Tray dense warehouse in-warehouse sorting method and system

A dense storage and pallet technology, which is applied in the field of in-storage picking methods and systems for pallet dense storage, can solve problems such as equipment waste, affecting storage density, storage efficiency, and site waste, so as to improve efficiency, improve operation efficiency, and optimize operations. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

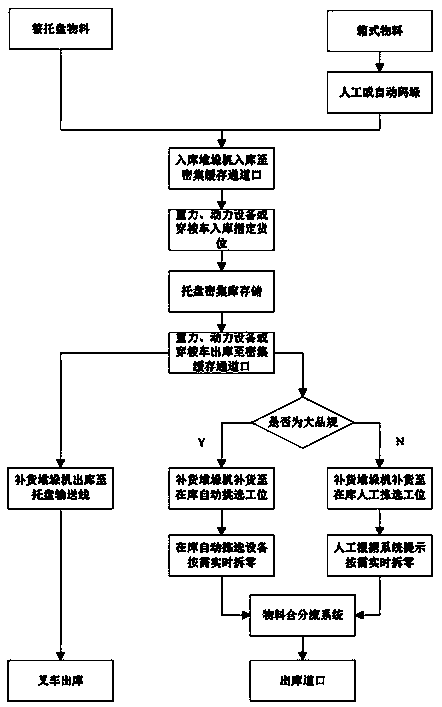

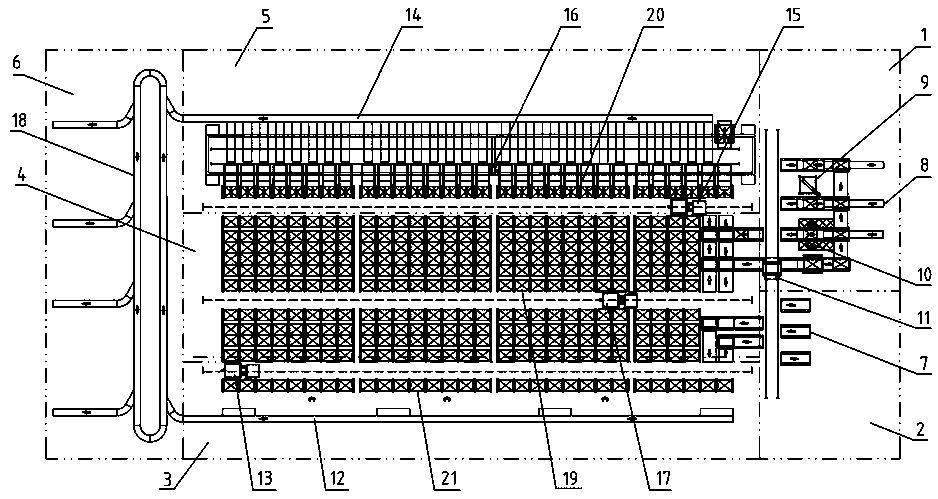

[0020] like figure 1 , 2 As shown, the pallet-intensive warehouse-in-warehouse picking method of the present invention is carried out according to the following steps:

[0021] Step 1. After the box-type material is identified by information, it is transported to the automatic palletizer 9 or the manual palletizing station 10 through the box-type material conveying line 8, and palletized into solid pallets, and the pallet material association is established, and recorded in WMS (warehouse management System, English abbreviation of WarehouseManagement System);

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com