Fuel cell, and a method for preparing the same

A fuel cell and dry cell technology, applied in the direction of fuel cells, fuel cell groups, fuel cell components, etc., can solve the problems of non-formation, leakage of fuel and oxidant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

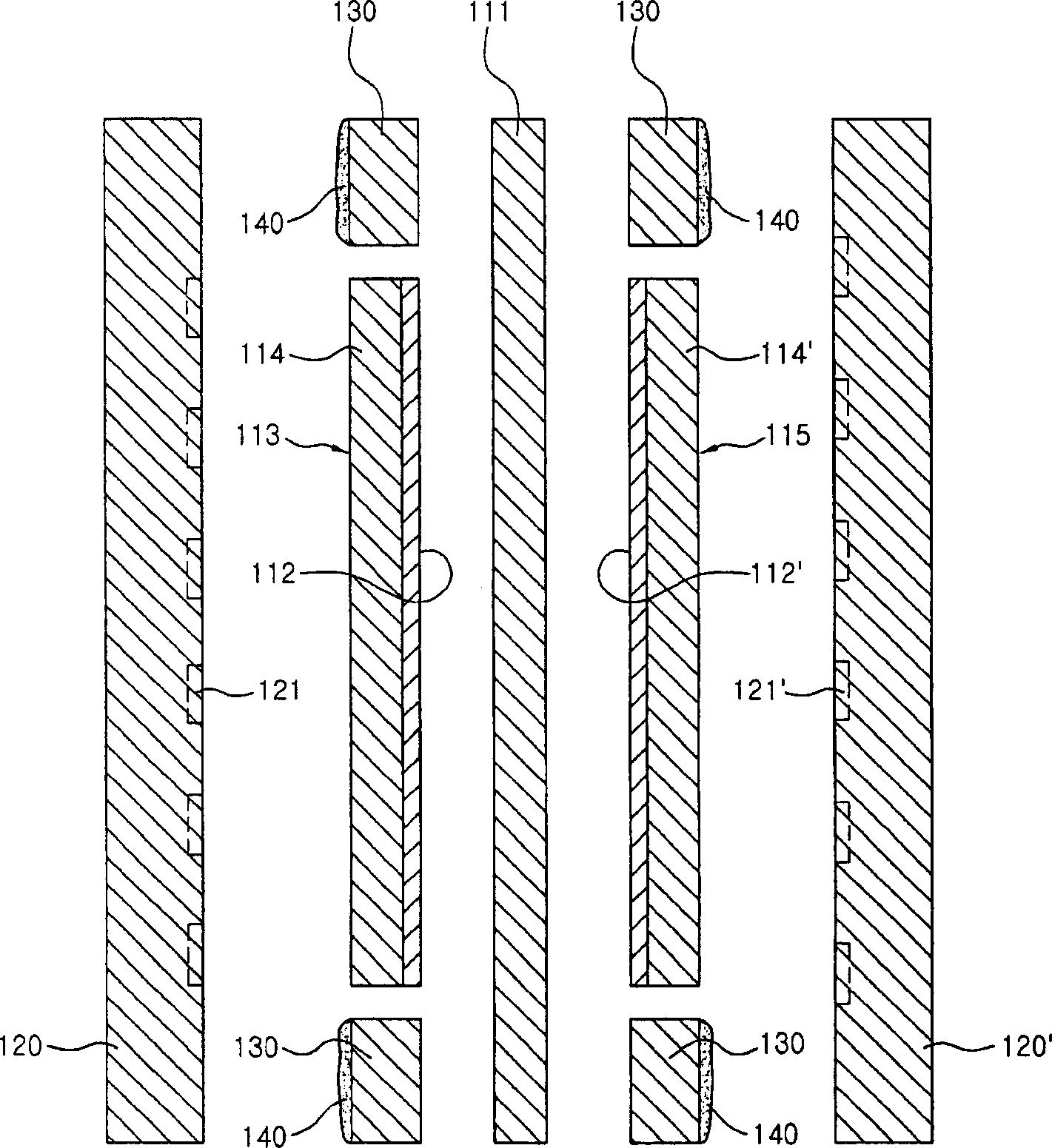

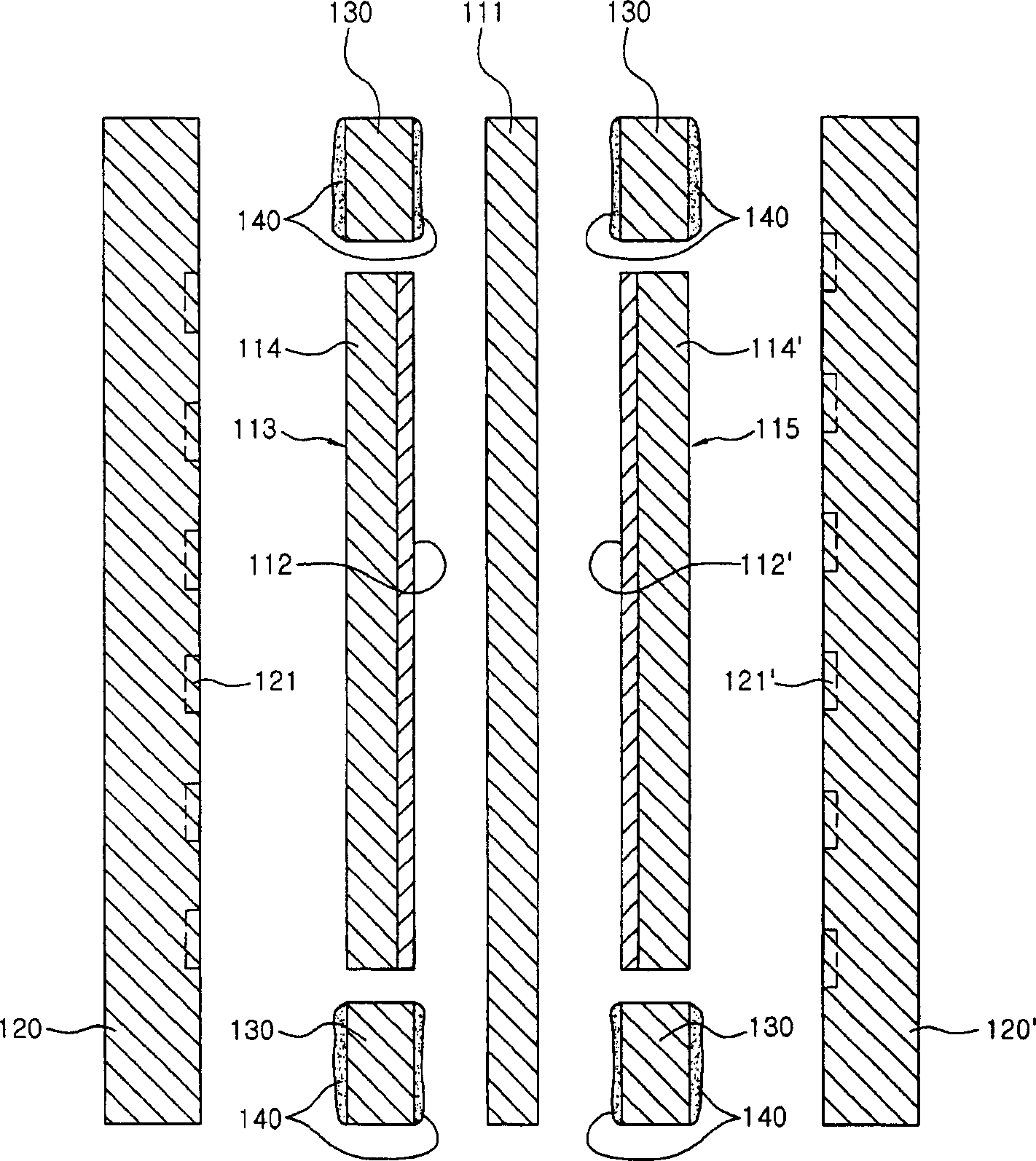

[0043] The membrane was prepared by forming a cathode layer and an anode layer each including a platinum catalyst on two sheets of carbon cloth, and placing the cathode layer and the anode layer in contact with both sides of a perfluorosulfonic acid membrane (Nafion® produced by DuPont) Electrode Assembly (MEA).

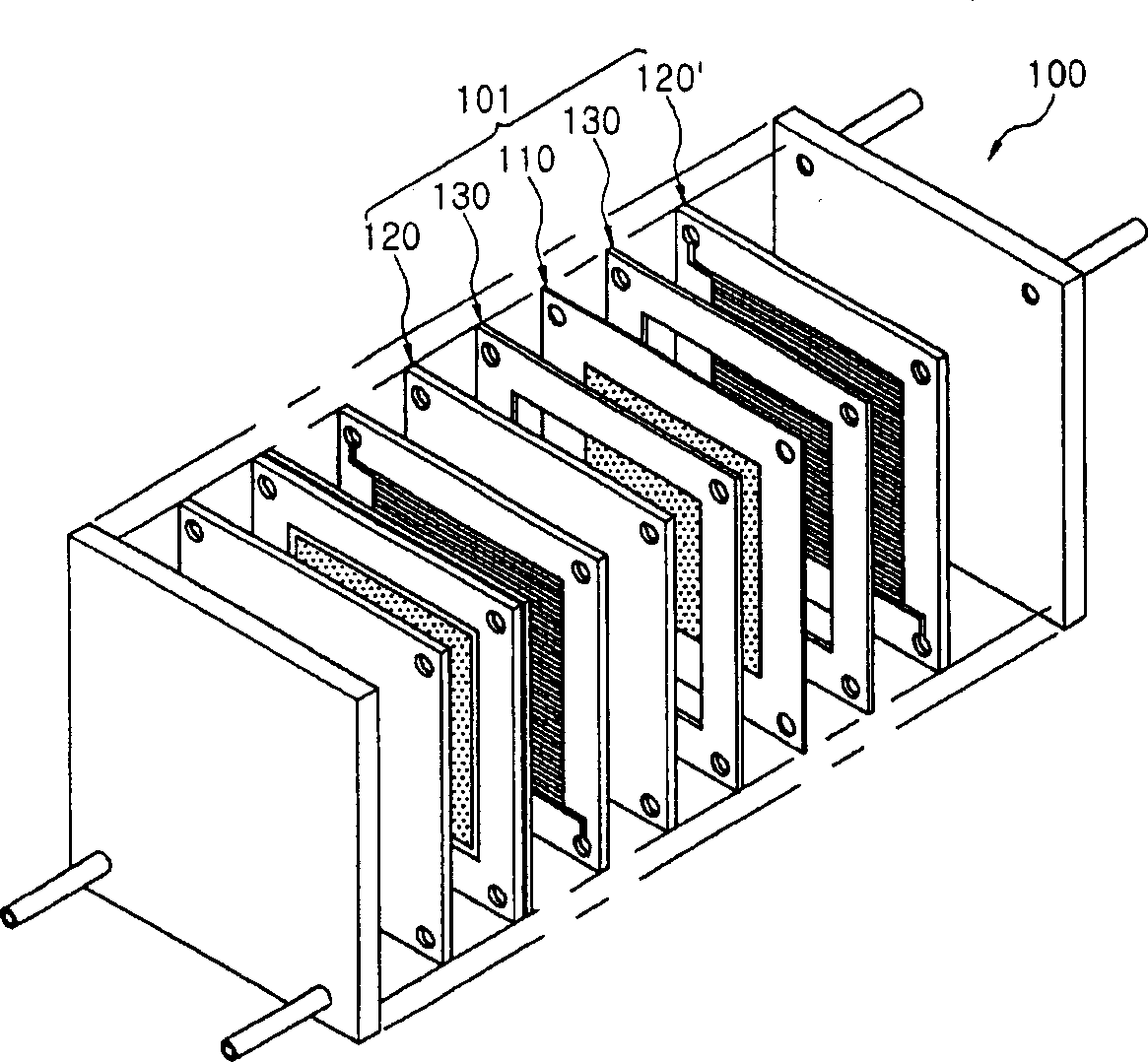

[0044] Subsequently, a 2-cyanoacrylate adhesive was applied to one side of each of the two prepared separators bonded to both sides of the electrolyte membrane on the outer edge of the above prepared MEA. The other side of the separator was coated with 2-cyanoacrylate adhesive, and a separator on which a liquid flow channel was formed was placed on both sides of the MEA with the separator, thereby manufacturing a dry battery. Then, a fuel cell is prepared by stacking the dry cells one on top of the other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com