Method and device for machining high-quality tiny through hole of hard and crisp material

A processing method and technology for hard and brittle materials, which are used in grinding devices, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in guaranteeing the quality of the aperture edge, tool damage, angle error, etc., and achieve simple and feasible means and devices. High-quality surfaces and machining, the effect of high-efficiency machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

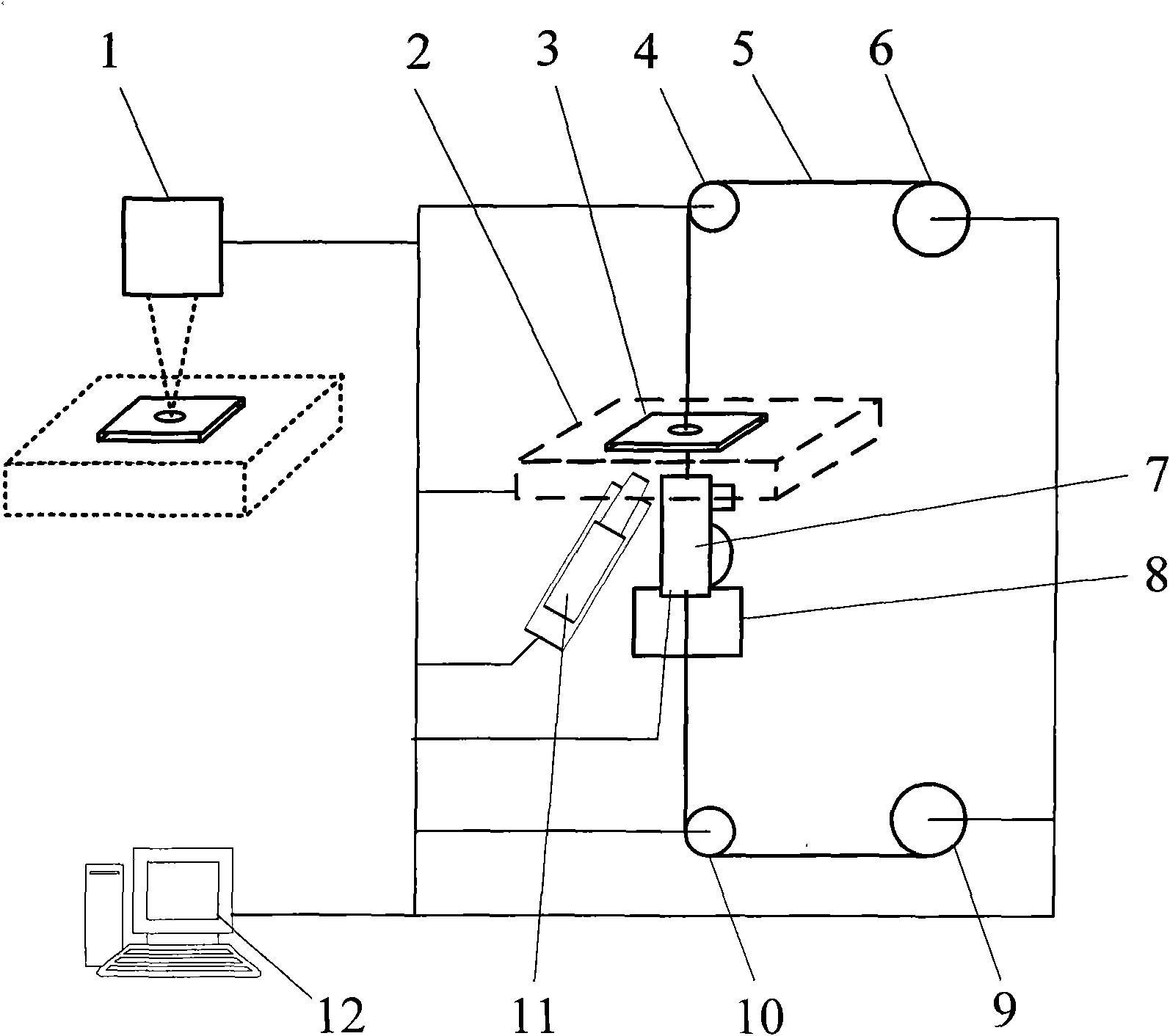

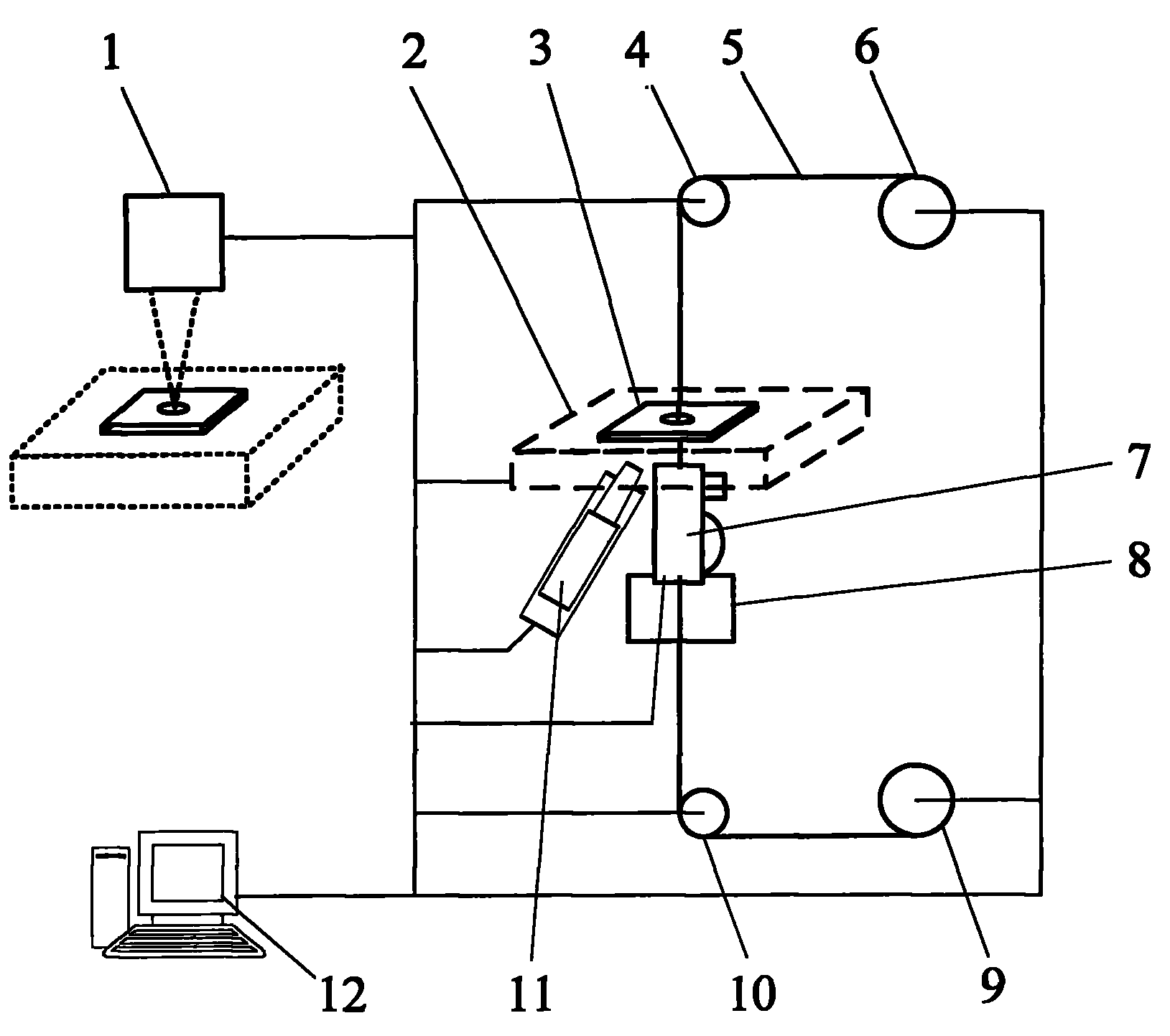

[0022] First, according to the material properties and processing technology of the workpiece 3, select the appropriate laser parameters to process the blank hole of the workpiece 3, and form a through hole on the workpiece. The aperture is slightly lower than the target diameter and larger than the diameter of the grinding wire 5, and then the workpiece 3 is installed. On the three-dimensional mobile clamping workbench 2 , estimate the position of the blank hole so that it is facing the grinding wire clamping guide wire device 7 under the three-dimensional mobile clamping workbench 2 .

[0023] The grinding wire 5 is wound on the rear wire disc 9, and the upper end of the grinding wire 5 is clamped into the grinding wire clamping wire guide device 7 through the rear guide wheel 10, and the clamping process is realized by the clamping knob of the grinding wire clamping wire guide device 7 , the degree of clamping needs to be controlled within a certain limit: the grinding wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com