Energy storage power station battery thermal runaway protection system

A technology of energy storage power station and protection system, applied in the field of battery thermal runaway protection system of energy storage power station, can solve the problems of low cooling efficiency and single battery temperature, and achieve safe and effective temperature control, good chemical stability, and high cooling capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

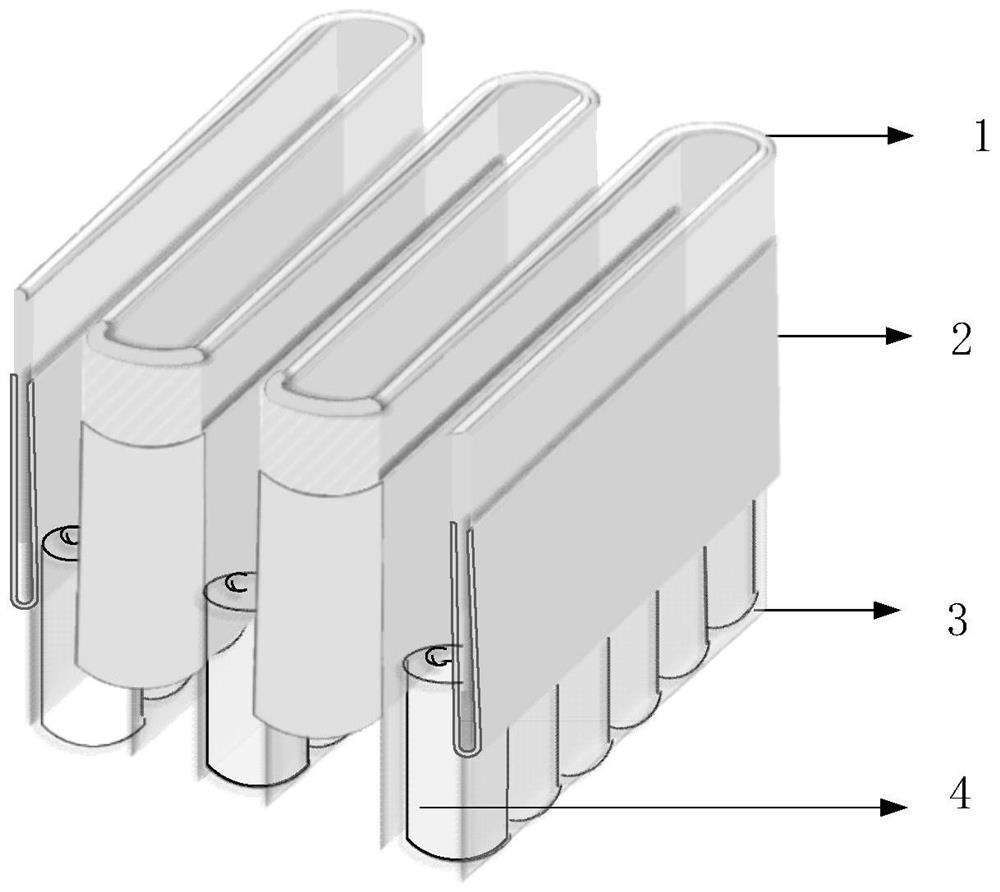

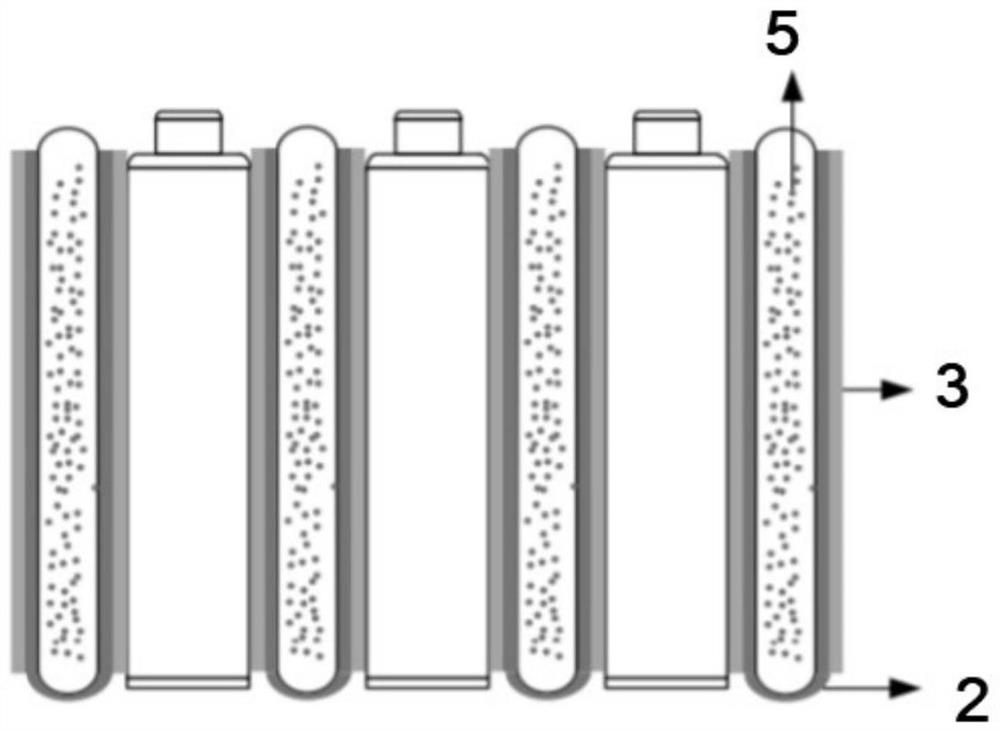

Method used

Image

Examples

Embodiment

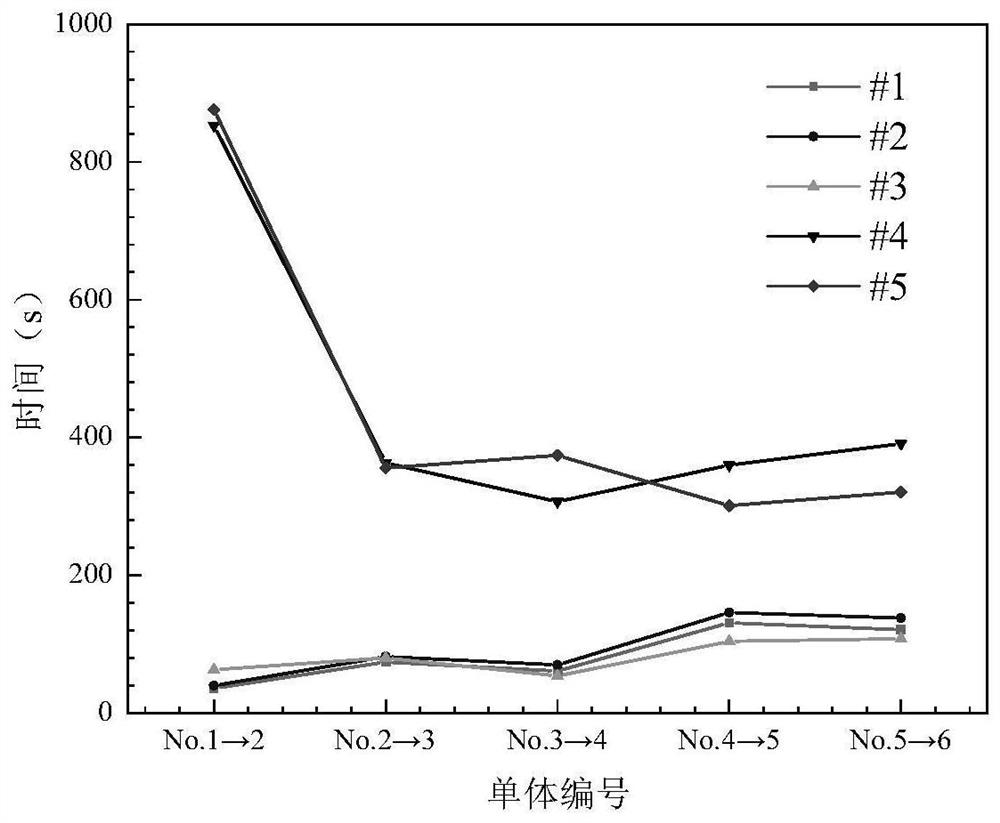

[0032] In order to compare the effect of solid-solid phase change materials and liquid-cooled plate battery components on thermal runaway propagation behavior, experiments were conducted using the controlled variable method. The materials used in the test include: battery module (6 batteries in series), battery thermal runaway trigger heater, paraffin / expanded graphite solid-solid composite phase change material cooling plate, cooling water circulator, cold liquid plate, and heat-conducting silicone layer. Table 1 lists the variable combinations for the five sets of experiments. The five experiment numbers are: 1#, 2#, 3#, 4#, 5#. The ambient temperature during the experiment was 25° C. and the atmospheric pressure was 101 KPa. The block heater consists of six circular heating tubes with a diameter of 18mm and a square iron block, the same size as the battery, with a maximum power of 780 watts. The thermal runaway of the battery is triggered by using the power supply to driv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com