Packaging process production line equipment and operating method

An assembly line and equipment technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of handling waste, increase labor intensity, waste and other problems, and achieve the effect of avoiding action waste, shortening packaging cycle, and avoiding product backlog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

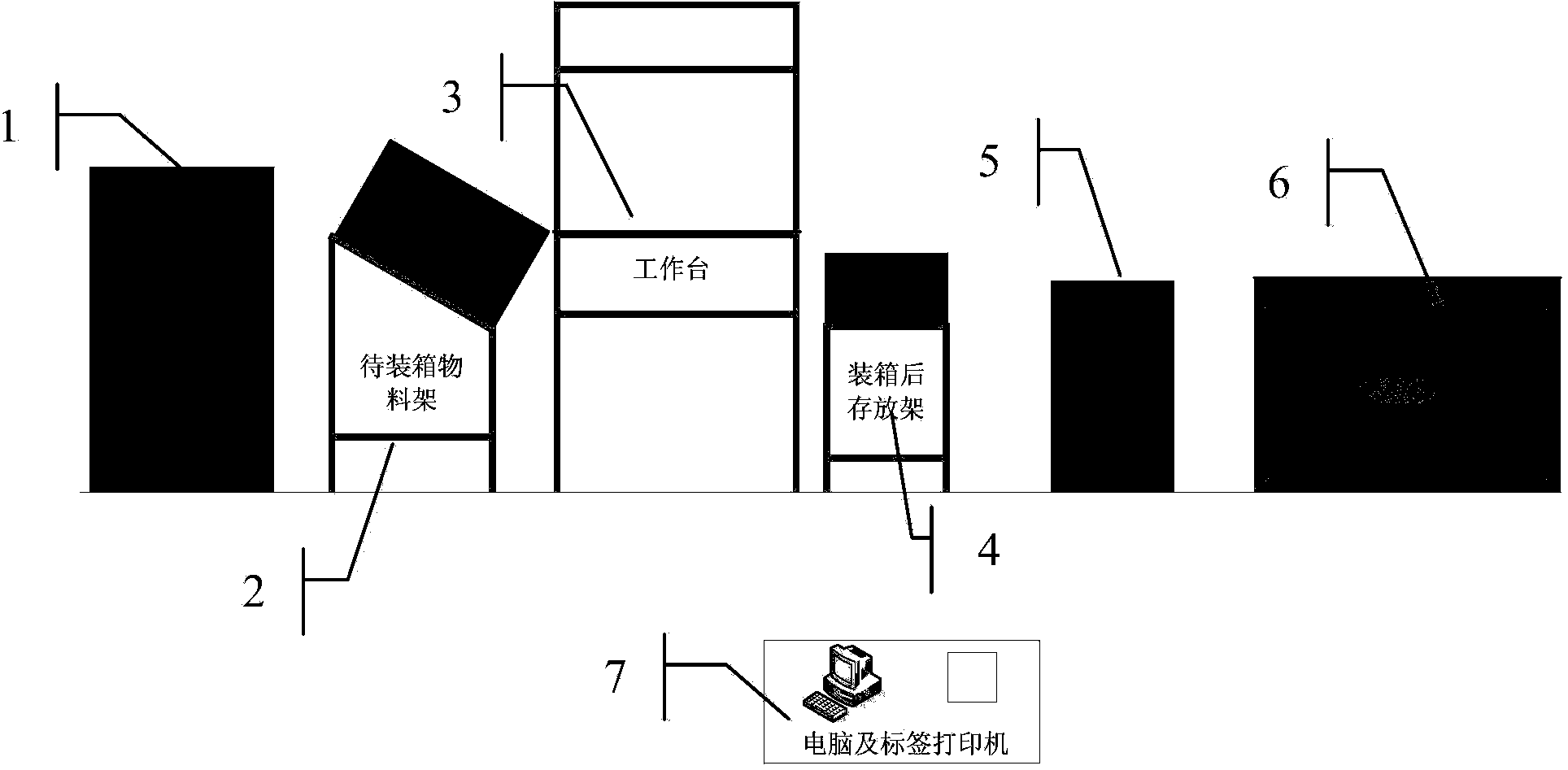

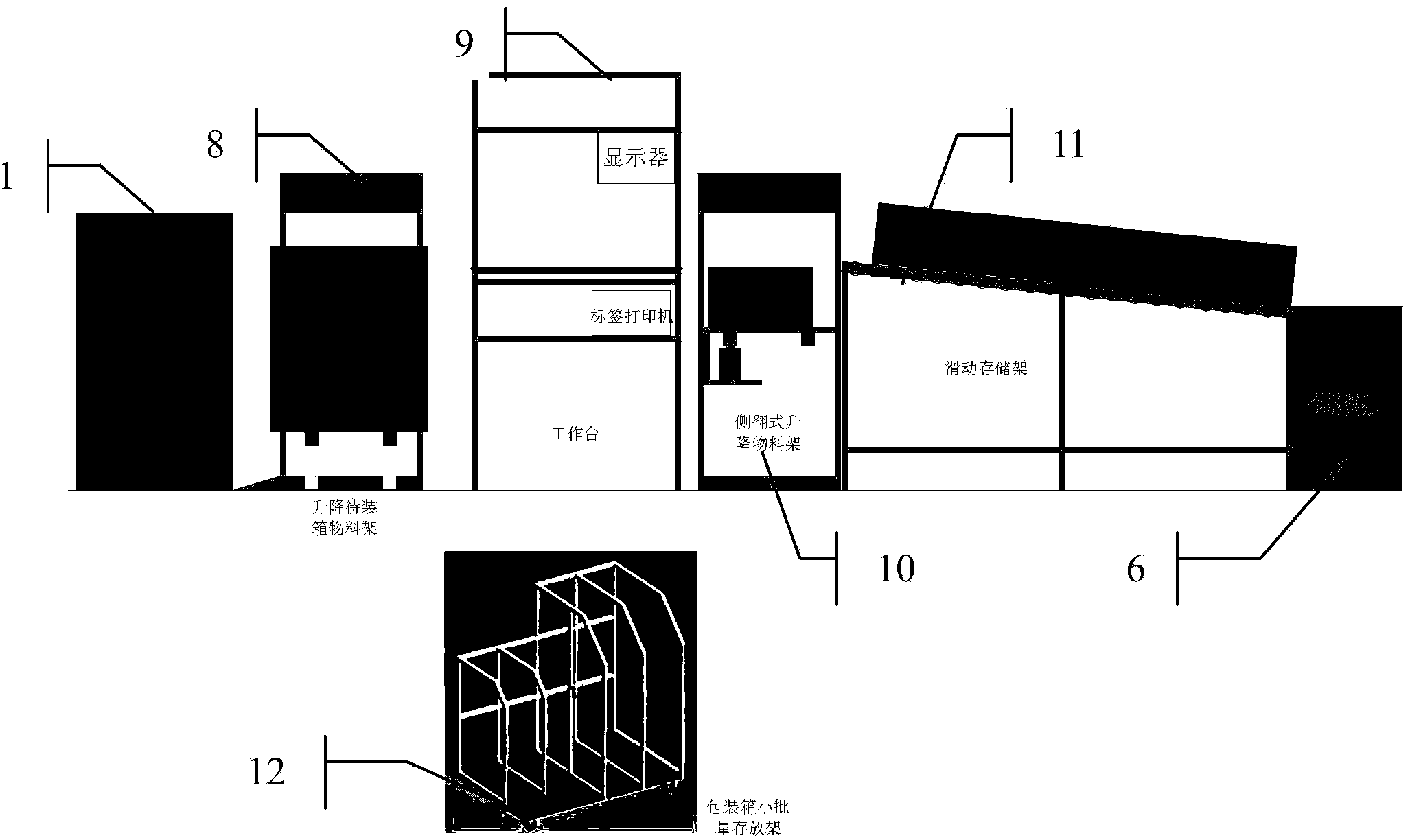

[0033] Below in conjunction with accompanying drawing, the present invention is described in detail:

[0034] The equipment is placed in sequence according to the storage area 1 of the goods to be packed, the lifting material rack 8 to be packed, the multi-functional workbench 9, the side-turning lifting material rack 10, the sliding storage rack 11 and the 6 packing machine; the packing box is temporarily stored The rack 12 belongs to the supporting tooling and is placed separately; the side-turning lifting material rack 10, the sliding storage rack 11 and the 6 balers are connected by the conveyor belt device of the sliding storage rack 11.

[0035] The working method is as follows:

[0036] 1. Take the goods to be packed from the goods to be packed 1 and place them on the 8-lift material rack to be packed. The operating height can be adjusted appropriately through the device button, and three boxes of goods to be packed can be stored, increasing the storage quantity and red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com