Excellent-quality steel bar controlled rolling and cooling method

A technology of controlled rolling, controlled cooling, and steel rods, which is applied in the field of controlled rolling and controlled cooling in steel rolling production. It can solve problems such as the inability to meet the production needs of high-quality special steel bars, and achieve a wide range of device adaptability to pressure, ensure cooling strength, and apply flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

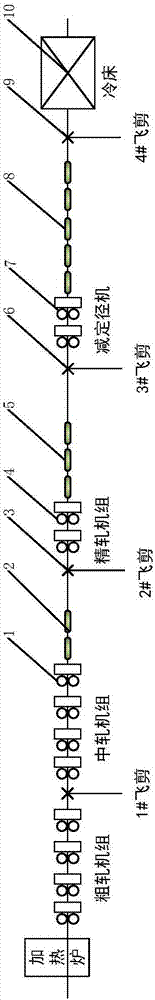

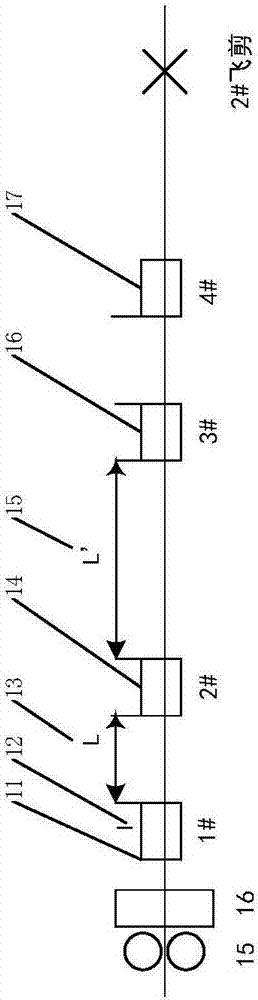

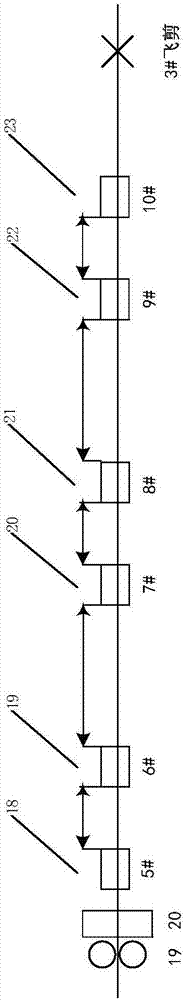

[0037] Embodiment 1: Taking the GCr15 bearing steel round bar of the finished product Φ20mm as an example, the attached Figure 1-4 The application technology of the controlled rolling and controlled cooling process of excellent special steel bars arranged as an example to further describe the process method, in which the cooling water pressure is 1.0MPa, the water temperature is 30℃, and the attached figure 2 The length of the middle l cooler (12) ranges from 500-1000mm, with figure 2 The range of the short temperature recovery length (13) of middle LⅠ section is 1000-1800mm, with figure 2 The range of the long temperature recovery length (15) of middle L'Ⅱ section is 2400-3600mm. attached figure 1The middle rolling unit (1) has rolled the round steel with a specification of Φ45mm, the temperature is 1048°C, and the roller table speed is 2.9m / s, and the round steel is sent to the attached figure 1 The middle stage I controls the cooling zone (2) for cooling, and opens t...

Embodiment 2

[0038] Embodiment two: take the 60Si2MnA spring steel round bar of the finished product Φ30mm as an example, adopt the attached Figure 1-4 The application technology of the controlled rolling and controlled cooling process of excellent special steel bars arranged as an example to further describe the process method, in which the cooling water pressure is 1.0MPa, the water temperature is 30℃, and the attached figure 2 The length of the middle l cooler (12) ranges from 500-1000mm, with figure 2 The range of the short temperature recovery length (13) of middle LⅠ section is 1000-1800mm, with figure 2 The range of the long temperature recovery length (15) of middle L'Ⅱ section is 2400-3600mm. attached figure 1 The middle rolling unit (1) has rolled the round steel with a specification of Φ45mm, the temperature is 1042°C, and the roller table speed is 3.0m / s, and the round steel is sent to the attached figure 1 The middle stage I controls the cooling zone (2) for cooling, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com