Galette for guiding, heating and transporting a thread

A technology for godet rollers and filaments, applied in induction heating, induction heating devices, and conveying filamentous materials, etc., can solve the problems of high energy loss, large heat loss of the godet roller shell, etc., and achieve the reduction of heat load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

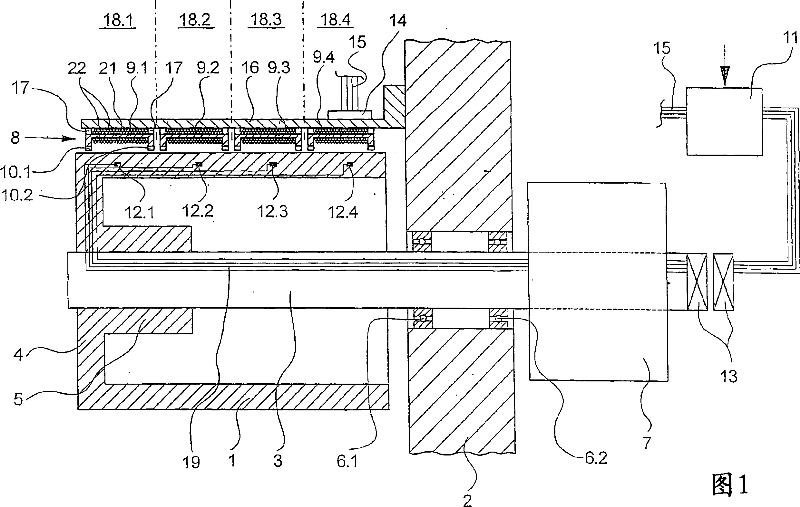

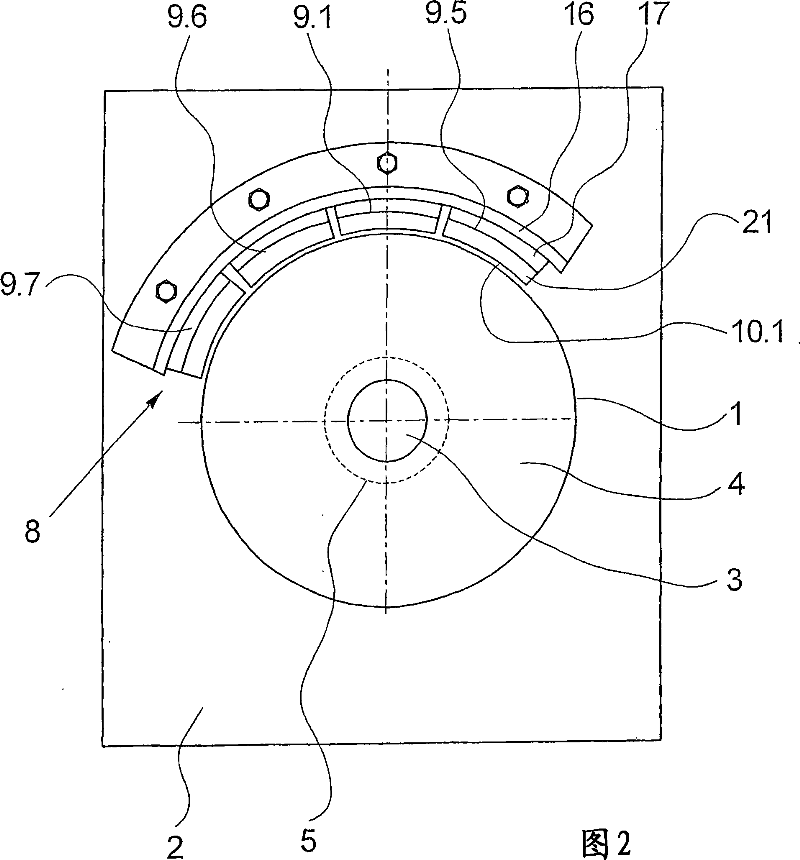

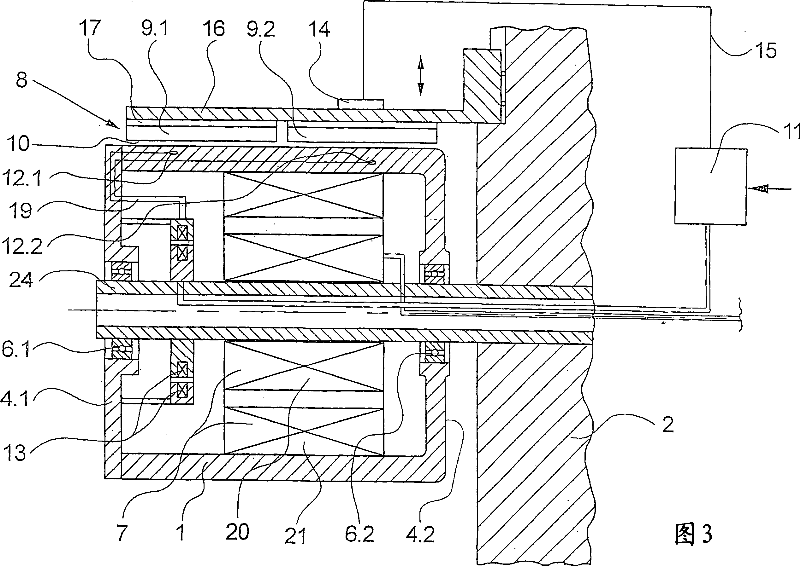

[0031] A first embodiment of the godet according to the invention is shown in several views in FIGS. 1 and 2 . 1 schematically shows a cross-sectional view, and FIG. 2 schematically shows a front view. If no particular figure is referred to in this regard, the following description applies to both figures.

[0032] The godet has a hollow cylindrical godet housing 1 which is pot-shaped at one end by an end wall 4 . On the side opposite the end wall 4, the godet housing 1 is open. The end wall 4 of the godet housing 1 is connected to a hub 5 which is fixed to rotate on the circumference of the shaft 3 . The shaft 3 is mounted rotatably cantilevered on a support 2 arranged laterally next to the godet housing. Bearings 6.1 and 6.2 are provided on the carrier 2 for this purpose. On the side of the support 2 opposite the godet housing 1 , the shaft is connected to an electric motor 7 . The shaft 3 passes through the motor 7 and has a free end on which a signal transmitter 13 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com