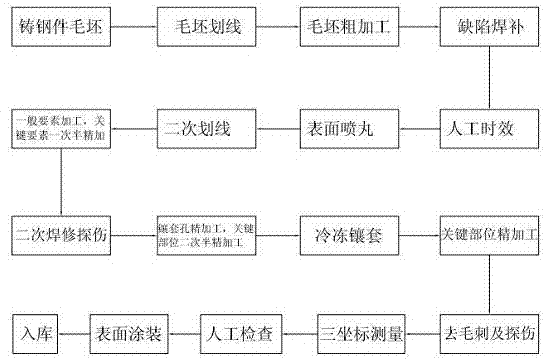

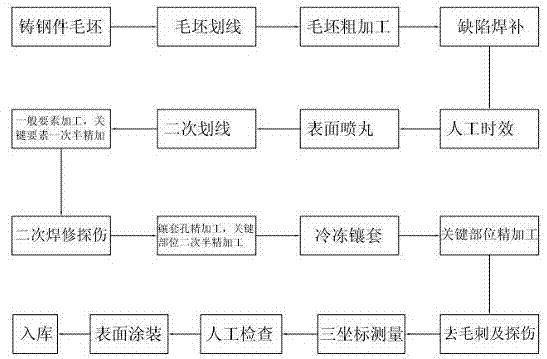

Process for controlling deformation of axle-hung box of locomotive

A shaft-holding box and process technology, which is applied in the field of locomotive shaft-holding box processing, can solve the problems of difficult machining of the axle-holding box and poor machining accuracy, and achieve the effects of ensuring quality, eliminating blanks, and reducing tooling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Steel casting blank: the axle holding box is a steel casting blank, and the overall steel casting blank is prepared, with a mass of 150Kg;

[0031] 2. Blank scribing: marking processing calibration datum line and rough machining surface and hole processing line: bearing holes and end faces at both ends of the shaft holding box, outer arc, upper mounting surface, lower mounting surface and inner opening at both ends;

[0032] 3. Rough machining of the blank: machining the bearing holes and end faces, the upper mounting surface, the lower mounting surface, the outer arcs at both ends, the left and right sides, and the inner openings at both ends of the shaft holding box;

[0033] 4. Defect welding repair: Welding repair is required for casting defects exposed after rough machining, such as shrinkage cavity, looseness, and insufficient processing allowance due to deformation;

[0034] 5. Artificial aging: conduct heat treatment on the rough-machined axle box with a...

Embodiment 2

[0053] 1. Steel casting blank: the axle holding box is a steel casting blank, and the overall steel casting blank is prepared, with a mass of 230Kg;

[0054] 2. Blank scribing: marking processing calibration datum line and rough machining surface and hole processing line: bearing holes and end faces at both ends of the shaft holding box, outer arc, upper mounting surface, lower mounting surface and inner opening at both ends;

[0055] 3. Rough machining of the blank: machining the bearing holes and end faces, the upper mounting surface, the lower mounting surface, the outer arcs at both ends, the left and right sides, and the inner openings at both ends of the shaft holding box;

[0056] 4. Defect welding repair: Welding repair is required for casting defects exposed after rough machining, such as shrinkage cavity, looseness, and insufficient processing allowance due to deformation;

[0057] 5. Artificial aging: conduct heat treatment on the rough-machined axle box with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com