Positive pole material of alkaline dry cell and high power alkaline dry cell, and preparation method

A positive electrode material and dry battery technology, applied in dry batteries, battery electrodes, primary battery electrodes, etc., to achieve the effects of improved storage performance, high current performance, and low degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

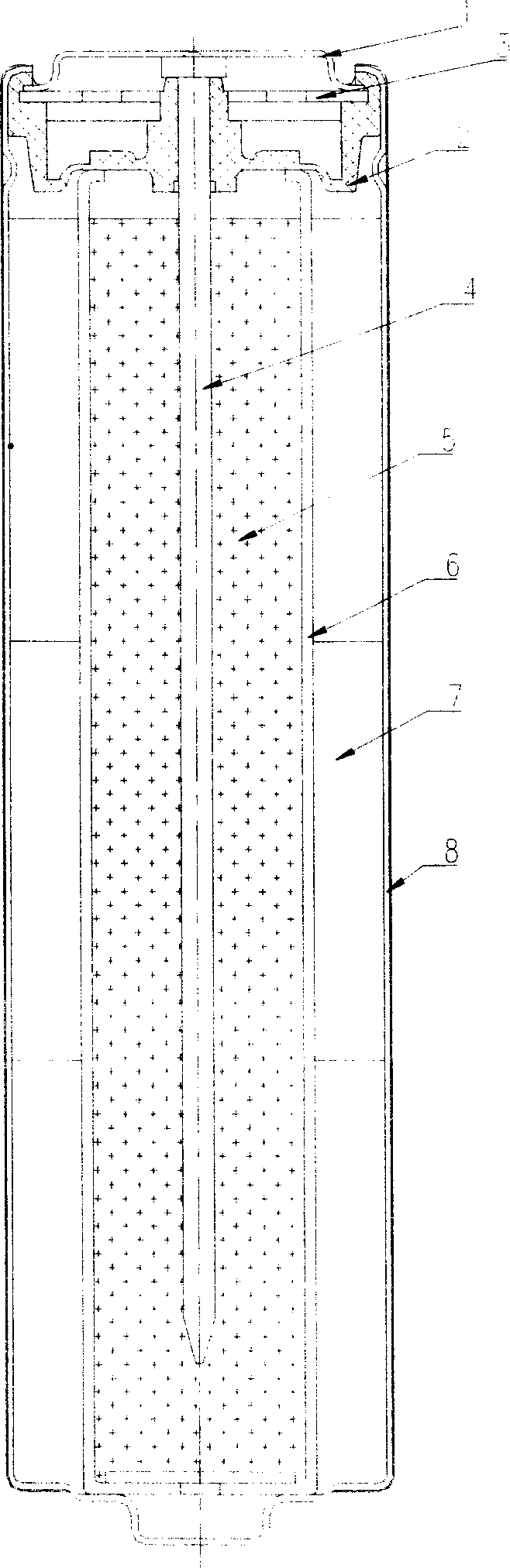

Image

Examples

Embodiment 1

[0029] Fully mix the active material nickel oxyhydroxide and conductive graphite at a weight ratio of 120:4~8, then add 2%~5% alkaline electrolyte (KOH or NaOH), stir evenly, and use 140~280kgf / cm 2 Tablets are pressed under high pressure, and then granulated and sieved (14-60 mesh) to form positive electrode particles with a certain particle size distribution, and then 0.1% to 0.5% of stearic acid additives are added to the positive electrode particles, and then Pass through the mold and apply a certain pressure to make it into a positive electrode ring; first mix the sodium polyacrylate and the indium compound in a ratio of 40 to 60:1, and then add it to the alkaline electrolyte (the concentration of KOH in the electrolyte is 30%) ~43%, the zinc oxide content is 1%~5%) to prepare a gel electrolyte, and then vacuumize and stir the zinc powder and gel electrolyte in a ratio of 300:130~180, and the obtained gel substance As negative electrode zinc paste.

[0030] The battery i...

Embodiment 2

[0032]In the same manner as in Example 1, replace the above-mentioned nickel oxyhydroxide with manganese dioxide to make the positive electrode ring, and form the alkaline dry battery 2# with the negative electrode zinc paste, and measure the 1000mA continuous discharge to The duration of 1.0v, the test results are shown in Table 1.

Embodiment 3

[0034] In the same manner as in Example 1, the nickel oxyhydroxide described in Example 1 is replaced by a two-component mixed substance composed of barium manganate and nickel oxyhydroxide as the positive electrode active material of the nickel dry battery, wherein the amount of barium manganate added is 0.1% of the amount of active material, the positive electrode ring is made in the same manner as in Example 1, and the negative electrode zinc paste is used to form alkaline dry battery 3#, and the duration of continuous discharge of 1000mA to 1.0v after storage for 20 days at the initial stage and at 60°C is measured, The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com