Energy-saving system and method based on air separation system

A technology of air separation system and energy-saving system, which is applied in the field of energy-saving system based on air separation system, can solve problems such as insufficient energy utilization, and achieve the effect of saving energy and reducing energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

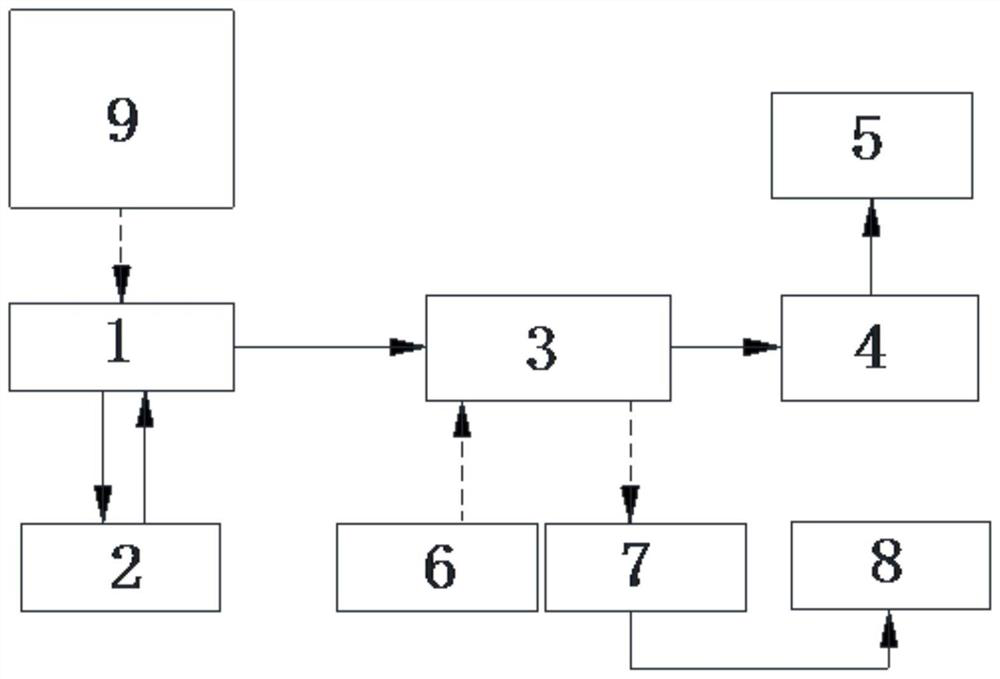

Embodiment 1

[0032] An energy-saving system based on an air separation system, comprising an air separation system lithium bromide unit 1, an air cooling tower 2, a water bath vaporizer 3, a rainwater recovery tank 4, a liquid gas storage tank 6 and a gas compressor 7.

[0033] The heat source inlet of the lithium bromide unit 1 of the air separation system is connected with the steam turbine, air compressor, nitrogen compressor and argon compressor in the air separation system unit 9 at the same time, and the cooling heat of the steam turbine, the interstage compression heat of the air compressor, and the nitrogen compressor The interstage compression heat of the argon compressor and the interstage compression heat of the argon compressor are used as the external heat energy of the lithium bromide unit 1 of the air separation system.

[0034] The external heat energy is cooled by the lithium bromide unit 1 of the air separation system to form steam condensate, which is transported to the w...

Embodiment 2

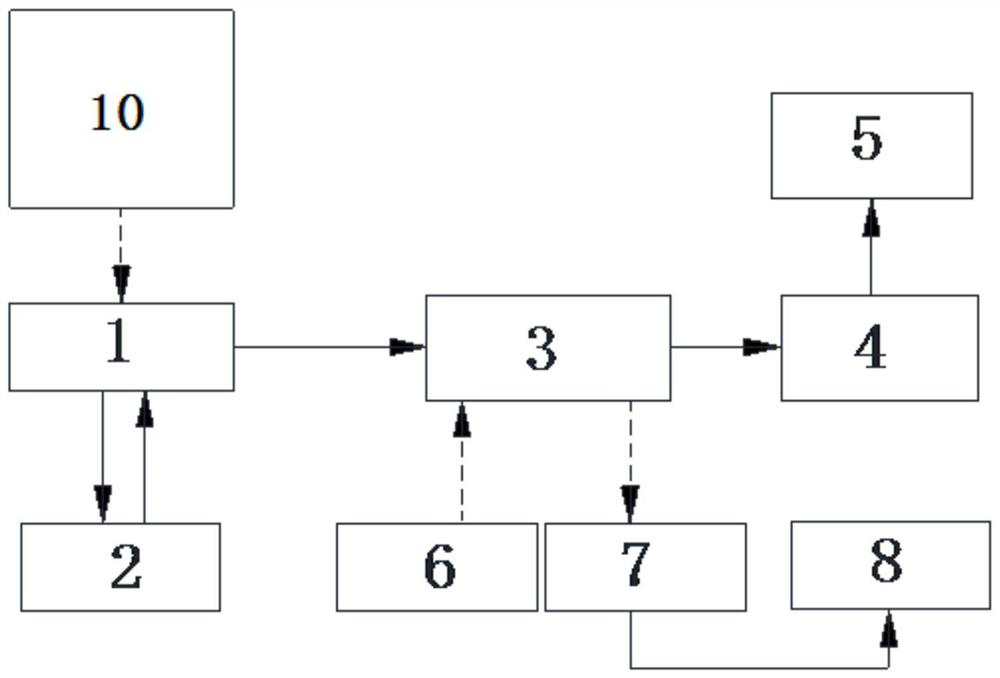

[0037] An energy-saving system based on an air separation system, comprising an air separation system lithium bromide unit 1, an air cooling tower 2, a water bath vaporizer 3, a rainwater recovery tank 4, a liquid gas storage tank 6 and a gas compressor 7.

[0038] The heat source inlet of the lithium bromide unit 1 of the air separation system is connected with the by-product steam of the steelworks (10) as the external heat energy of the lithium bromide unit 1 of the air separation system.

[0039] The external heat energy is cooled by the lithium bromide unit 1 of the air separation system to form steam condensate, which is transported to the water-bath vaporizer 3 as its heat medium, exchanges heat with the liquid argon in the water-bath vaporizer 3, and then enters the rainwater recovery tank 4. The rainwater recovery tank 4 and The external circulating water system 5 is connected. The liquid argon is converted into a gaseous state after heat exchange with steam condensed...

Embodiment 3

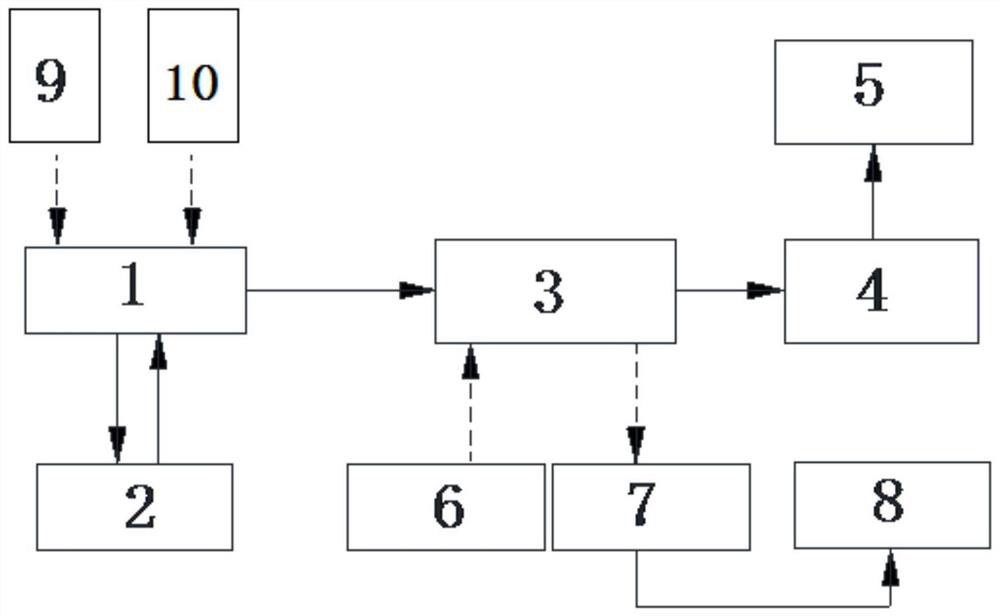

[0042] An energy-saving system based on an air separation system, comprising an air separation system lithium bromide unit 1, an air cooling tower 2, a water bath vaporizer 3, a rainwater recovery tank 4, a liquid gas storage tank 6 and a gas compressor 7.

[0043] The heat source inlet of the lithium bromide unit 1 of the air separation system is connected with the steam turbine, air compressor, nitrogen compressor, argon compressor in the air separation system unit 9, and the steel plant 10 at the same time, and the cooling heat of the steam turbine, the stage of the air compressor The interstage compression heat, the interstage compression heat of the nitrogen compressor, the interstage compression heat of the argon compressor, and the by-product steam of the steel plant 10 are used as the external heat energy of the lithium bromide unit 1 of the air separation system.

[0044] The external heat energy is cooled by the lithium bromide unit 1 of the air separation system to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com