Novel heat management system for vehicle-mounted lithium ion batteries

A technology of lithium-ion battery and thermal management system, which is applied in the field of thermal management system of tree-branch type vehicle-mounted lithium-ion battery, can solve the problems that electric vehicles are not widely used, the state of the battery pack is inconsistent, and the life of the battery is shortened. Achieve the effect of lowering the temperature, compact structure and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

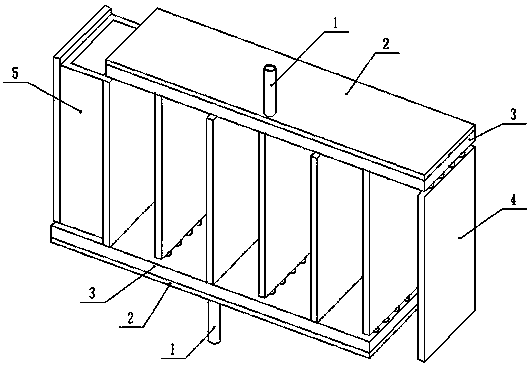

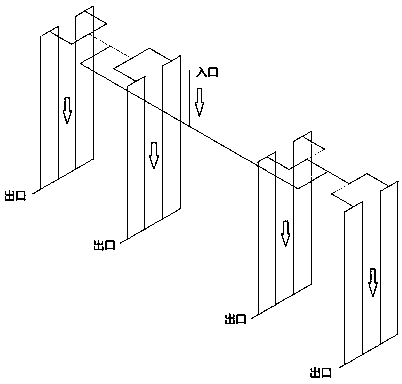

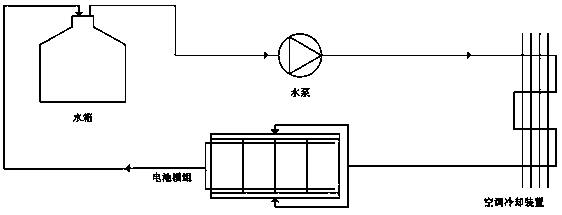

Image

Examples

Embodiment 1

[0034] Example 1: Taking the high temperature environment in midsummer as an example, combined with the working conditions of the automobile, the ambient temperature is 40°C. When the battery discharge rate is 1C, without installing the cooling system, the maximum temperature of the battery cell is 63.42°C, which is much higher than the normal operating temperature of the battery.

[0035] After installing the thermal management system, the ambient temperature is set to 40°C, the battery discharge rate is 1C, the cooling fluid medium is liquid water, the cooling fluid temperature is 30°C, and the fluid flow in the cooling cold plate is set to 0.3g / s and 0.5g / s, 1g / s, 2g / s, 3g / s, 5g / s, the average temperature of each battery in the battery module is calculated. The maximum temperature of the battery module, the temperature difference between the battery cells, and the internal temperature difference of the battery cells are all kept within a low range. The fluid flow rate in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com