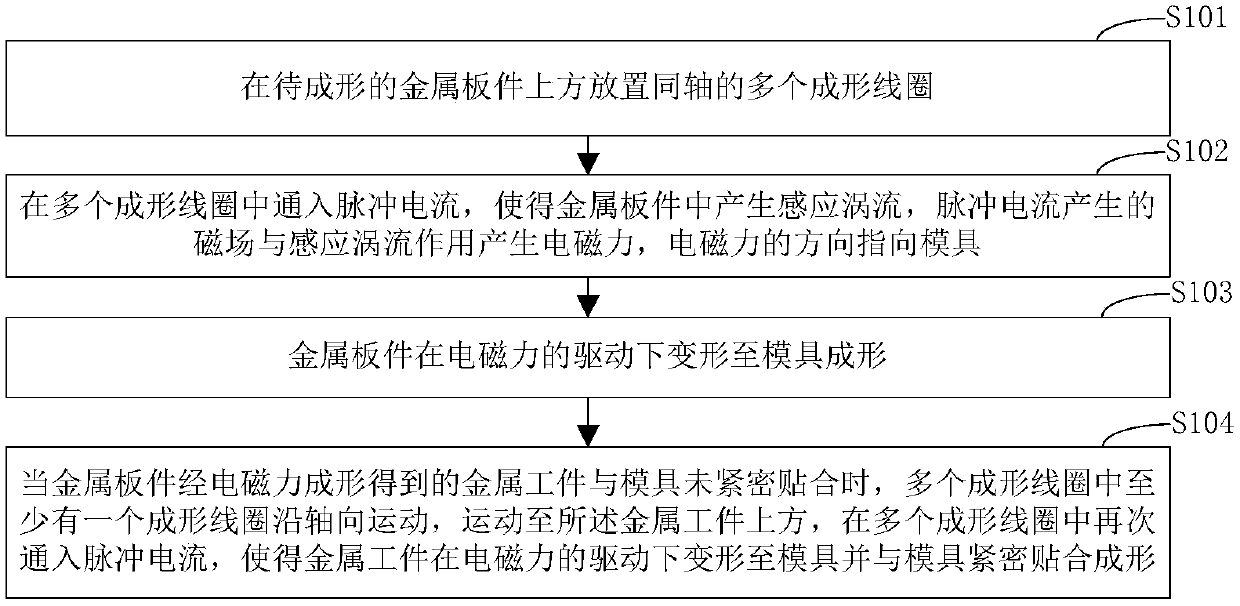

Electromagnetic forming method and device of metal plate

An electromagnetic forming and metal plate technology, which is applied in the field of metal forming and manufacturing, can solve the problems of low structural strength of forming coils, uncontrollable electromagnetic force distribution, poor quality of multiple forming, and achieve good mold adaptability and restrain the attenuation of electromagnetic force. , the effect of improving the forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

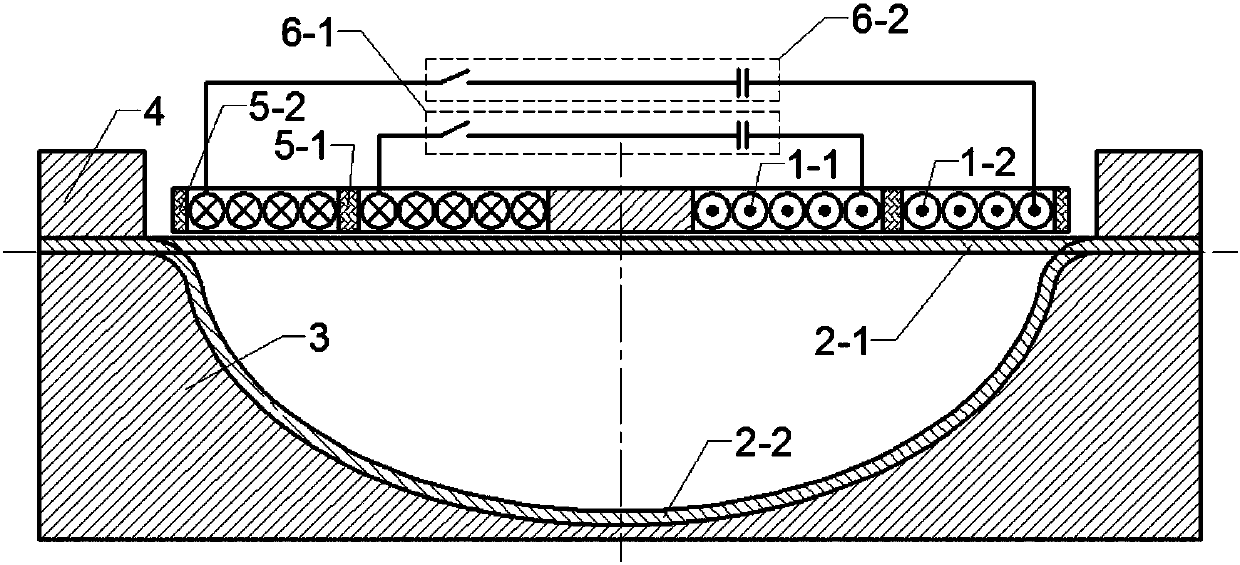

no. 1 example

[0065] figure 2 The first embodiment of the electromagnetic forming device for sheet metal provided by the present invention, the electromagnetic forming device includes a first forming coil 1-1, a second forming coil 1-2, a sheet blank (metal sheet to be formed) 2 -1. Mold 3, blank holder 4, first power supply 6-1 and second power supply 6-2, wherein the plate blank 2-1 can be made of aluminum alloy material, and this type of aluminum alloy material has high electrical conductivity and good plasticity , low strength and easy to form; the longitudinal section of the forming die 3 is an elliptical profile; the first forming coil 1-1 and the second forming coil 1-2 are integrated, and the outermost layers are all made of high-strength fiber material 5-1 and 5-2 is reinforced, and the axial direction cannot be moved. The forming method corresponding to the electromagnetic forming device comprises the following steps:

[0066] (1) Place the sheet blank 2-1 on the upper surface ...

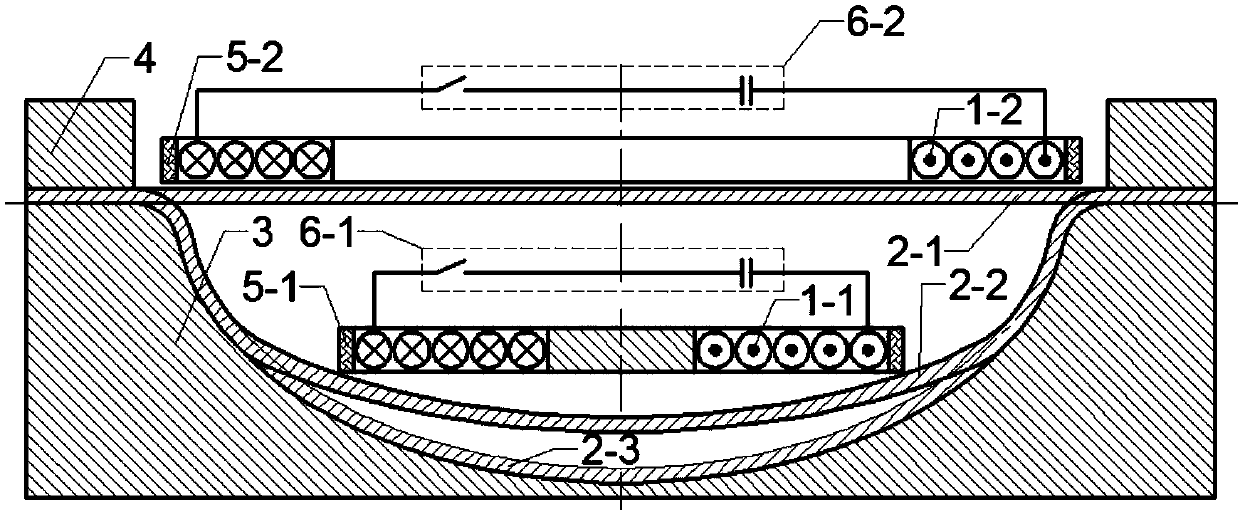

no. 2 example

[0071] image 3 The second embodiment of the electromagnetic forming device for sheet metal provided by the present invention, the electromagnetic forming device includes a first forming coil 1-1, a second forming coil 1-2, a sheet blank 2-1, a mold 3, and a blank holder Circle 4, the first power source 6-1 and the second power source 6-2, wherein the plate blank 2-1 can be made of aluminum alloy material, which has low electrical conductivity and high strength and is difficult to form. The first forming coil 1-1 and the second forming coil 1-2 are two independent coils, and the first forming coil 1-1 can move along the axial direction. The forming method corresponding to the electromagnetic forming device comprises the following steps:

[0072] (1) Place the sheet blank 2-1 on the upper surface of the mold 3, place the blank holder 4 on the sheet and apply a certain pressure, wherein the outer diameter of the blank holder 4 and the sheet blank 2-1 The outer diameter of and ...

no. 3 example

[0079] Figure 4 The third embodiment of the electromagnetic forming device for sheet metal provided by the present invention, the electromagnetic forming device includes a first forming coil 1-1, a second forming coil 1-2 and a third forming coil 1-3, and a sheet blank 2 -1. Mold 3, blank holder 4, first power source 6-1 and second power source 6-2, wherein the plate blank 2-1 can be made of aluminum alloy material, and this type of aluminum alloy material has high electrical conductivity and good plasticity , low strength, easy to form; the longitudinal section of the forming die 3 is an elliptical profile; the first forming coil 1-1, the second forming coil 1-2 and the third forming coil 1-3 are a whole, and the outermost layers are all made of The high-strength fiber materials 5-1, 5-2 and 5-3 are reinforced, and the overall axial direction cannot move. The forming method corresponding to the electromagnetic forming device comprises the following steps:

[0080] (1) Place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com