Cell-gel material composite microsphere as well as preparation method and application thereof

A gel material and composite microsphere technology, applied in the field of biomedical materials, can solve the problems of loading cells, poor mechanical properties, material breakage, etc., and achieve the effects of maintaining the biological properties of collagen, centralized distribution, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

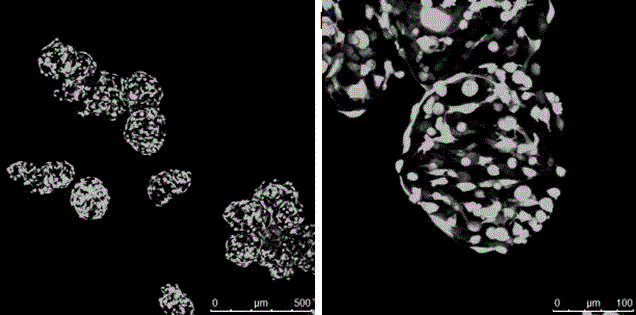

[0049] The preparation process flow of the present invention is (as Figure 9 shown): the pH of the gel material solution is adjusted with the cell suspension to make a gel material-cell mixture, which is dispersed in an oily solution and gelled, and then the obtained product is washed to obtain a cell-loaded mixture. Microspheres; microspheres are then dispersed in the continuous phase solution of temperature-sensitive materials or photosensitive materials, and gelled to form heterogeneous hydrogels.

[0050] Among them, when temperature-sensitive materials are used, the cell material mixture needs to be mixed under low temperature conditions; when photosensitive materials are used, a photoinitiator needs to be added to the cell material mixture; dispersion treatment is to make the cell material mixture Disperse in oily solution; after continuous stirring and dispersion for a period of time, gelatinize the crude microspheres; obtain microspheres after repeated washing and sep...

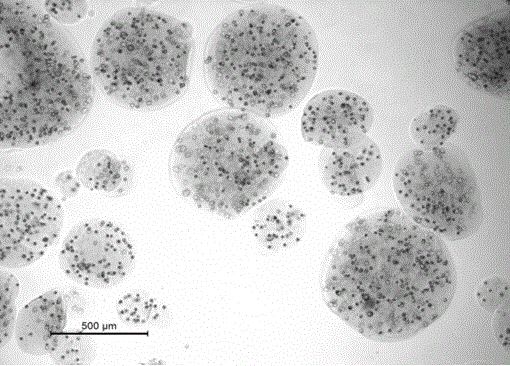

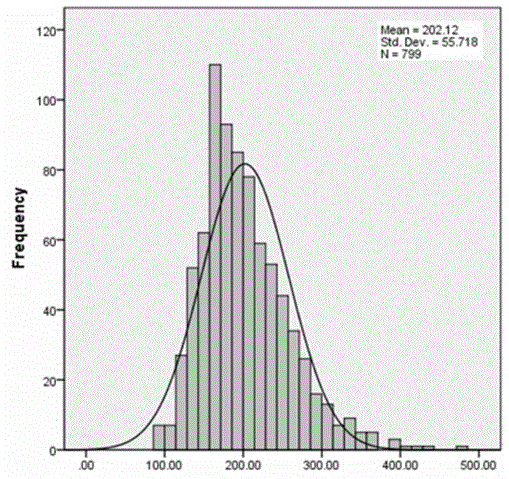

Embodiment 1

[0053] (1) Take 200mL rapeseed oil, add a small amount of Tween-60, stir the rapeseed oil with a magnetic stirrer at a speed of 1500rpm in an ice bath, and slowly add 1mL of a collagen solution with a concentration of 15mg / mL to the dish Stir continuously in the seed oil for 20 minutes, raise the temperature of the above water-oil phase mixture to 37°C, and keep stirring for 10 minutes. After the stirring is completed, clean and separate the mixture, remove the oil phase, and obtain an average particle size of about 30 micron collagen microspheres.

[0054] (2) Disperse the collagen microspheres prepared in step (1) in a collagen solution with a concentration of 15 mg / mL, transfer the above-mentioned collagen solution containing microspheres to a mold, raise the temperature to 37°C and keep for 30 minutes to obtain collagen Heterogeneous Collagen Hydrogel with Collagen Microspheres Encapsulated by Continuous Phase. The resulting hydrogel was dissected, and under a scanning el...

Embodiment 2

[0056] (1) Take 4mL of olive oil and 6mL of corn oil and stir and mix at a speed of 800rpm to obtain a mixed oil phase solution. Under stirring conditions, 4mL of hyaluronic acid (transparent Hyaluronic acid) solution (the concentration of hyaluronic acid is 3 mg / mL) was slowly added dropwise into the above mixed oil phase solution, and stirred continuously for 30 min. The wavelength is 365nm, the light intensity is 30mW / cm 2 The ultraviolet radiation of 360s triggers the polymerization reaction, gels the hyaluronic acid microspheres, and keeps stirring for 10 minutes; washes and separates the mixed solution, removes the oil phase, and obtains hyaluronic acid microspheres with an average particle size of about 1000 microns. ball.

[0057] (2) The hyaluronic acid microspheres prepared in step (1) are dispersed in the hyaluronic acid solution modified by maleic anhydride with a concentration of 8 mg / mL, and the above-mentioned hyaluronic acid solution containing microspheres is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com