Special automatic cleaning instrument for low-voltage direct current electromagnetic pulse-type contact lenses

An electromagnetic pulse and contact lens technology, which is applied in the directions of cleaning methods, chemical instruments and methods, cleaning methods and utensils using liquids, etc., can solve the problems of matching cleaning effects, etc., and achieves easy portability, strong decontamination ability, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

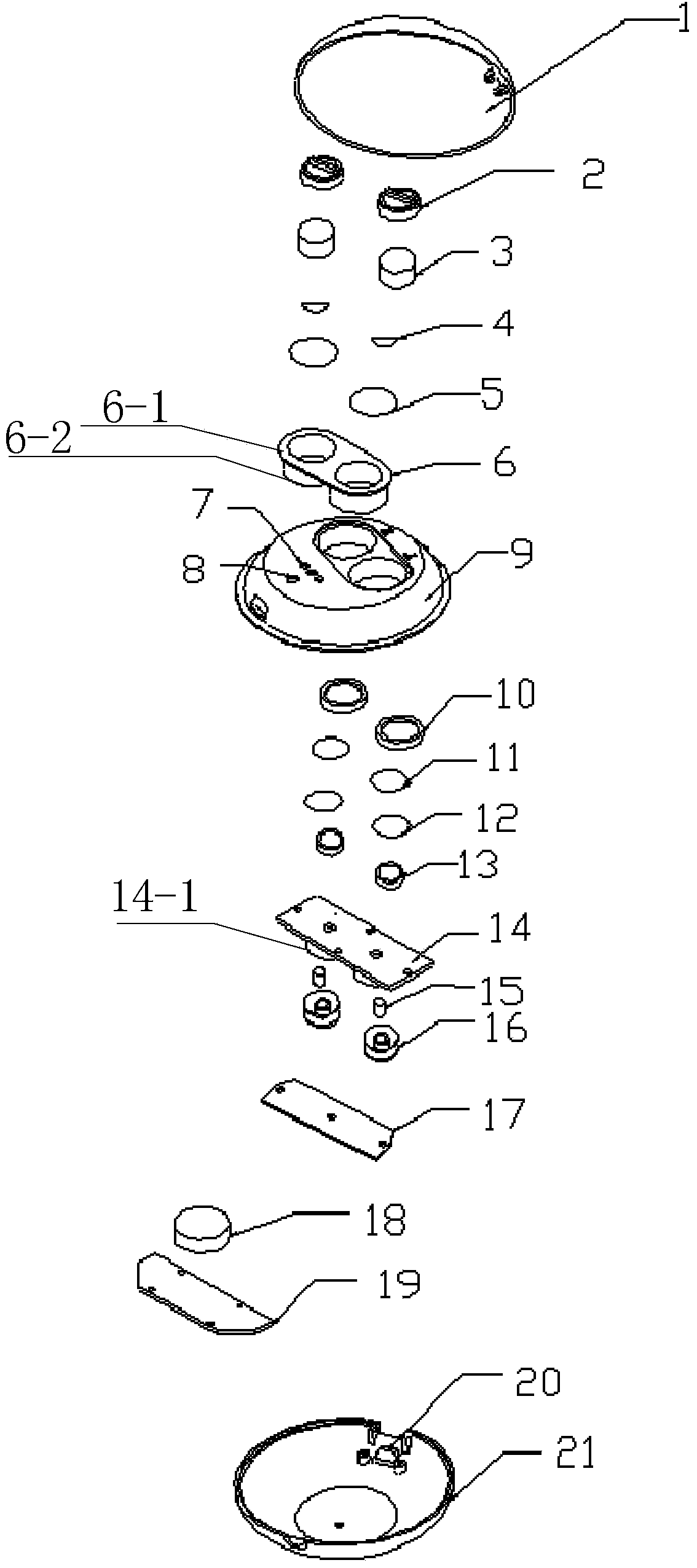

[0052] Example 1 As shown in Figures 3(a), 3(b), 3(c), and 3(d),

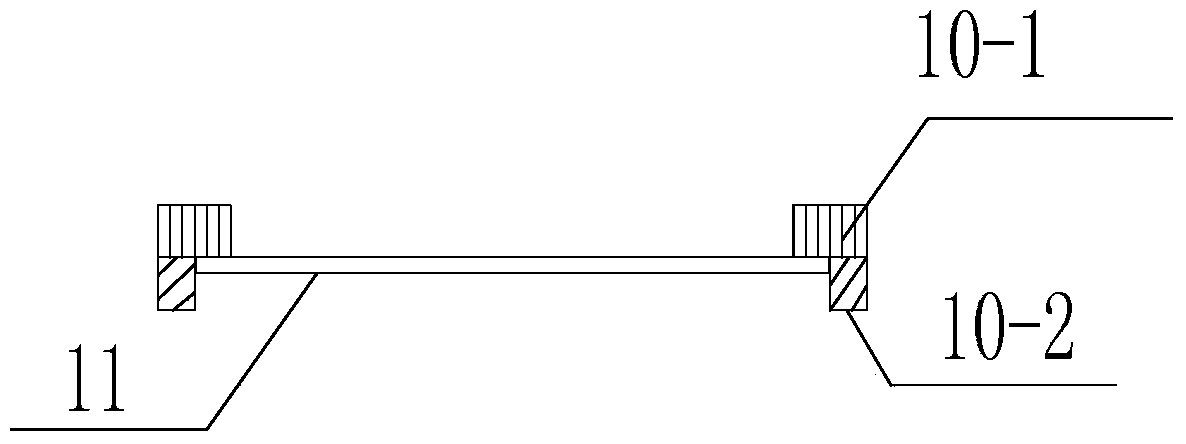

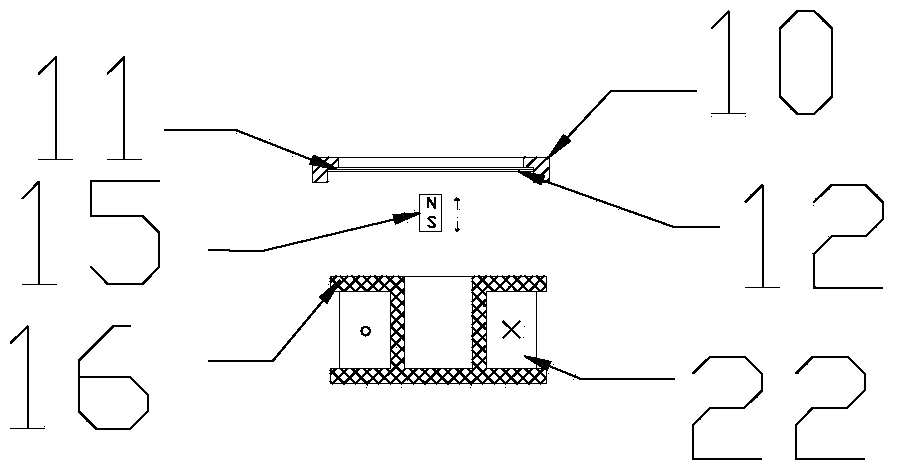

[0053] As shown in Figure 3(a), the power part includes a magnetic steel column 15, a coil frame 16, a coil 22, a copper sheet and a first pressing plate, and the copper sheet is a permanent magnet; the copper sheet is arranged on the nano-silver pad and the first pressing plate Between, the cross section of the bobbin is U-shaped, the coil is wound on one end of the U-shaped bobbin, and the bobbin is set in the raised through groove of the first pressure plate, and the U-shaped opening end corresponds to the copper sheet; the through groove of the first pressure plate A second pressing plate is arranged on the top, and the second pressing plate is fixedly connected with the first pressing plate, and the inner side wall of the through groove of the first pressing plate and the upper surface of the second pressing plate form a cavity for placing the coil skeleton.

Embodiment 2

[0055] As shown in Figure 3(b), the power part includes a magnetic steel column 15, a coil bobbin 16, a coil 22, a magnetic steel column, a copper sheet, and a first pressure plate, and the magnetic steel column is a permanent magnet, and one end of the magnetic steel column is connected to the bottom of the copper sheet. The surface is fixed; the copper sheet is set between the nano-silver pad and the first pressure plate, the section of the coil frame is a cylinder, the coil is wound on the outer wall of the coil frame, and the coil frame is set in the raised channel of the first pressure plate, and the copper sheet Correspondingly: a second pressure plate is provided on the first pressure plate through groove, the second pressure plate is fixedly connected with the first pressure plate, and the inner side wall of the first pressure plate through groove and the upper surface of the second pressure plate form a cavity for placing the coil skeleton.

Embodiment 3

[0057] As shown in Figure 3(c) and 3(d), the power part includes a magnetic steel column 15, a coil bobbin 16, a coil 22, a magnetic steel column, a copper sheet and a first pressure plate, and the copper sheet is arranged on the nano-silver pad and the first Between the pressure plates, one end of the magnetic steel column is fixed to the lower surface of the copper sheet; the coil frame is a cylinder or its cross-section is mountain-shaped, and its material is metal; the coil is wound on the coil frame, and the coil frame is arranged on the first pressure plate In the through groove raised, corresponding to the copper sheet; the second pressure plate is arranged on the first pressure plate through groove, the second pressure plate is fixedly connected with the first pressure plate, and the inner side wall of the first pressure plate through groove is formed with the upper surface of the second pressure plate. The cavity for placing the bobbin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com