Power battery equalizing charge method and system

A technology for balanced charging and power batteries, applied in secondary battery charging/discharging, battery circuit devices, secondary battery repair/maintenance, etc., can solve problems such as slow speed, unsuitable series battery system, etc., to improve service life and performance The effect of complete consistency, operation and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

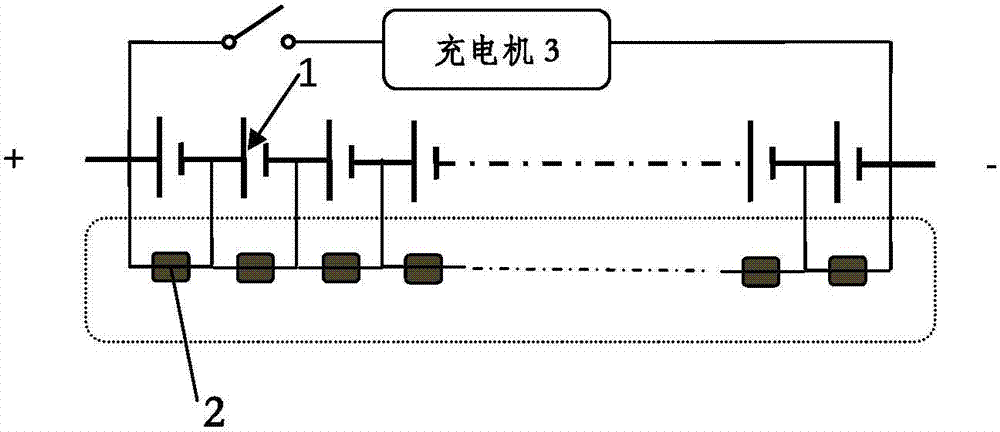

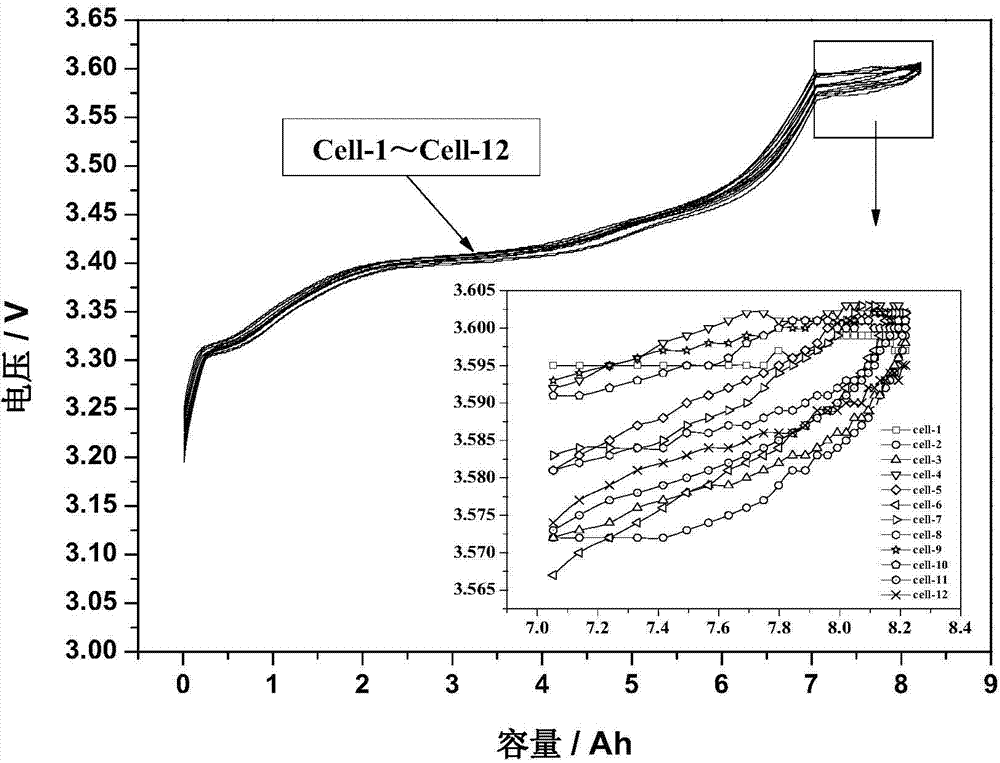

[0048] A power battery pack for electric bicycles, consisting of 12 lithium-ion power batteries in series (each battery module is a single lithium-ion power battery), and its upper limit charging voltage is 43.2V, of which, the single lithium-ion power battery The rated capacity is 8Ah, and the charging cut-off voltage is 3.595V. The charging balance module adopts switching power supply.

[0049] First use the charger to charge the battery system with a constant current, and the charging current is 4A. When the voltage of any lithium-ion power battery reaches the charging cut-off voltage (3.595V) or the battery system reaches the upper limit charging voltage (43.2V), stop charging the charger. In this embodiment, the charging cut-off voltage of the single battery is the pre-arriving condition.

[0050]Then the charge equalization module carries out equalization charge to each lithium-ion power battery respectively, and the output voltage of each charge equalization module is...

Embodiment 2

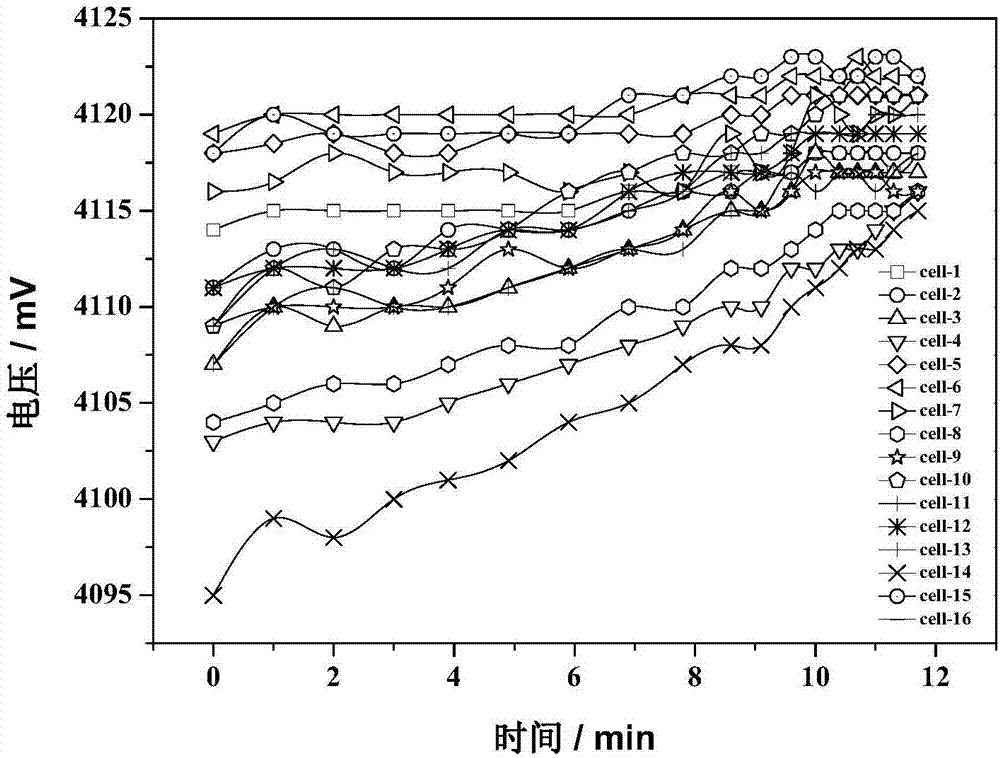

[0053] A power battery system for electric vehicles consists of 94 lithium-ion battery modules connected in series. Each battery module (composed of 5 lithium-ion monomer batteries connected in parallel) has a rated capacity of 125Ah and a nominal voltage of 3.65V. The cut-off voltage is 4.1V, and the upper limit charging voltage of the battery system is 385V.

[0054] First use an external charger to charge the battery system with a constant current, and the charging current is 30A. When the voltage of any battery module reaches the charging cut-off voltage (4.10V) or the battery system reaches the upper limit charging voltage (385V), the battery management system will automatically cut off the charging circuit of the charger. In this embodiment, the upper limit charging voltage of the battery system is the first arrival condition.

[0055] Then the charging equalization module starts to perform equalization charging on each single battery, and the output voltage of each cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com