Electrochemical system

An electrochemical and battery technology, applied in the field of electrochemical systems, can solve problems such as insufficient medium distribution and performance fluctuations of bipolar plates, and achieve the effects of eliminating performance fluctuations, preventing bypass flow, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

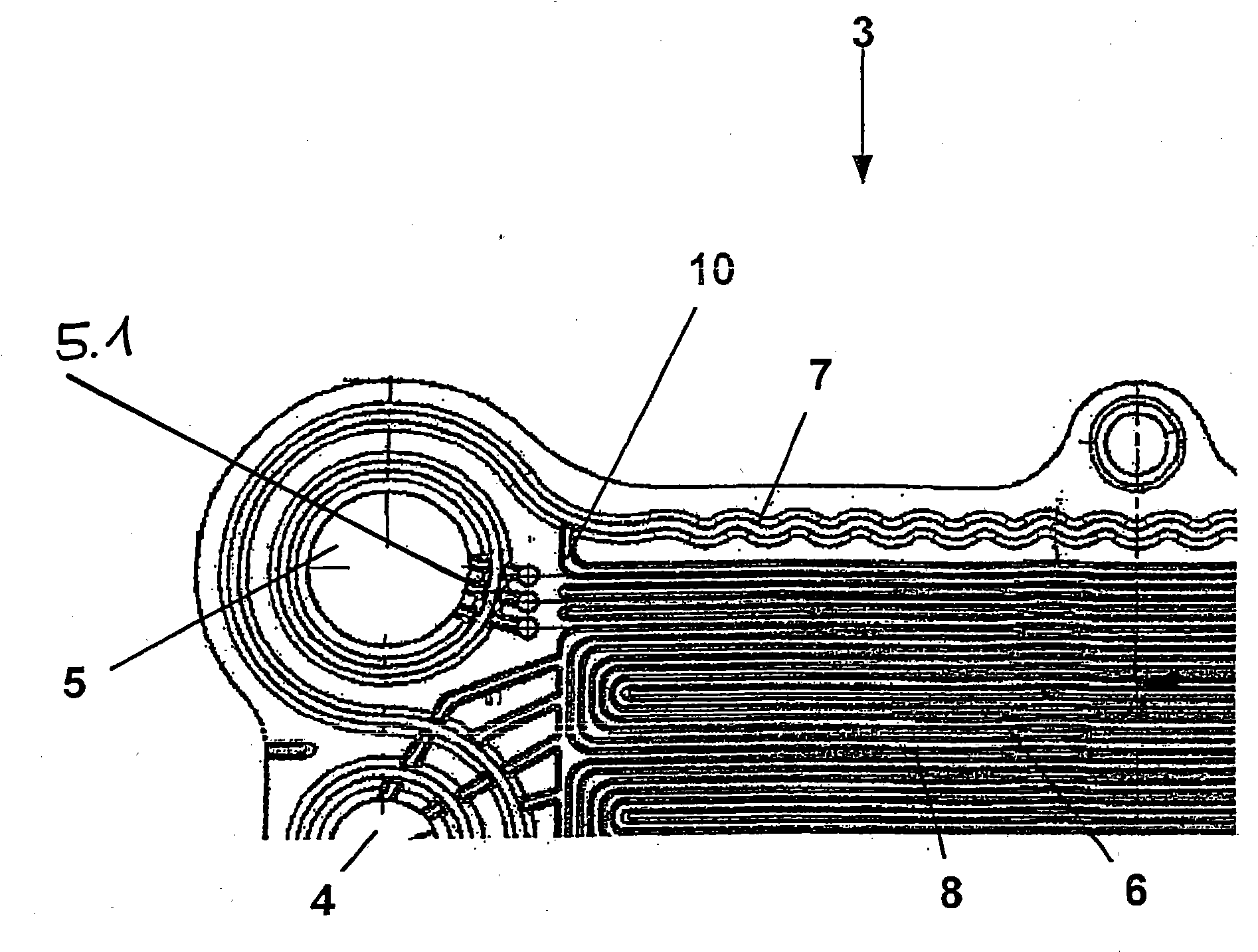

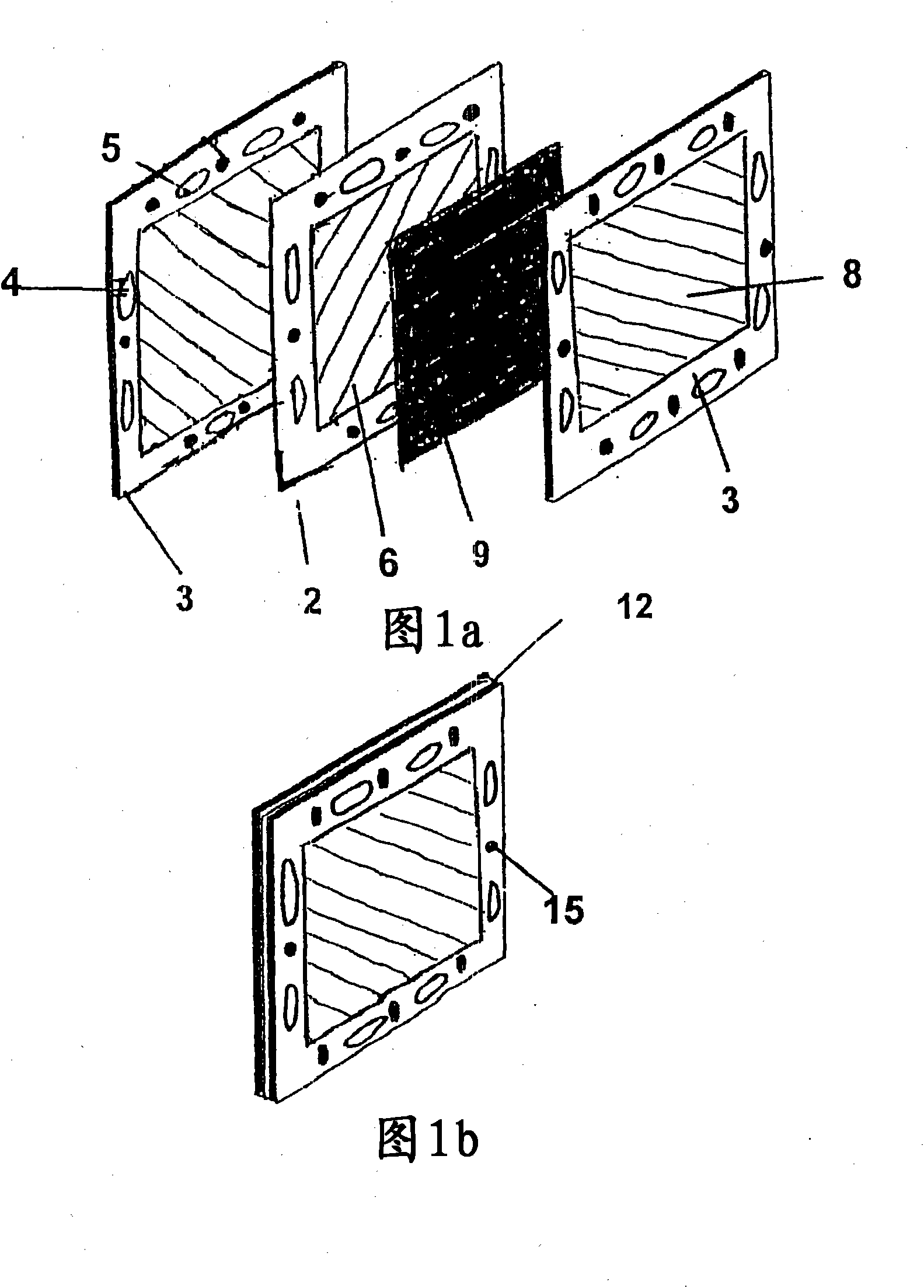

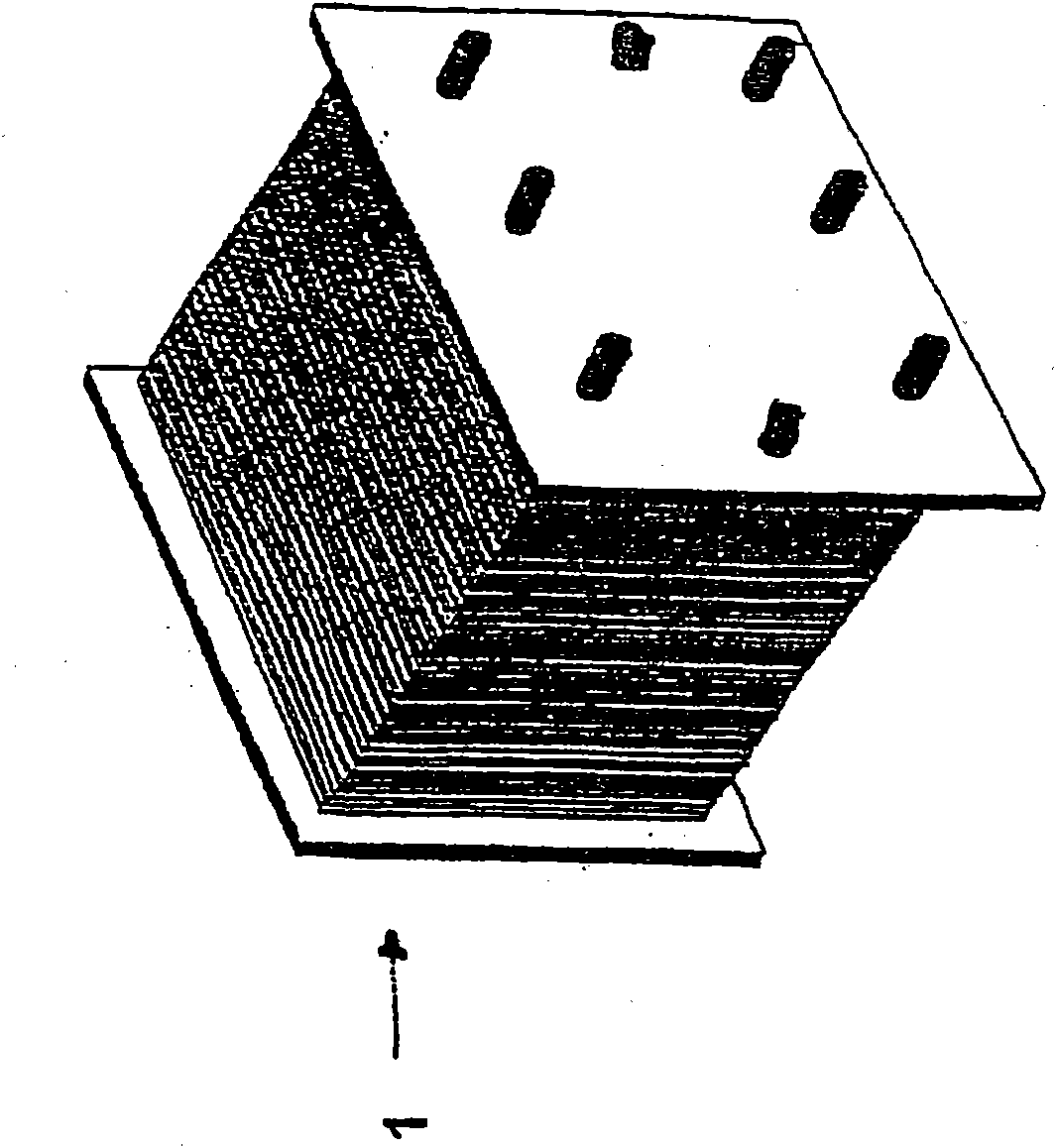

[0038] 1 a to 1 c show the basic configuration of an electrochemical system in the form of a fuel cell stack 1 . It comprises several layers of fuel cell devices 12 (see FIG. 1 b ). The layers of the fuel cell arrangement 12 are held together by end plates which exert compressive stress on the layers of the fuel cell arrangement, for example via clamping bolts as shown in FIG. 1c.

[0039] The configuration of the fuel cell device 12 is explained in more detail below.

[0040]FIG. 1 a shows the internal construction of the fuel cell device 12 in an exploded view. Firstly there is a cell (for example a fuel cell) 2 which comprises a polymer membrane which is capable of conducting ions and which has catalytic layers on both sides at least in the electrochemically active region 6 . Furthermore, two bipolar plates 3 between which the fuel cell 2 is arranged are arranged in the fuel cell arrangement 12 . Furthermore, a gas diffusion layer 9 is arranged in the region between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com