Method for machining gear side face of bevel gear workpiece

A processing method and technology of bevel gears, which are applied to gear tooth manufacturing devices, gear tooth manufacturing tools, components with teeth, etc. Cutting, high production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

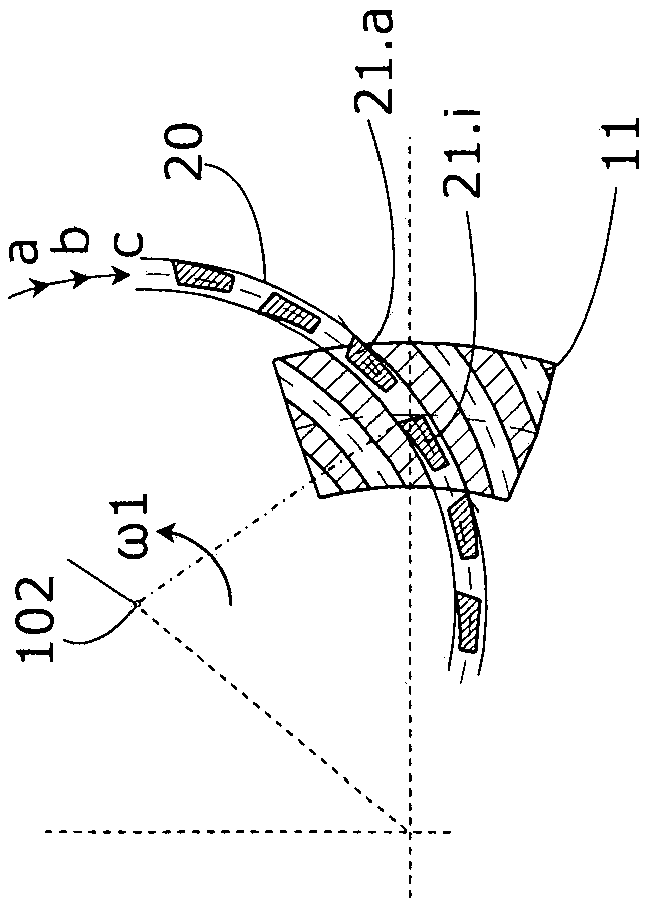

[0065] exist Figure 1A An exemplary basis for the single-index method (also known as intermittent index method, single-index method, or face milling) is shown in . Specifically, this is the single-division completion method.

[0066] The single-index half-finish method is used as the arc gear cutting method in the range of the first pass.

[0067] exist Figure 1A The single-division completion method is schematically shown in . In the present example, the common rolling motion of the bevel gear workpiece 11 and the cutterhead 20 , which occurs more slowly than the rotation ω1 of the cutterhead 20 , is not shown for the sake of simplicity. The picture shows a quasi-snapshot of the rolling process. The cutters 21.a, 21.i of the cutterhead 20 (for example the bar cutters of the bar cutterhead 20) perform a continuous movement in the form of a circular arc. The rotational movement of the cutter head 20 (here counterclockwise) is indicated by the arrow marked with ω1. To crea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com