Static electricity controllable abrasive particle flow processing method based on charge tip aggregation effect

A technology of aggregation effect and processing method, which is applied in metal processing equipment, used abrasive treatment devices, abrasive materials, etc., can solve the problems of processing efficiency, low resource utilization, and difficult to improve processing quality, so as to improve effective participation. rate, increase the probability of impact, improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

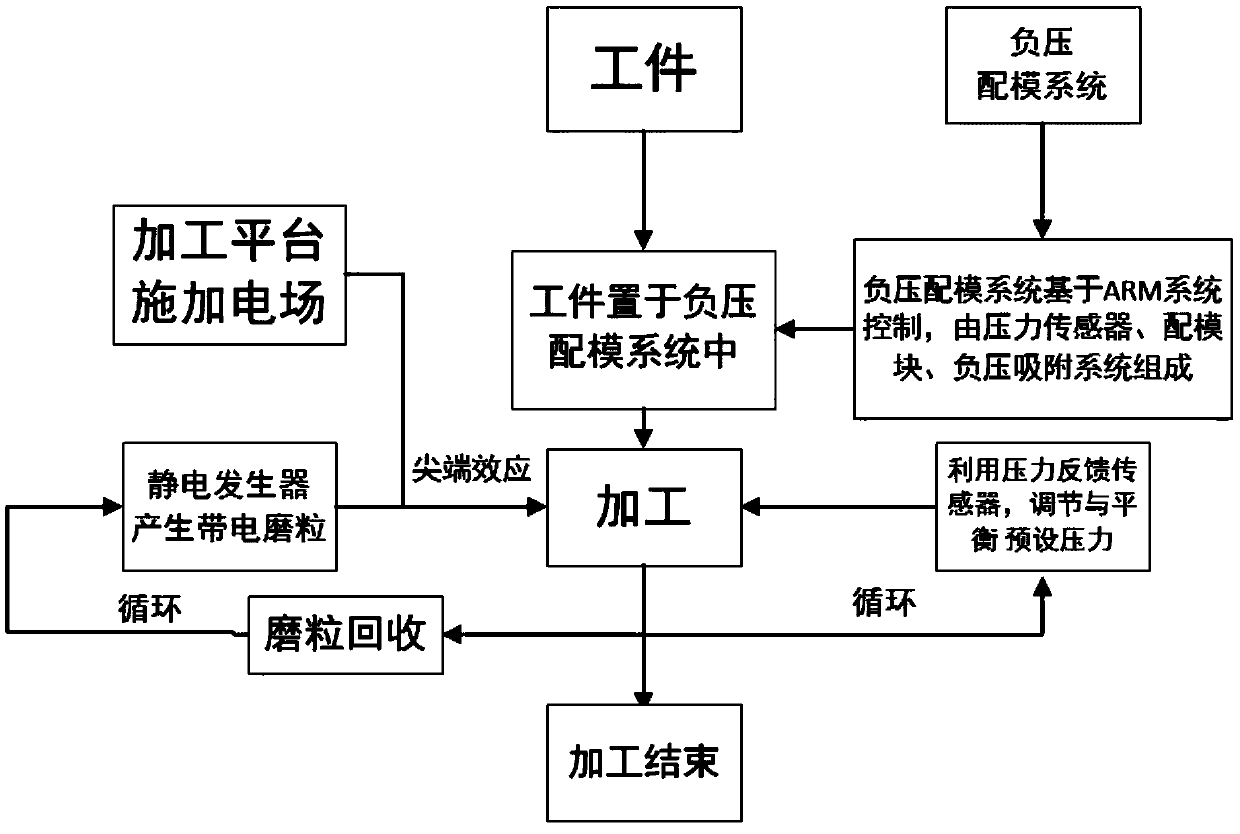

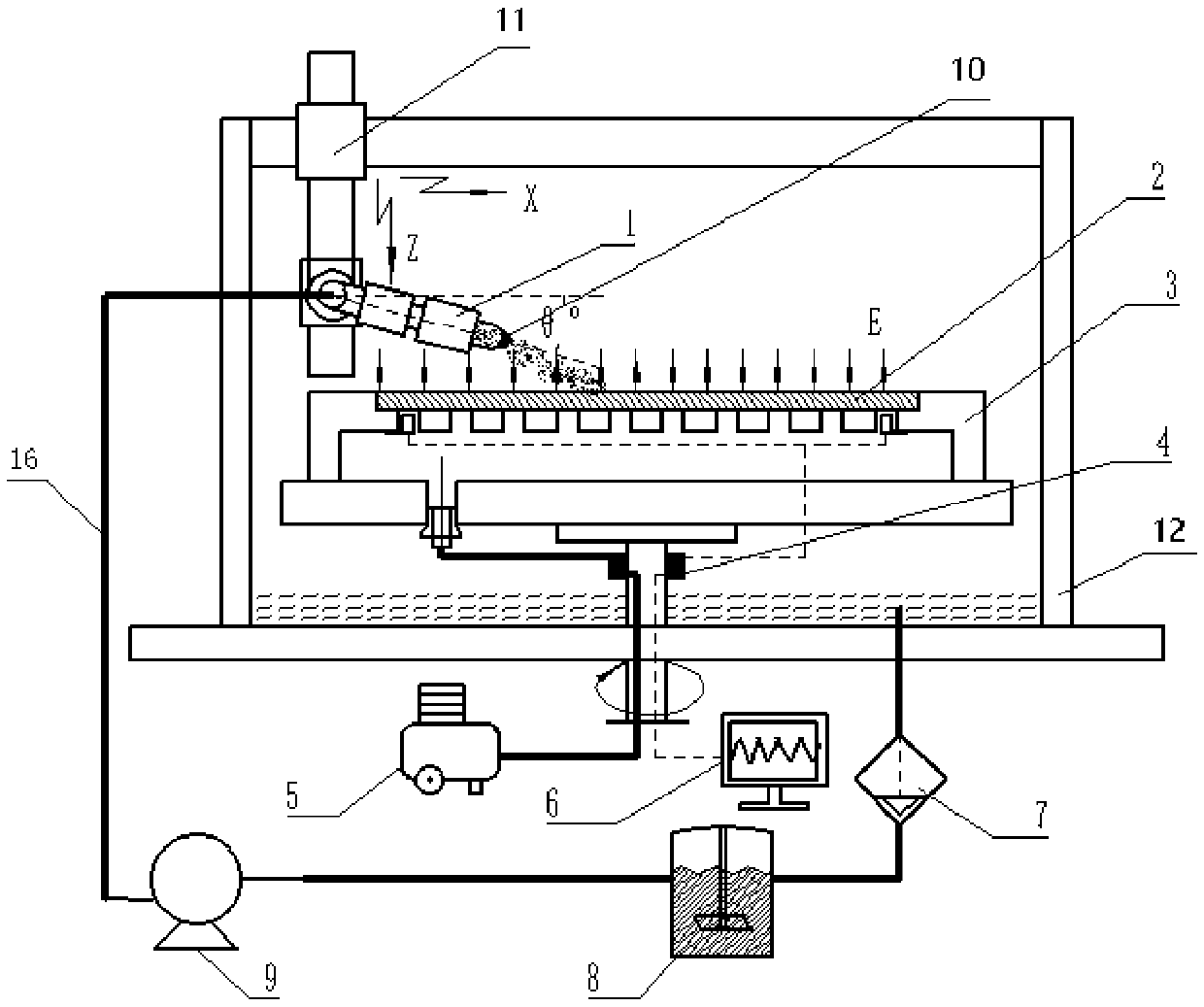

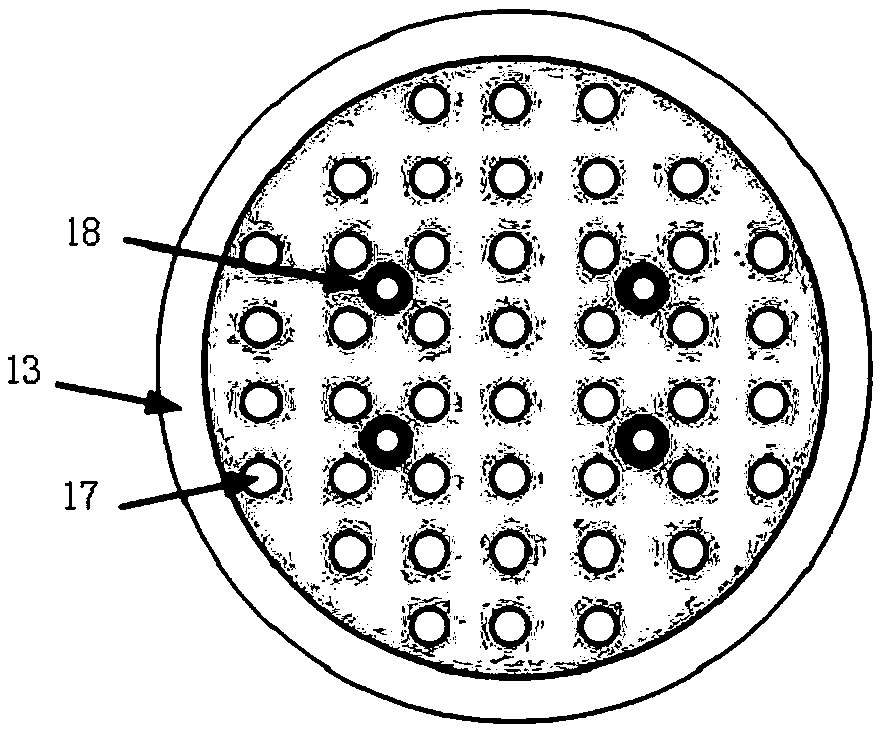

[0028] Such as Figure 1~6 As shown in , an electrostatic controllable abrasive flow processing method based on the charge tip aggregation effect includes the following steps:

[0029] The first step: use the negative pressure mold matching method to fix the workpiece and the negative pressure mold matching device. The sensor can realize online detection and solve the problem of repeated installation and positioning. In the mold device, the negative pressure mold matching device solves the problem of uncontrollable edge contact pressure mutation and uneven material removal, and solves its edge effect;

[0030]The second step: set up the polishing system on the workbench, combine the principle of electrostatic induction and Coulomb's law, make the abrasive grains flow with non-electrolyte as the carrier pass through the high-voltage electrostatic field, and then the abrasiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com