Base-adjustable fixture for elongated workpiece with outer contour needing to be milled

A technology of long workpieces and outer contours, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of high labor intensity, damage of fixtures, and long processing time, so as to improve operation safety and avoid bending Or deformation, to ensure the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

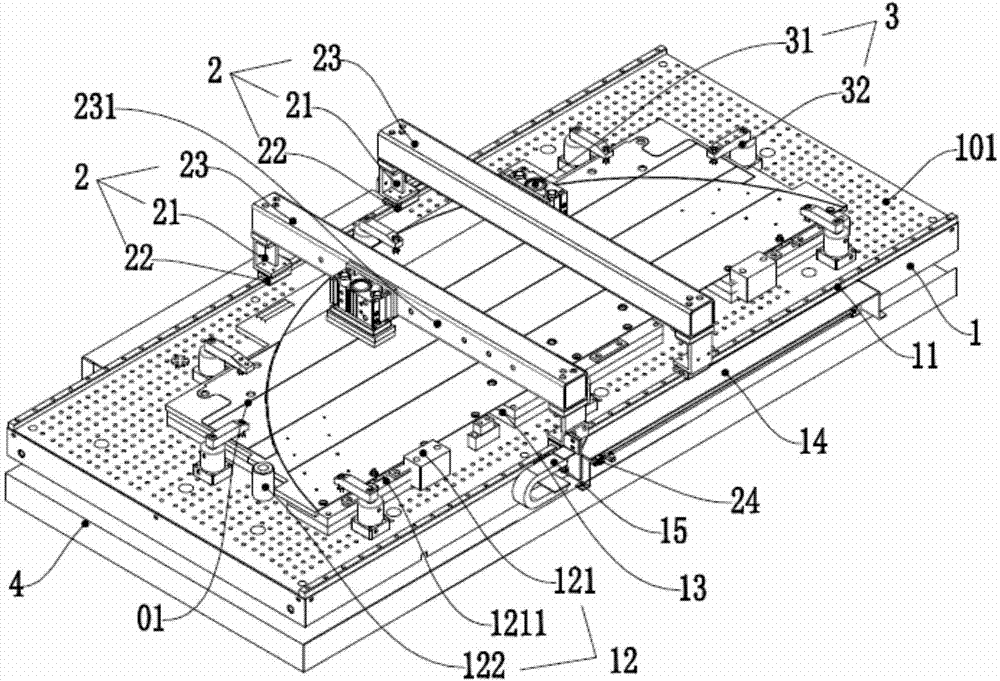

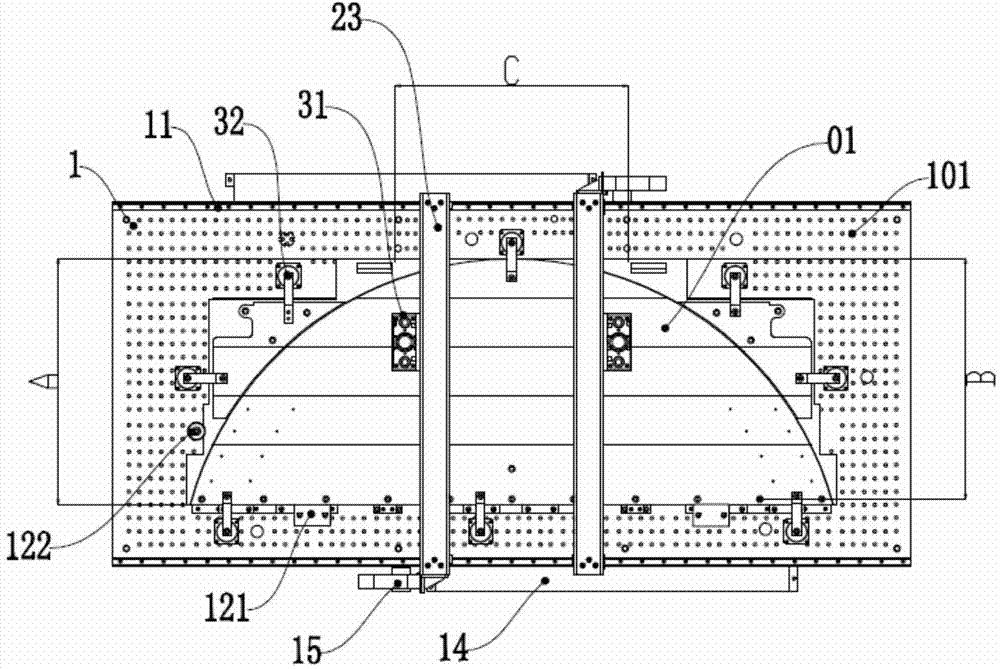

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0027] An adjustable base fixture for a long workpiece whose outer contour needs to be milled, comprising a base 1, a moving gantry device 2, a positioning device 3, a chip collection groove 4 and a control system;

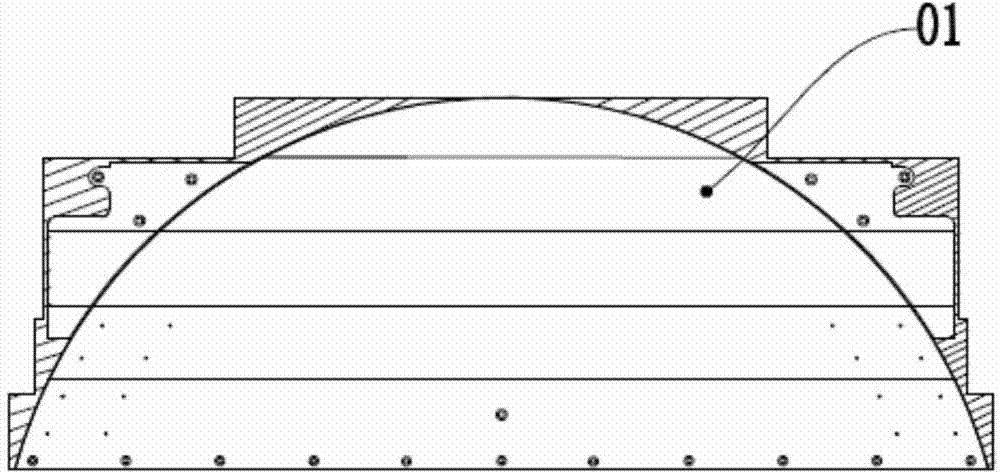

[0028] The upper and lower sides of the base 1 are respectively equipped with a transverse guide rail 11, and the upper surface of the base 1 is provided with a plurality of installation through holes 101 vertically and horizontally, and the upper surface of the base 1 is provided with a limit position for limiting the blank workpiece 01. device 12, the limiting device 12 is arranged on the base 1 at intervals through the installation through holes 101 according to the outer contour shape of the rough workpiece 01 to be processed, and the chip collecting groove 4 is arranged on the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com