Surface finish method for magnesium alloy parts

A surface processing and magnesium alloy technology, applied in metal processing equipment, surface-polished machine tools, manufacturing tools, etc., can solve problems such as low degree of automation, and achieve the effect of improving processing efficiency and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Embodiments of the present invention will be described in detail below with reference to the drawings.

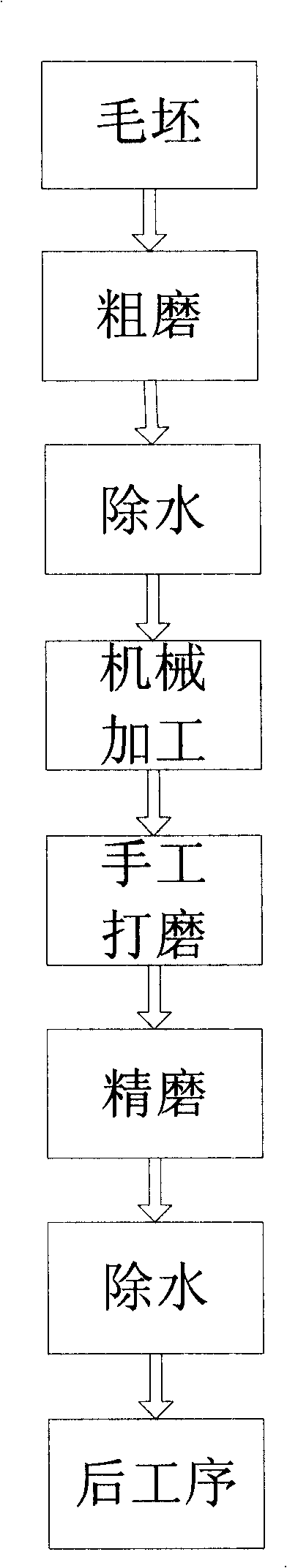

[0010] like figure 1 As shown, the surface processing method of the magnesium alloy part provided by the present invention comprises first rough grinding the blank of the magnesium alloy part, and then performing fine grinding on the blank, wherein the rough grinding and fine grinding include respectively rough grinding and fine grinding. Under the condition of grinding, the magnesium alloy part blank, abrasive material and water-containing grinding liquid are put into the grinding container of the grinding machine for grinding, and after rough grinding and fine grinding, within 20 minutes, preferably 3-15 minutes, remove the rough grinding and Water on the surface of the blank after fine grinding.

[0011] In the processing technology of magnesium alloy, at first use die-casting technology to make magnesium alloy material have basic shape, then carry out mechanical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com