform allocates shelf storage space for the incoming goods in the corresponding storage area according to the strategy of centralized placement of the same grou...

Embodiment 2

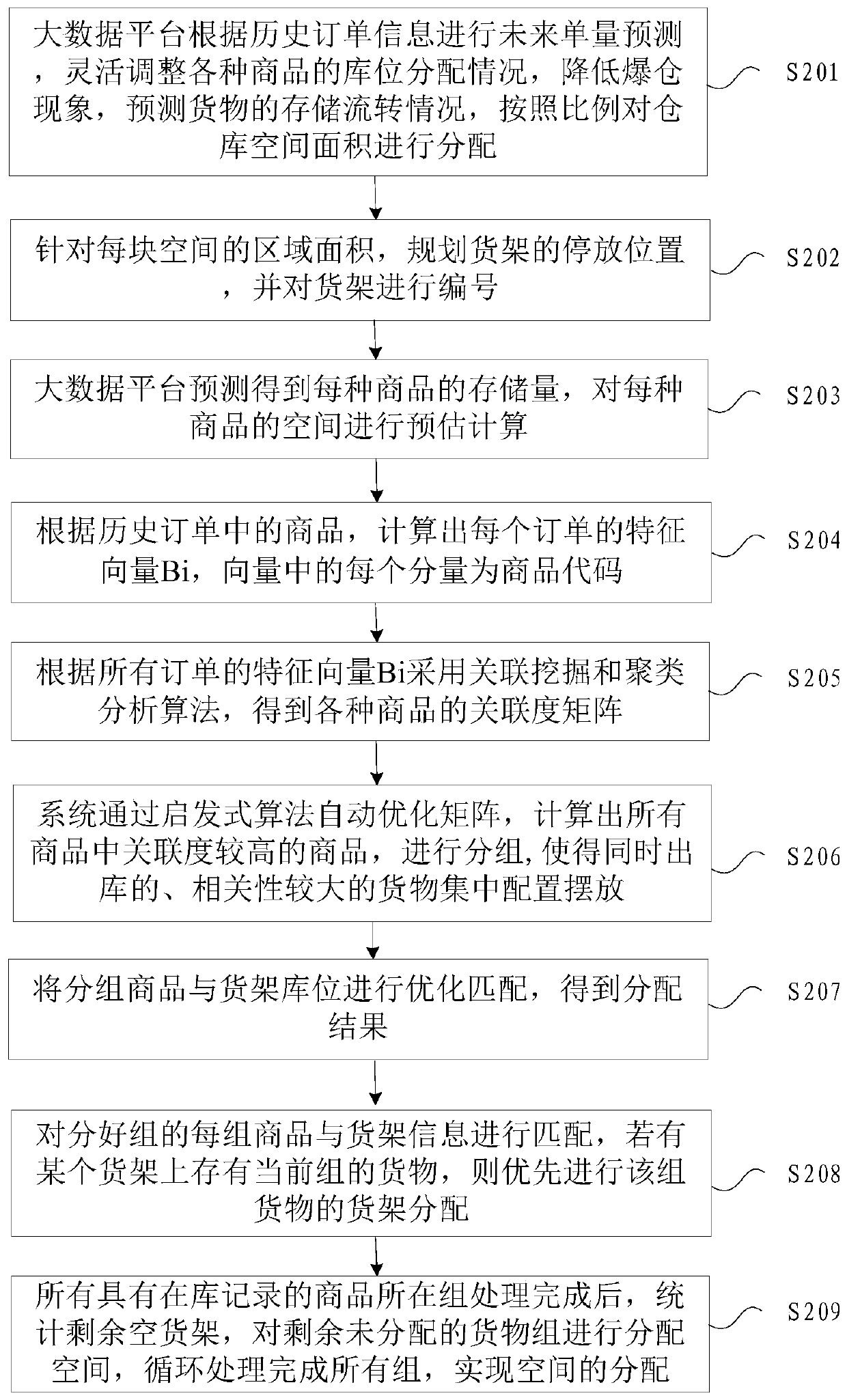

[0035] In order to facilitate the understanding of the technical solution provided by the present invention, a specific embodiment will be described in detail below.

[0036] In the warehouse of the logistics distribution center, there are many kinds of goods. Even if the orders are combined and picked, it often happens that each shelf carried by the robot contains only one kind of goods in the order.

[0037] Moreover, the goods in the warehouse are highly mobile and unstable. Moreover, the goods are greatly affected by seasons and holidays, so it is not easy to grasp.

[0038] In addition, the number of shelves handled by robots in the warehouse is large, and the waste of energy resources is very serious. Secondly, the warehouse space is limited, and the movement of multiple robots tends to increase the frequency of occupation and waste time.

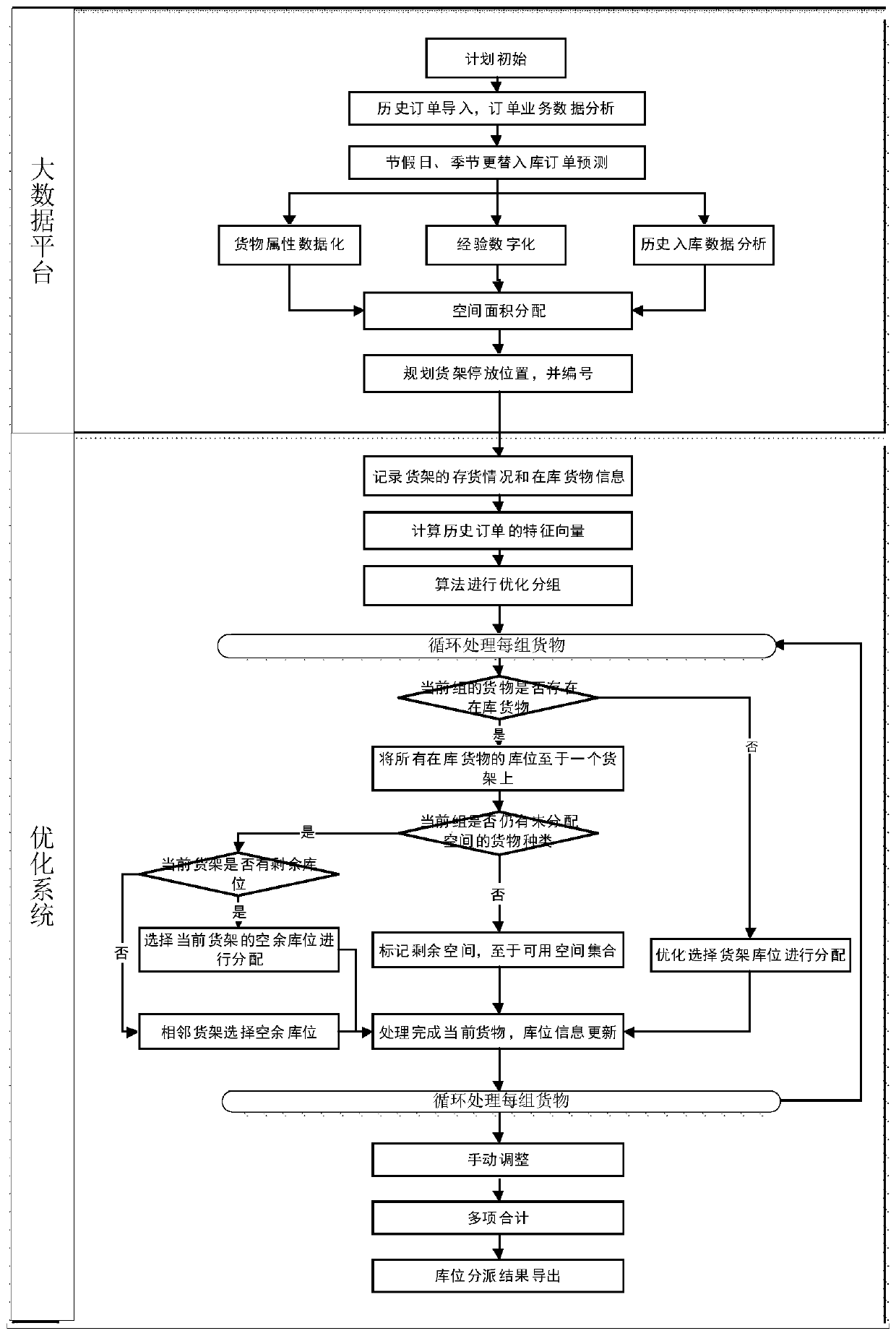

[0039] to this end, figure 2 It shows a warehouse storage location optimization allocation method based on big data, such as f...

Embodiment 3

[0063] This embodiment also provides a big data-based warehouse storage location allocation system. The device is used to implement the above embodiments and preferred implementation modes, and those that have already been described will not be described in detail. The term "module" as used below may be a combination of software and / or hardware that realizes a predetermined function. Although the devices described in the following embodiments are preferably implemented in software, implementations in hardware, or a combination of software and hardware are also possible and contemplated.

[0064] Figure 4 It is a schematic structural diagram of a warehouse storage allocation system based on big data according to an embodiment of the present invention, as shown in Figure 4 As shown, the system includes a big data platform 10 and an optimization platform 20.

[0065] The big data platform 10 is used to predict the amount of incoming orders within a predetermined period accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com