Patents

Literature

43results about How to "High quality surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

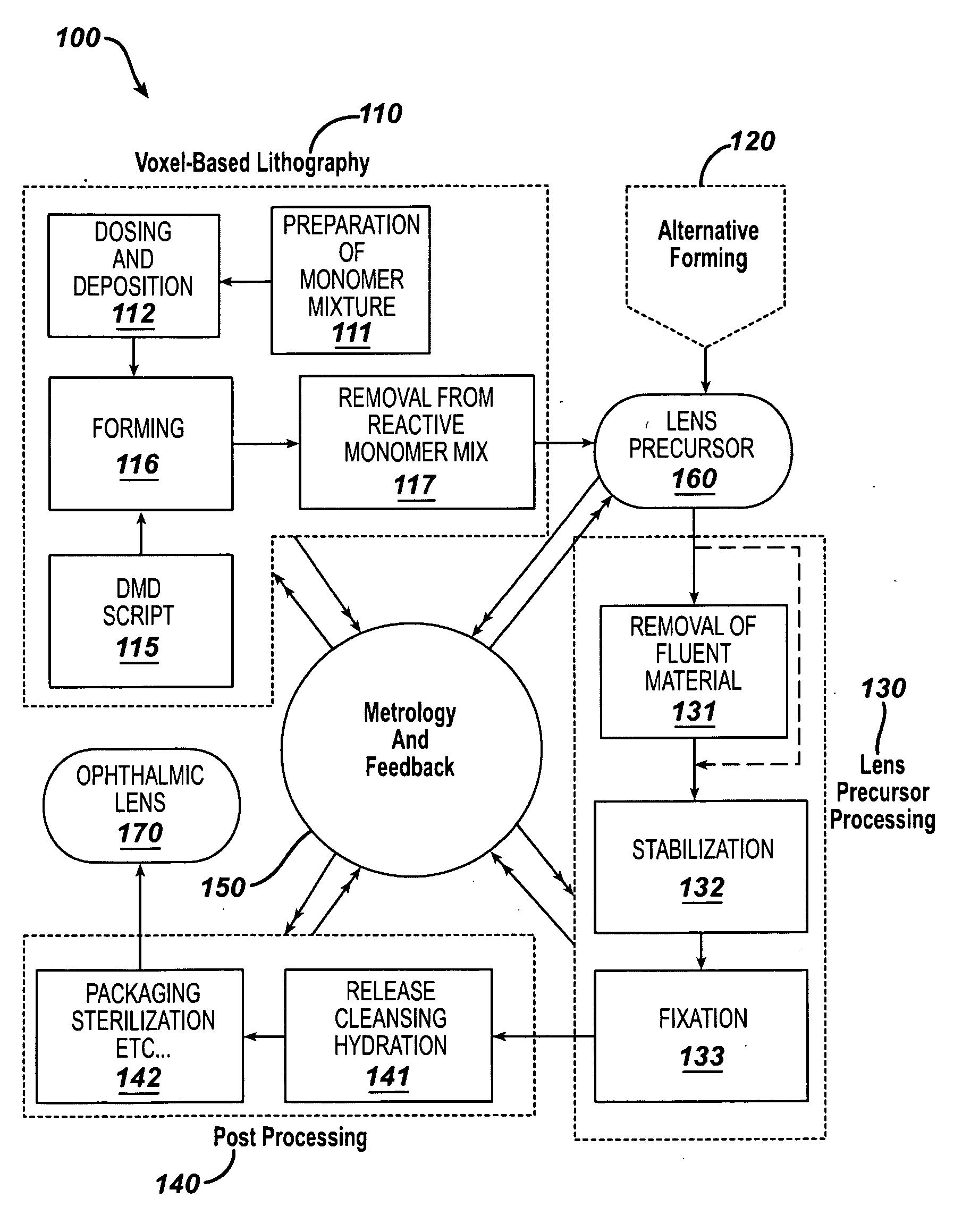

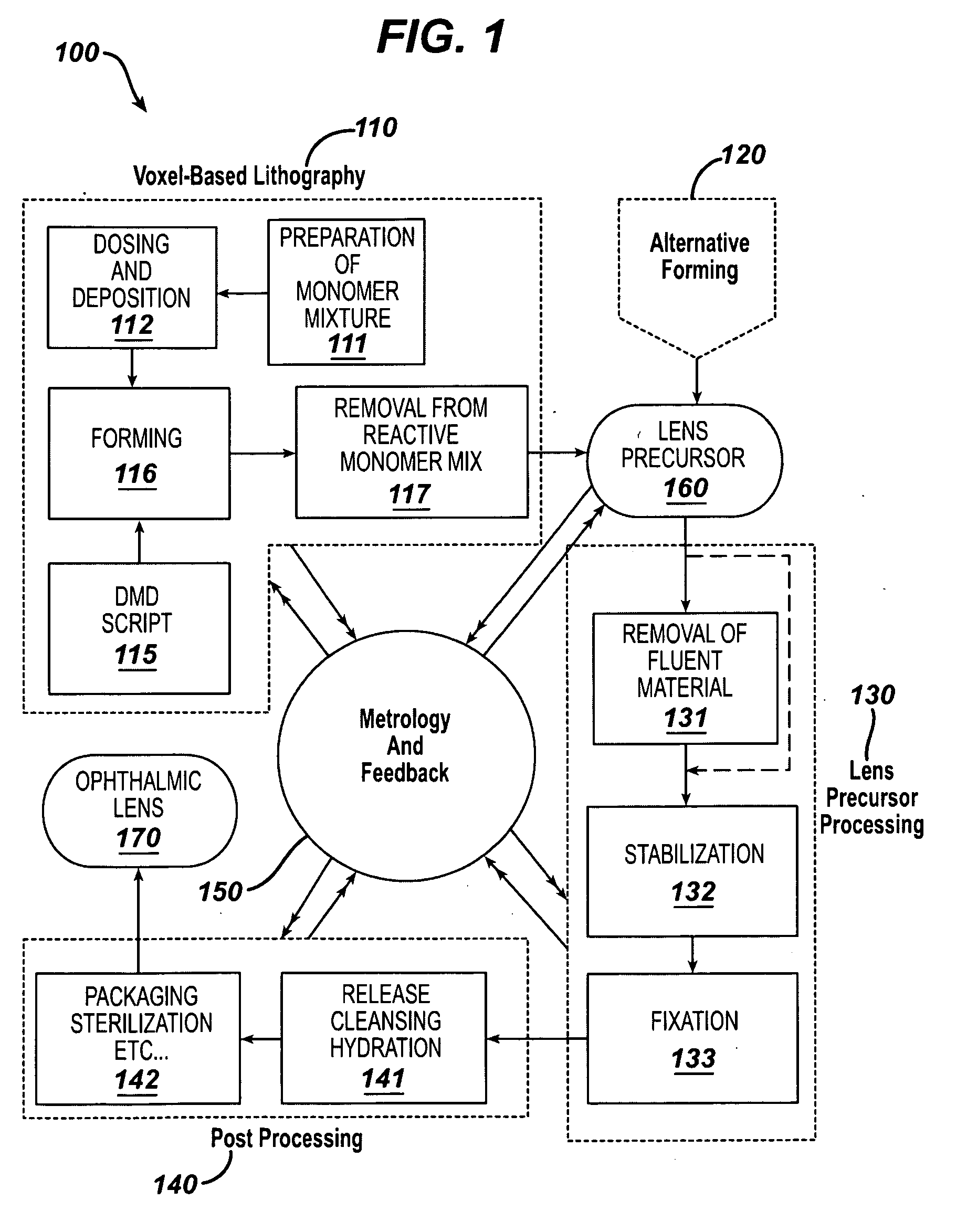

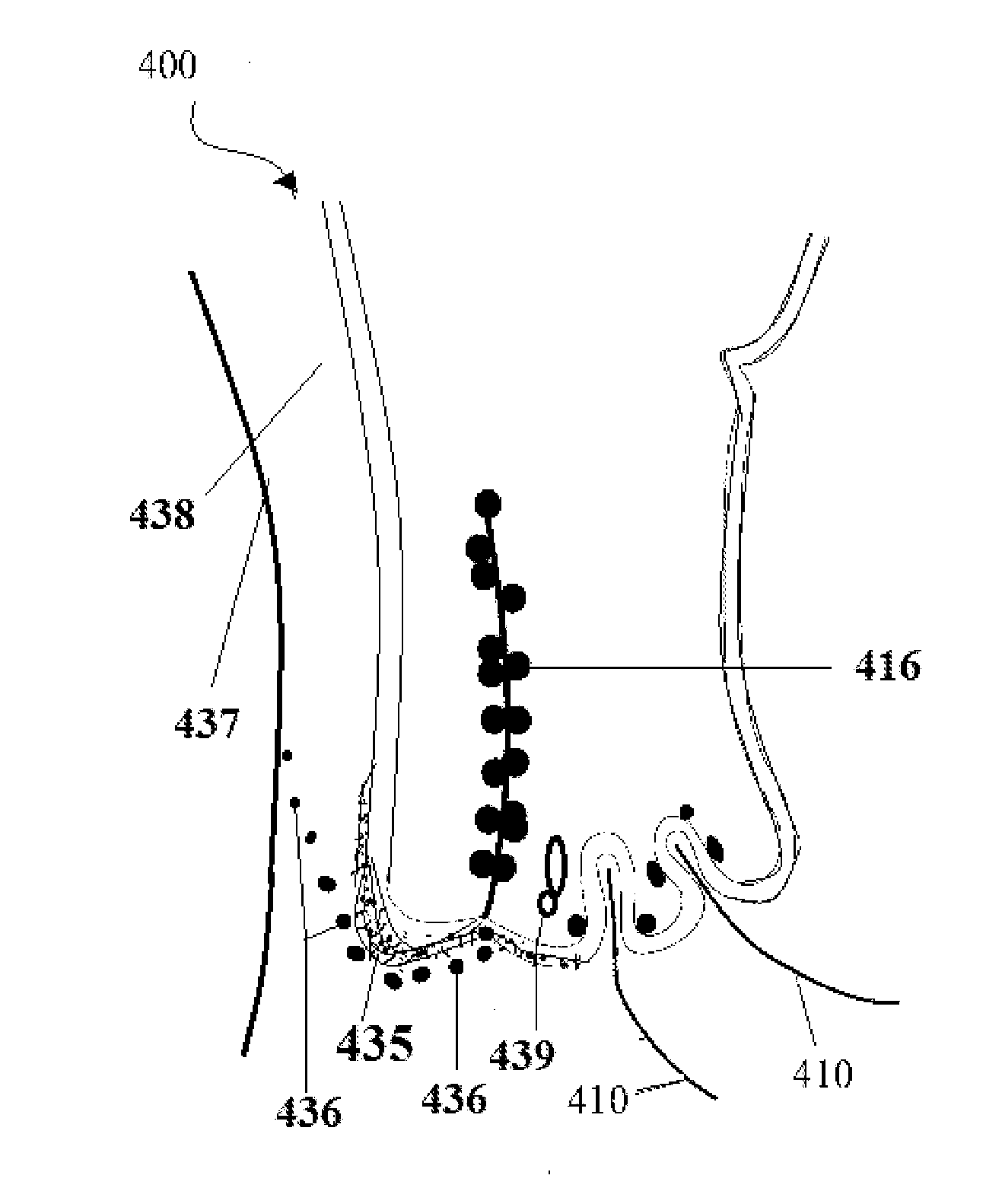

Methods for formation of an ophthalmic lens precursor and lens

ActiveUS20090051059A1Quality improvementHigh-quality surfaceAdditive manufacturing apparatusOptical articlesFree formLens plate

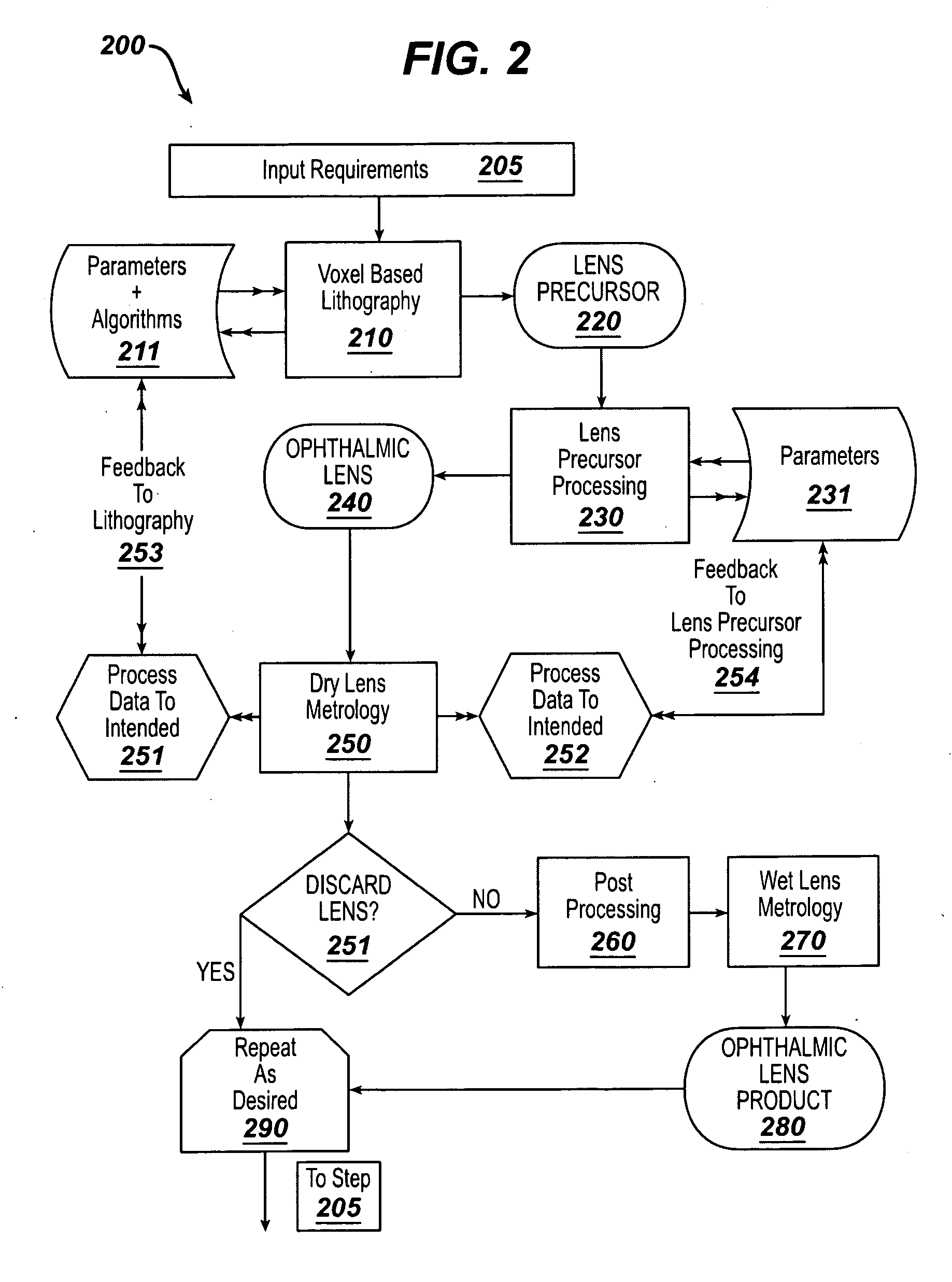

This invention discloses methods for generating one or both of an ophthalmic lens precursor with at least a portion of one surface free-formed from a Reactive Mixture. In some embodiments, an ophthalmic lens precursor is formed on a substrate with an arcuate optical quality surface via a source of actinic radiation controllable to cure a definable portion of a volume of Reactive Mixture.

Owner:JOHNSON & JOHNSON VISION CARE INC

New methods of treating dry eye syndrome

The invention relates to a method of insulin eye drops for treating dry eye syndrome due to any and all etiological factors (Keratoconjunctivitis sicca), including Sjogren's syndrome, Meibomian gland dysfunction (MGD) and other glandular malfunction in the eye lids, lacrimal glands, cornea, conjunctiva, and exposed scleral surface of the eye. It is treated with Insulin and / or IGF-I with or without known anti-dry eye syndrome therapeutic, pharmaceutical, biochemical and biological agents or compounds.

Owner:SHANTHA TOTADA R +2

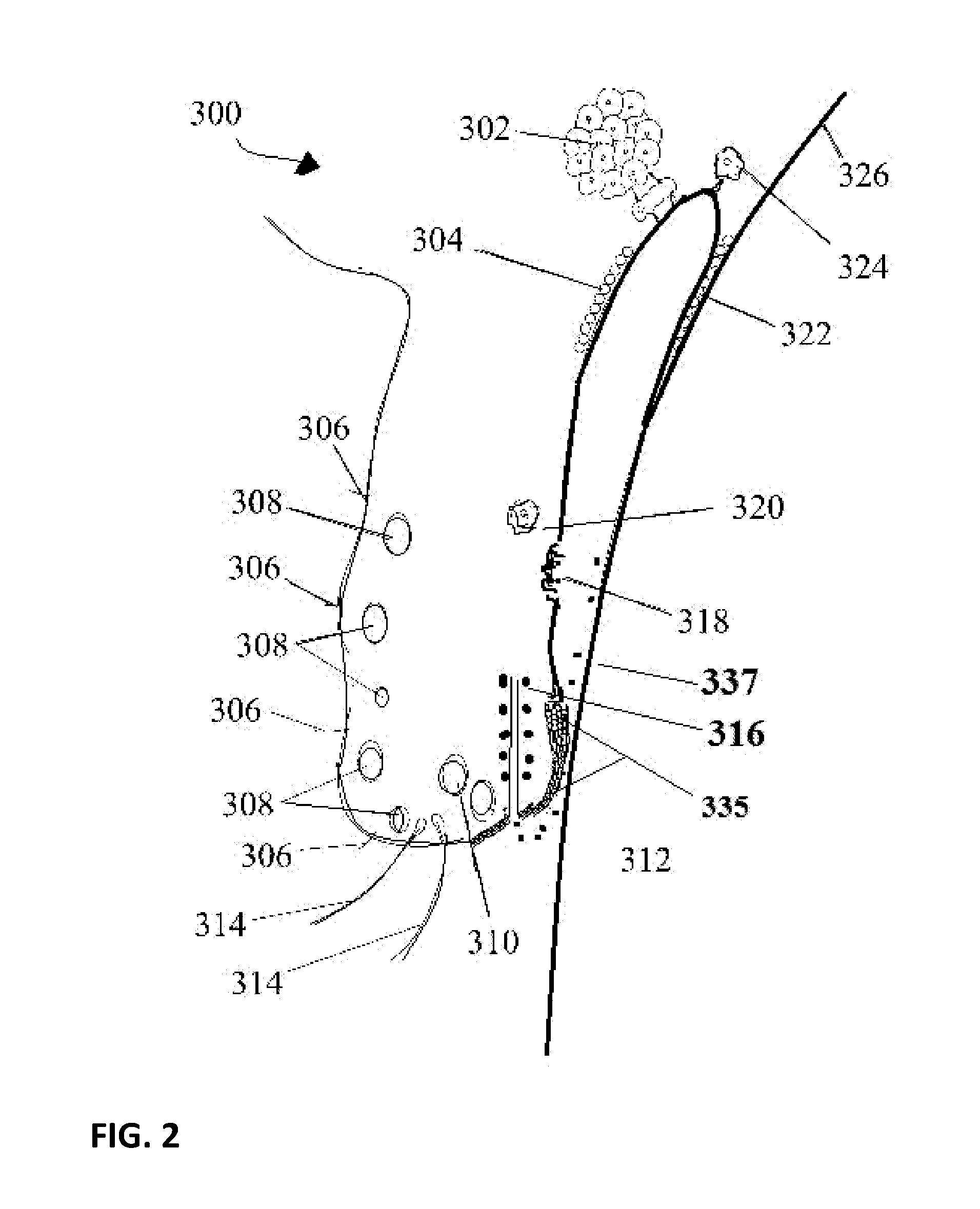

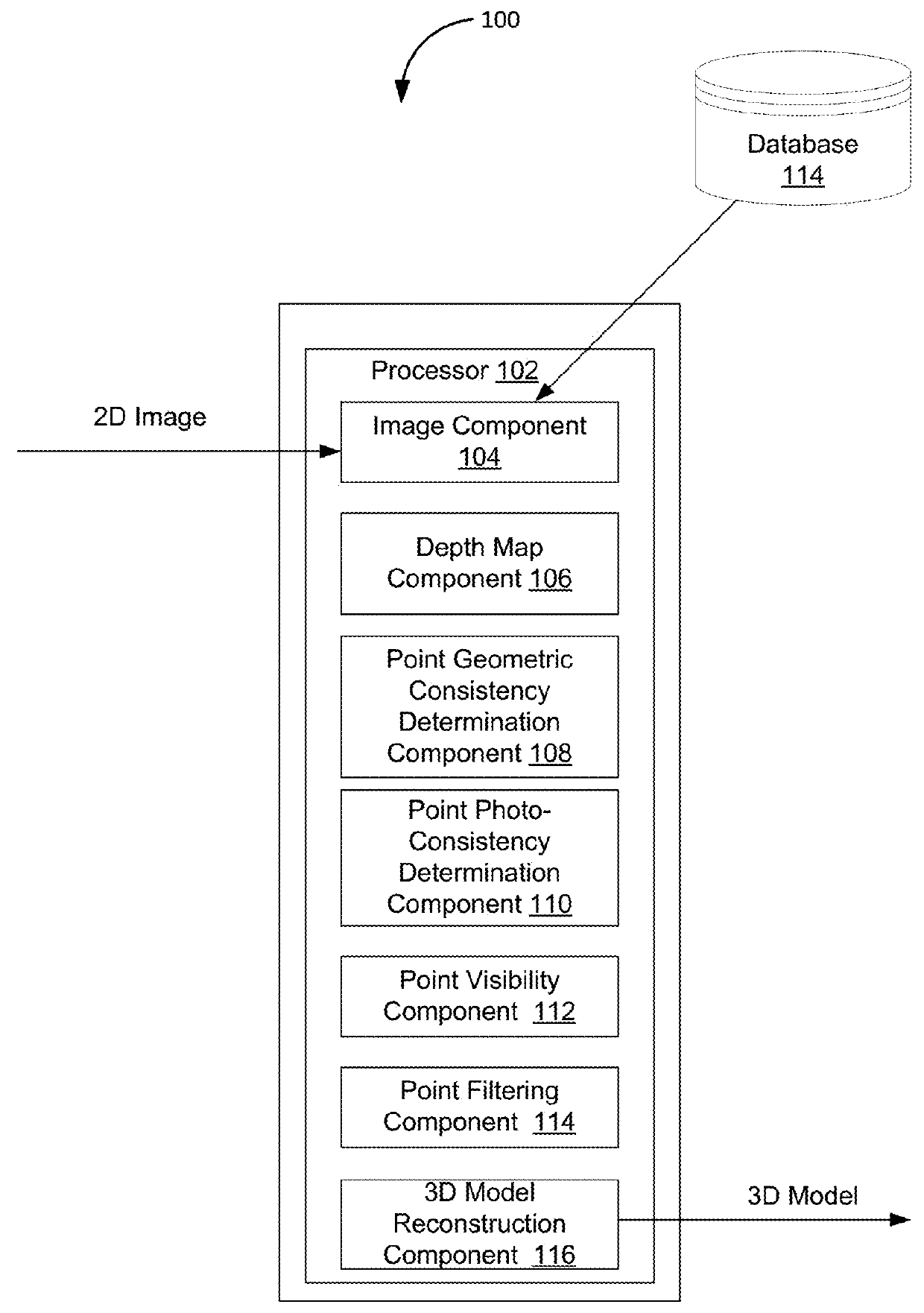

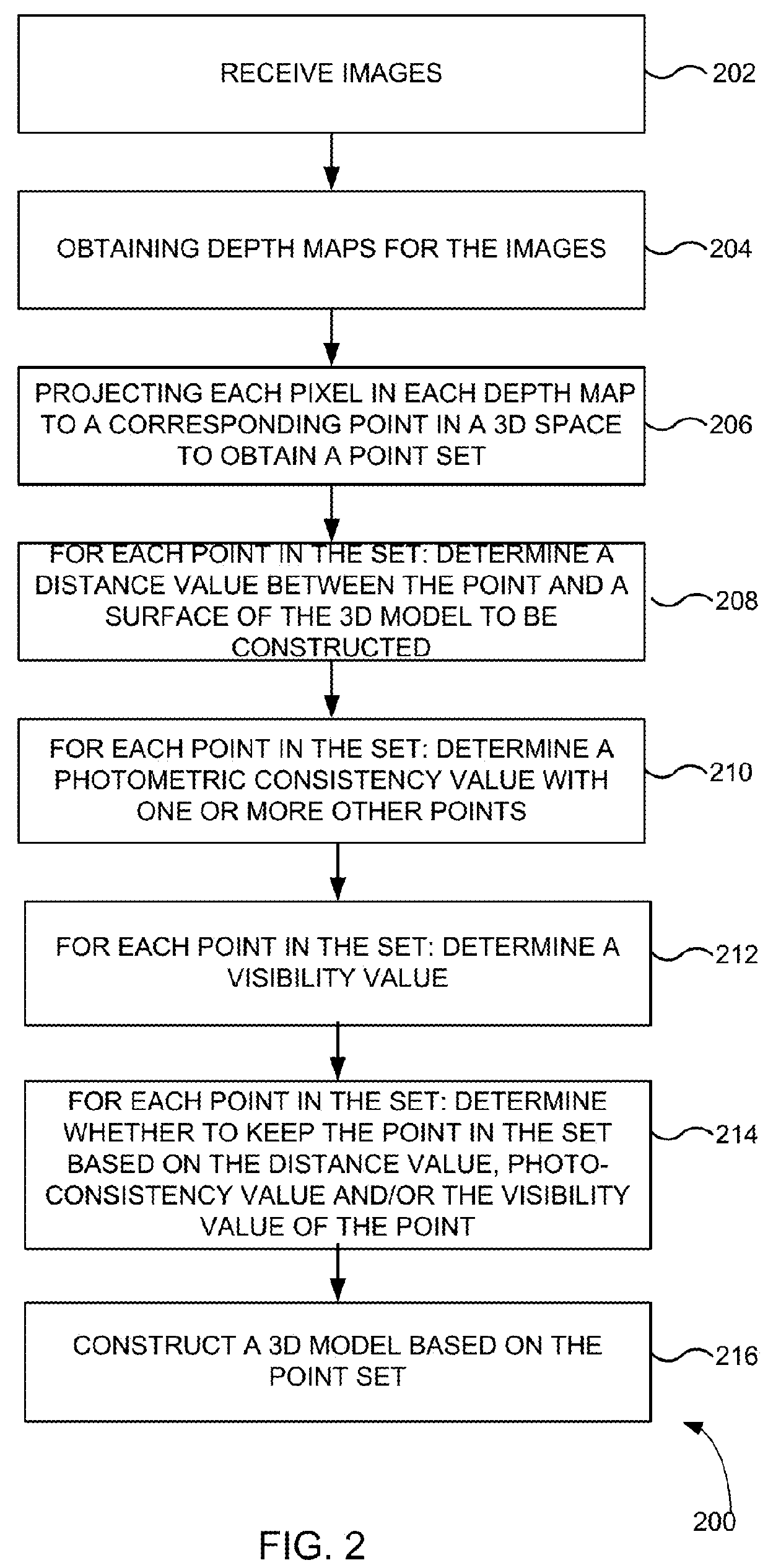

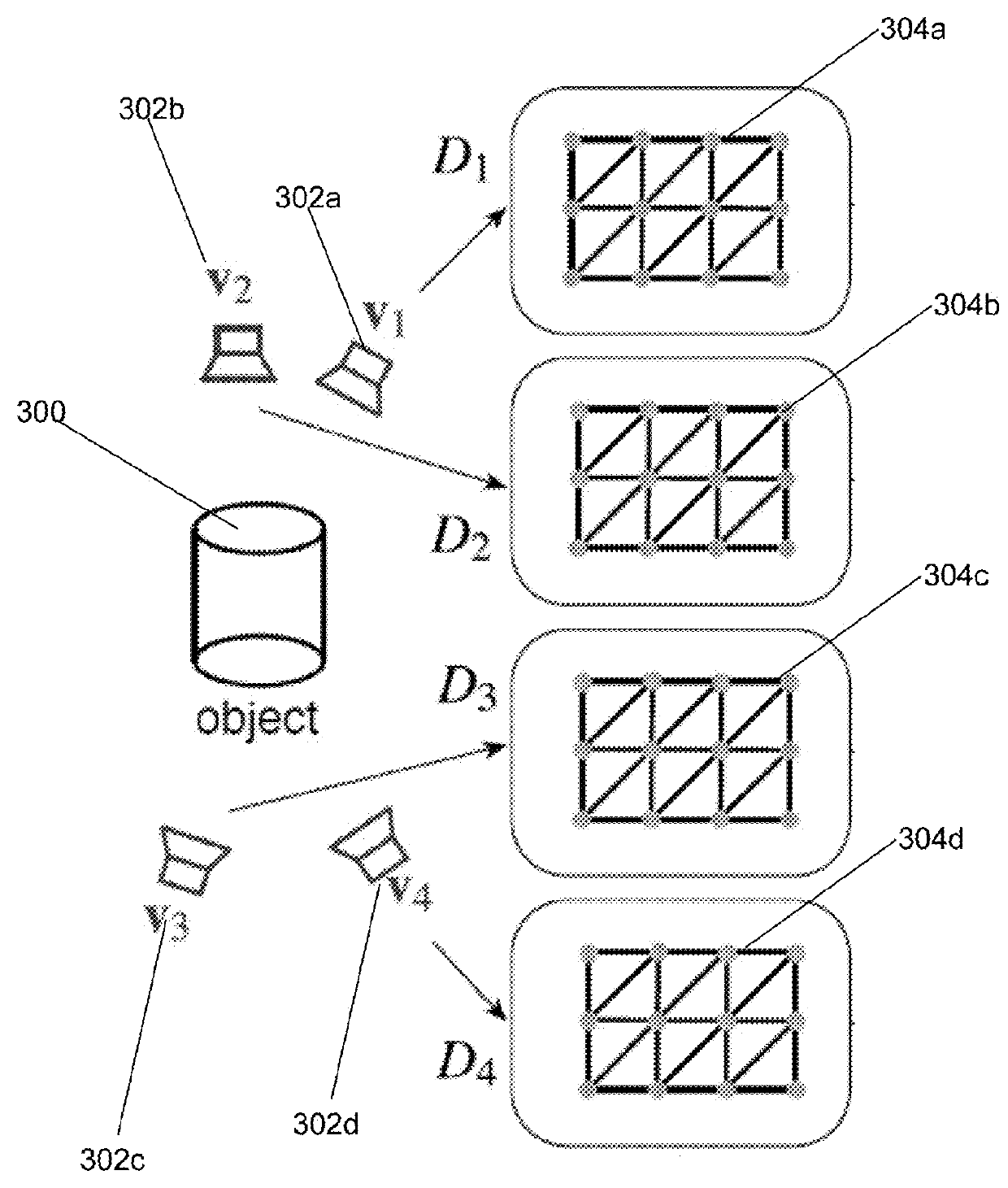

Point cloud noise and outlier removal for image-based 3D reconstruction

ActiveUS20180096463A1Good removal effectLess smoothingImage enhancementImage analysisPoint cloudNoise removal

Enhanced removing of noise and outliers from one or more point sets generated by image-based 3D reconstruction techniques is provided. In accordance with the disclosure, input images and corresponding depth maps can be used to remove pixels that are geometrically and / or photometrically inconsistent with the colored surface implied by the input images. This allows standard surface reconstruction methods (such as Poisson surface reconstruction) to perform less smoothing and thus achieve higher quality surfaces with more features. In some implementations, the enhanced point-cloud noise removal in accordance with the disclosure can include computing per-view depth maps, and detecting and removing noisy points and outliers from each per-view point cloud by checking if points are consistent with the surface implied by the other input views.

Owner:ETH ZURICH EIDGENOSSISCHE TECHN HOCHSCHULE ZURICH +1

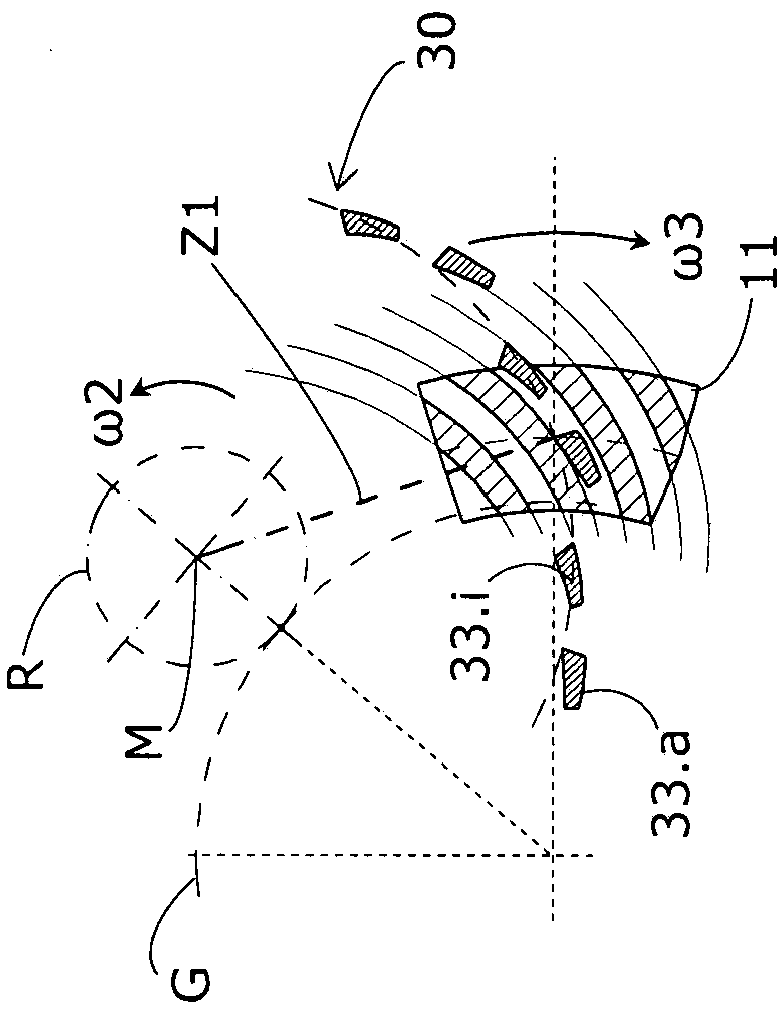

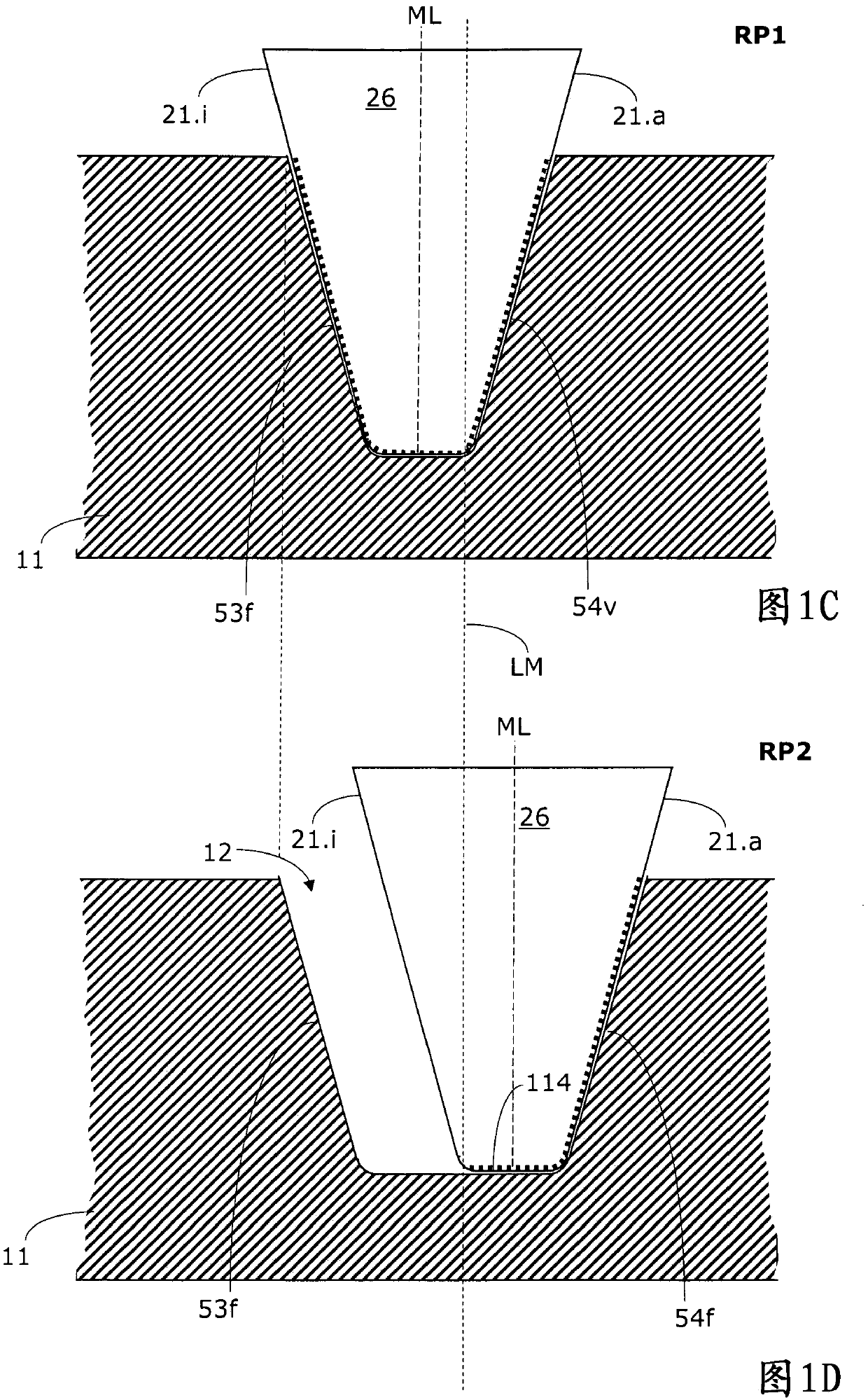

Reflective optical element for use in an EUV system

ActiveUS20110051267A1Increase reflectionHigh-quality surfaceMirrorsPhotomechanical apparatusCatoptricsEngineering

A reflective optical element (10) for use in an EUV system is disclosed. The reflective optical element includes a base body, which is produced at least partly from a substrate material. At least one cooling channel through which a cooling medium can flow is arranged in the base body. A material having a thermal conductivity of greater than 50 W / mK is provided as substrate material. The reflective optical element also includes a polishing layer, which is applied on the substrate material. The polishing layer includes an amorphous material which can be processed via polishing.

Owner:CARL ZEISS SMT GMBH

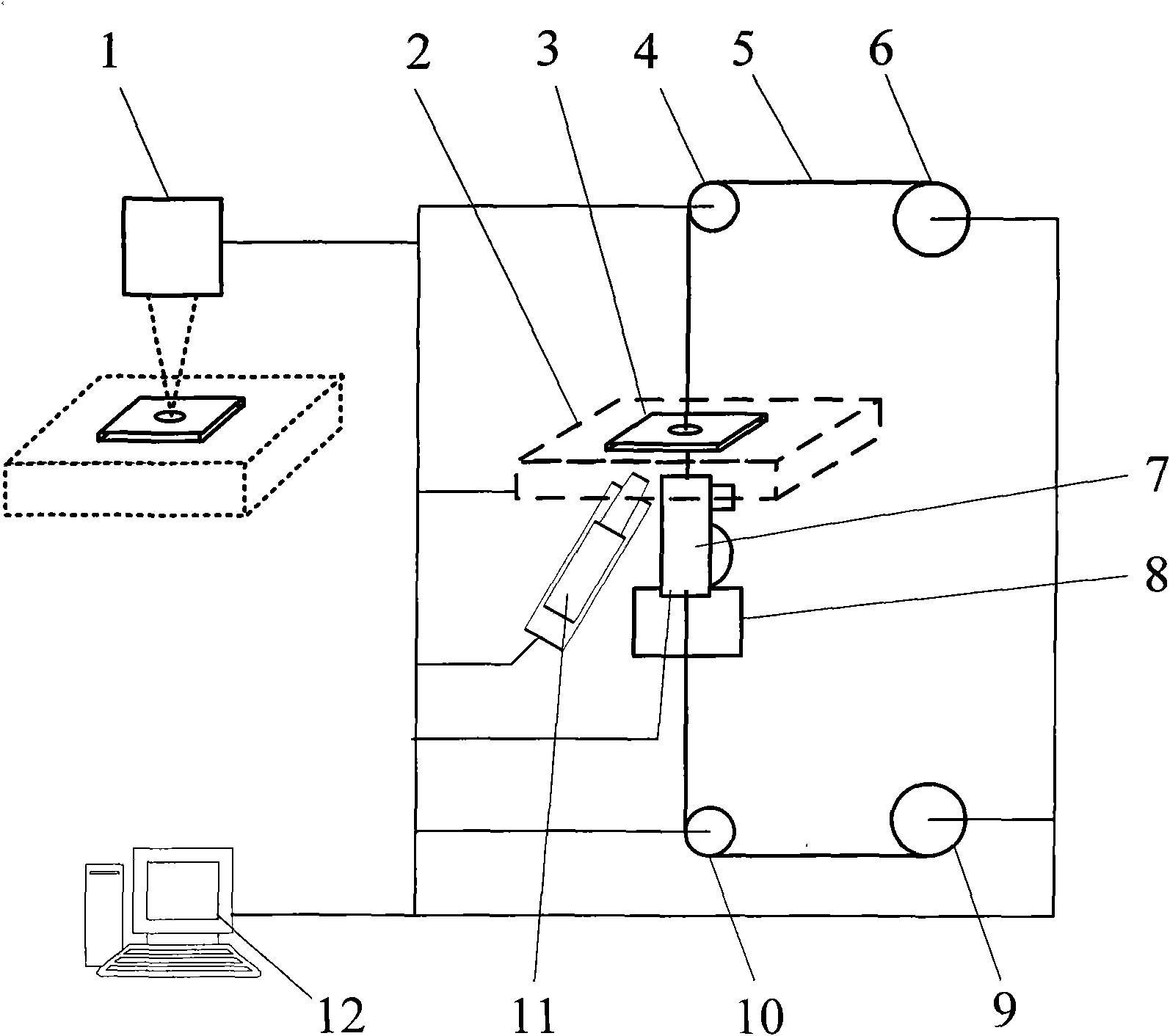

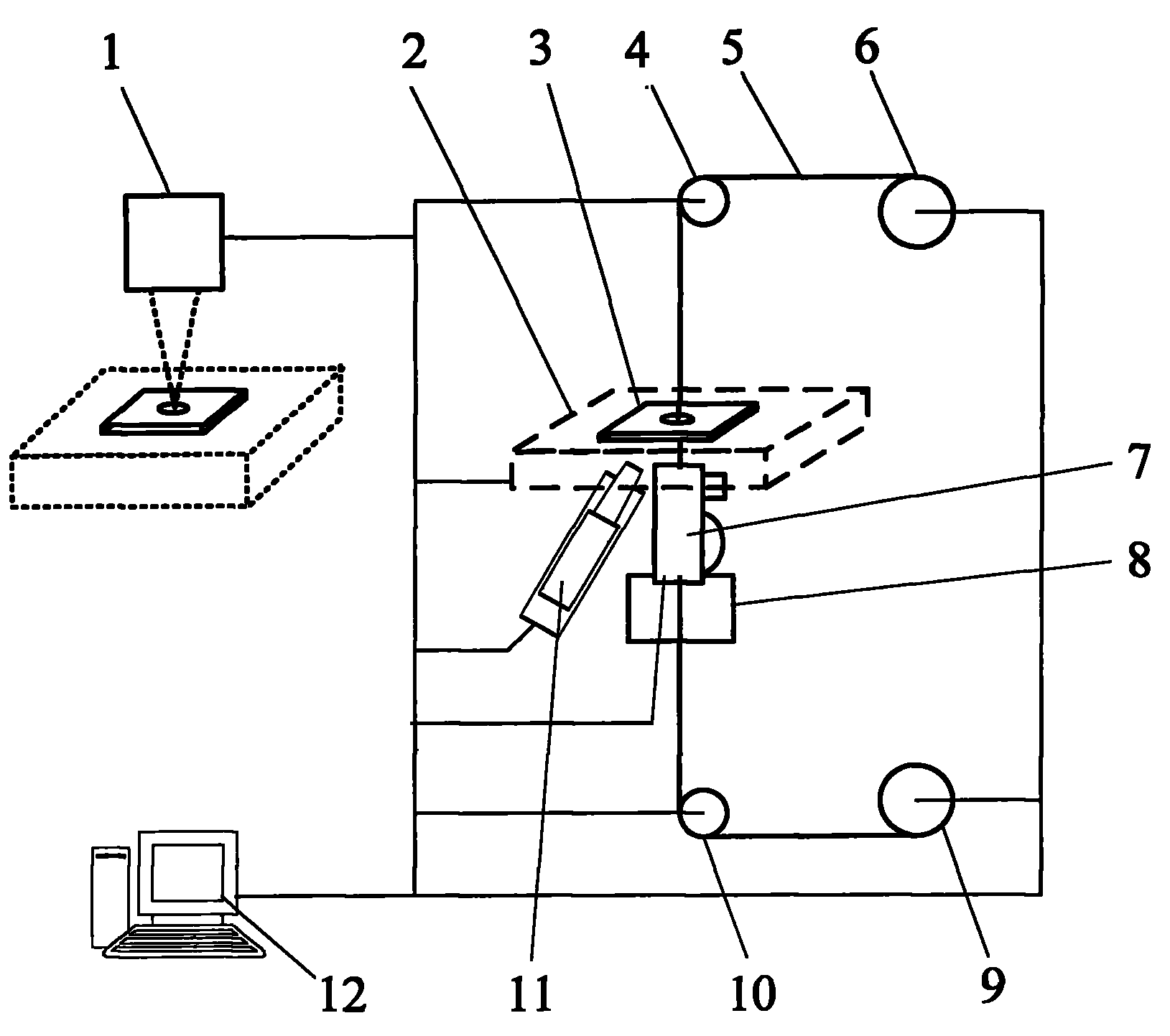

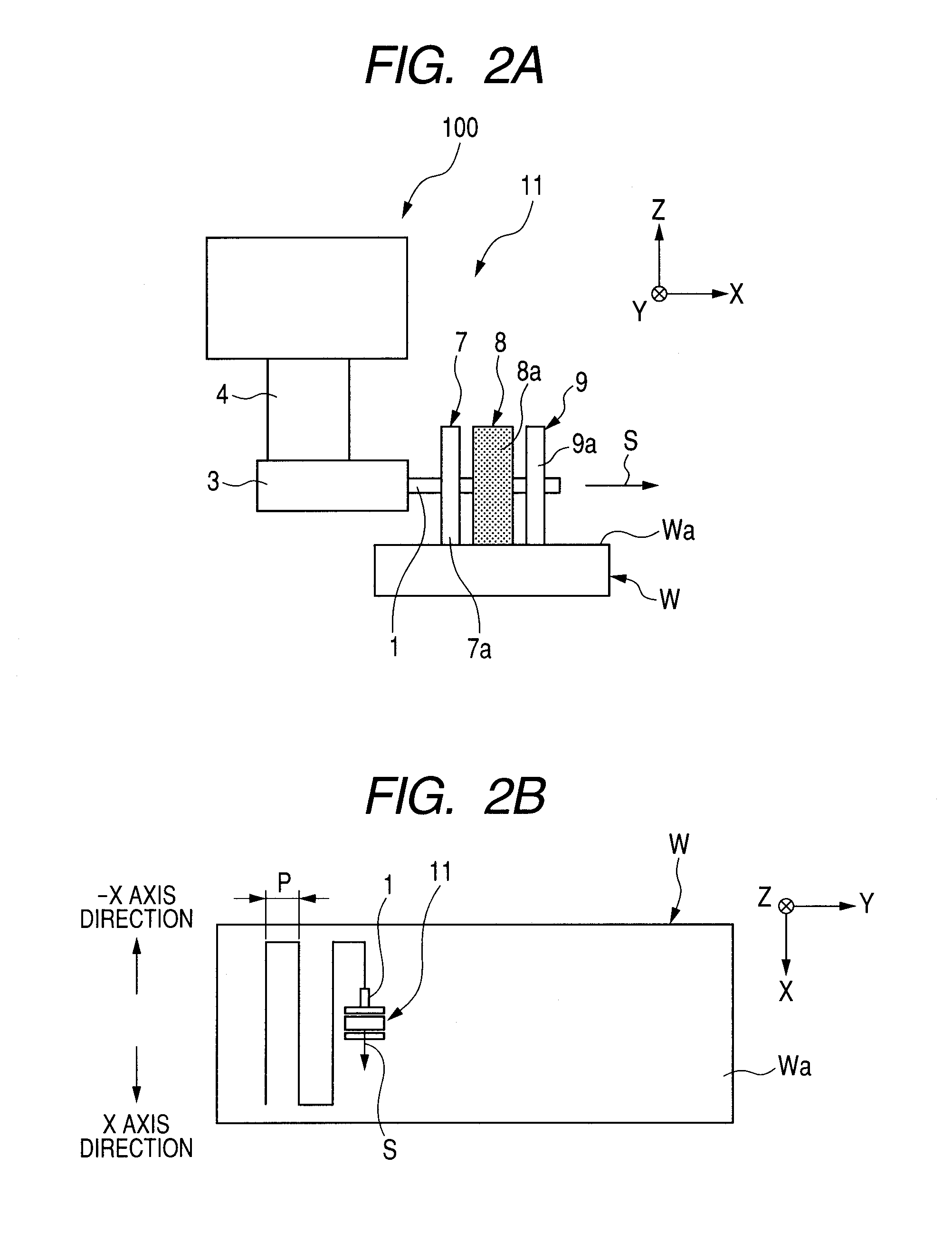

Method and device for machining high-quality tiny through hole of hard and crisp material

InactiveCN102172883ARealization means and devices are simple and easyHigh quality surface and processingLapping machinesRoughcastMicroscope

The invention discloses a compound machining method which processes by aiming at the hard and crisp material micrometer-scale (less than 100 micrometers) apertures and causes the hard and crisp material to have high-quality aperture walls and edges. A blank hole is processed on an appointed position on a hard and crisp material to be processed by a specific laser beam; then, a special grinding wire penetrates into the blank hole to be ground; the grinding wire is controlled by an industrial personal computer to carry out longitudinal reciprocating motion, and the workbench of a clamping workpiece moves to realize machining operation; and during machining, the effect of a micropore is detected by an observation microscope until the obtained high-quality aperture walls and the edges can be obtained. The invention also provides a device for machining the high-quality tiny through hole of the hard and crisp material.

Owner:HARBIN INST OF TECH

Polishing particle and method for producing polishing particle

InactiveUS20020129559A1High removal rateQuality improvementPigmenting treatmentOther chemical processesSurface roughnessSlurry

By providing an abrasive having a ratio of volume-cumulative (95%) average particle size (D95) to volume-cumulative (50%) average particle size (D50) (D95 / D50) falling within a range of 1.2 to 3.0 or an abrasive having a volume-cumulative (95%) average particle size (D95) falling within a range of 0.1-1.5 .mu.m and containing coarse particles having a size more than 10 times the volume-cumulative (50%) average particle size (D50) in an amount, based on the total mass of all the particles, of 1 mass % or less, there can be provided an abrasive, an abrasive slurry, a method for producing an abrasive, and a polishing method which attain, during accurate polishing of substrates such as electronics substrates, a high removal rate and a high-quality surface; i.e., a surface having a high flatness, low surface roughness, and substantially no microscratches or micropits.

Owner:SHOWA DENKO KK

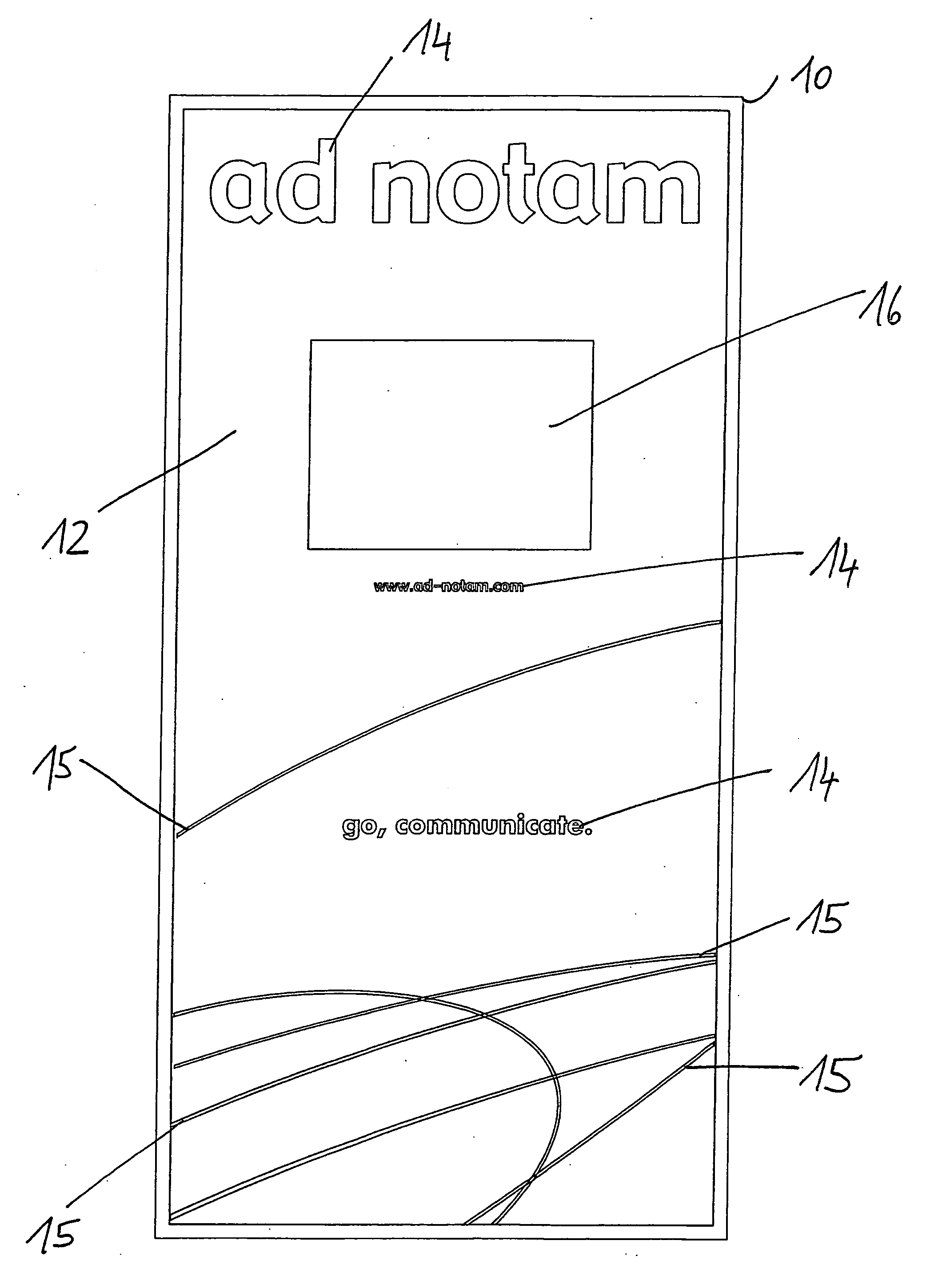

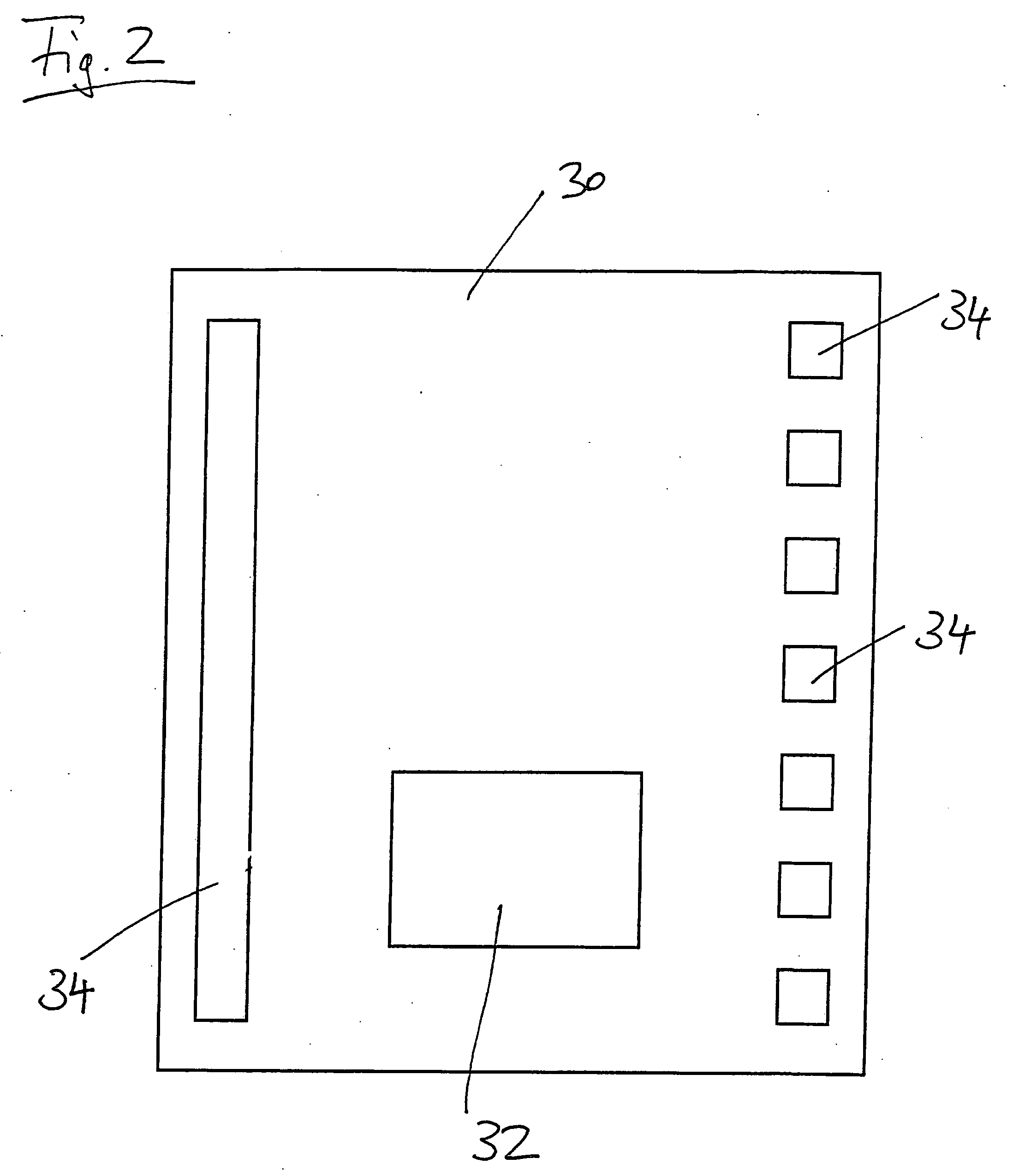

Wall element

InactiveUS20050257435A1Easy to cleanHigh-quality surfaceBuilding constructionsIlluminated signsSpecular reflectionWall plate

A wall panel has a glass outer face which in turn is provided with a decorative design, for example by painting, mirroring, partial mirroring, coating, printing or else placing an inlay or the like behind it. In addition, this wall panel is designed to cooperate with a flat screen in such a way that the decorative design forms a cut-out adapted to the flat screen, through which cut-out the image display can then be viewed on the user side.

Owner:MIRROR IMAGE INC

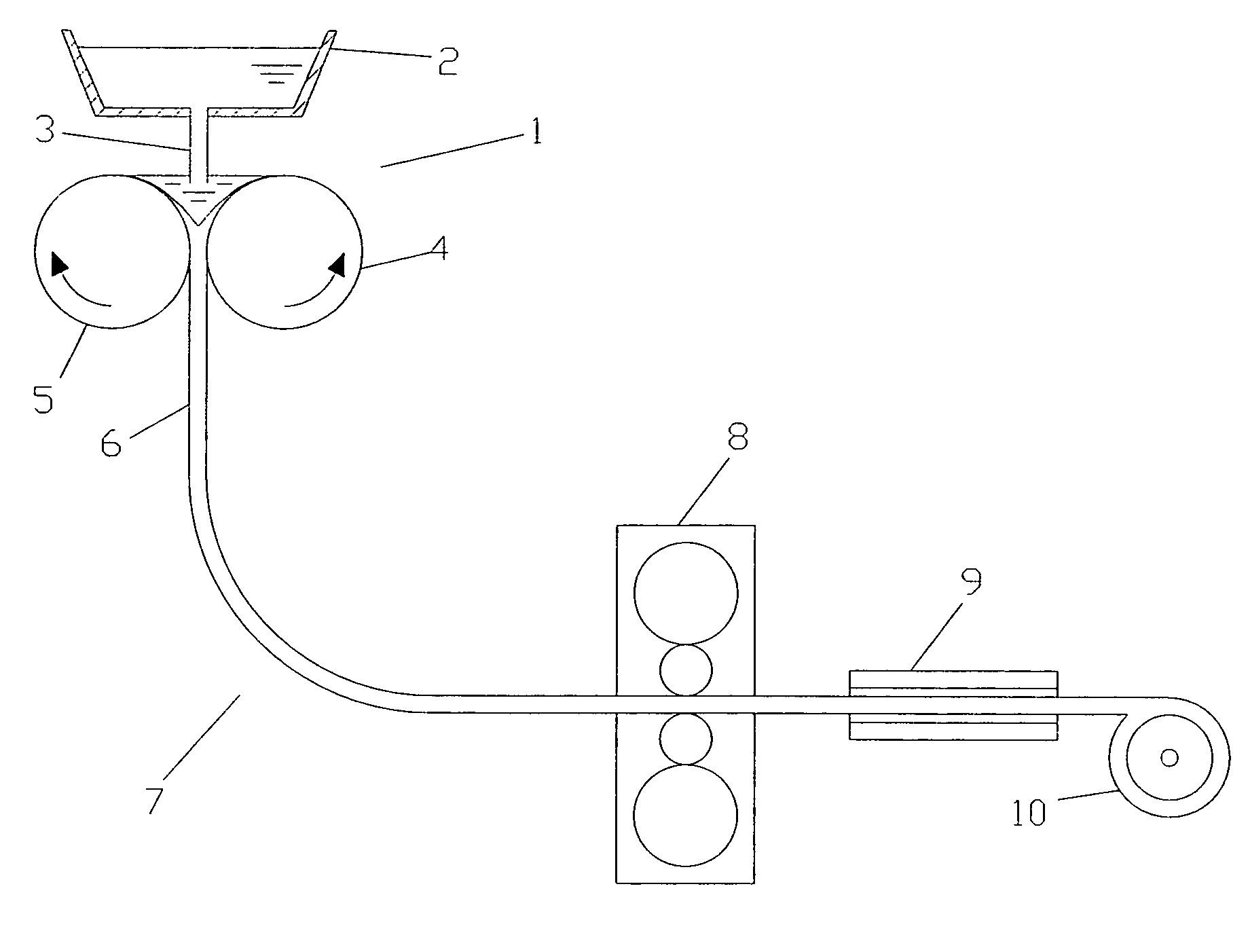

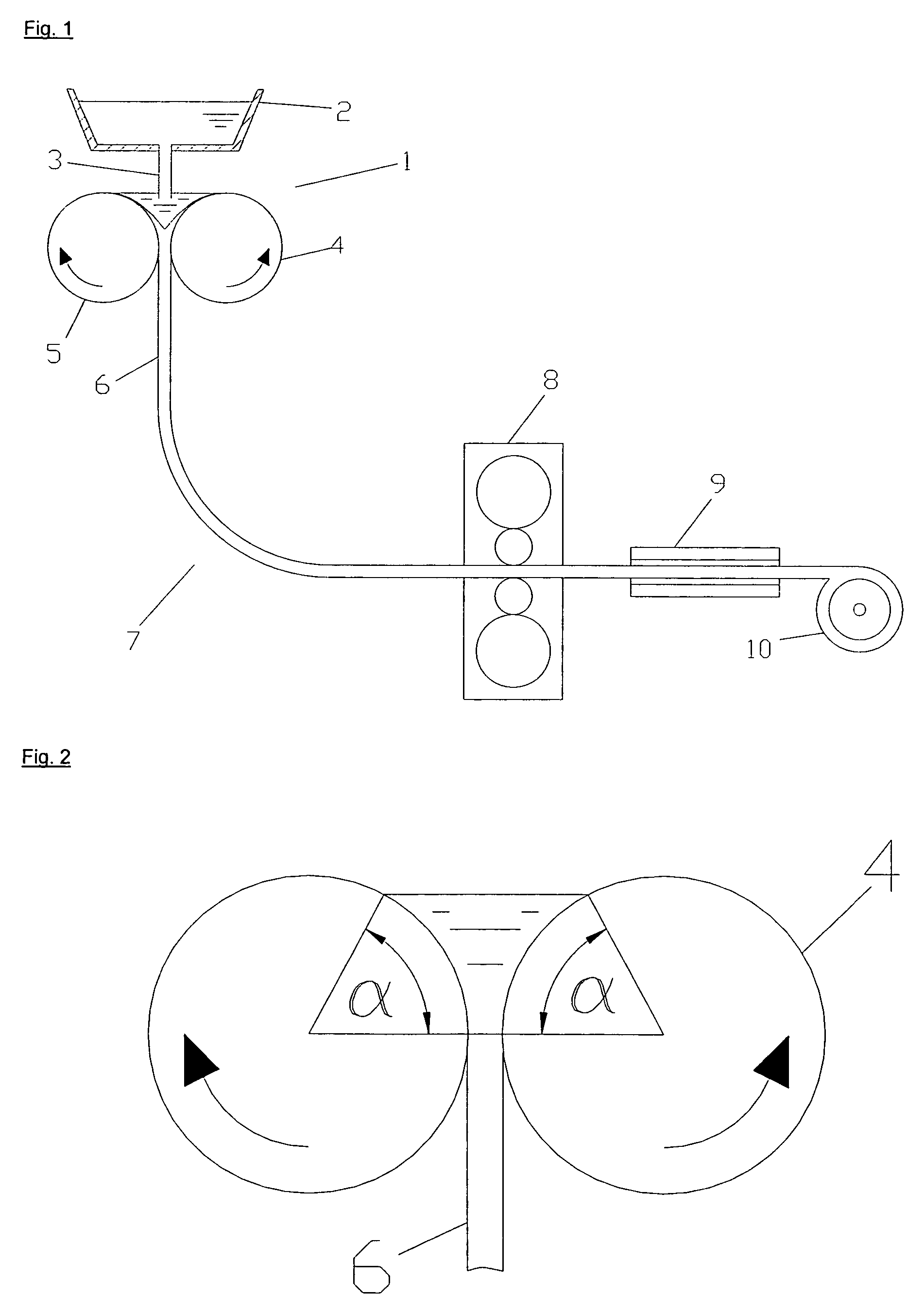

Installation for continuously producing a thin steel strip

A process for the continuous production of a thin steel strip, in which a steel melt from a melt reservoir is introduced onto one or more, in particular two, cooled shaping wall surfaces which move synchronously with a casting strip, in particular rotate in the form of casting rolls and at least partially solidifies at the shaping wall surface to form the casting strip. The steel melt, in terms of the crucial alloying constituents, contains less than 1% by weight of Ni and less than 1% by weight of Cr and less than 0.8% by weight, in particular less than 0.4% by weight, of C and at least 0.55% by weight of Mn. In the process, recesses are arranged on the shaping wall surface in a random pattern, distributed uniformly over the shaping wall surface, and the roll separating force (RSF) at the shaping wall surface is set to a value of between 5 and 150 N / mm, in particular between 5 and 100 N / mm.

Owner:VOEST ALPINE AG

Polishing particle and method for producing polishing particle

InactiveUS7037352B2High removal rateImprove flatnessPigmenting treatmentOther chemical processesSurface roughnessSlurry

By providing an abrasive having a ratio of volume-cumulative (95%) average particle size (D95) to volume-cumulative (50%) average particle size (D50) (D95 / D50) falling within a range of 1.2 to 3.0 or an abrasive having a volume-cumulative (95%) average particle size (D95) falling within a range of 0.1-1.5 μm and containing coarse particles having a size more than 10 times the volume-cumulative (50%) average particle size (D50) in an amount, based on the total mass of all the particles, of 1 mass % or less, there can be provided an abrasive, an abrasive slurry, a method for producing an abrasive, and a polishing method which attain, during accurate polishing of substrates such as electronics substrates, a high removal rate and a high-quality surface; i.e., a surface having a high flatness, low surface roughness, and substantially no microscratches or micropits.

Owner:RESONAC HOLDINGS CORPORATION

Sapphire processing method

InactiveCN106057647AGood removal effectHigh quality surfaceSemiconductor/solid-state device manufacturingProcessing costLubricant

The invention discloses a sapphire processing method, for the purpose of providing a processing method which can reduce the processing cost of sapphire and improve the processing efficiency while ensuring and improving the processing quality of a sapphire substrate. The method successively comprises the following steps: A, crystal rod cutting; B, grinding processing; C, cleaning, D, annealing processing; E, cleaning, and F, chemical mechanical polishing processing. A grinding lubricant for the chemical mechanical polishing processing is an aluminum oxide polishing solution.

Owner:ZHEJIANG CRYSTAL OPTECH

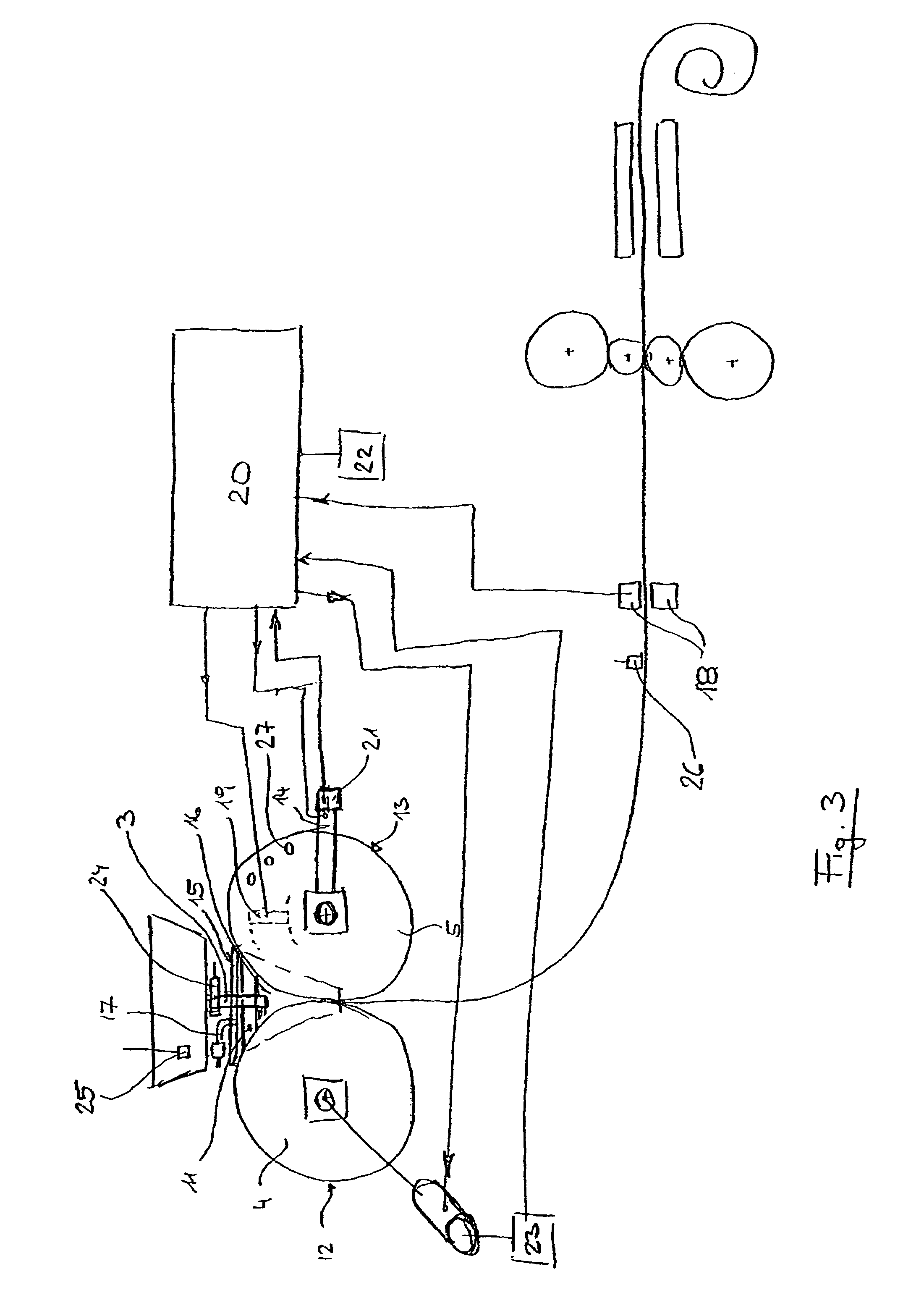

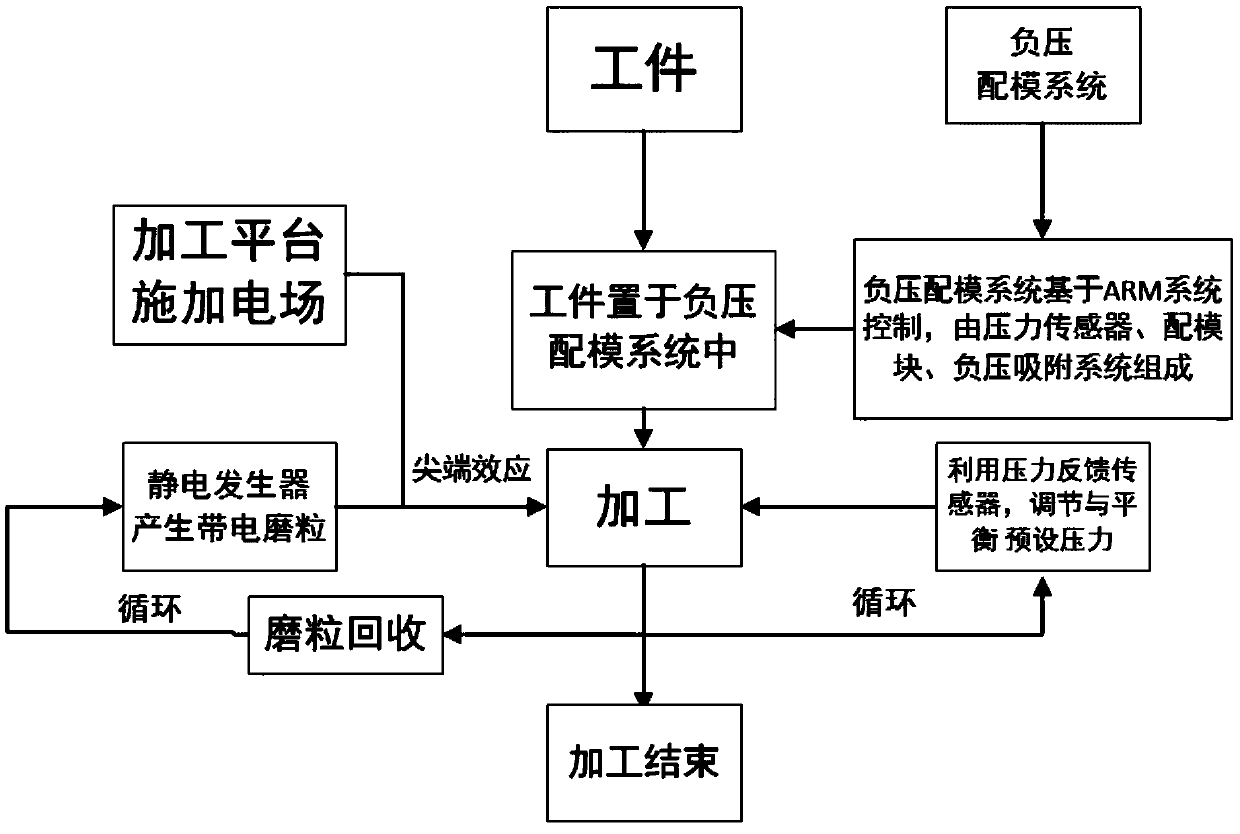

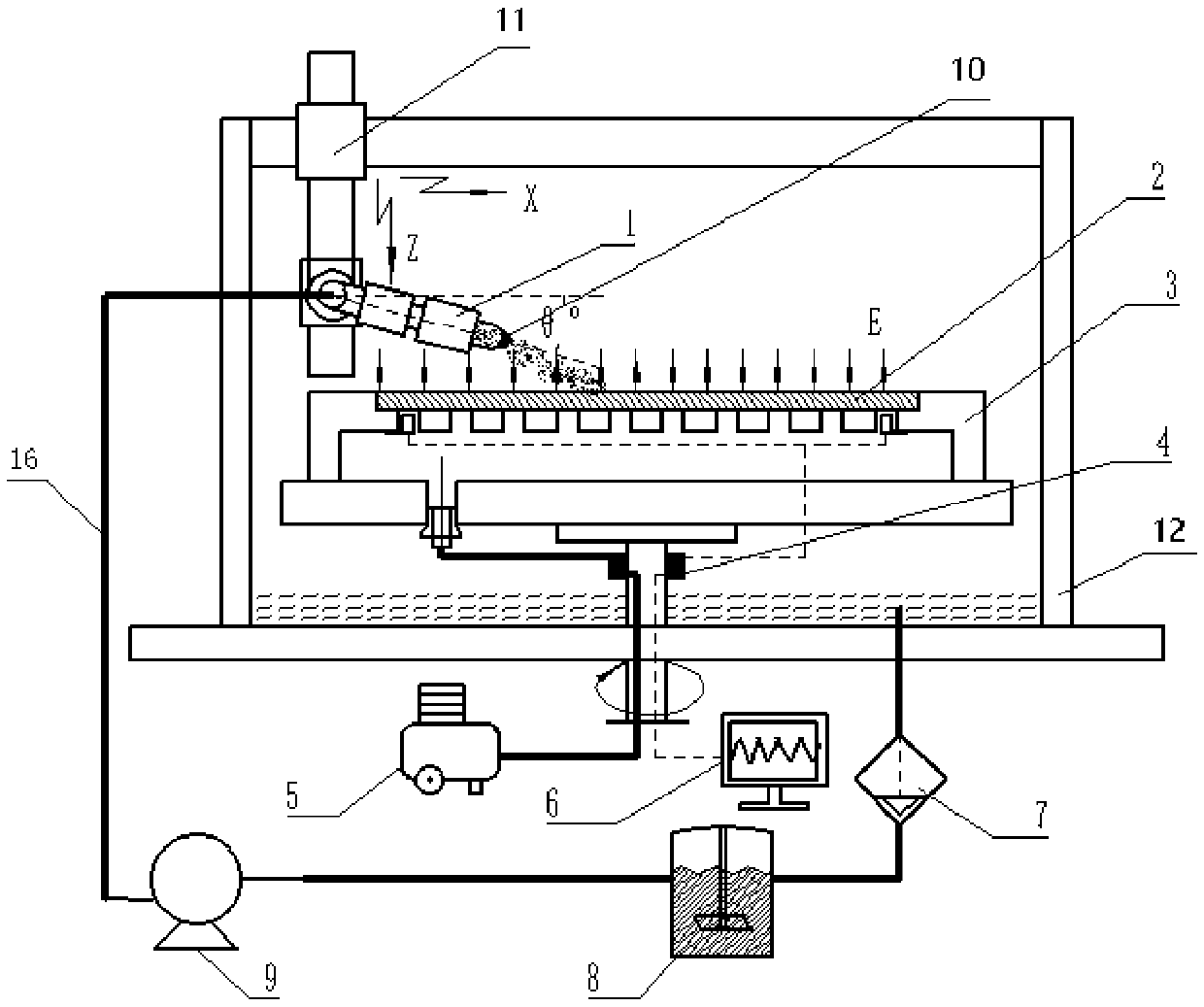

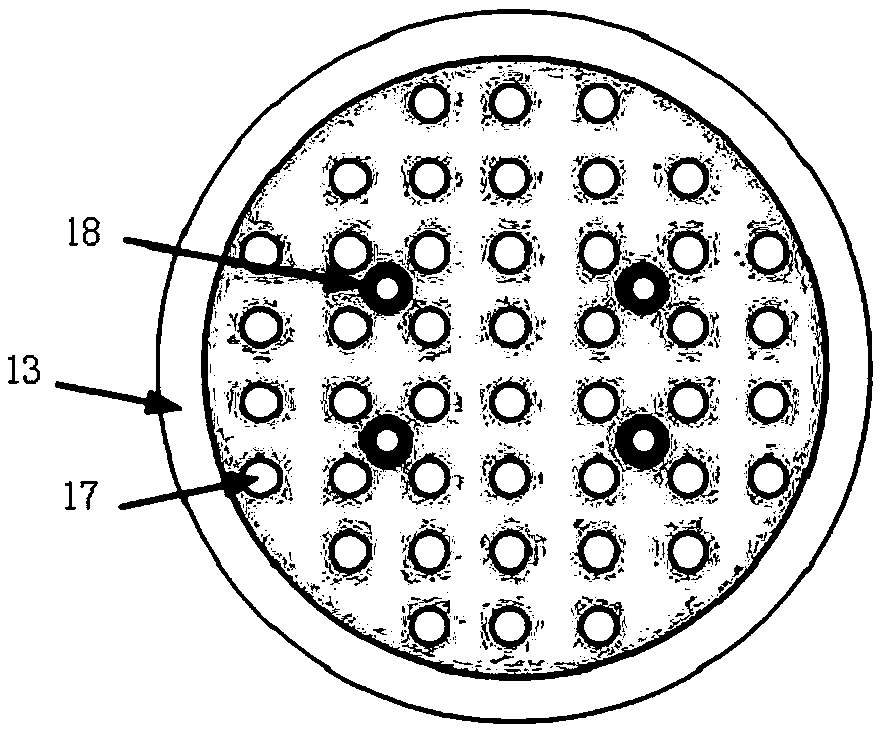

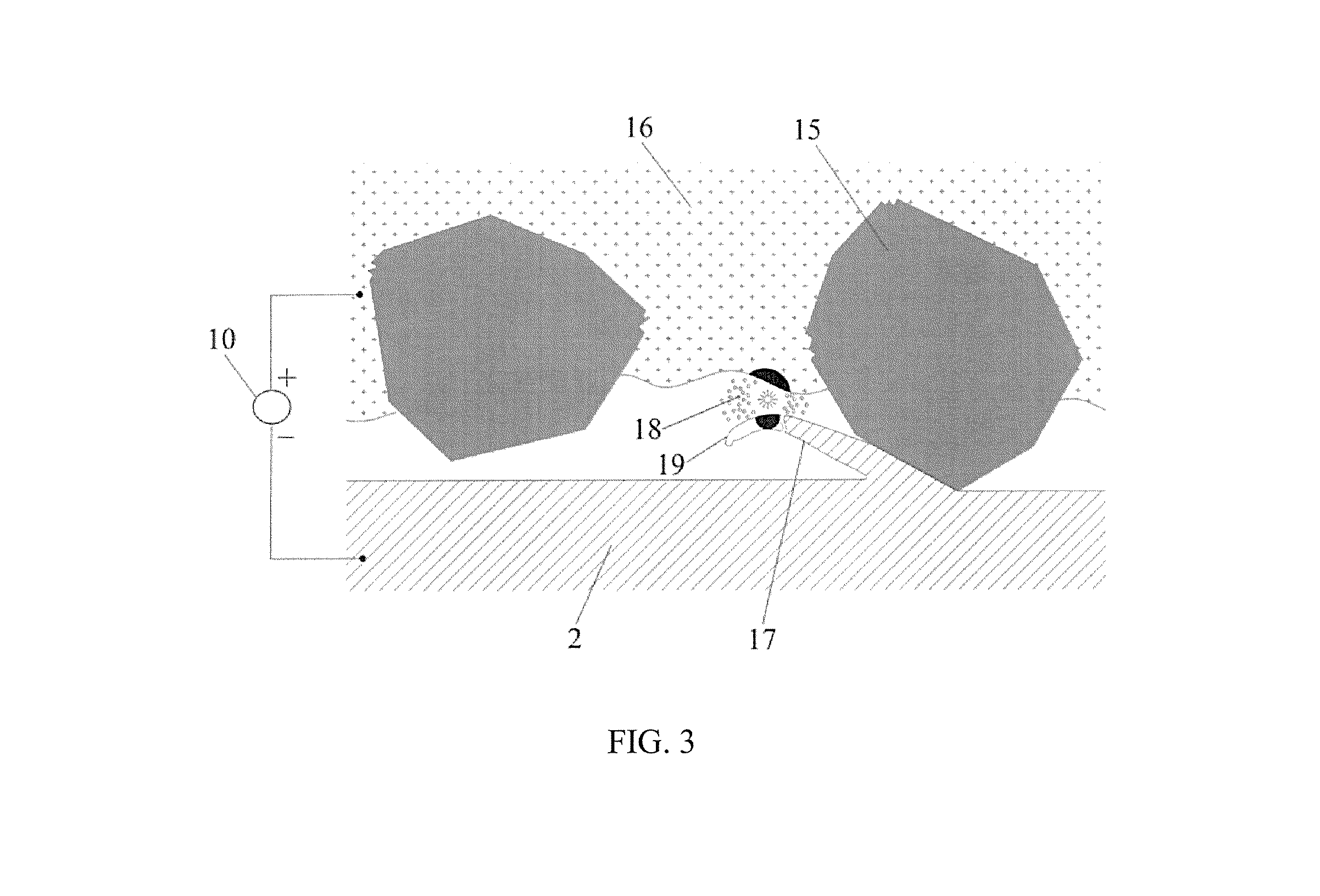

Static electricity controllable abrasive particle flow processing method based on charge tip aggregation effect

ActiveCN109551374AControllable distributionReduce particle size unevennessAbrasive machine appurtenancesMicroscopic scaleHigh pressure

The invention discloses a static electricity controllable abrasive particle flow processing method based on a charge tip aggregation effect. An abrasive particle flow with non-electrolyte as a carrieris subjected to a high-voltage electrostatic field to be charged, so that the distribution of the abrasive particles in the flow field can be controlled, and negative influences produced by abrasiveparticle size unevenness and large-particle-size abrasive particles in the processing process are reduced; an electric field is applied to the flow field, the distribution characteristics of the abrasive particles with the negative charge on the collision area on the surface of a workpiece with the positive charge are changed through the electric charge tip aggregation effect, the possibility of collision of the abrasive particles to the microscopic surface crest of the workpiece is increased, workpiece surface crest removal is accelerated, the flow-in angle of the abrasive particles is periodically swung in a pulse mode, the optimal polishing alternating force acting on the workpiece is obtained by effectively adjusting and controlling the pulse frequency and the swing angle, and it is ensured that the high-quality surface is obtained on the premise of efficient removal.

Owner:ZHEJIANG UNIV OF TECH

Metallization of polymer composite parts for painting

InactiveUS6872294B2Uniform appearingHigh quality surfaceElectrolysis componentsVolume/mass flow measurementMetal coatingElectrogalvanization

The quality of painted surfaces of polymer composites is improved by first forming an electroless metal coating on the molded surface of the composite and then electroplating a coating of zinc or zinc alloy on the metallized composite surface. The “galvanized” composite surface provides a good base for electrostatic deposition of either liquid or powder paint and the zinc surface prevents the formation of defects in the painted surface during heating of the composite to dry or cure the paint film.

Owner:GM GLOBAL TECH OPERATIONS LLC

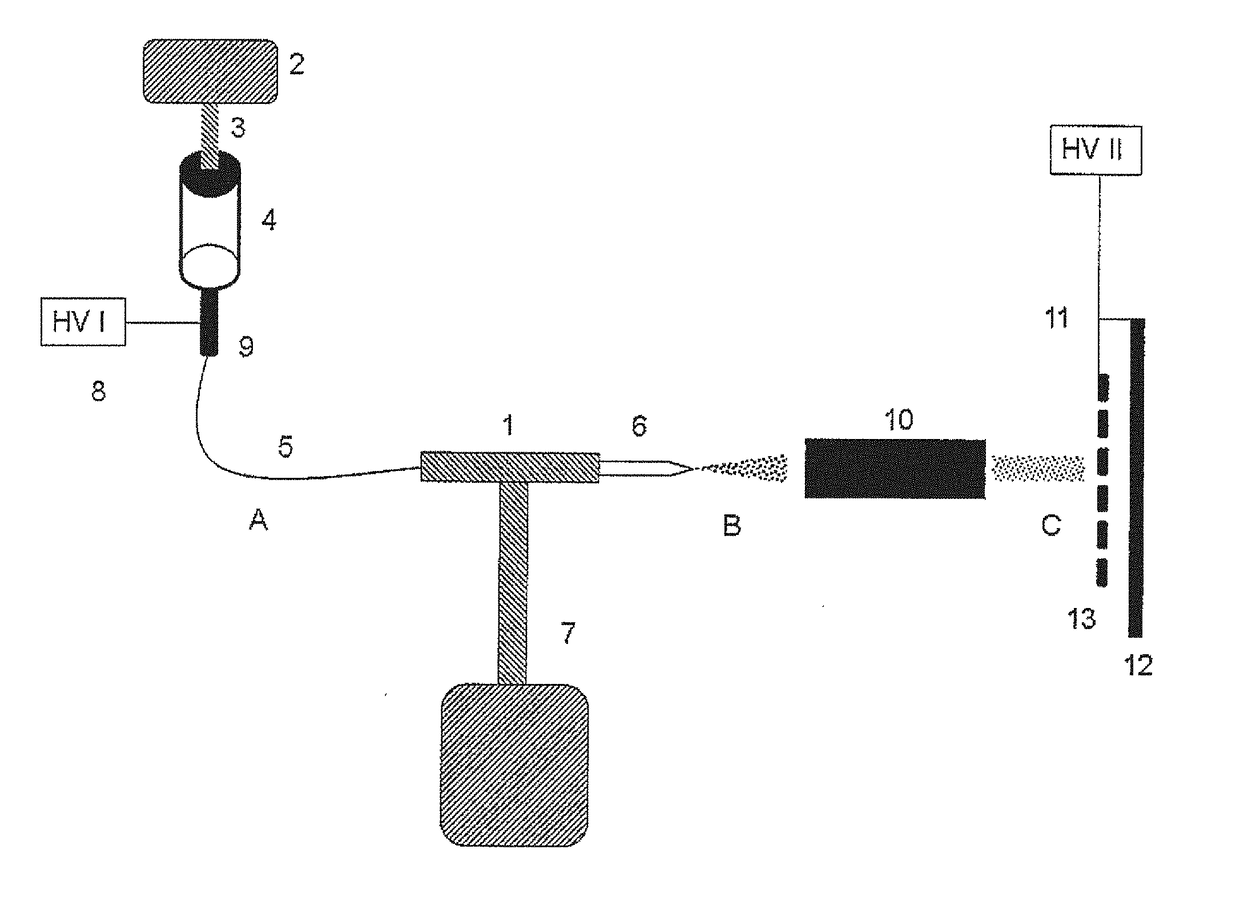

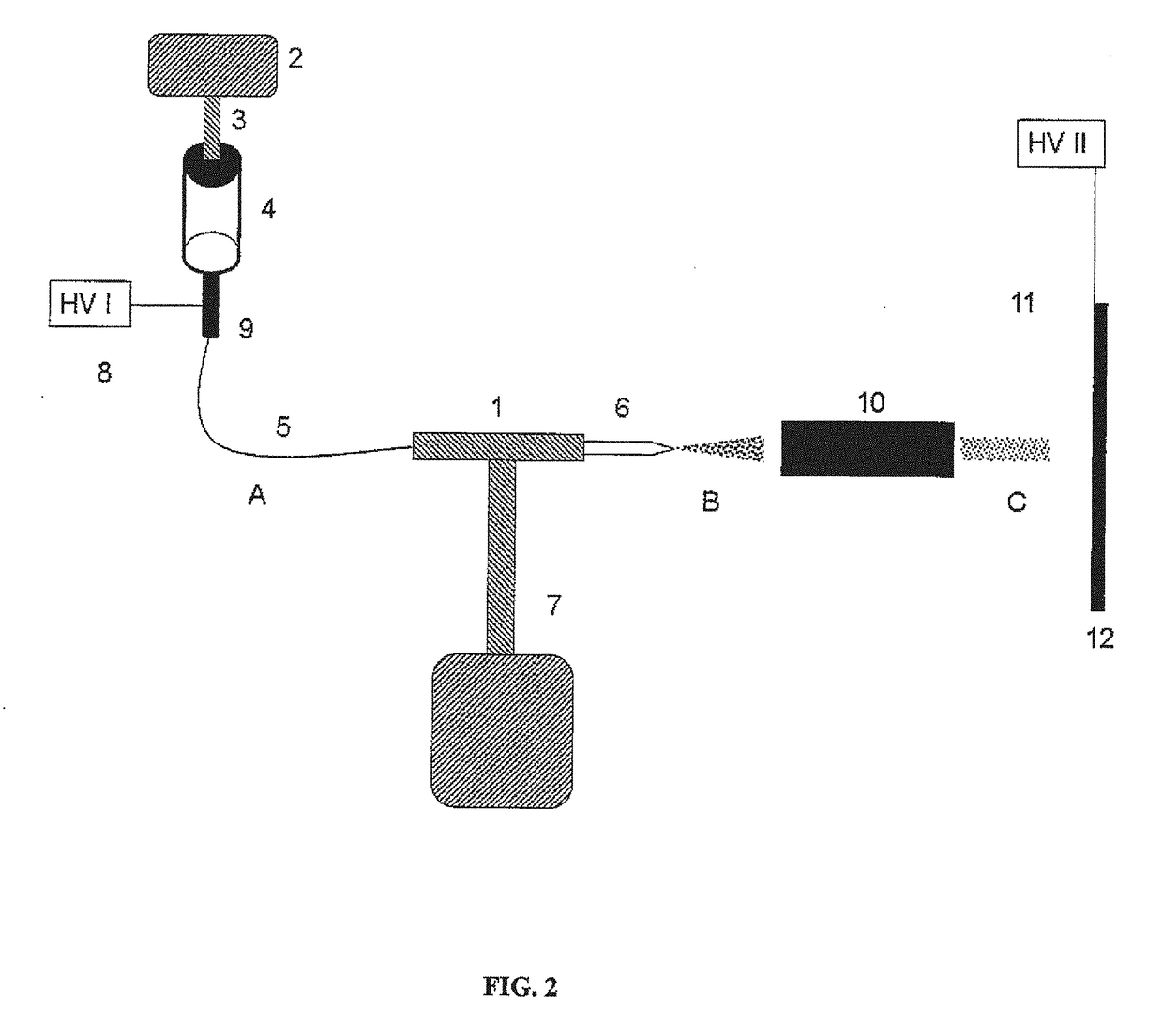

Method of Surface Modification by Proteins for Analyte Preconcentration for Desorption-Ionization Mass Spectrometry Techniques and for Immunochemical Assays

ActiveUS20170242030A1High-quality surfaceOvercome disadvantagesSamples introduction/extractionPreparing sample for investigationProtein solutionEvaporation

A method for modification of solid substrates with proteins for efficient surface preconcentration of an analyte from multi-component samples before the detection based on desorption-ionization mass spectrometry and immunochemical assays. The claimed subject is a method of modification of surfaces used as substrates for desorption-ionization mass spectrometry and immuno-chemical assays. The method is based on electronebulization (electrospraying) of protein solution, depending on the intended application either enzymes, lectins, or antibodies. The formed charged electrospray is dried in real time by its passing through an evaporation compartment and the resulting beam of desolvated ions impacts onto the surface and binds to it firmly. Such modified surface can be then used for a selective interaction with an affinity partner of the deposited protein, its preconcentration or enzymatic modification followed by an analysis by means of desorption-ionization mass spectrometry or immunochemical assays.

Owner:NOVAK +3

Container, in Paticular a Self-Supporting Container, and a Method for Producing the Same

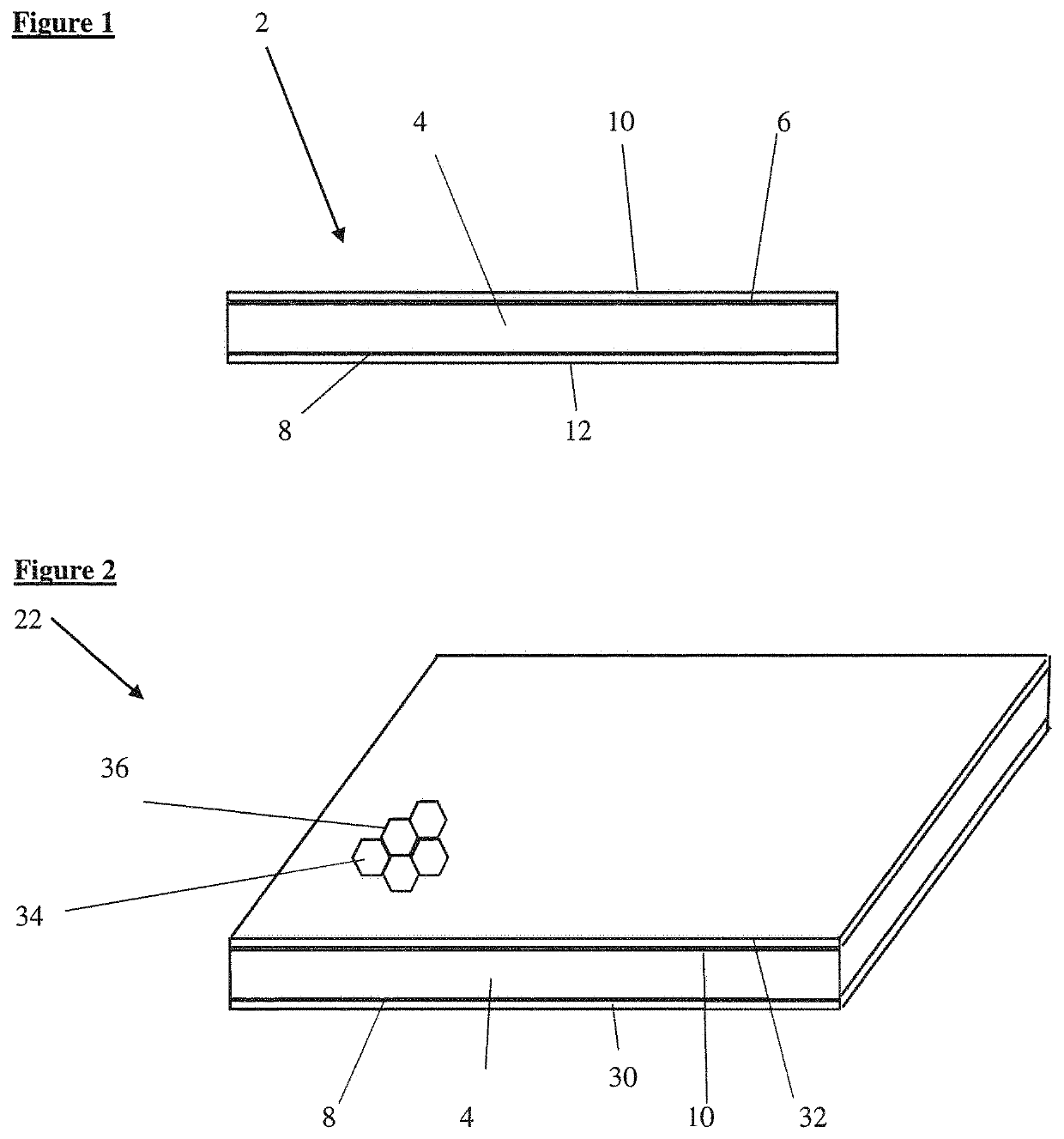

InactiveUS20140106100A1Improve material performanceQuality improvementLayered productsPedestrian/occupant safety arrangementFiberEngineering

The present general inventive concept relates to a container, preferably a tank, in particular for liquids, wherein the container comprises at least one fiber-reinforced plastic component, wherein the fiber-reinforced plastic component comprises a combination mat, in particular a sandwich mat having a nonwoven structure and reinforcement materials that are connected to the nonwoven structure, in particular fiber materials.

Owner:WEIRATHER GEORG

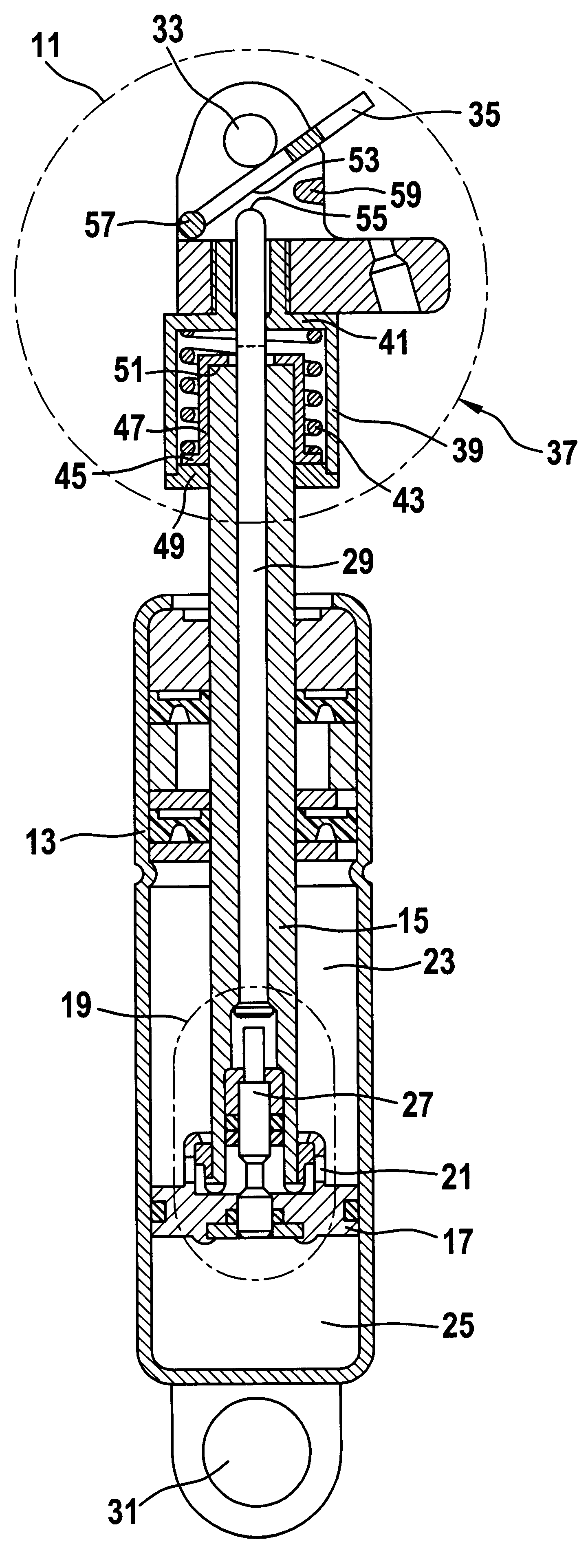

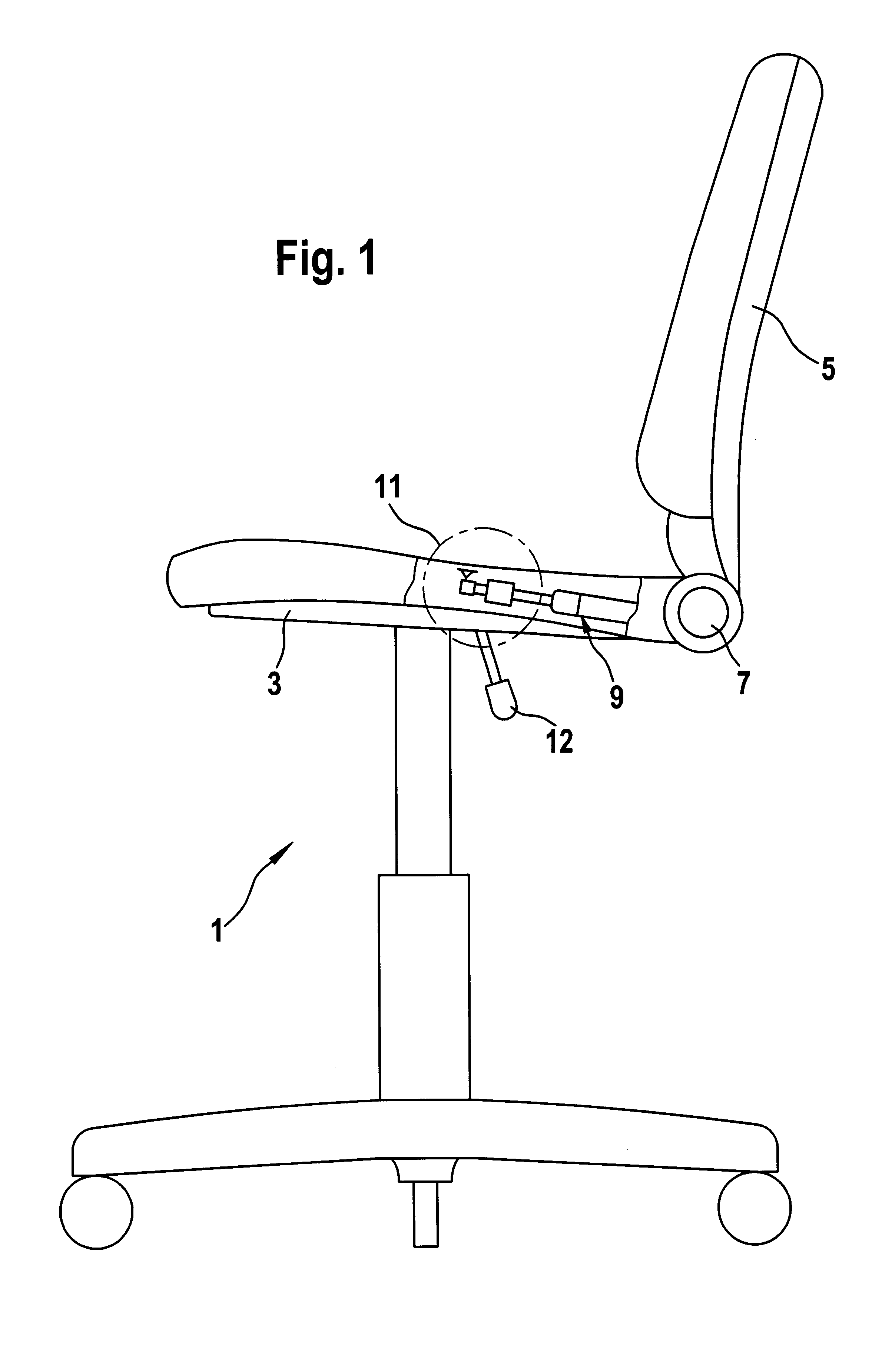

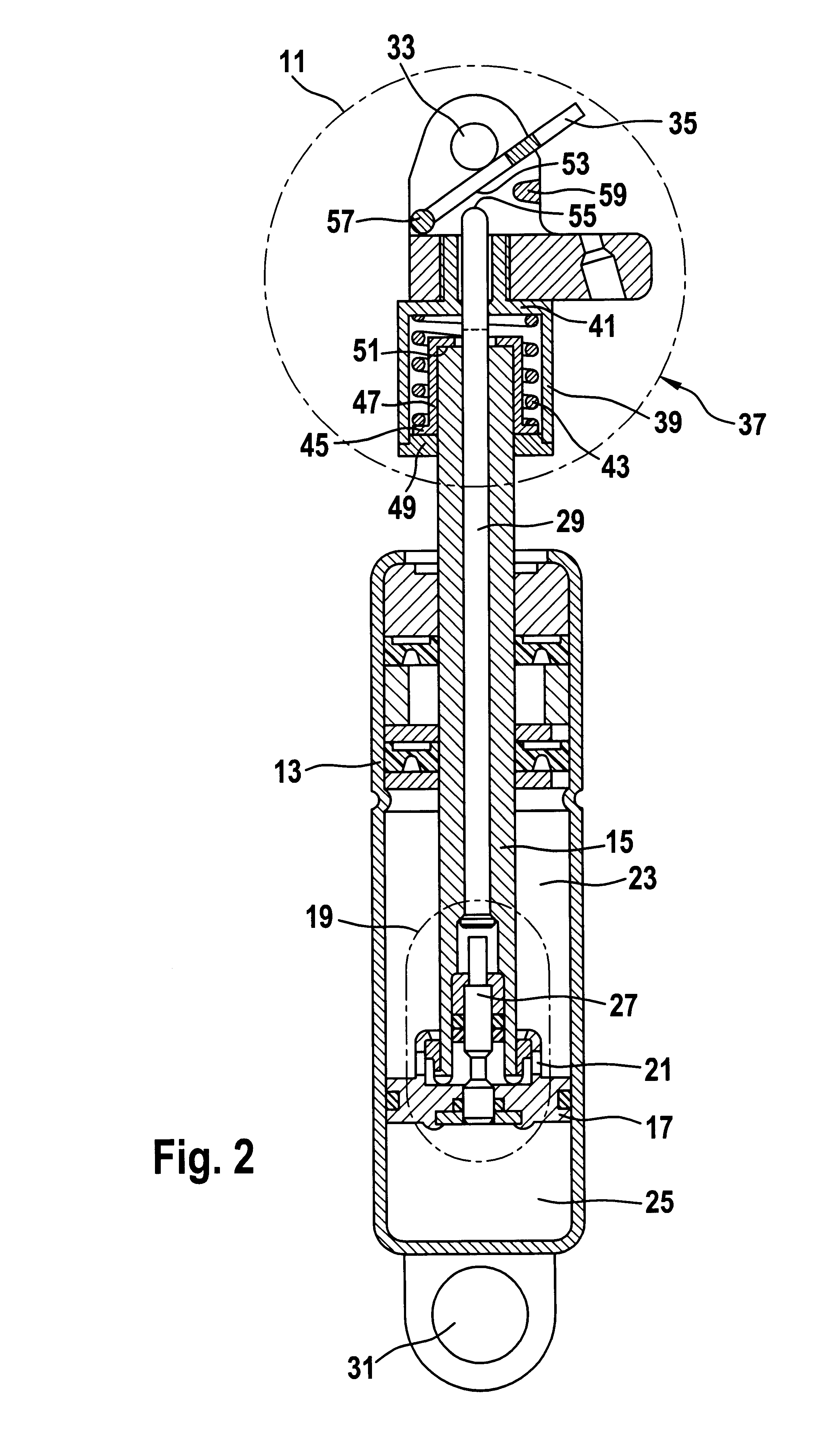

Activation device for a piston/cylinder unit

InactiveUS6705201B2High-quality surfaceImprove guidanceSpringsServomotor componentsGas springBiological activation

A piston / cylinder unit, in particular a gas spring, includes a valve device for the operational motion of a piston rod. The valve device is activatable by an activation device, the activation device being connected near an actuation device and being connected to a load contact device, which influences the function of the valve device. The load contact device connects the actuation device to the valve device for the purpose of changing the adjustability of the valve device when the gas spring is loaded.

Owner:STABILUS

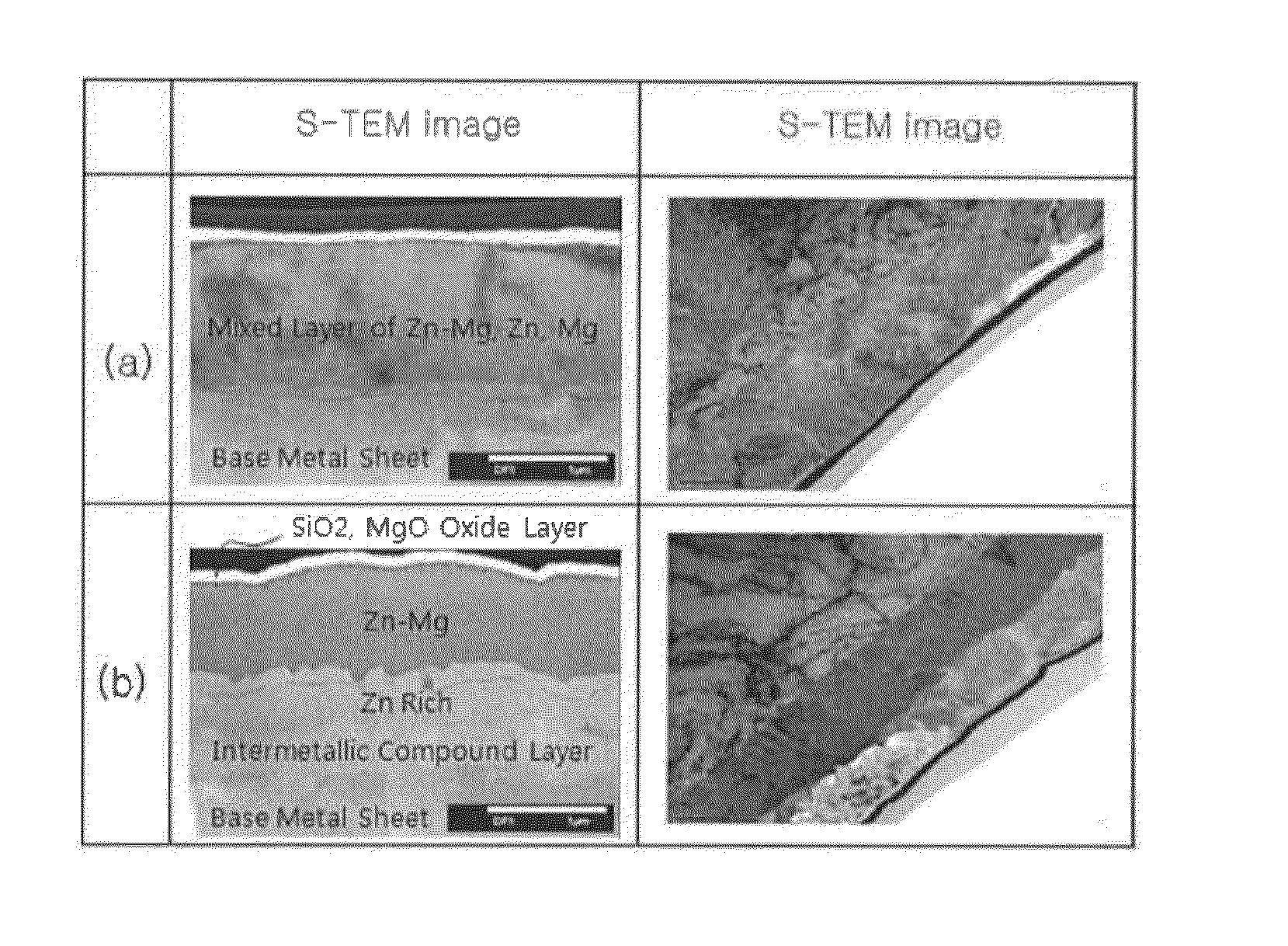

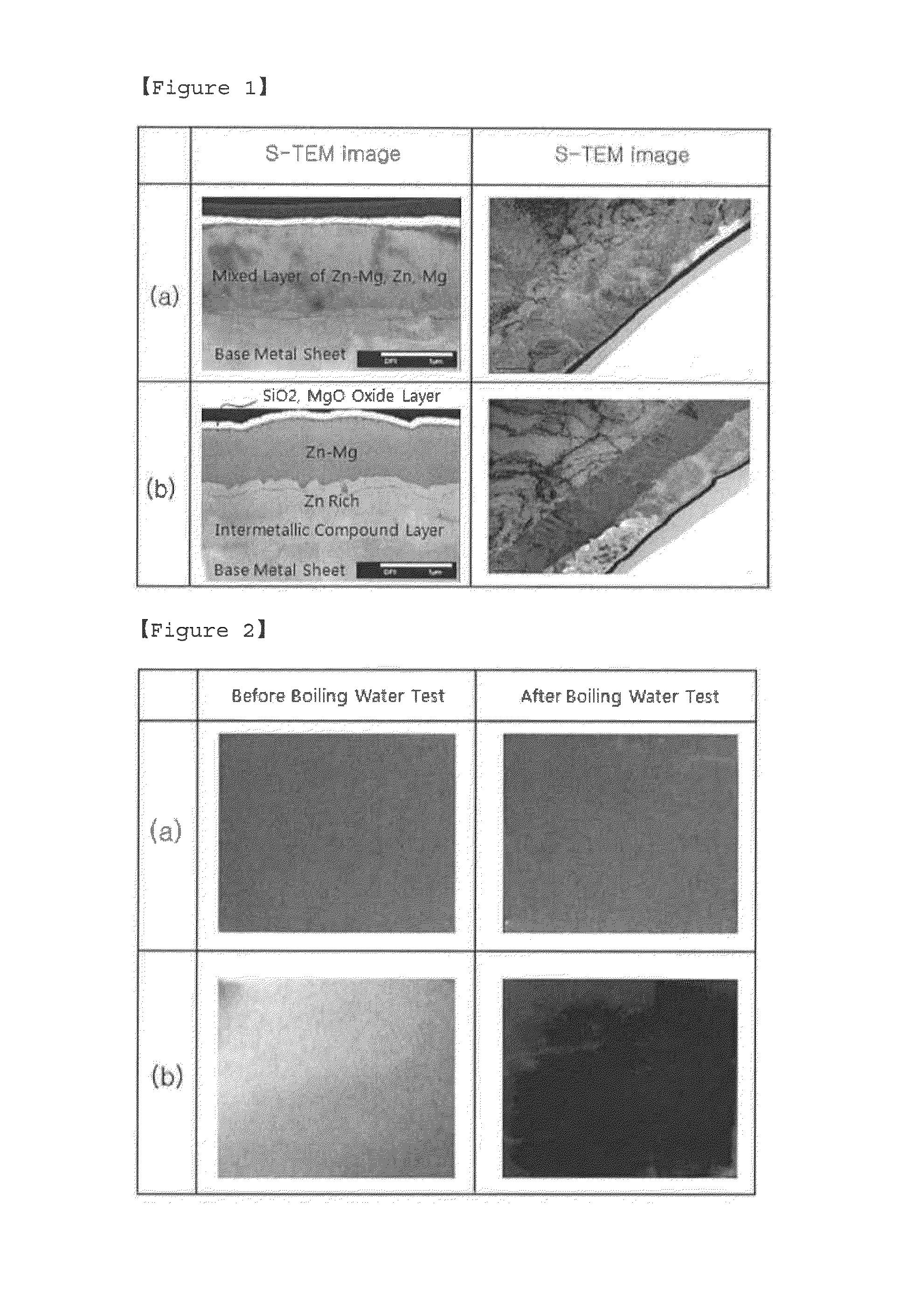

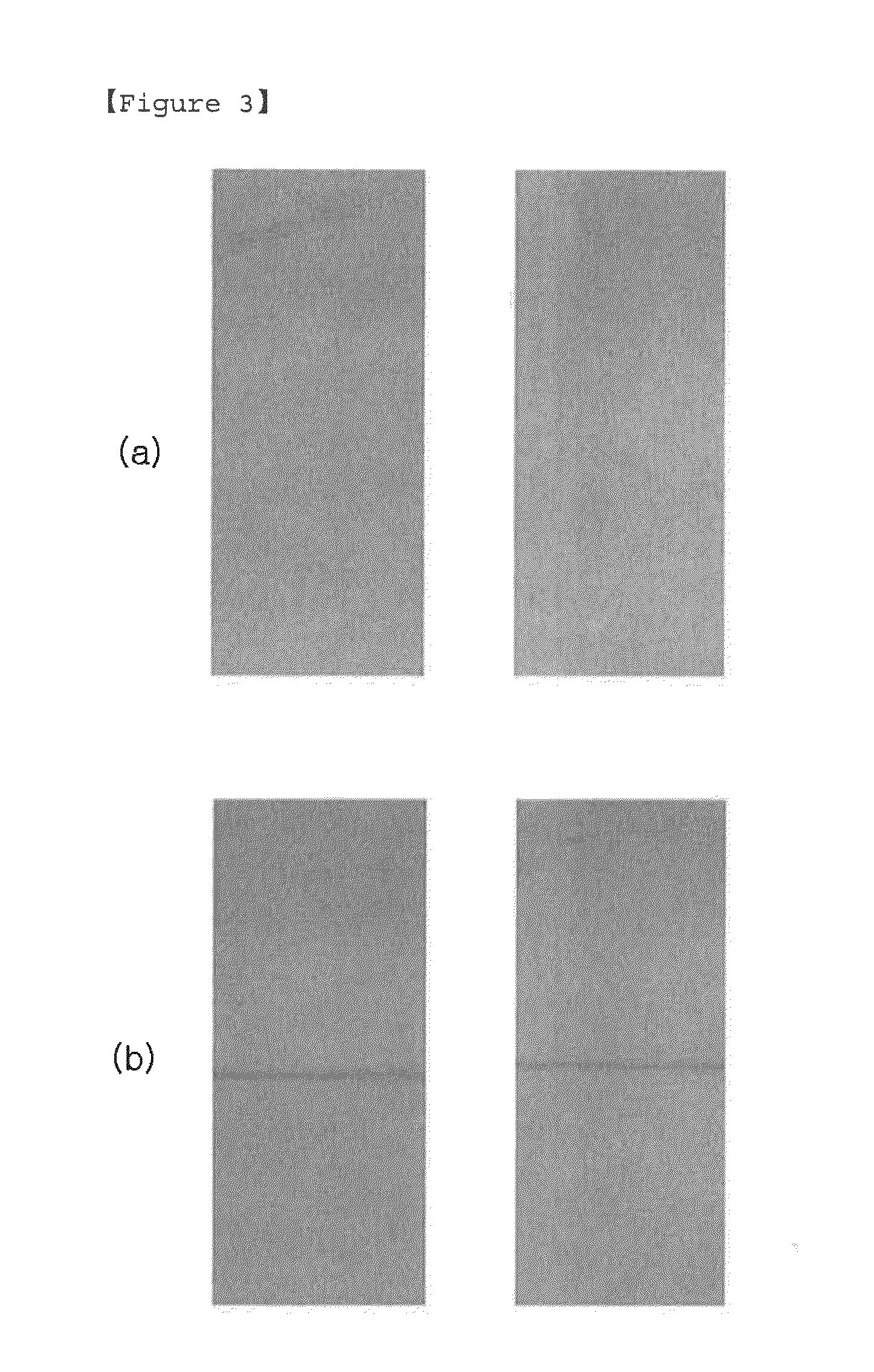

Zn-mg alloy-coated steel sheet with excellent blackening resistance and excellent adhesion and method for manufacturing same

ActiveUS20150030875A1Increased durabilityHigh-quality surfaceAnodisationVacuum evaporation coatingIntermetallicCoating adhesion

The present invention relates to a Zn—Mg alloy-coated steel sheet with excellent blackening resistance and excellent coating adhesion and to a method for manufacturing same. Provided are a Zn—Mg alloy-coated steel sheet with excellent blackening resistance and excellent adhesion and a method for manufacturing same, the steel sheet comprising: a substrate steel sheet; a Zn—Fe intermetallic compound layer formed on the substrate steel sheet; a first Zn—Mg coating layer formed on the Zn—Fe intermetallic compound layer and comprising a Zn—Fe intermetallic compound in which the content of Zn is 95% by weight or higher; a second Zn—Mg coating layer formed on the first Zn—Mg coating layer and comprising a Zn—Mg intermetallic compound in which the content of Zn is 80 to 95% by weight; and an oxide film formed on the second Zn—Mg coating layer and comprising a metallic oxide.

Owner:POHANG IRON & STEEL CO LTD

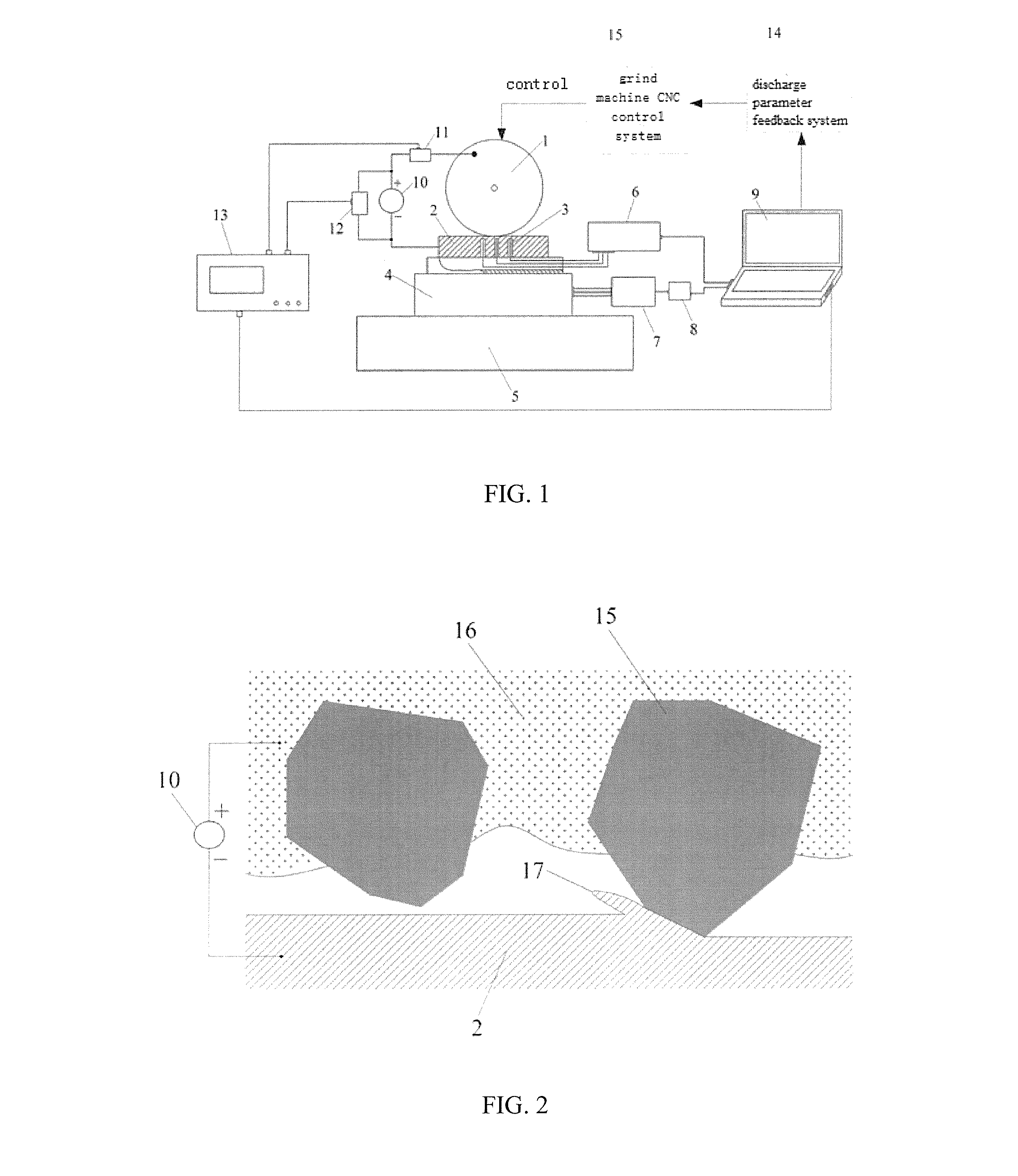

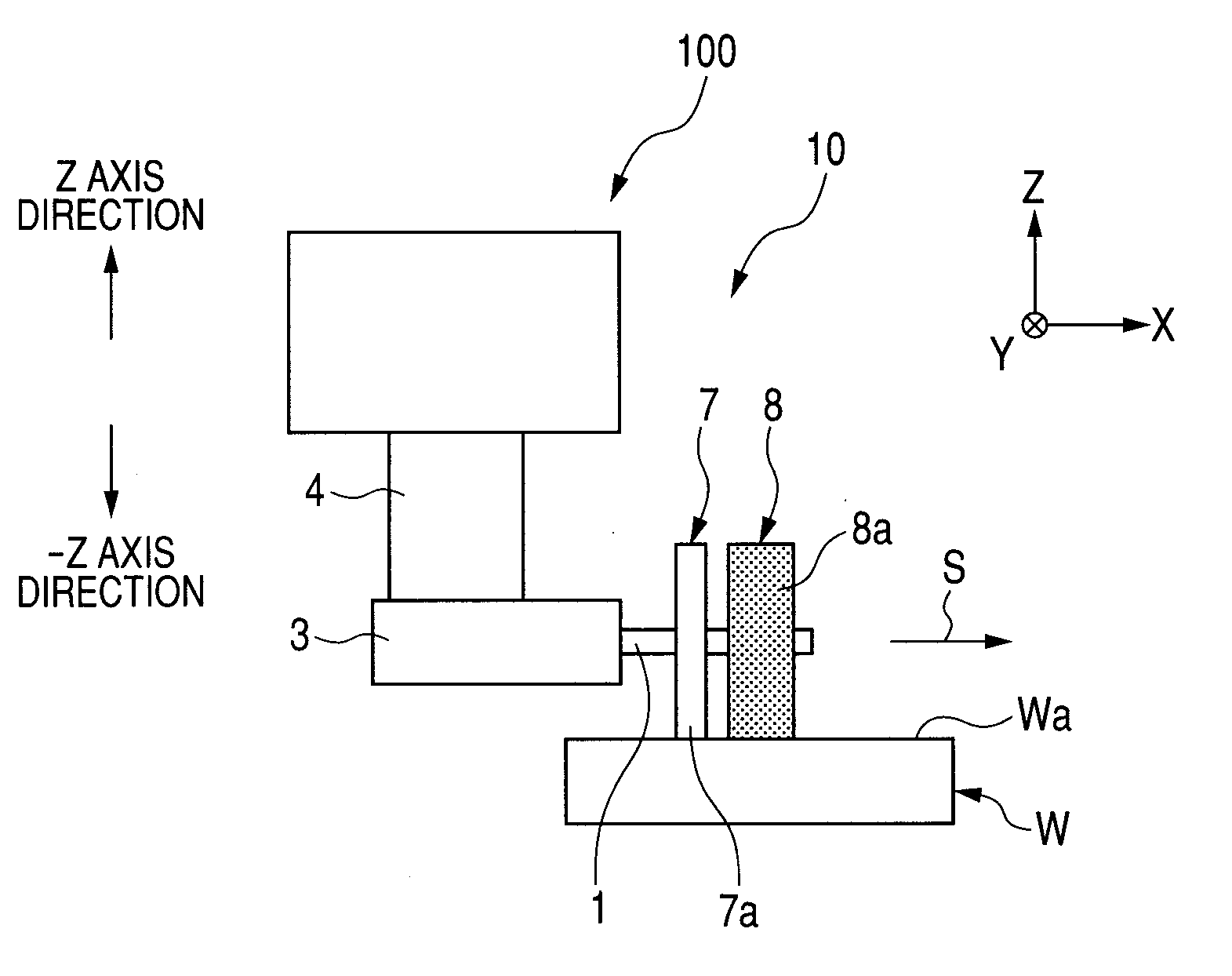

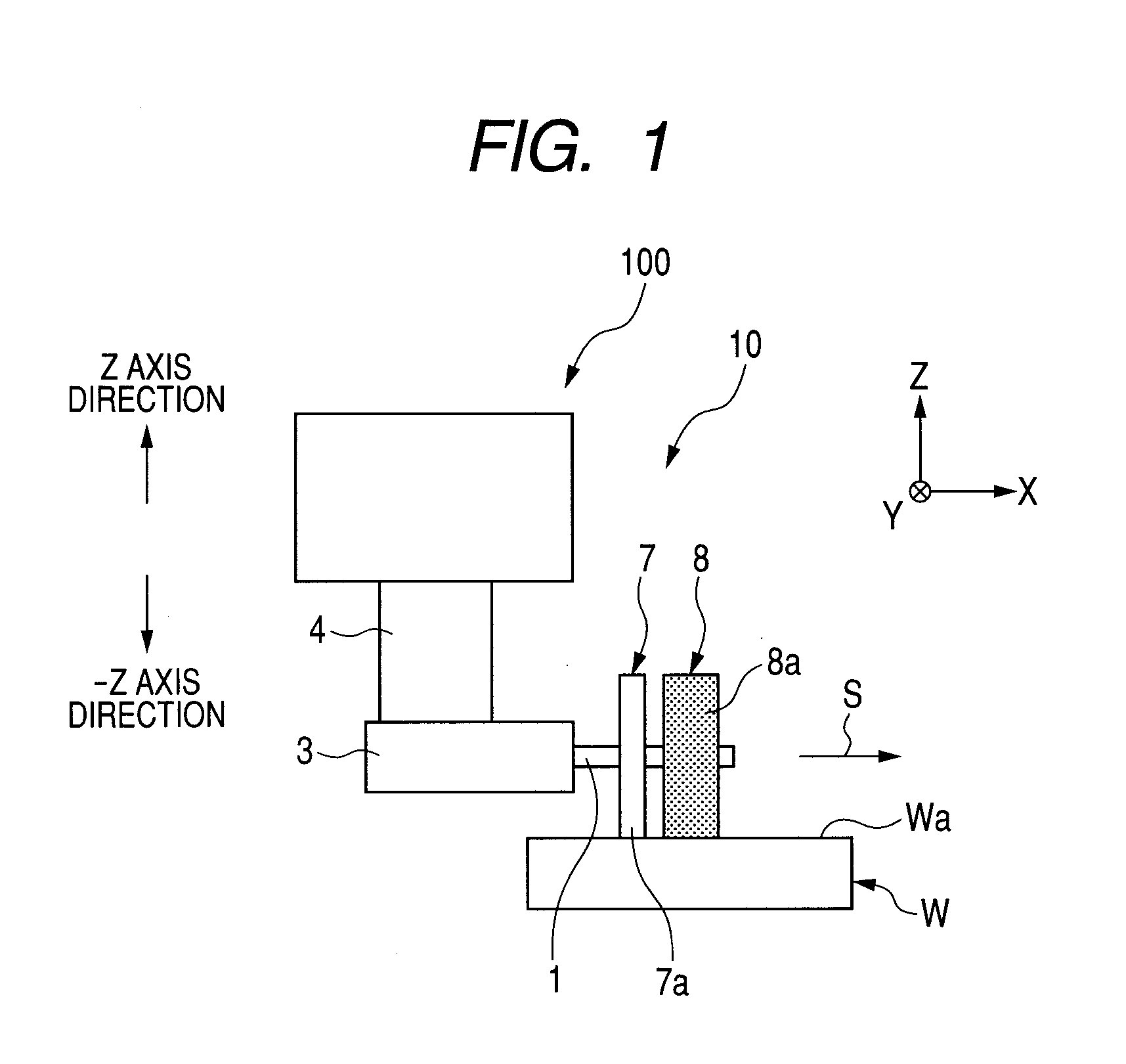

Intelligent Grinding Device for Short Pulse Electrical Melt Chip Removal Cooling

ActiveUS20170014967A1Reducing grinding forceReduce grinding temperatureGrinding feed controlGrinding machinesEngineeringPulse power supply

An intelligent grinding device for short pulse electrical melt chip removal cooling, includes a diamond grinding wheel, a pulse power supply, a force meter sensor, thermocouple in a hole of work piece for measuring machining temperature, a voltage sensor, a current sensor, a temperature collecting card, a charge amplifier, a force meter, a digital oscilloscope and a discharge parameter feedback adjustment system. The pulse power supply has a positive pole connecting with the grinding wheel, and a negative pole connecting with the work piece. The voltage sensor and the current sensor respectively put collected discharge voltage and current wave of the discharge circuit to be stored in a display terminal through the digital oscilloscope. The thermocouple connects with the display terminal by the temperature collecting card.

Owner:SOUTH CHINA UNIV OF TECH

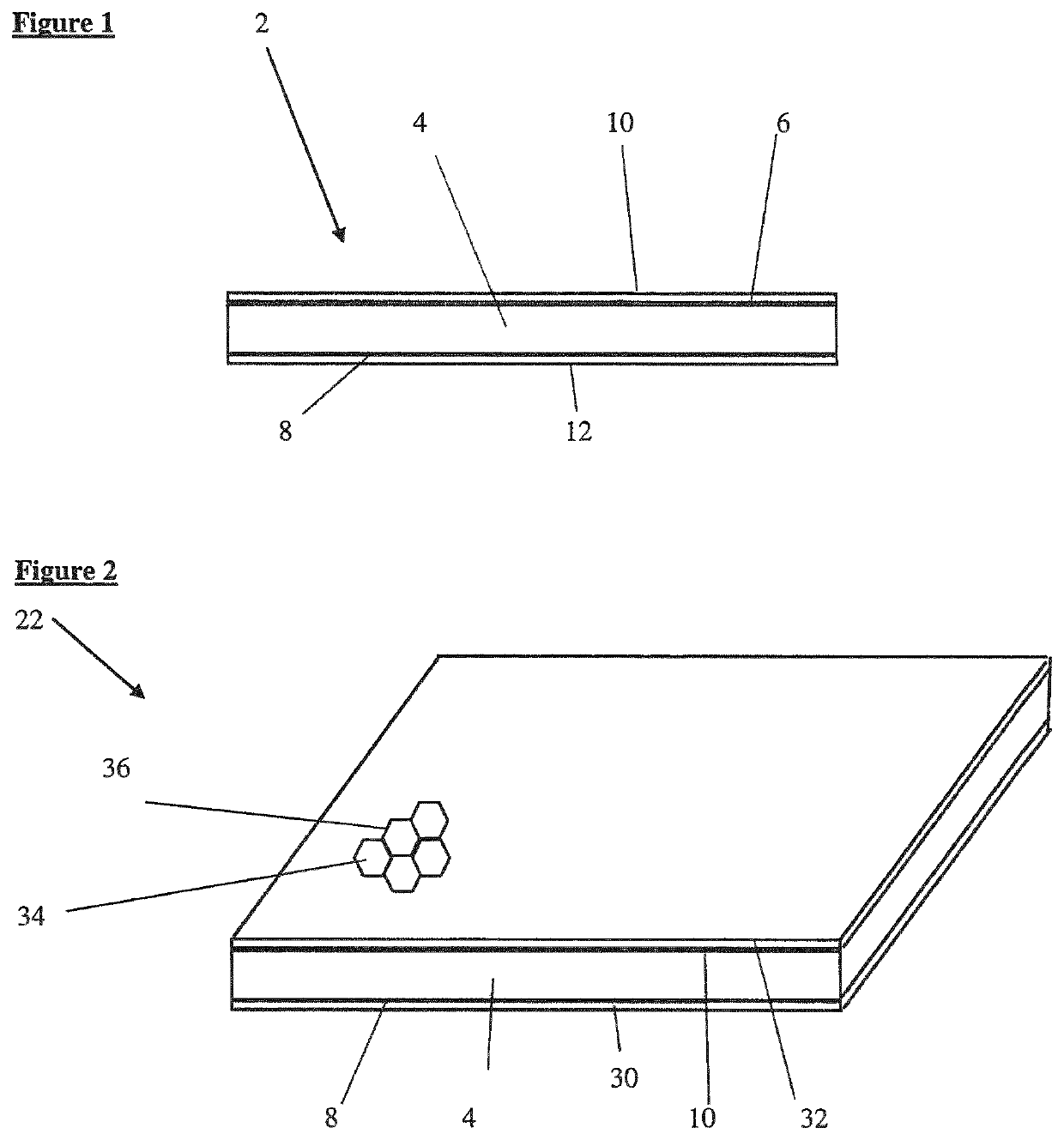

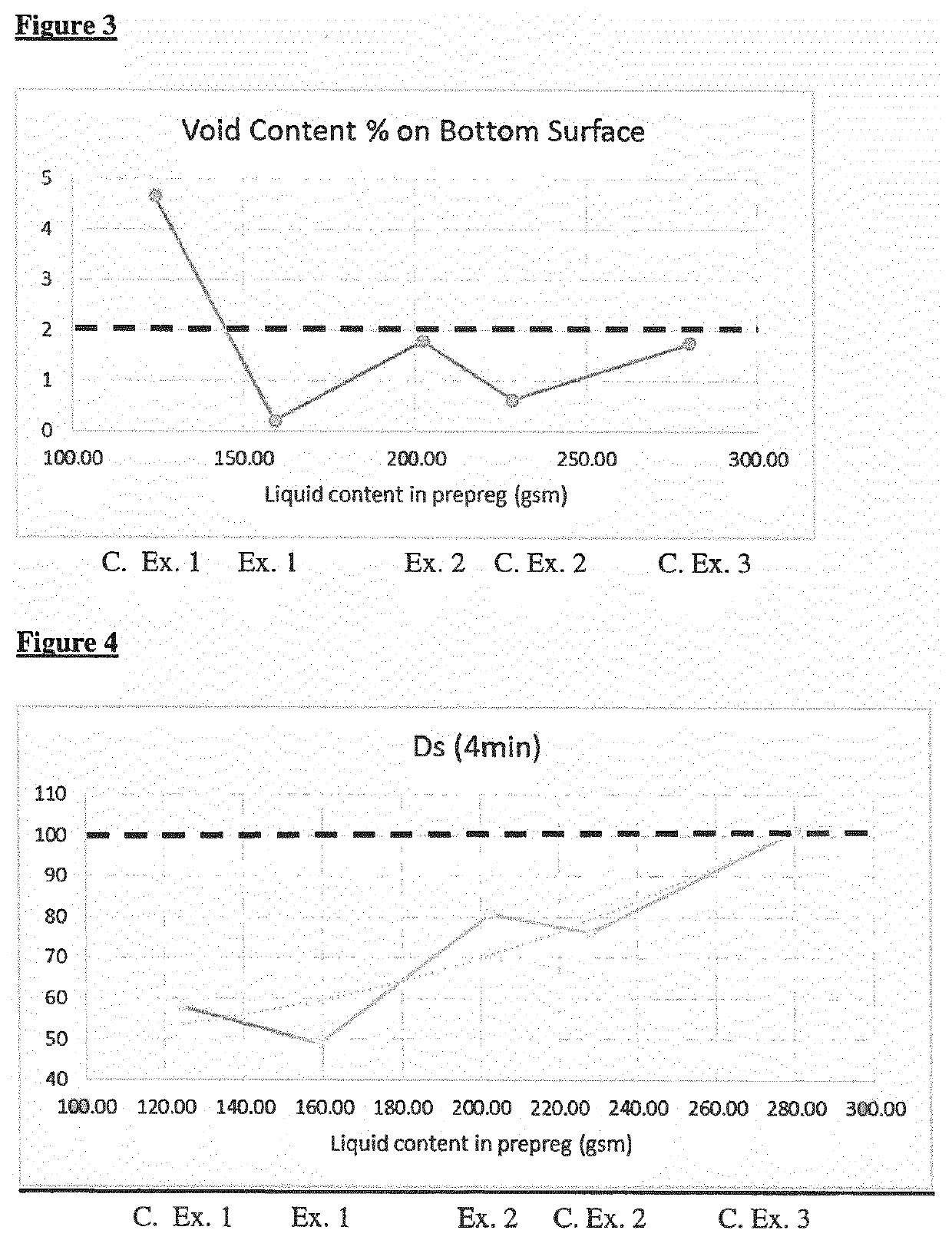

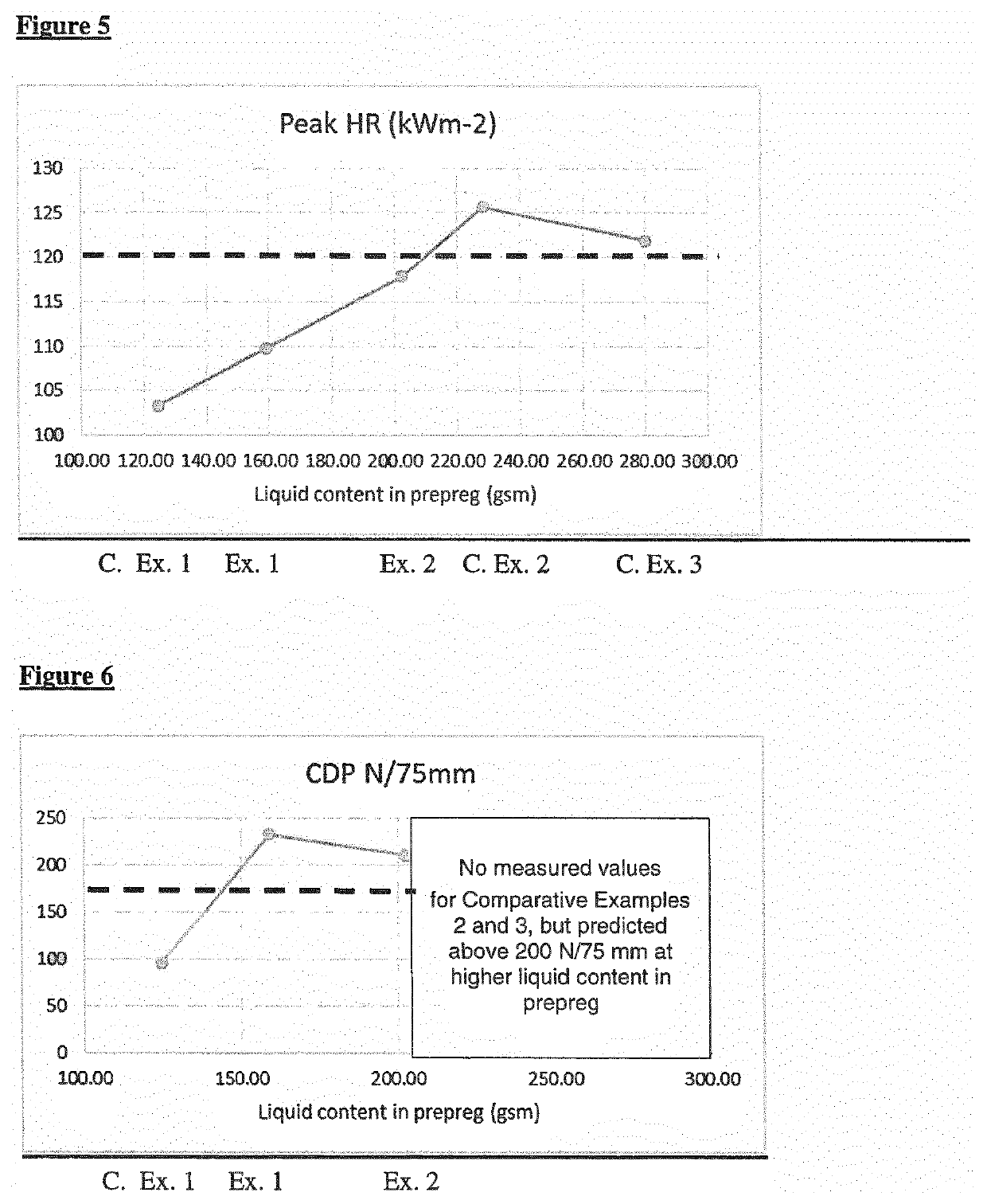

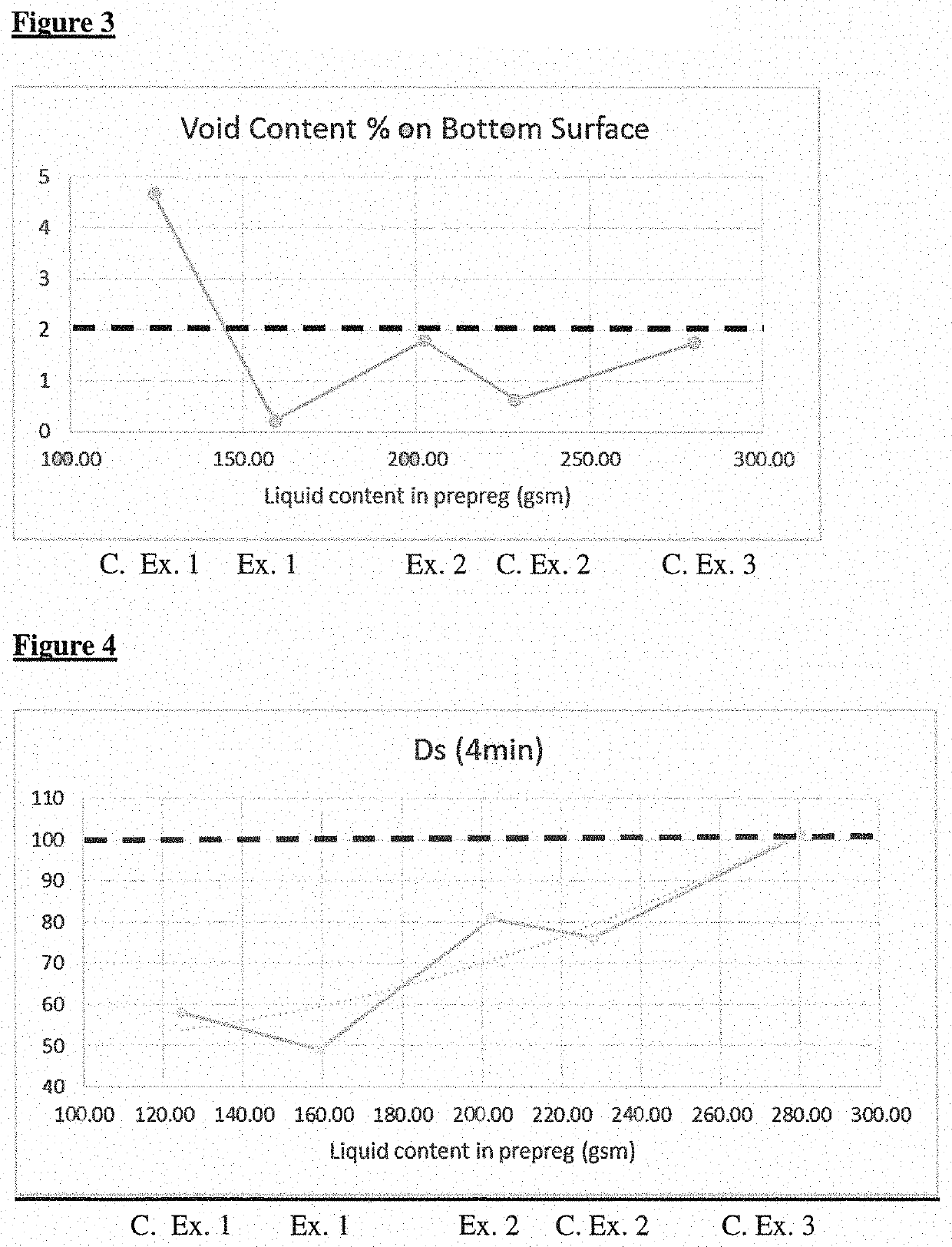

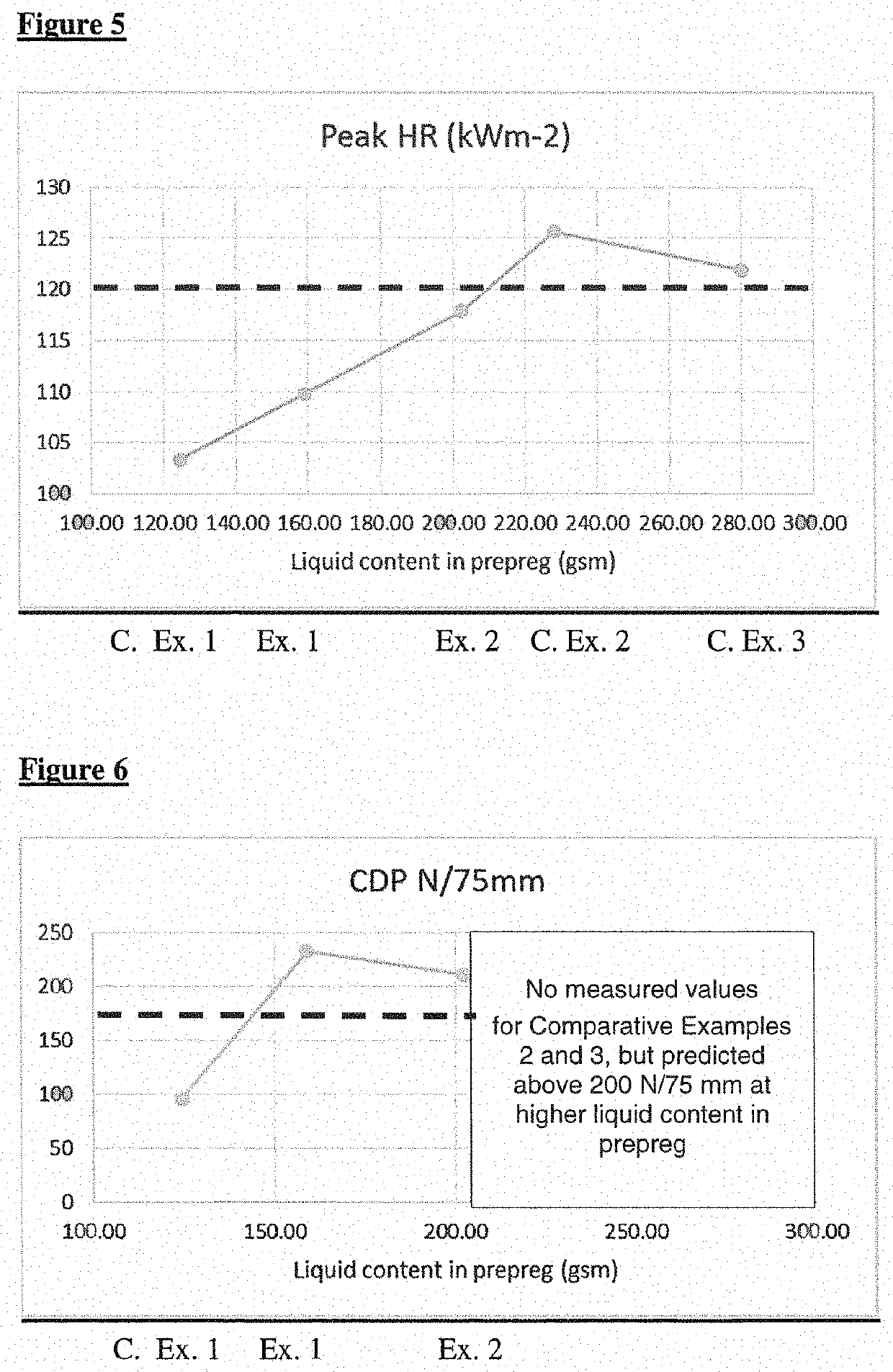

Fire-Retardant Composite Materials

ActiveUS20210002439A1Maintain good propertiesGood property aesthetic propertySynthetic resin layered productsVehicle componentsEpoxyPolymer science

A prepreg for the manufacture of a fibre-reinforced composite material having fire retardant properties, the prepreg comprising from 42 to 52 wt % of an epoxide resin matrix system and from 48 to 58 wt % fibrous reinforcement, each wt % being based on the total weight of the prepreg, the fibrous reinforcement being at least partially impregnated by the epoxide resin matrix system;wherein the epoxide resin matrix system includes as components:a. a mixture of (i) at least one epoxide-containing resin and (ii) at least one catalyst for curing the at least one epoxide-containing resin; andb. a plurality of solid fillers for providing fire retardant properties to the fibre-reinforced composite material formed after catalytic curing of the at least one epoxide-containing resin,wherein the weight ratio of component a. to component b. is from 1.4:1 to 1.86:1.

Owner:GURIT (UK) LTD

Heated Floor Element having a Surface Layer

InactiveUS20070196614A1Improve stabilitySufficient break resistanceLayered productsThin material handlingSurface layerAdhesive glue

The invention relates to a floor element which is light-weight and easily transported, easily removed and therefore usable several times, is pleasant to walk on and can be used together with a floor heating system. The planar element for floors comprises a multilayer flag on the upper face of which a thin pressure-proof and abrasion-resistant flag, especially a natural stone flag, is disposed and on the lower face of which a pressure-proof light-density layer, fastened thereto by an adhesive glue, is disposed. Grooves are arranged in the vertical marginal areas of the light-density layer and connecting elements can be fixed in said grooves for connecting adjacent multilayer flags. According to the invention, the light-density layer consists of an expanded polypropylene foam.

Owner:KELLNER PETER

Double-head cutting tool in mechanical processing

The invention relates to a metal cutter with new knifepoint structure, which is characterized in two knifepoints. Wherein, said dual-knifepoint structure can break the relation between the abrasions of main blade and the knifepoint 2 that machining finely, to avoid the effect of main blade abrasion; and the knifepoint 2 has lower force and thermal load, to improve the surface quality. The invention can be used in variable cutters, as integrated high-speed steel blade, welded right alloy cutter, etc.

Owner:EAST CHINA UNIV OF SCI & TECH

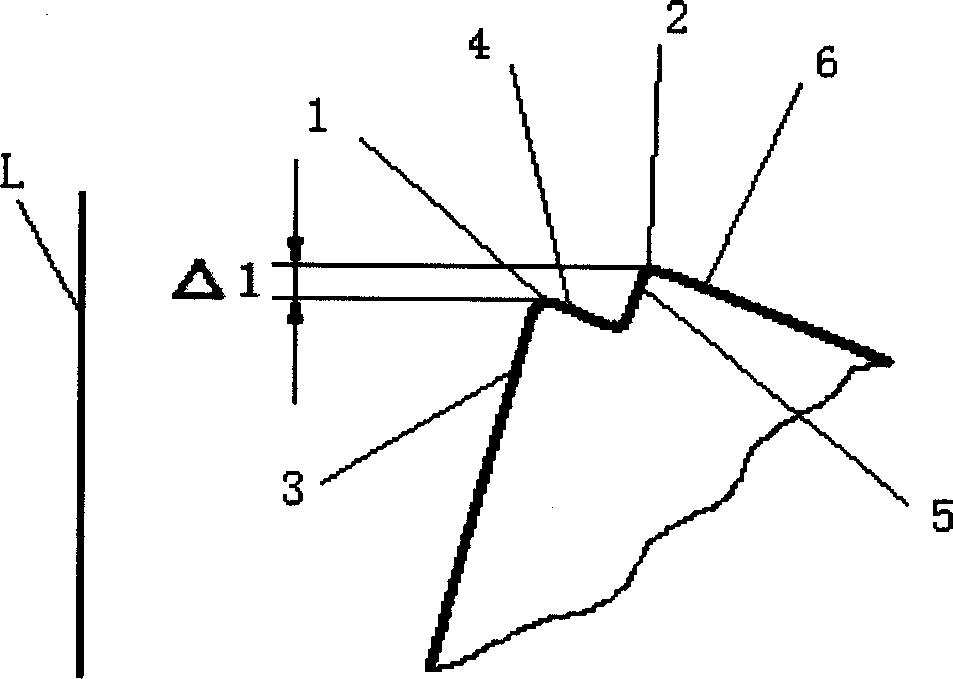

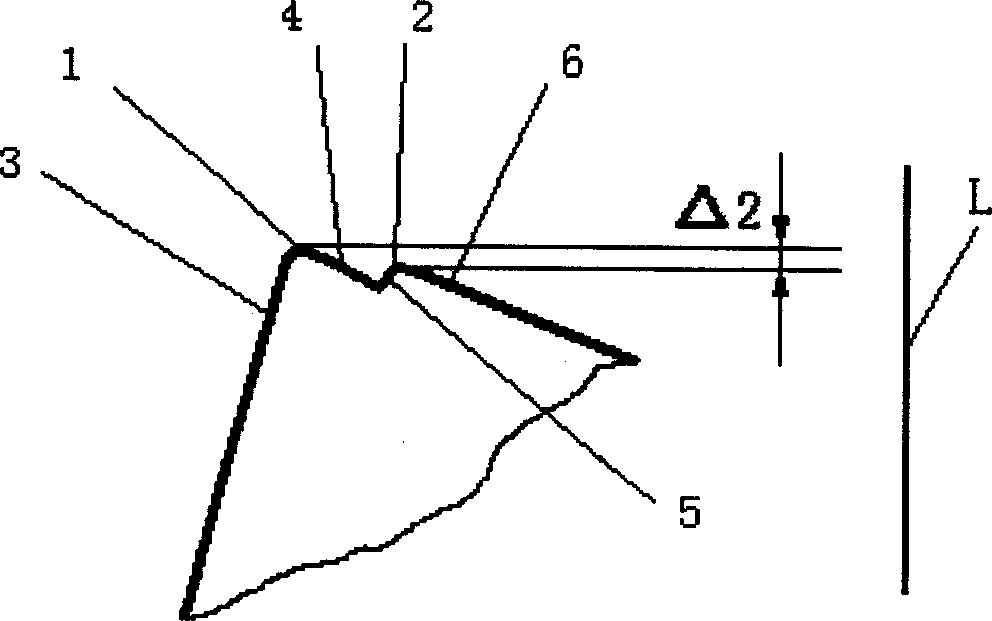

Polishing method for a workpiece and polishing tool used for the polishing method

InactiveUS20110028074A1High porosityHigh-quality surfaceEdge grinding machinesFlexible-parts wheelsPorosityMaterials science

Provided is a polishing tool capable of forming a high-quality surface of a workpiece for a short period of time. A polishing tool includes: a rotation shaft arranged parallel to a sending direction of moving the polishing tool relative to a workpiece; and at least two polishing bodies. The polishing body includes a foamed resin such as a foamed polyurethane resin, and has an outer peripheral surface having a porosity higher than that of the polishing body. The polishing body includes a non-foamed resin such as a non-foamed polyurethane resin being a material more rigid than that for the polishing body. When polishing-processing, the polishing body performs polishing removal on a surface of the workpiece, and the polishing body smoothes a waviness formed on the surface through the polishing removal.

Owner:CANON KK

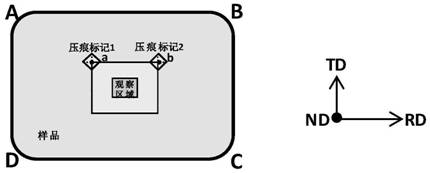

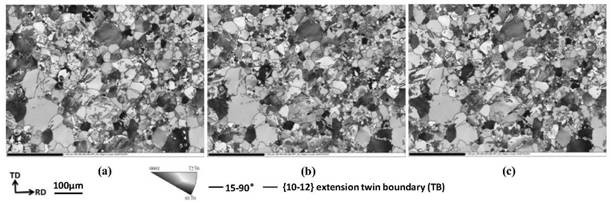

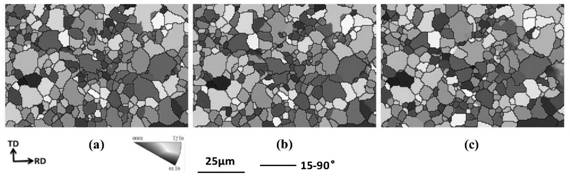

In-situ EBSD observation method for microscopic orientation evolution of recrystallized grains of magnesium alloy

InactiveCN111999323AImprove the success rate of sample preparationGuaranteed follow-up observationMaterial analysis using radiation diffractionEtchingMetallic materials

The invention belongs to the field of metal material structure analysis sample preparation and structure observation characterization, and particularly relates to an in-situ EBSD observation method for microcosmic orientation evolution of recrystallized grains of magnesium alloy. The method comprises the steps of firstly, carrying out mechanical polishing on a magnesium alloy sample, then preparing indentation mark points on the surface to be detected, and conducting EBSD observation for the first time on a target area after ion etching; and taking out the sample, carrying out recrystallization annealing heat treatment and ion etching, finding the same area according to the indentation mark points, carrying out EBSD observation for the second time, and similarly, completing subsequent required in-situ EBSD observation. According to the method, in-situ tracking characterization of recrystallization nucleation, grain growth and microscopic orientation evolution in the same area in the recrystallization annealing process of the magnesium alloy is achieved, and the problems that the magnesium alloy is low in calibration rate due to a surface stress layer, an oxide layer and pollutants,accurate positioning cannot be achieved, and in-situ EBSD observation is difficult to achieve are solved. The process is simple and controllable, the technical requirements on sample preparation of experimenters are low, and the experiment success rate is high.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

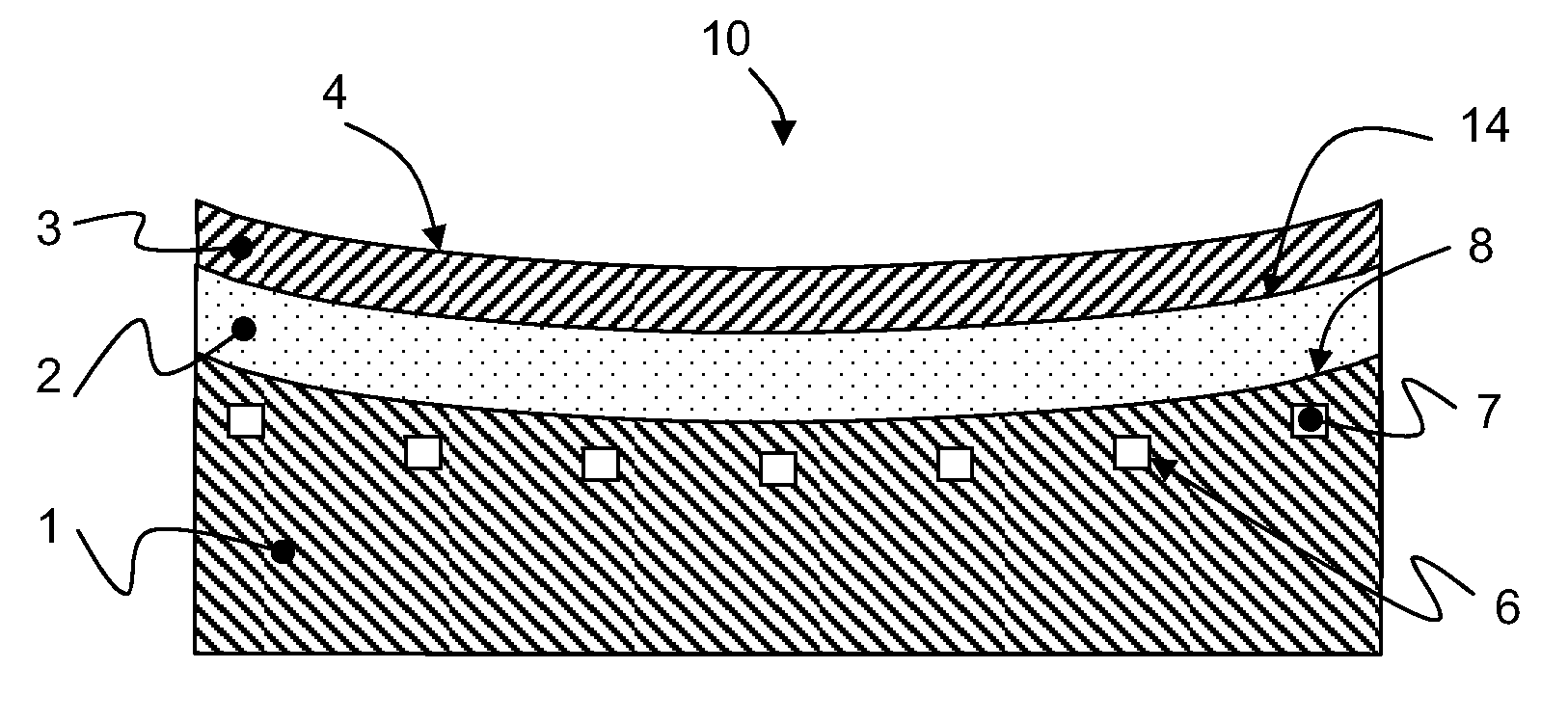

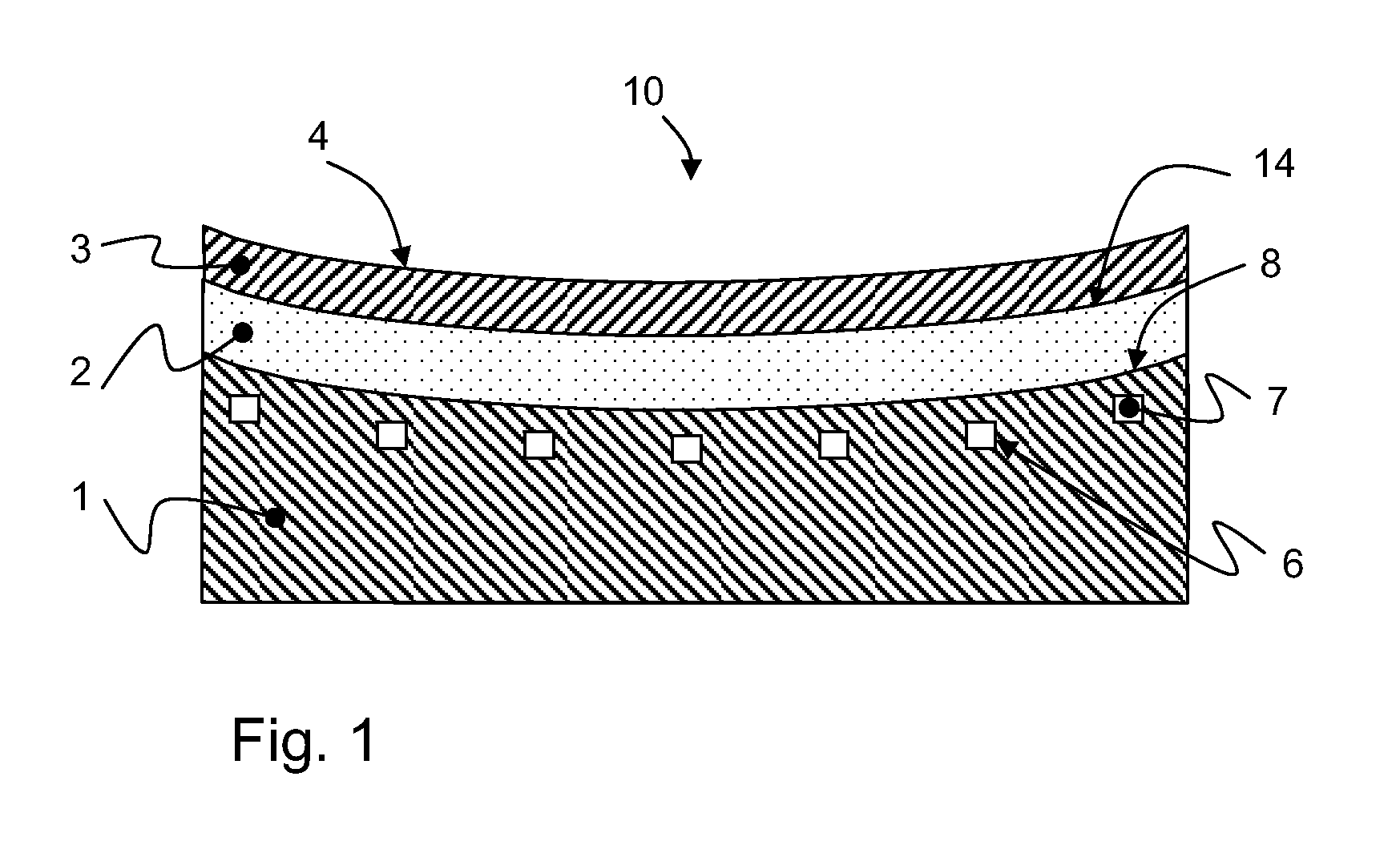

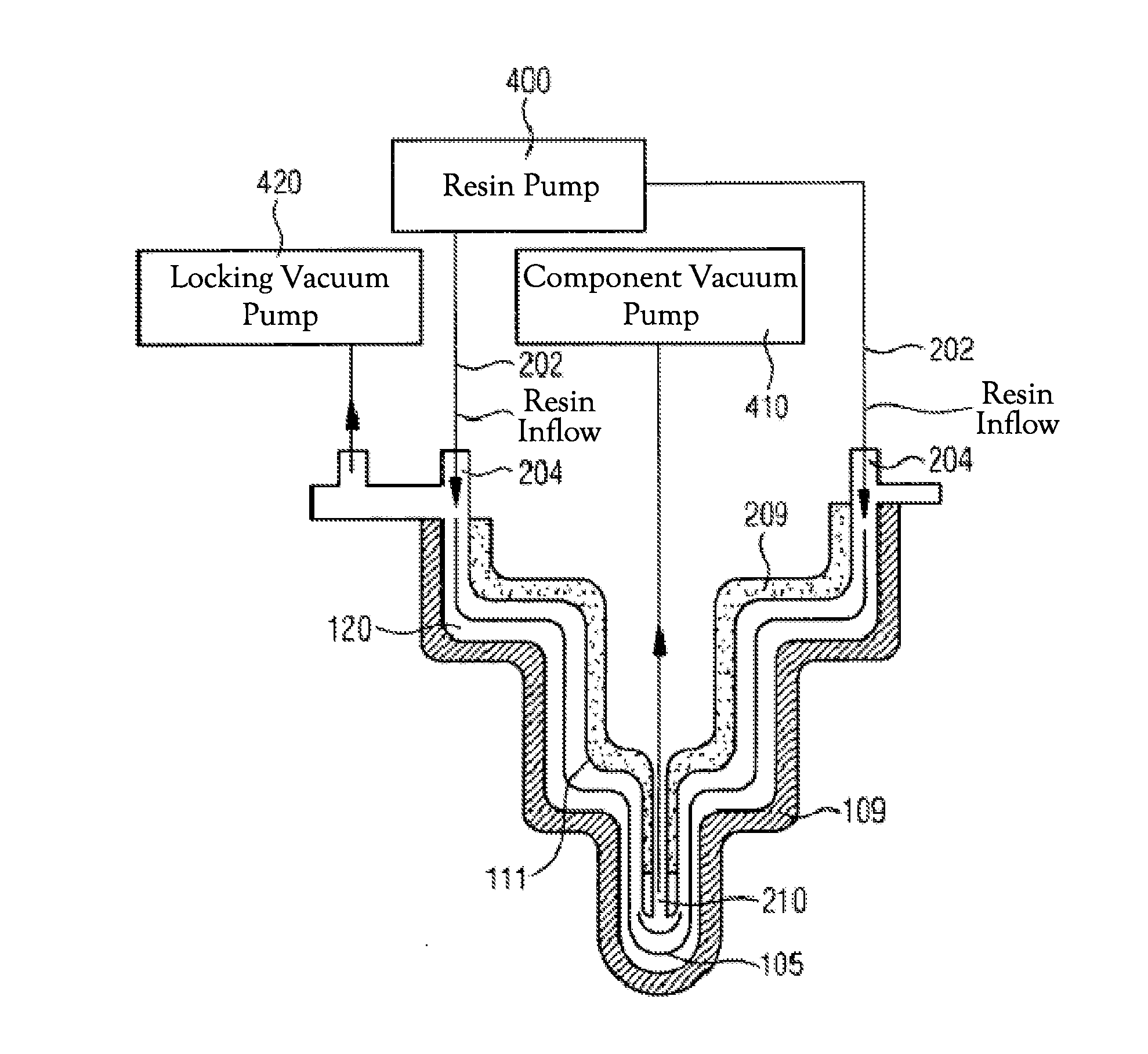

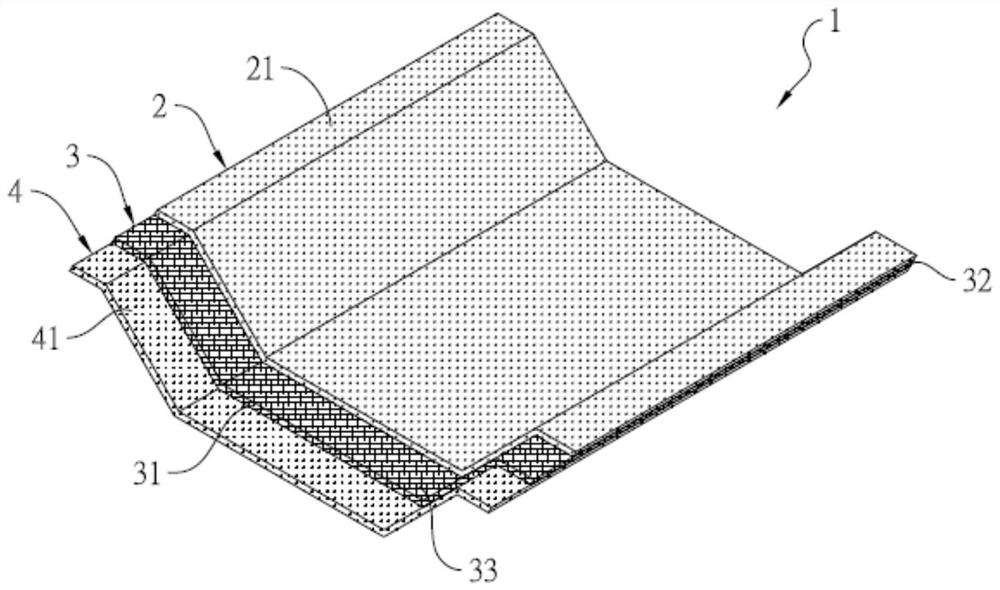

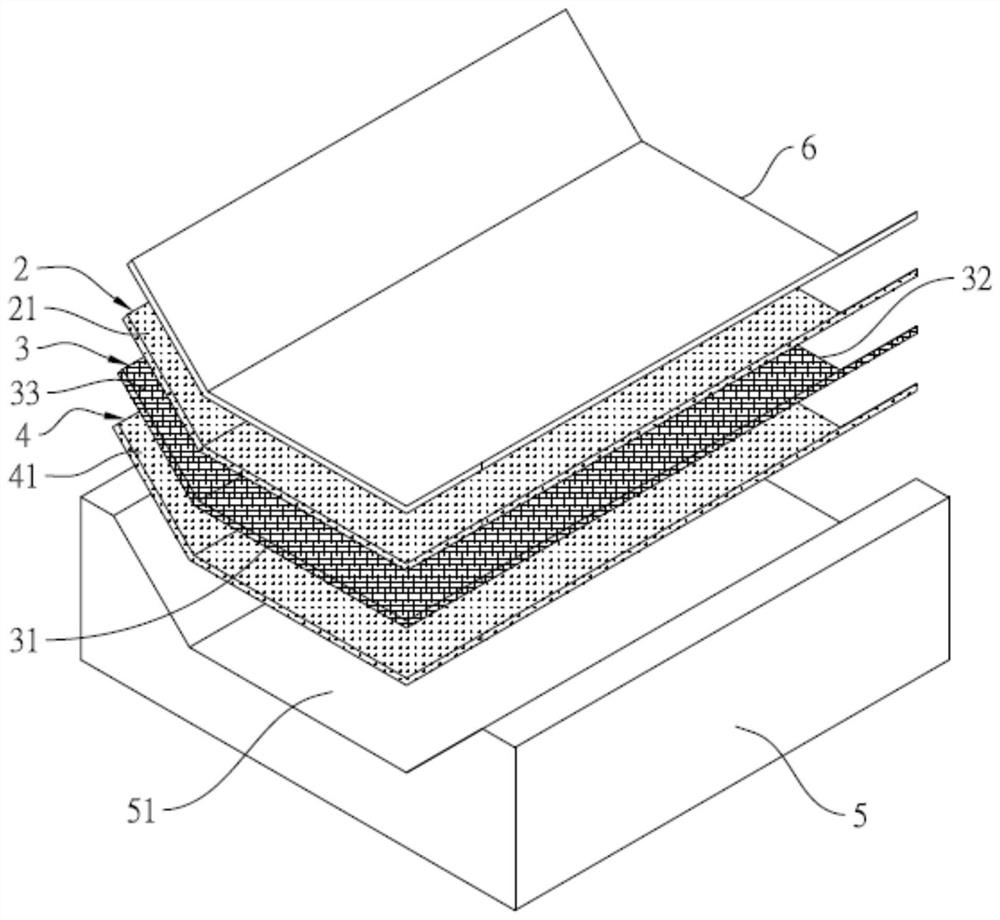

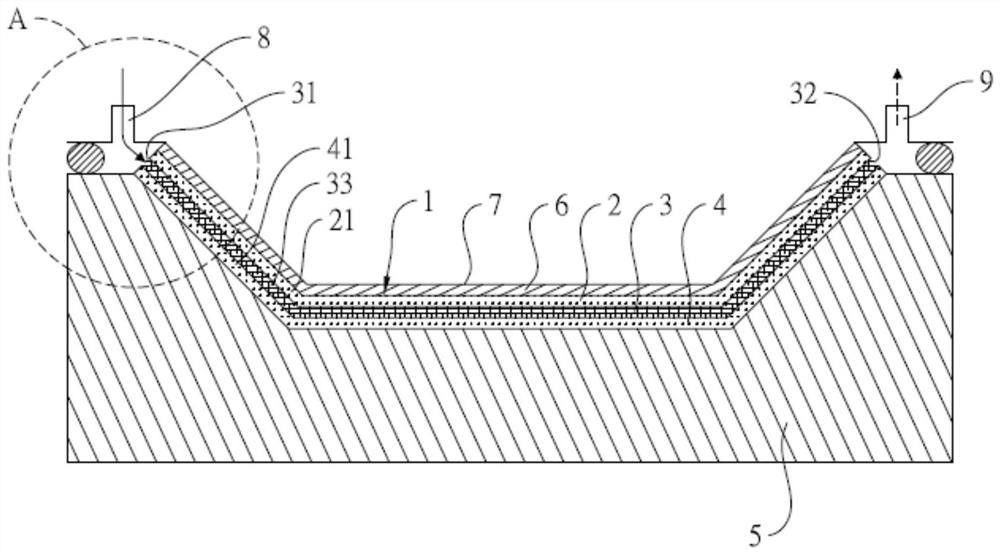

Composite material structure and preparation method thereof

PendingCN113942275AHigh quality surfaceLamination ancillary operationsSynthetic resin layered productsInter layerVacuum pressure

The invention discloses a composite material structure and a preparation method thereof. The composite material structure mainly comprises a first fiber layer, at least one flow guide middle layer and a second fiber layer which are sequentially overlapped from top to bottom. The preparation method disclosed by the invention comprises the following steps: sequentially overlapping and laying a second mold, a first fiber layer, at least one flow guide middle layer and a second fiber layer on the surface of a first mold from top to bottom, and then covering and sealing by using a vacuum plastic film; after a space between the vacuum plastic film and the first mold is vacuumized, enabling a liquid-state resin to respectively flow upwards and downwards through each flow guide middle layer by utilizing vacuum pressure so as to soak the first fiber layer and the second fiber layer, and simultaneously enabling the liquid-state resin to flow from the first end to the second end; and after the first fiber layer, each flow guide middle layer and the second fiber layer are completely impregnated with the liquid-state resin, closing the feeding end, and finally, waiting for the liquid-state resin to be cured and molded.

Owner:HOCHENG CORPORATION

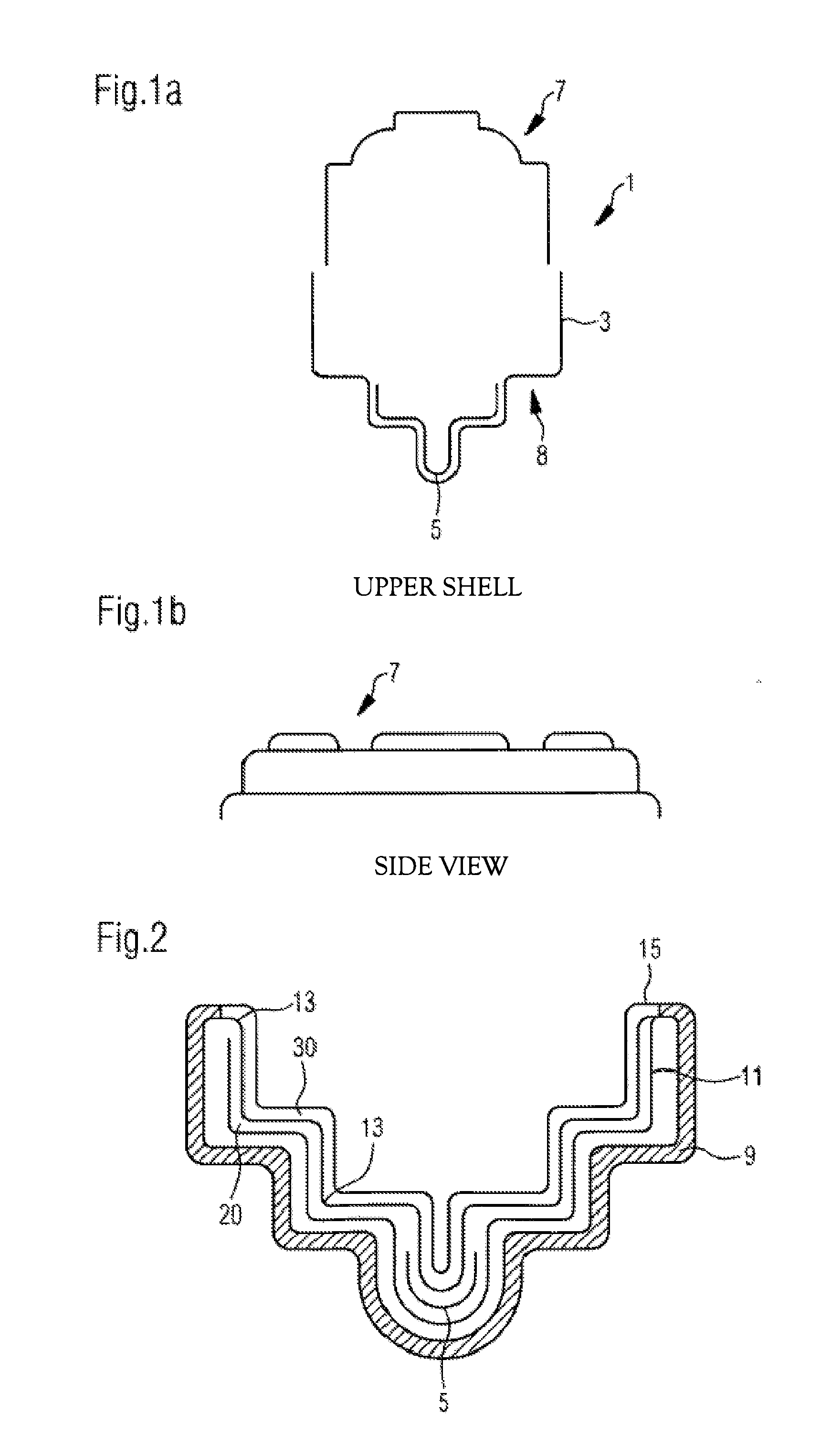

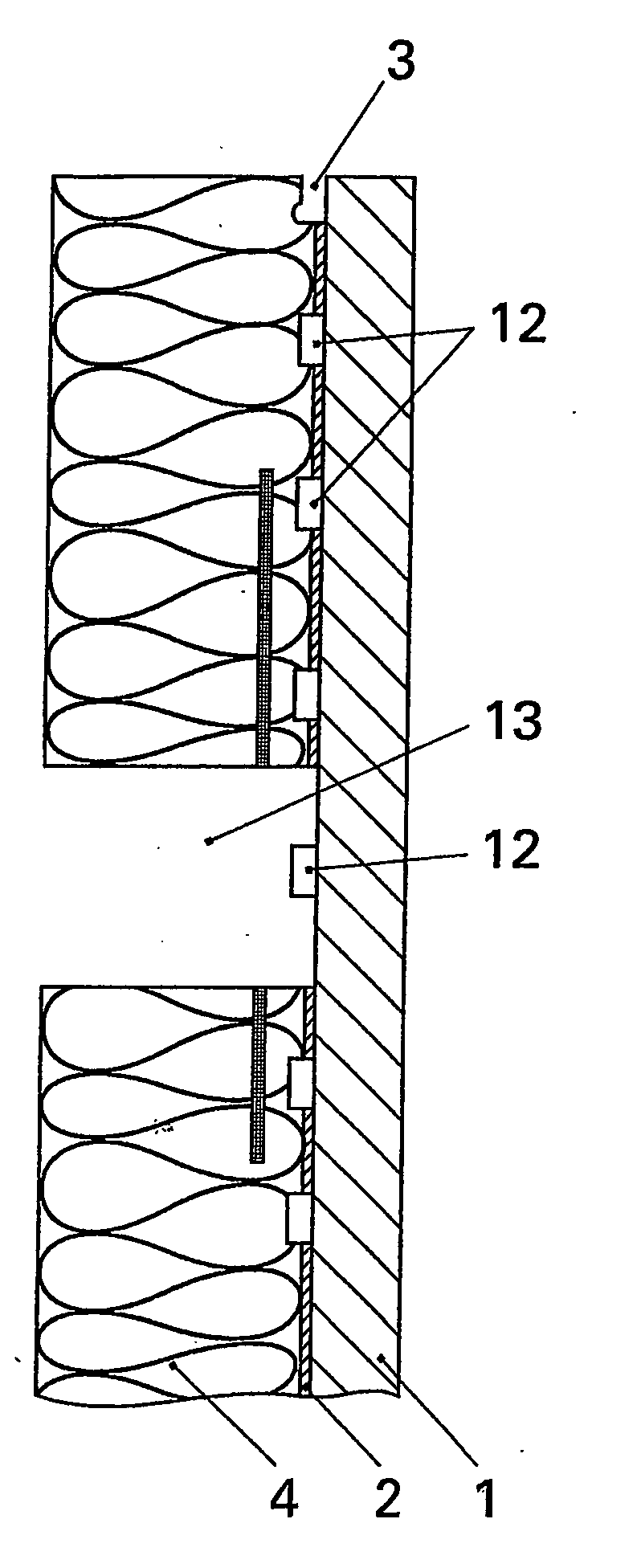

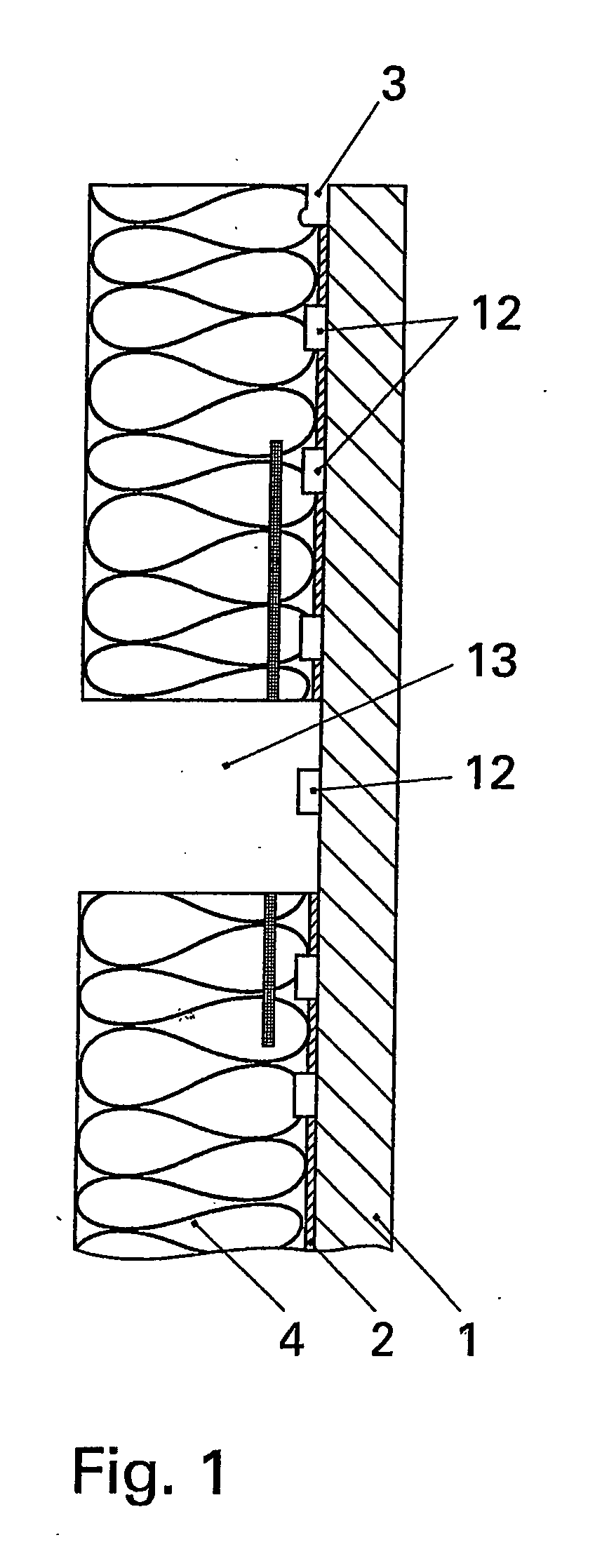

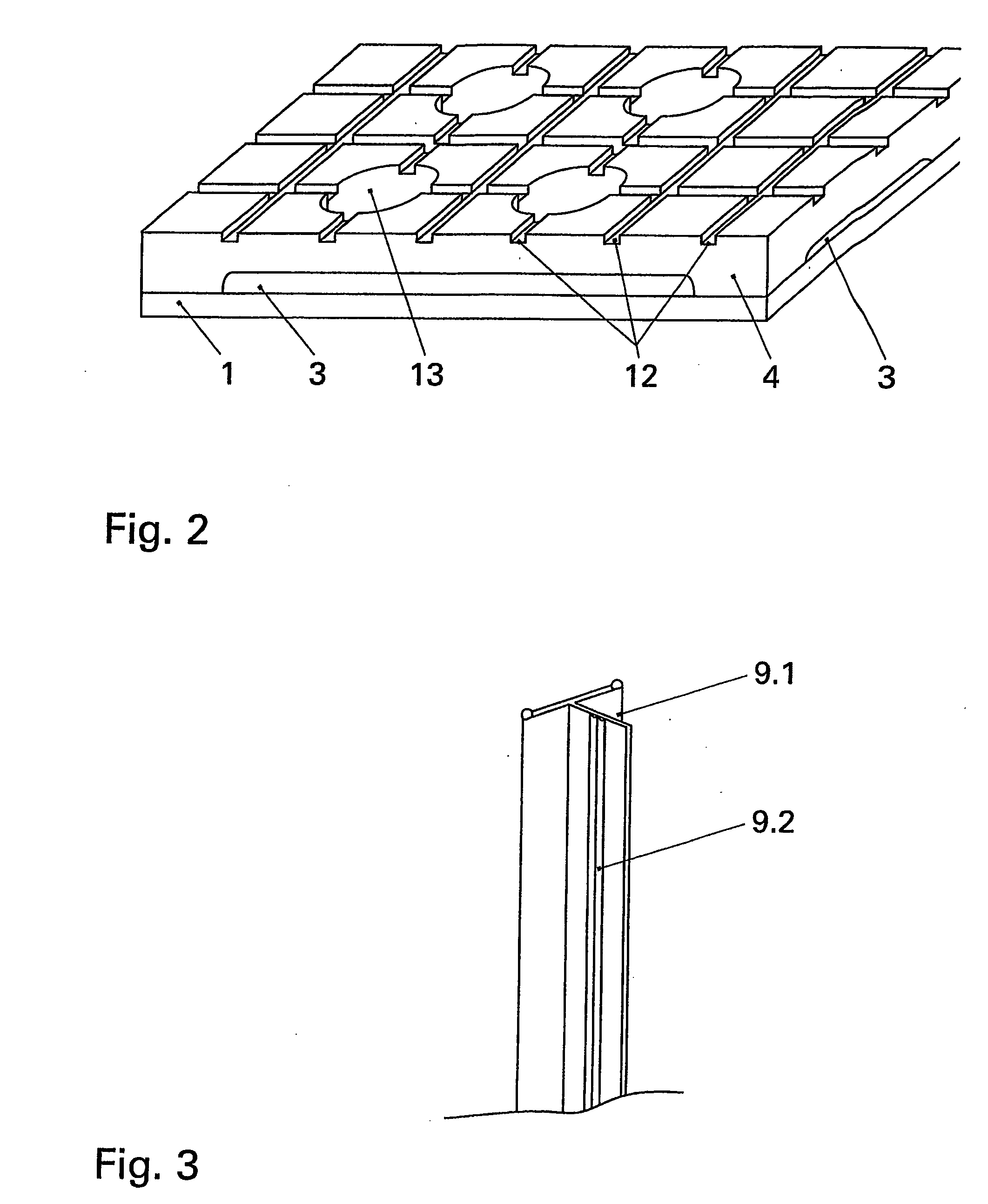

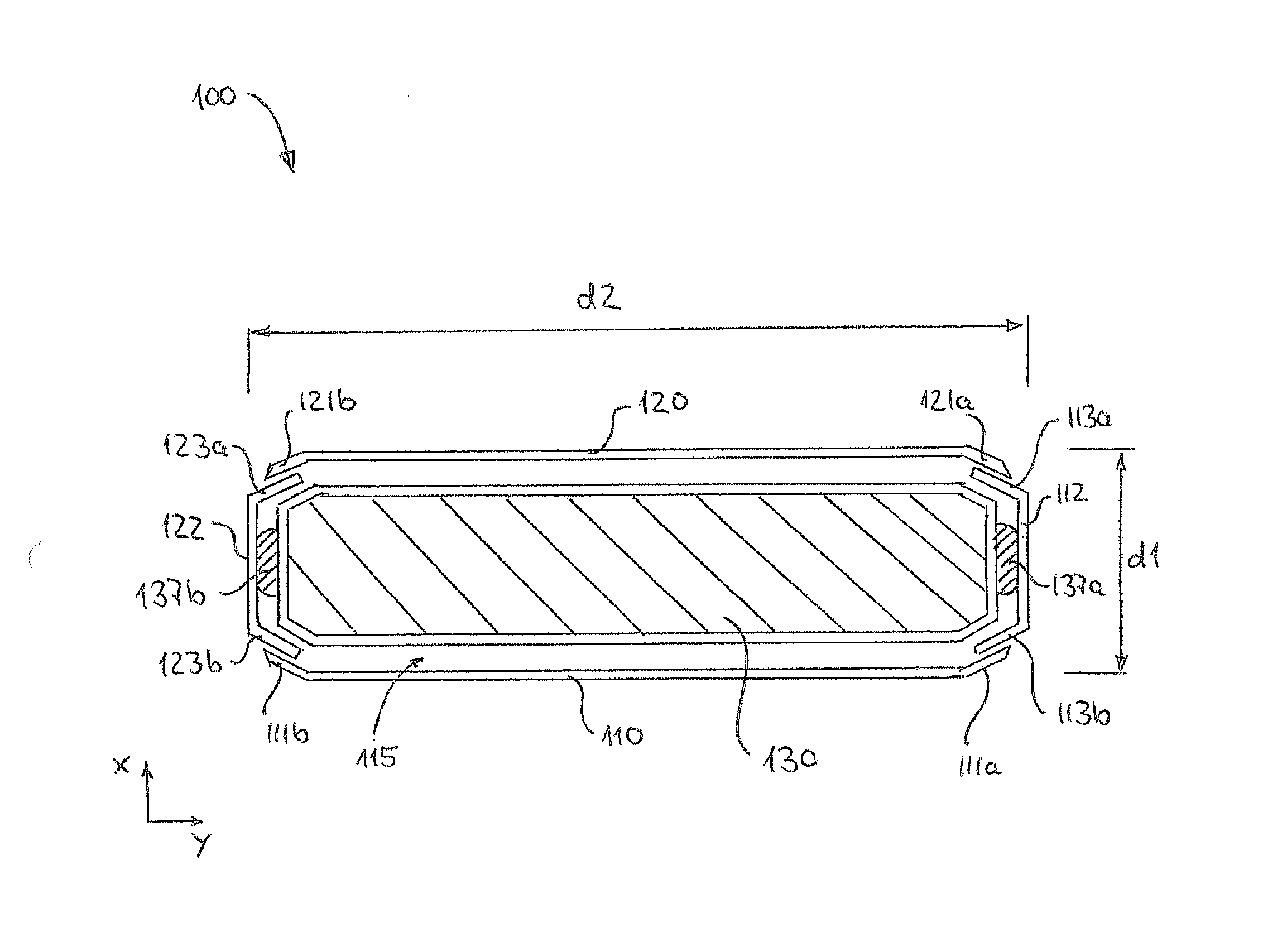

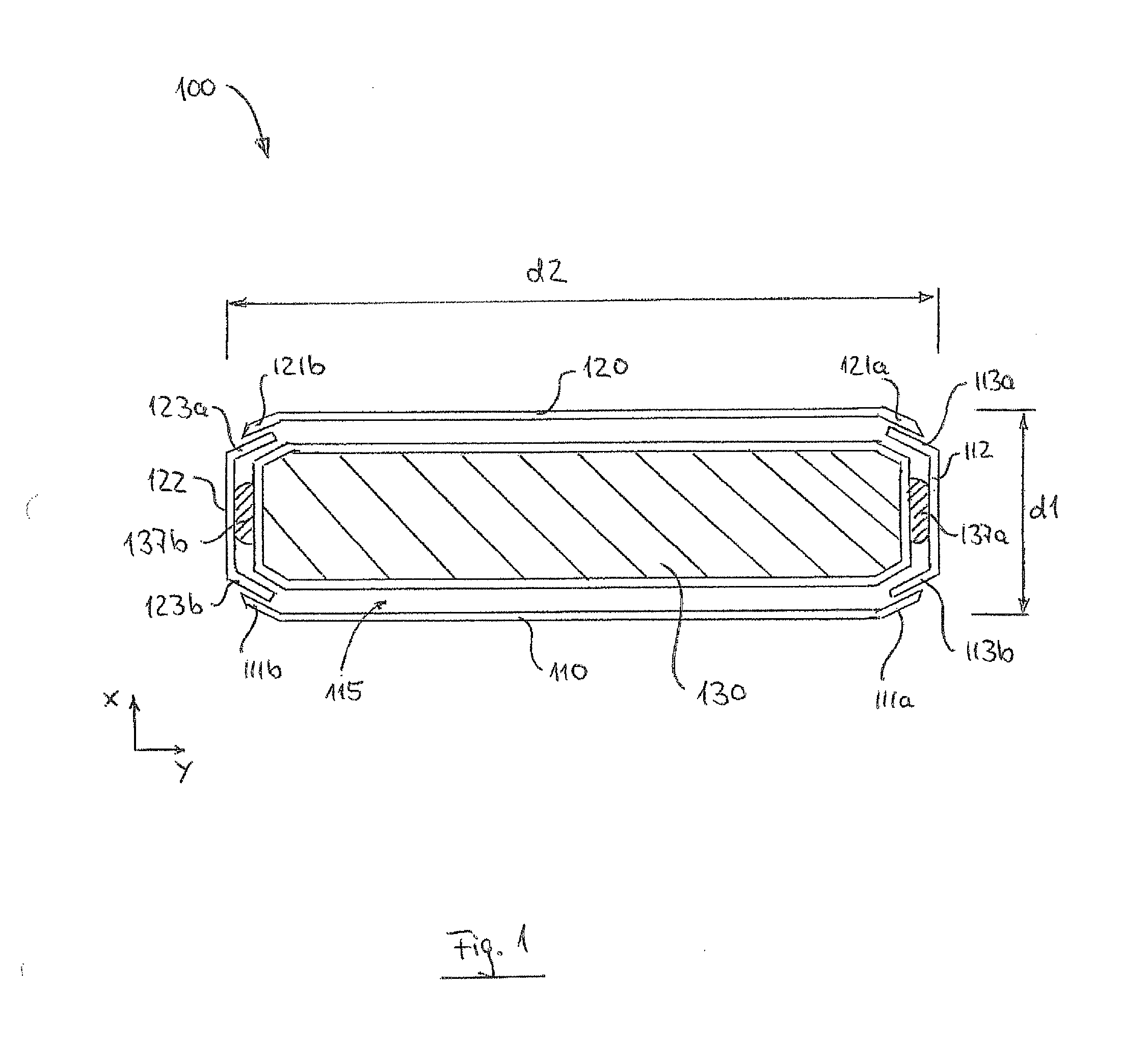

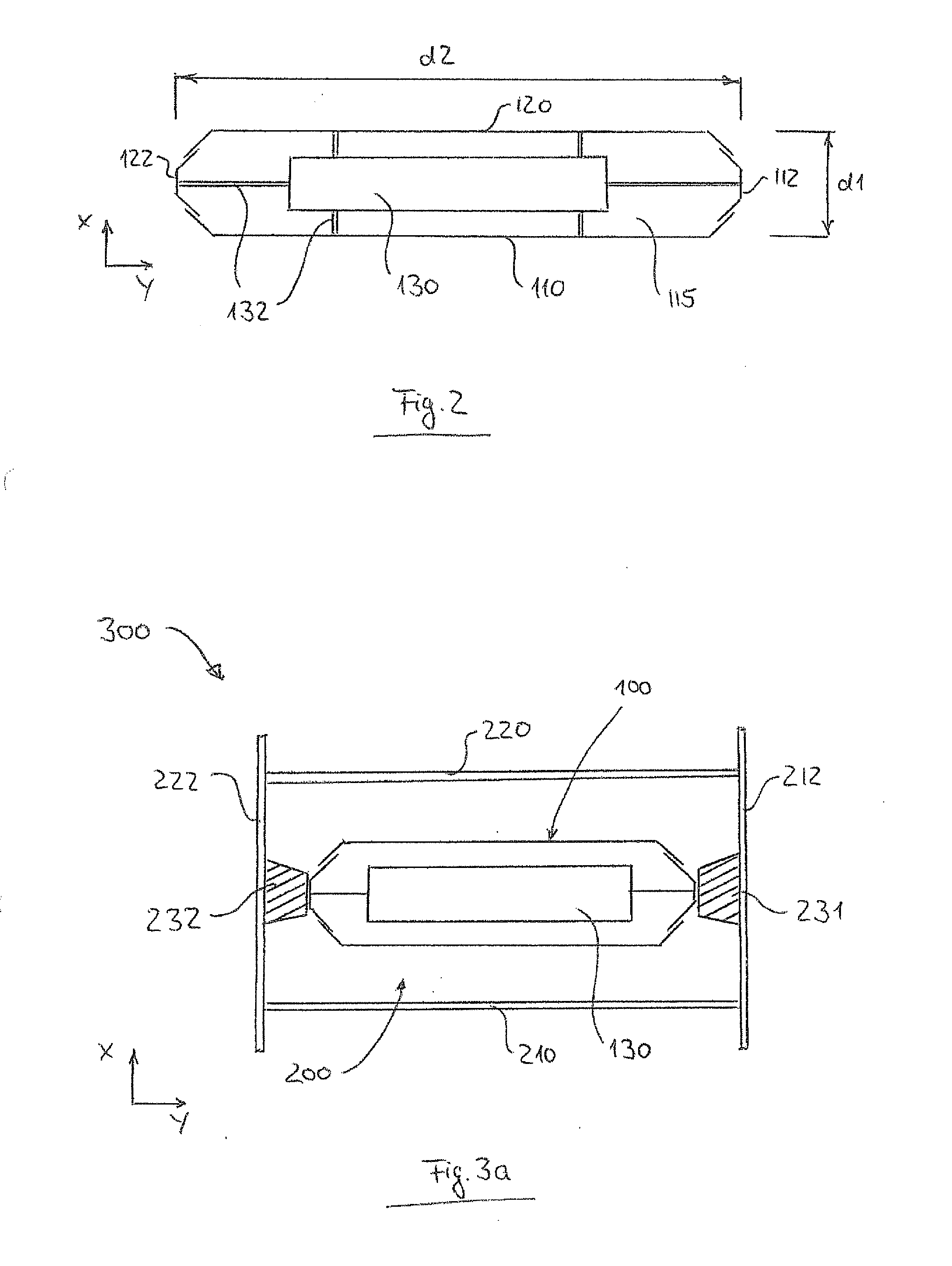

Shrinkable Core for Forming Hollow Precast Load Bearing Wall Panels

InactiveUS20150251333A1Avoid fracturesAvoid crackingEnvelopes/bags making machineryWrappers shrinkageWall plateEngineering

A shrinkable core (100) for inserting in a mold (200) for forming a precast load bearing wall panel having a cavity, the shrinkable core (100) comprises a first wall (110) and a second wall (120), a first side element (112) and a second side element (122), and a spacing element (130). The first wall (110) and second wall (120) are spaced from to each other by a first distance (d1) to define an internal region (115) in-between. The first side element (112) and the second side element (122) are arranged to close opposite edge portions of the spaced first wall (110) and second wall (120) such that fluid concrete cannot pass the opposite edge portions to get into the internal region (115), the first side element (112) and second side element (122) being spaced by a second distance (d2). The spacing element (130) is configured to vary at least one of the first distance (d1) and the second distance (d2) such that a circumference along the first and second walls (110, 120) and the first and second side elements (112, 122) shrinks monotonically with lowering said at least one distance.

Owner:ALWATAN UNITS CO

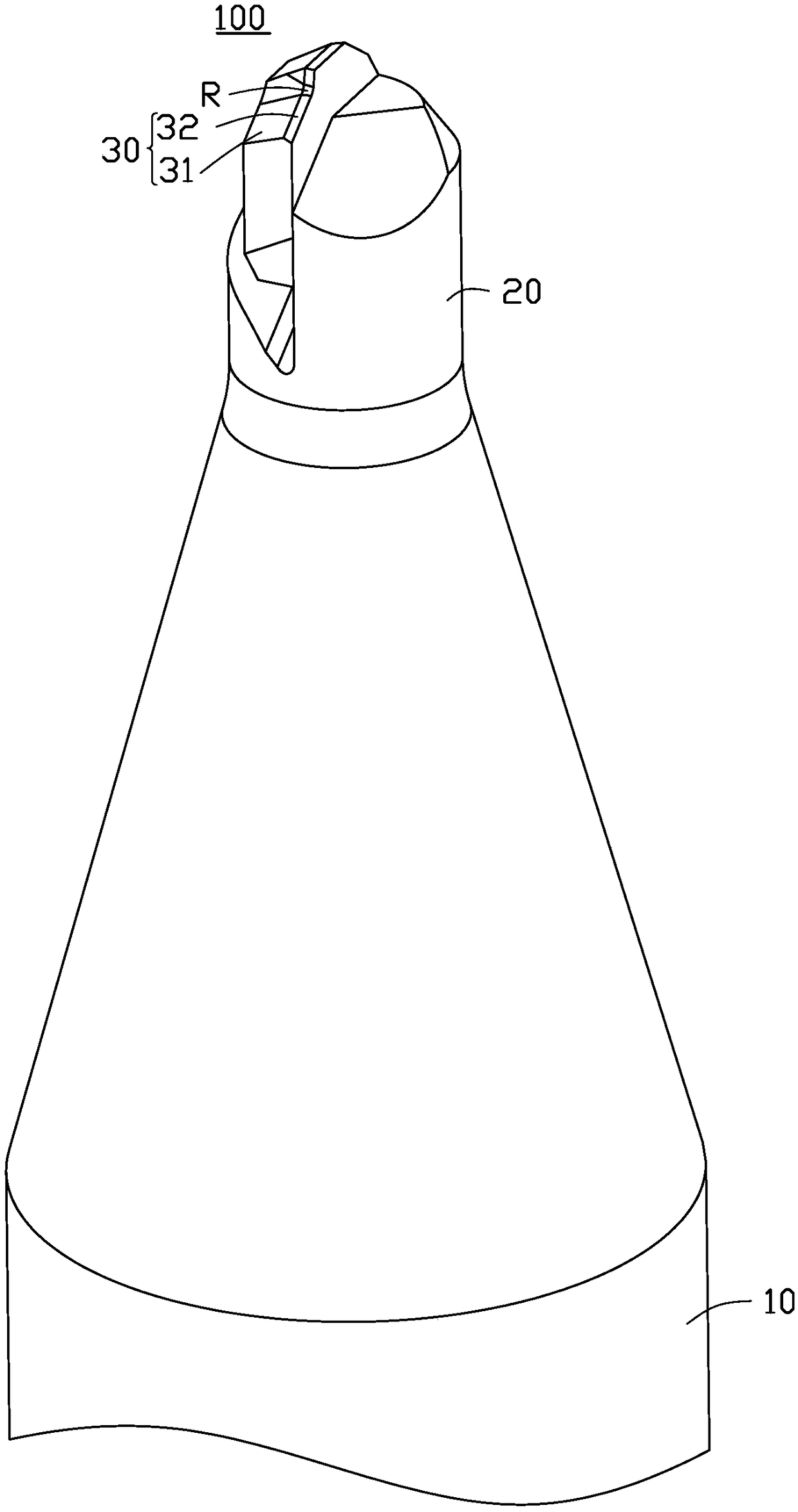

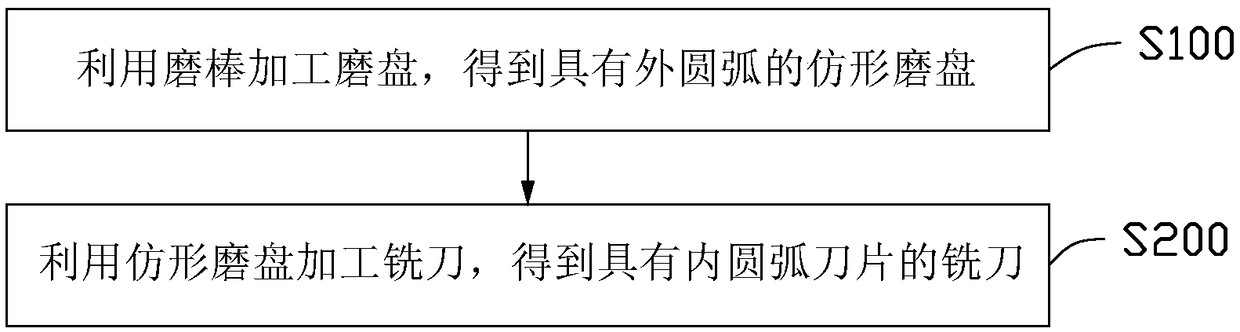

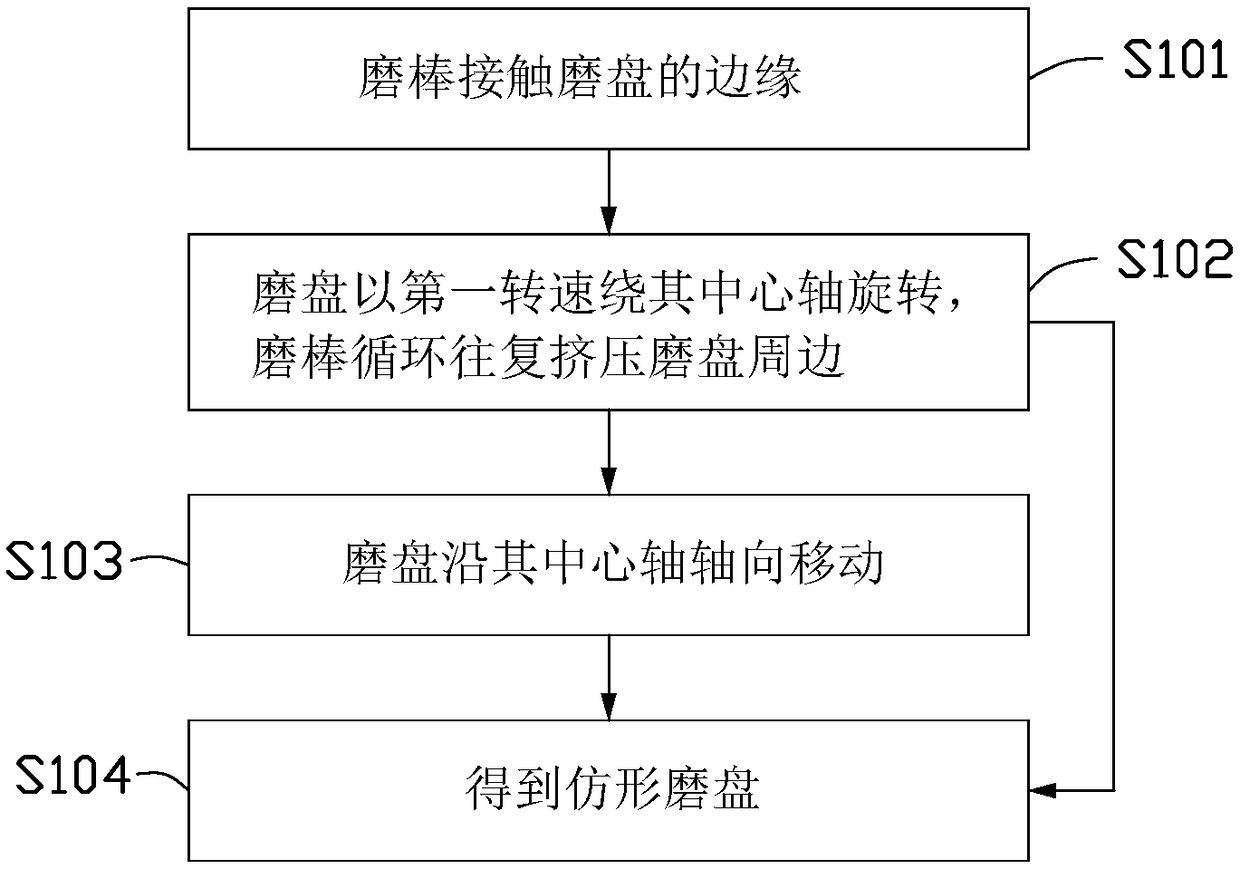

Milling cutter machining method

InactiveCN109158962AImprove processing efficiencyHigh quality surfaceMilling cuttersNumerical controlMilling cutter

The invention provides a milling cutter machining method. The milling cutter machining method adopts a numerical control grinding device, the numerical control grinding device comprises a grinding disc, a grinding bar and a milling cutter mounting device, and the milling cutter machining method comprises following steps that the grinding bar is used for machining the grinding disc, and the profiling grinding disc with the outer arc is obtained; the profiling grinding disc is used for machining a milling cutter, and the milling cutter with an inner arc blade is obtained. The milling cutter machining method is high in machining efficiency, the arc edge of a product machined by the milling cutter obtained through the method is regular, the product has highlight and high brightness, and free of burrs, and the product with the high-quality surface is obtained.

Owner:JIZHUN PRECISION IND HUIZHOU

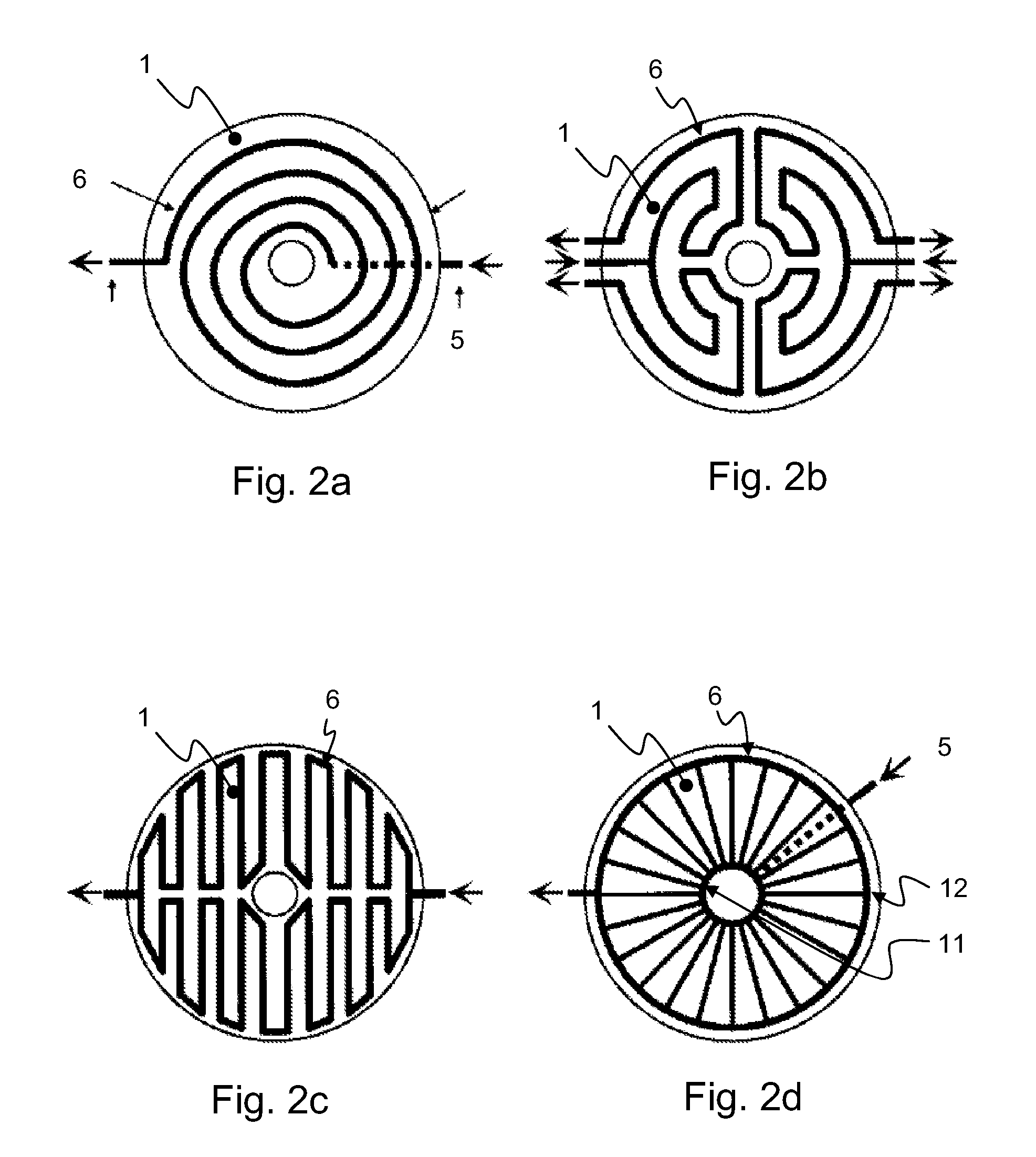

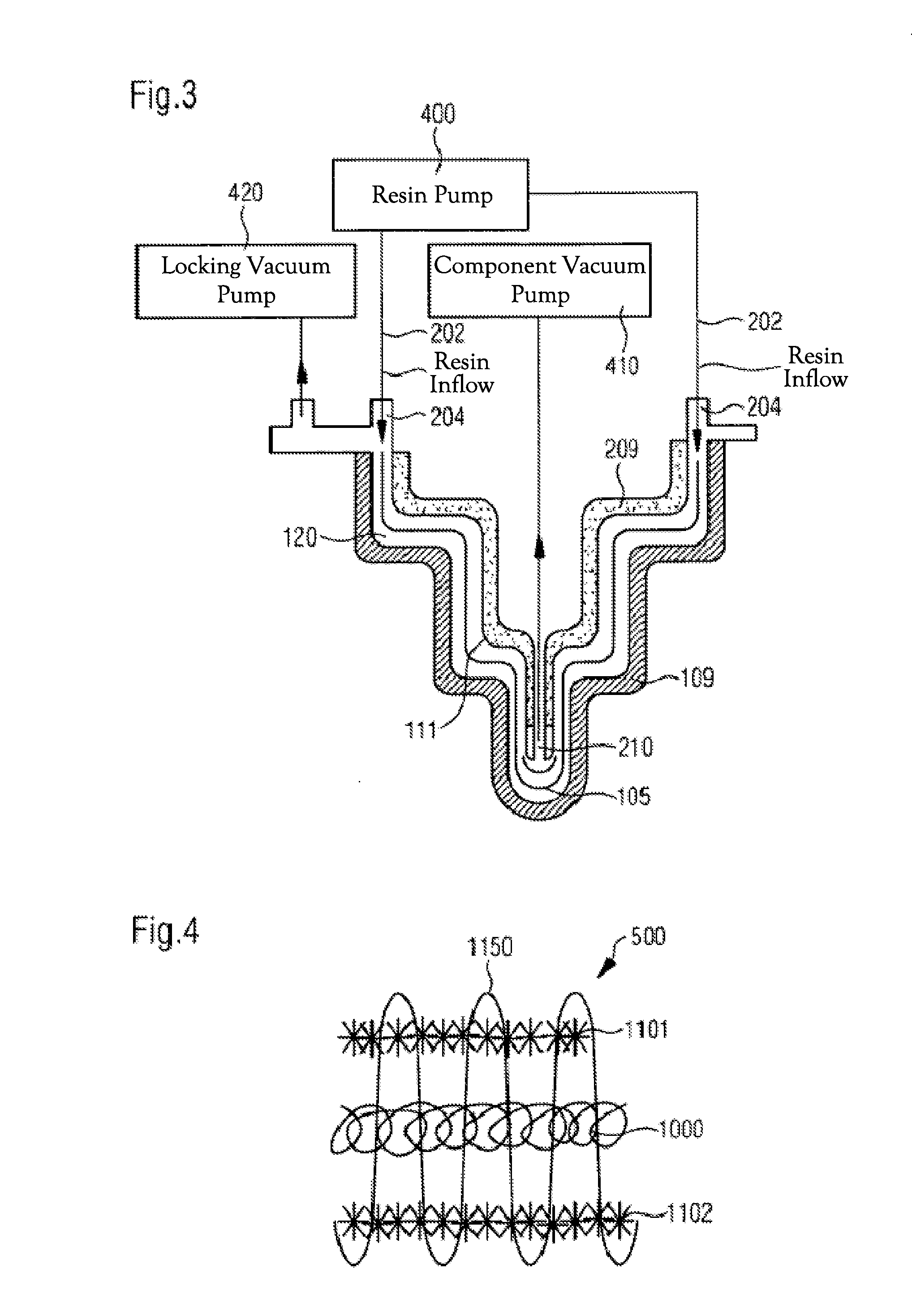

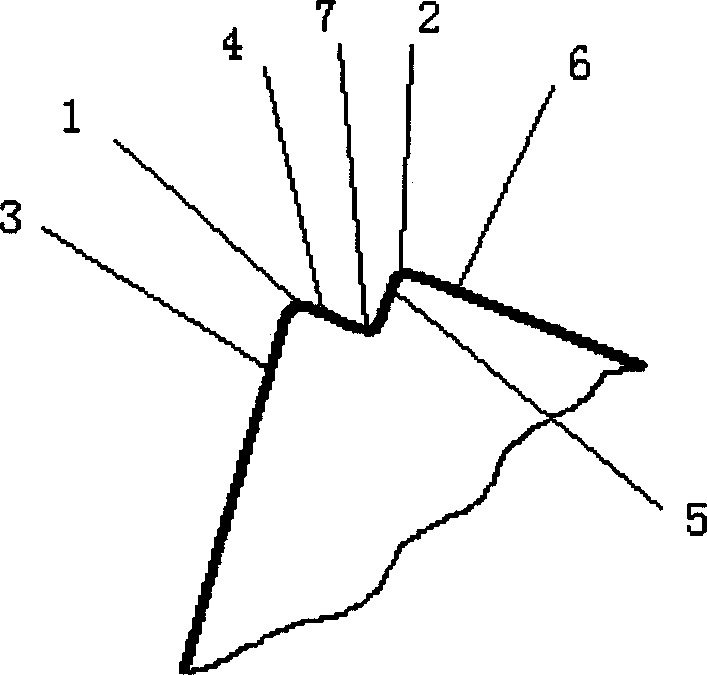

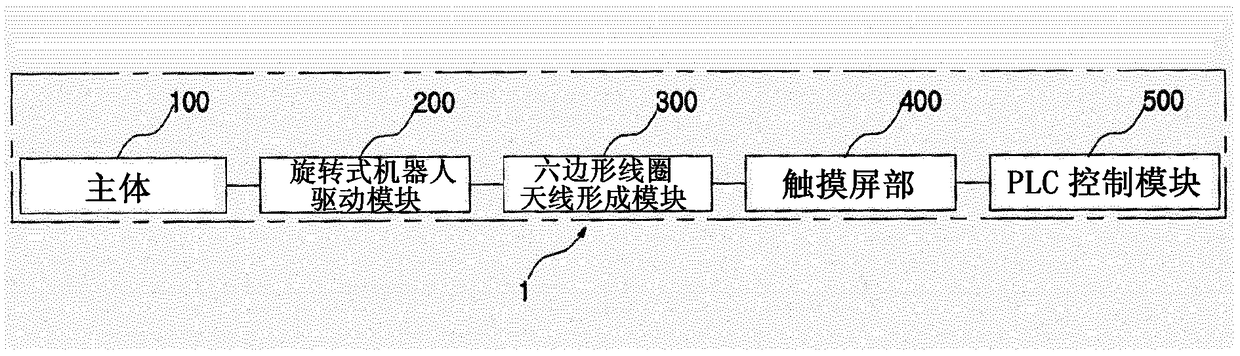

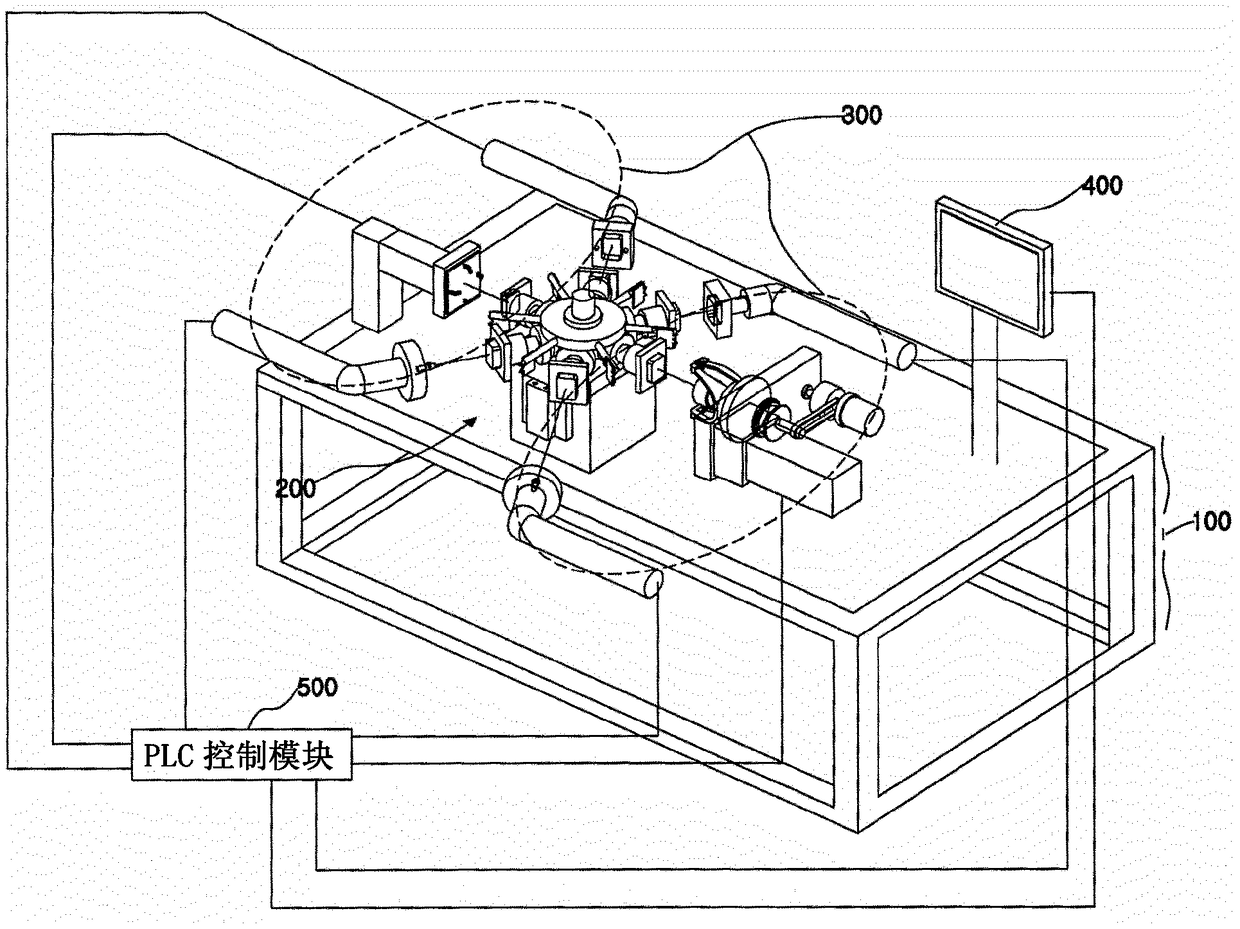

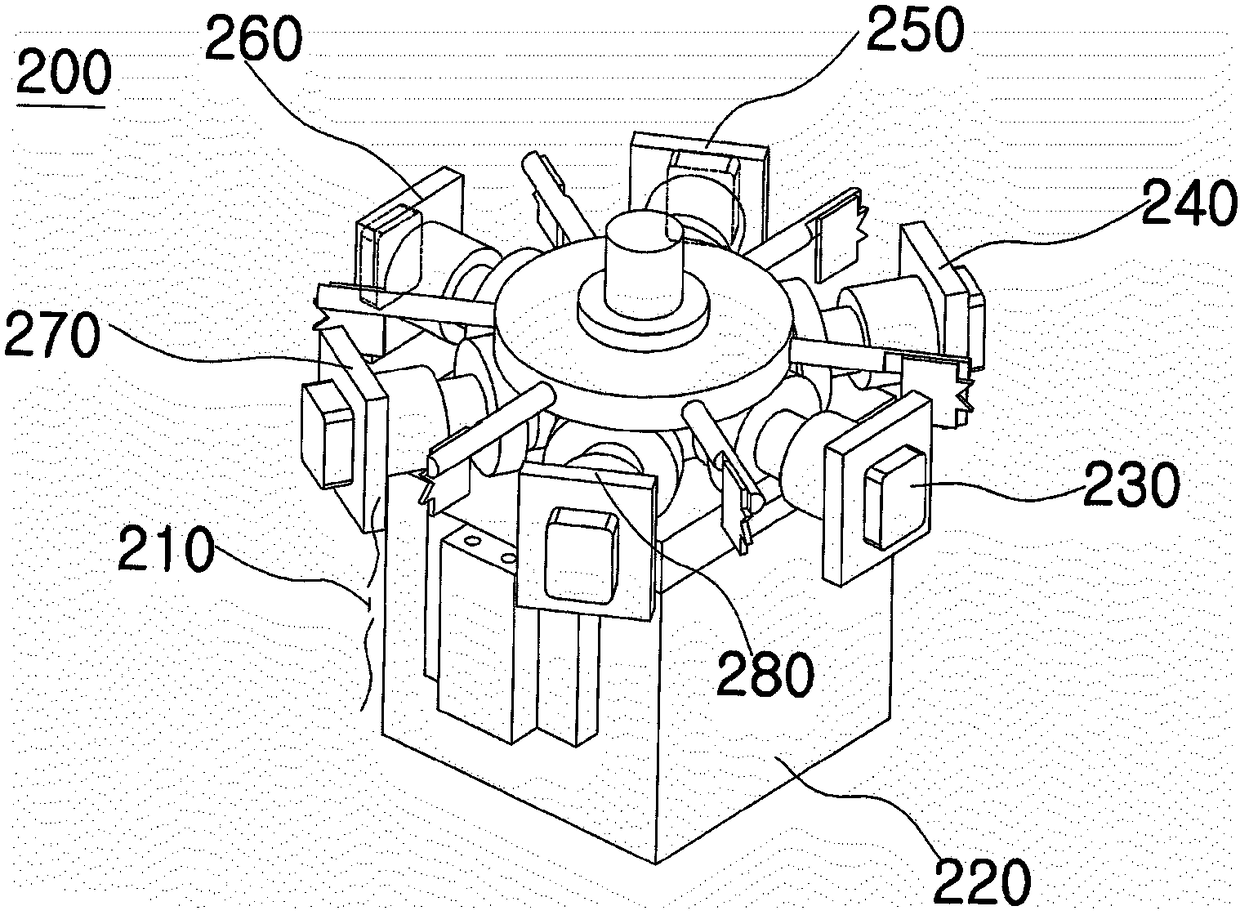

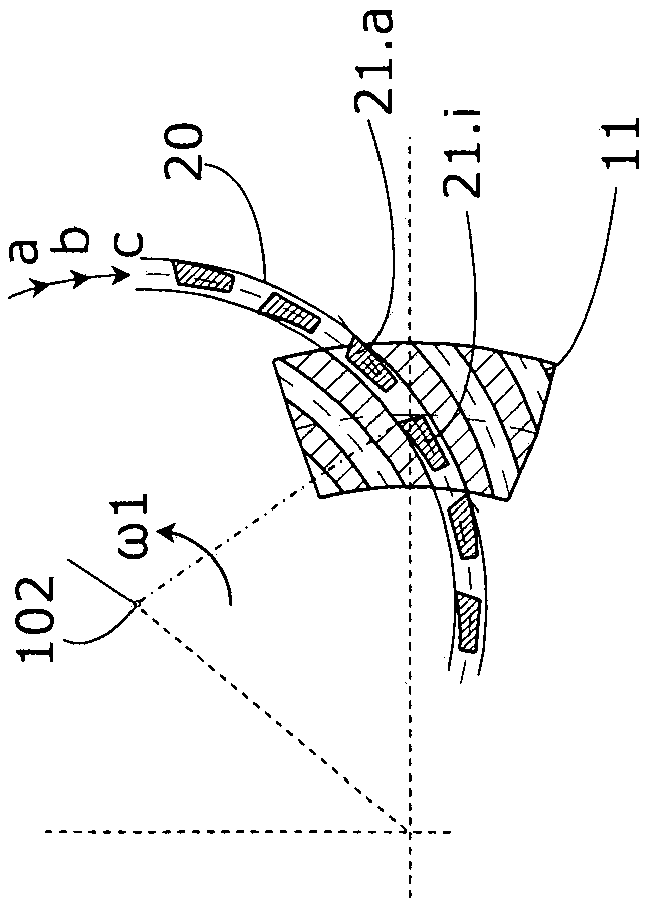

Rotary-type smart automatic manufacturing apparatus for planar coil antenna

ActiveCN108370097AFully automatedReduce labor costsProgramme-controlled manipulatorAntenna supports/mountingsWire rodEngineering

The objective of the present invention is to provide a rotary-type smart automatic manufacturing apparatus for a planar coil antenna, the apparatus comprising: a main body (100); a rotary-type robot drive module (200); a hexagon coil antenna forming module (300); a touch screen unit (400); and a PLC control module (500), whereby the apparatus can automatically form a planar coil antenna with a flattened surface by performing planar-coil winding, pressing, cold-pressing, transferring, air spraying, and preheating processes on a received planar rectangular wire while sequentially rotating at oneplace in a rotary manner, which makes it possible to: do a work without a plurality of workers and reduce 80% of personnel expenses over the related art through the automation of the entire process;manufacture a good planar coil antenna with a uniformly-flattened surface by primarily flattening the coil antenna using the force of a press and secondarily flattening the coil antenna using the force of a press and a cold-spraying process when manufacturing the planar rectangular coil antenna; and mass-produce a planar coil antenna with a flattened surface through planar-coil winding, pressing,cold-pressing, transferring, air spraying, and pre-heat driving processes using first to sixth robot arms driven under the control of the PLC control module.

Owner:TOMSCO +1

Fire-retardant composite materials

ActiveUS11149126B2Improve mechanical propertiesReduce/eliminate fill and fairingSynthetic resin layered productsVehicle componentsEpoxyPolymer science

A prepreg for the manufacture of a fibre-reinforced composite material having fire retardant properties, the prepreg comprising from 42 to 52 wt % of an epoxide resin matrix system and from 48 to 58 wt % fibrous reinforcement, each wt % being based on the total weight of the prepreg, the fibrous reinforcement being at least partially impregnated by the epoxide resin matrix system;wherein the epoxide resin matrix system includes as components:a. a mixture of (i) at least one epoxide-containing resin and (ii) at least one catalyst for curing the at least one epoxide-containing resin; andb. a plurality of solid fillers for providing fire retardant properties to the fibre-reinforced composite material formed after catalytic curing of the at least one epoxide-containing resin,wherein the weight ratio of component a. to component b. is from 1.4:1 to 1.86:1.

Owner:GURIT (UK) LTD

Method for machining gear side face of bevel gear workpiece

ActiveCN109702276AImprove production efficiencyNo need for eccentric driveGear teeth manufacturing toolsGear-cutting machinesGear wheelCoupling

A method for machining a bevel gear workpiece, comprising the steps that the bevel gear workpiece is fastened on a first workpiece main shaft of a first multi-axis machine tool; a first cutterhead comprising at least one internal cutting edge and at least one external cutting edge is fastened to a tool spindle of the multi-axis machine tool, and continuous rotation driving is carried out on the first cutterhead; a single-indexing machining method is adopted, and a rough cutting bevel gear workpiece is used, and the rough-cut bevel gear workpiece is removed from the first multi-axis machine tool, performing heat treatment on the rough cutting bevel gear workpiece; the rough cutting bevel gear workpiece is fastened on a workpiece main shaft of the second or the first multi-axis machine tool,and the second cutter disc is fastened to the first multi-axis machine tool or the second multi-axis machine tool, wherein the second cutterhead comprises an internal cutting edge and an external cutting edge which are arranged in a grouping mode; continuous rotation driving is carried out on the rough-cut bevel gear workpiece, and the coupling of the second cutterhead is driven continuously, anda continuous indexing machining method is adopted to finish machining of the concave tooth side surface and the convex tooth side surface of the bevel gear workpiece.

Owner:KLINGELNBERG AG

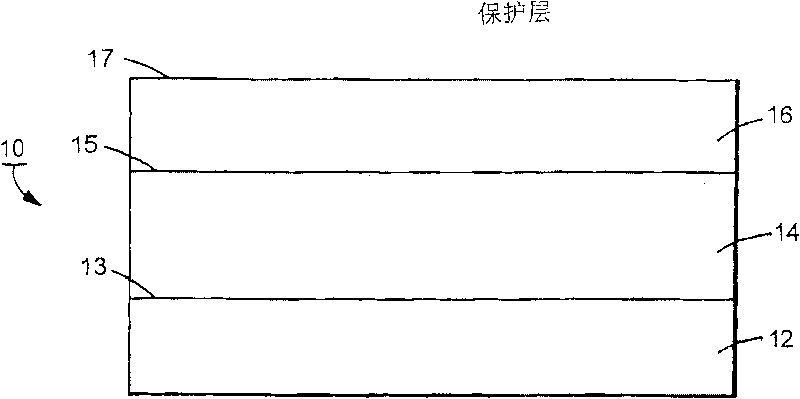

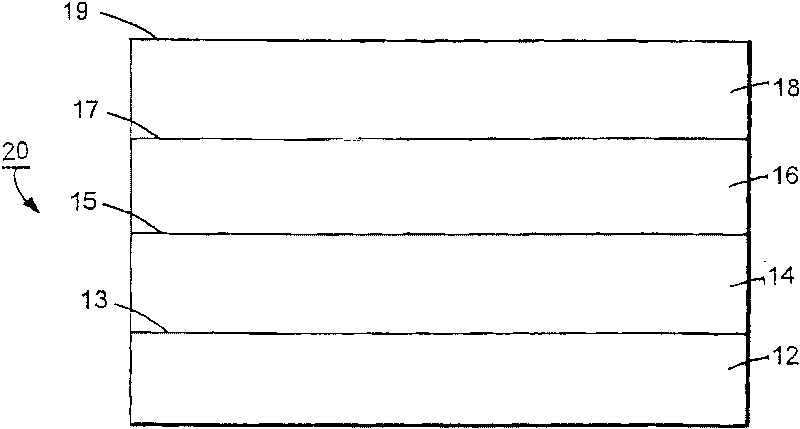

Multi-layer articles and method of making same

InactiveCN1364321BReduce widthHigh quality surfaceFrom gel statePolycrystalline material growthVolumetric Mass DensityMaterials science

The invention relates to multi-layer articles and methods of making such articles. The methods include first conditioning an underlying layer, such as a buffer layer or a superconductor layer, then disposing a layer of material on the conditioned termination plane. The conditioned termination plane can be a high quality termination plane. Superconductor articles formed by these methods can exhibitrelatively high critical current densities.

Owner:AMERICAN SUPERCONDUCTOR

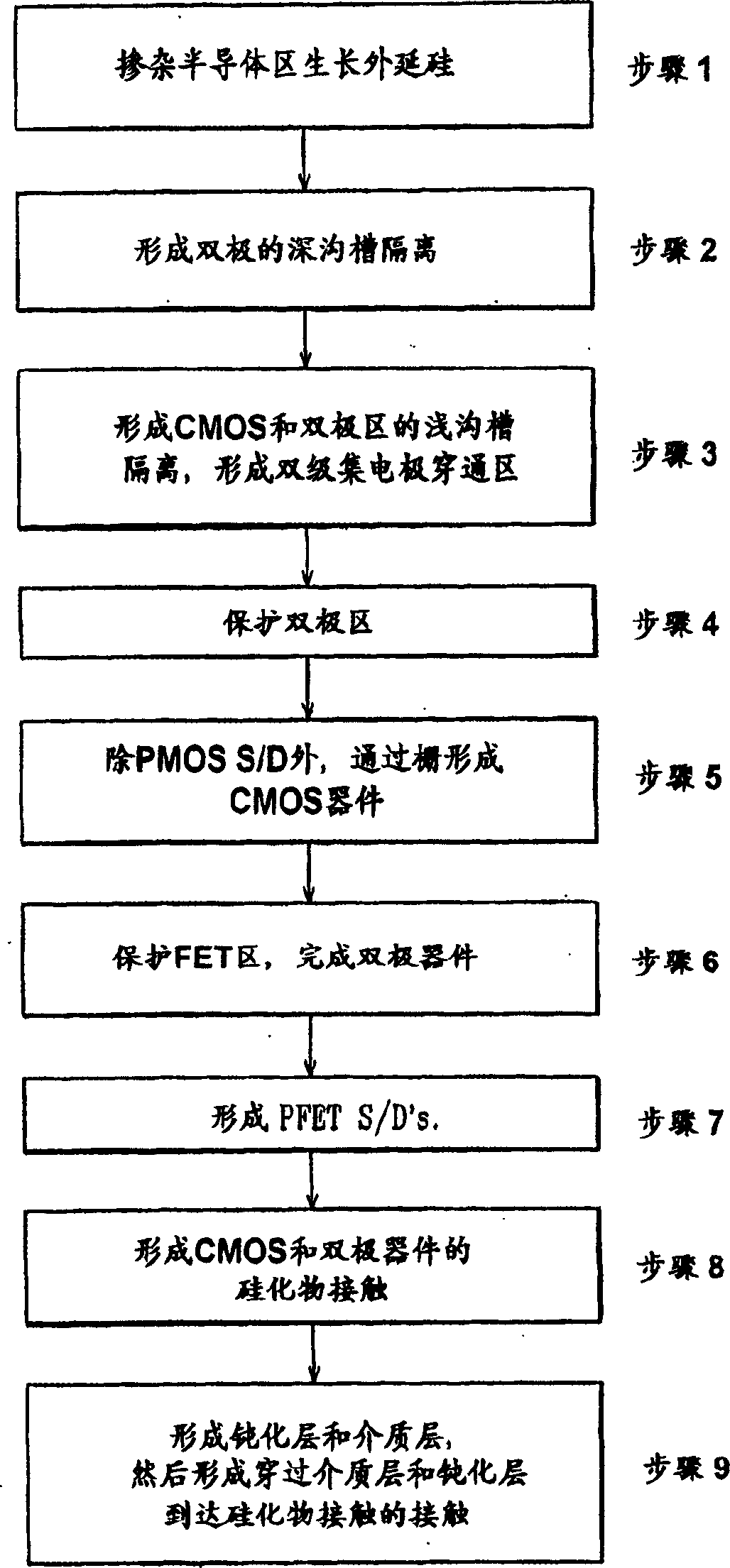

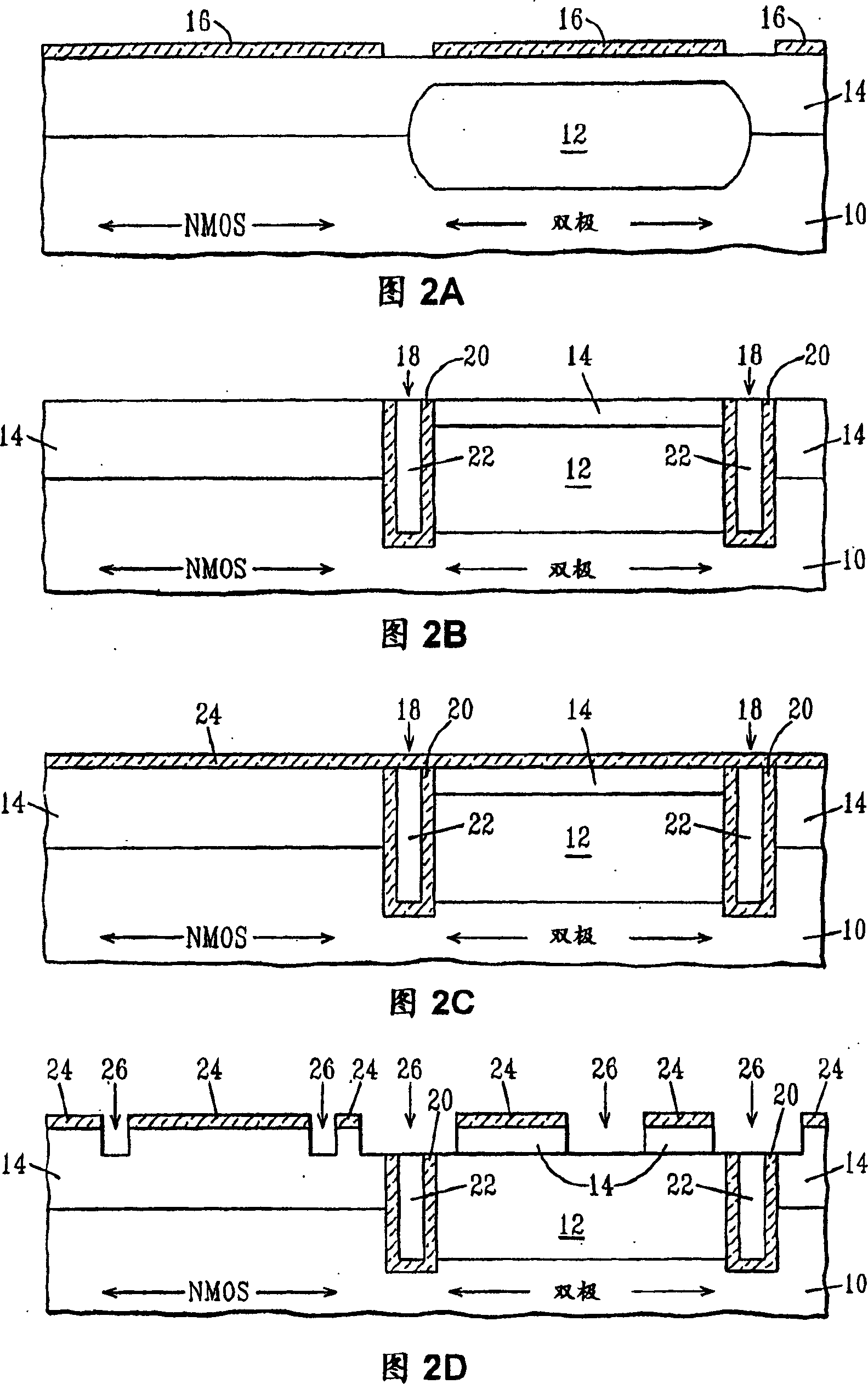

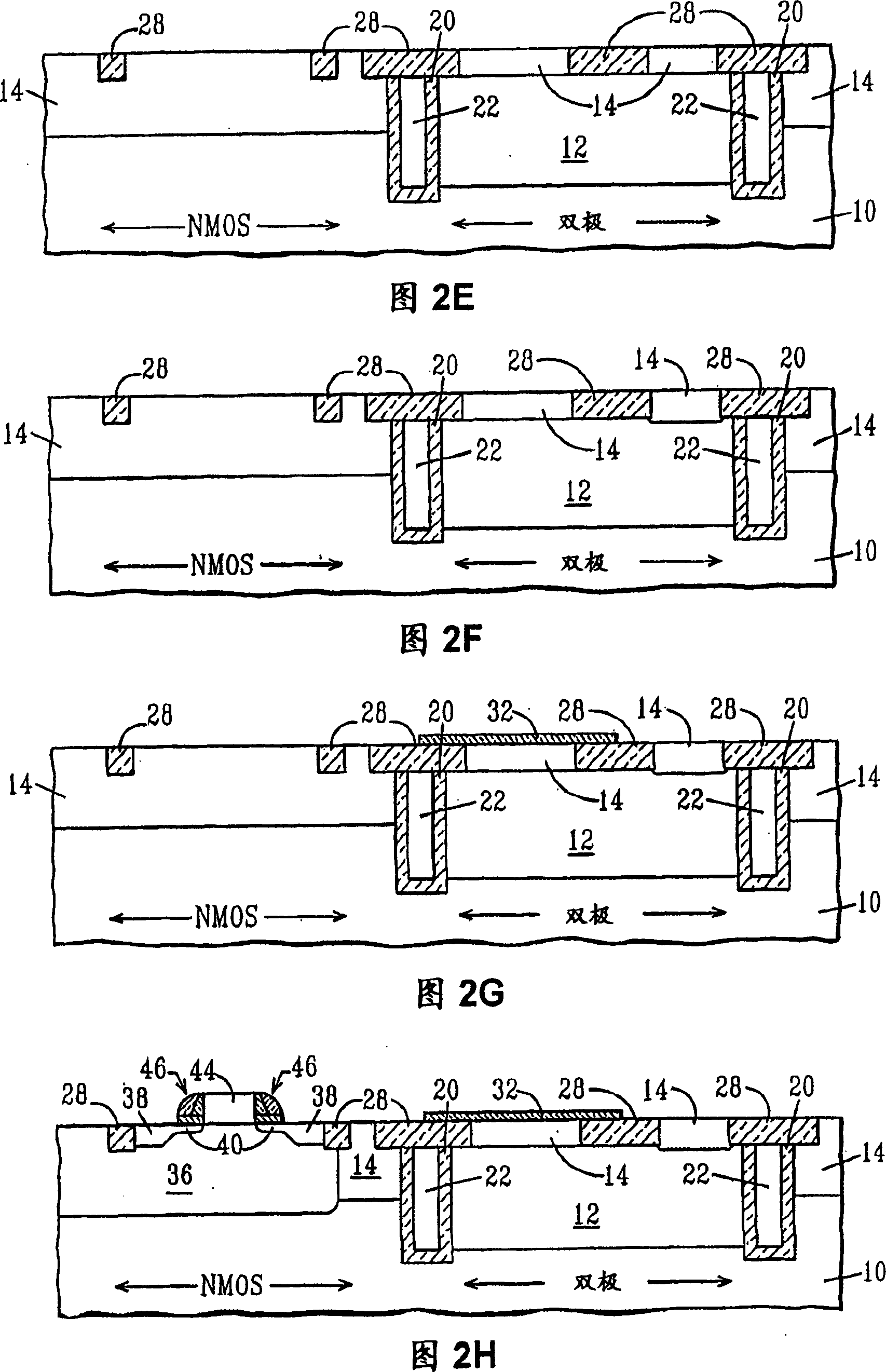

Method of epitaxial bipolar device and complementary metallic oxide semiconductor device

InactiveCN1157780CHigh quality surfaceTransistorSolid-state devicesOxide semiconductorIntegrated circuit

A method of forming a semiconductor integrated circuit such as a BiCMOS integrated circuit comprises the steps of: (a) forming a first portion of a bipolar device in a first region of a substrate; (b) forming a first protective layer over the first region to protect the first portion of the bipolar devices; (c) forming field effect transistor devices in second regions of the substrate; (d) forming a second protective layer over the second regions of the substrate to protect the field effect transistor devices; (e) removing the first protective layer; (f) forming a second portion of the bipolar devices in the first region of the substrate; and (g) removing the second protective layer.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com