Treated copper foil for copper clad laminate, copper clad laminate, and printed wiring board using the copper clad laminate

A technology of copper-clad laminates and printed wiring boards, which is applied to printed circuit components, secondary treatment of printed circuits, and improvement of metal adhesion on insulating substrates. It can solve the problems of reduced peel strength, less penetration, circuit peeling, and falling and other problems, to achieve the effect of reducing the deterioration rate of the peel strength, high industrial applicability, and strengthening the peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

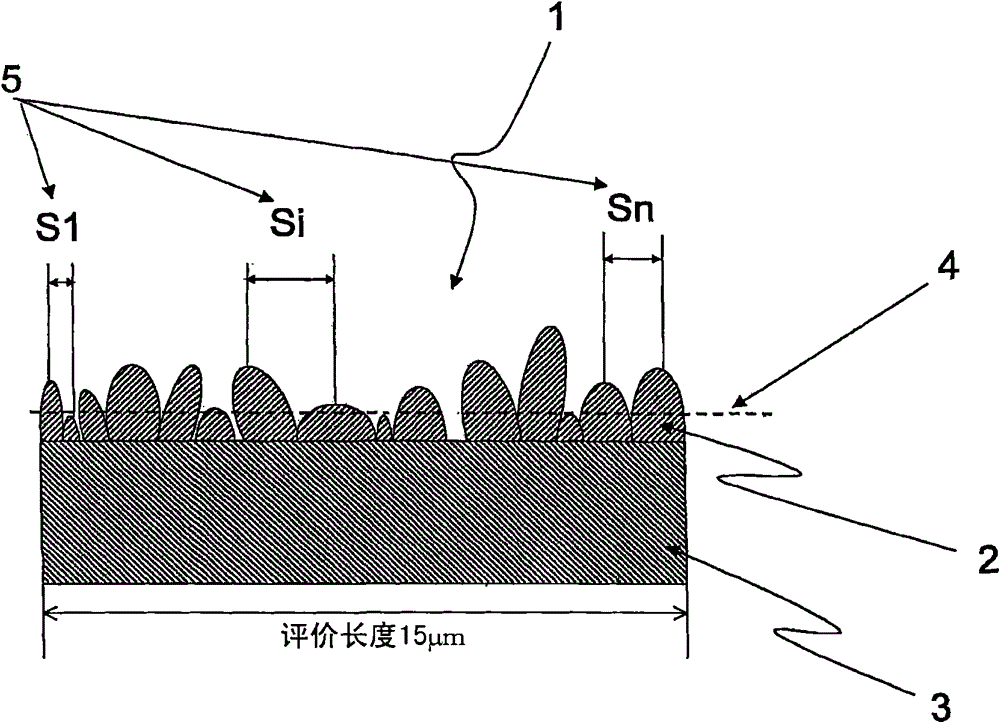

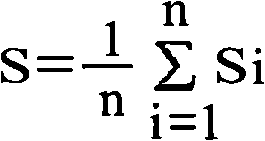

Image

Examples

Embodiment 1

[0118] Untreated electrolytic copper foil was prepared under the following electrolyte composition, additives, electrodes, liquid temperature, and electrolytic conditions.

[0119] (Manufacturing method of untreated electrolytic copper foil)

[0120] Adjust sulfuric acid to 100g / L, copper sulfate pentahydrate to 280g / L sulfuric acid-copper sulfate aqueous solution, add as additives: 20mg / L polyethylene glycol (average molecular weight: 20000; manufactured by Sanyo Chemical Co.), 20mg / L polyethylene Imine (trade name: Epomin; product code: PP-061; average molecular weight: 1200; manufactured by Nippon Shokubai Co., Ltd.), 6 μmol / L sodium 3-mercapto-1-propanesulfonate, 20 mg / L chloride ion. The electrolyte solution containing the additive is filled between the insoluble anode made of titanium coated with platinum metal oxide and the cathode roll made of titanium as the cathode, and the current density is 50A / dm 2 , A current was passed at a liquid temperature of 50° C. to obtai...

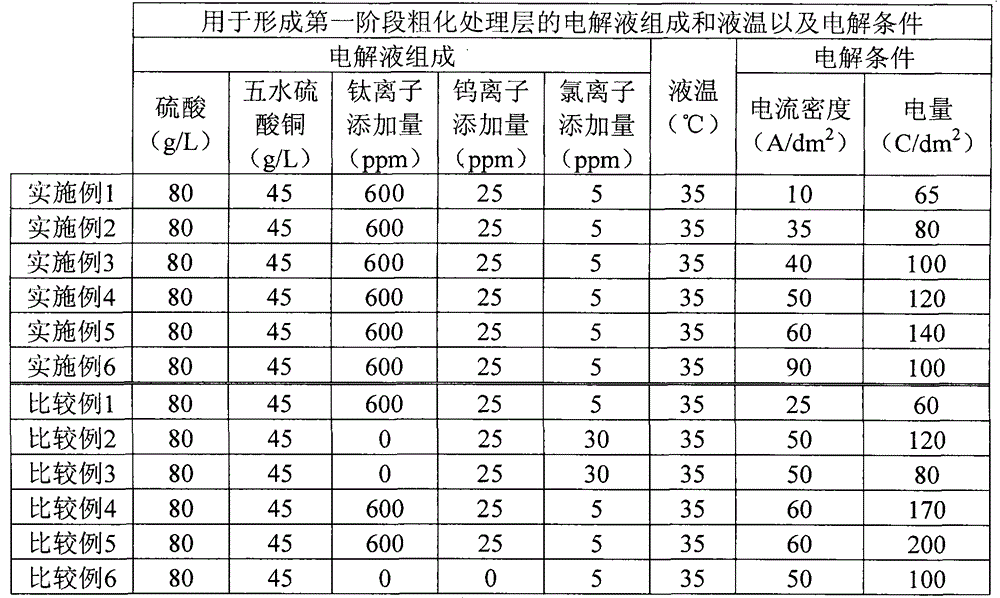

Embodiment 2~6 and comparative example 1~6

[0135](untreated electrolytic copper foil)

[0136] The same untreated electrodeposited copper foil as used in Example 1 was used.

[0137] (first stage coarsening layer)

[0138] As shown in Table 1, in addition to changing the concentration of each additive added in the electrolytic solution forming the first-stage roughening treatment layer, changing the current density and the electric quantity, other conditions and methods are the same as those of the aforementioned Example 1 to obtain the first step. One-stage coarsening process layers.

[0139] (Second stage coarsening layer)

[0140] According to the same electrolyte composition, liquid temperature, electrodes, and electrolysis conditions as in Example 1, a second-stage roughening treatment layer is set.

[0141] (chromate layer)

[0142] According to the same electrolyte composition, liquid temperature, pH, electrodes and electrolysis conditions as in Example 1, a chromate layer is set.

Embodiment 7

[0174] (untreated electrolytic copper foil)

[0175] The same untreated electrodeposited copper foil as used in Example 1 was used.

[0176] (first stage coarsening layer)

[0177] According to the same electrolyte composition, additives, liquid temperature, electrodes, and electrolysis conditions as in Example 3, the first-stage roughening treatment layer is set.

[0178] (Second stage coarsening layer)

[0179] According to the same electrolyte composition, liquid temperature, electrodes, and electrolysis conditions as in Example 1, a second-stage roughening treatment layer is set.

[0180] Next, according to the electrolyte composition, liquid temperature, pH, electrodes, and electrolysis conditions shown below, a nickel layer containing molybdenum is applied to the surface of the aforementioned second-stage roughening layer.

[0181] (nickel layer containing molybdenum)

[0182] Adjust nickel sulfate hexahydrate to be 45g / L, disodium molybdenum (VI) dihydrate to be 15g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com