Multi-layer articles and method of making same

A technology for multi-layer products and deposition layers, which can be used in manufacturing tools, chemical instruments and methods, cable/conductor manufacturing, etc. The effect of high density and low impurity density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0164] Prepare a precursor solution as described below. About 51.4gY(CH 3 CO 2 ) 3 4H 2 O was dissolved in about 514 g of water. About 77.6gBa(CH 3 CO 2 ) 2 Dissolved in about 388g of water, about 91gCu(CH 3 CO 2 ) 3 2H 2 O was dissolved in about 1365 g of water. These three solutions are then mixed together. About 243 g of the solution obtained are mixed with about 10 ml of pure trifluoroacetic acid. The solution was dried under vacuum at about 60°C until all solvent was removed and only solids remained. The solid was then dissolved in methanol and diluted to a total volume of about 50 ml to form a precursor solution.

Embodiment 2

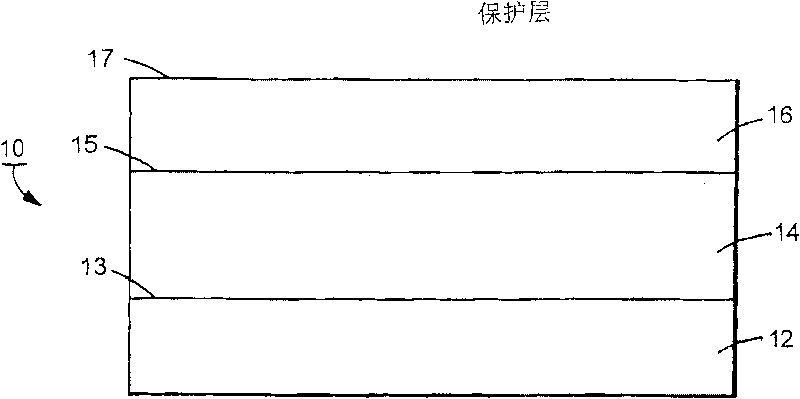

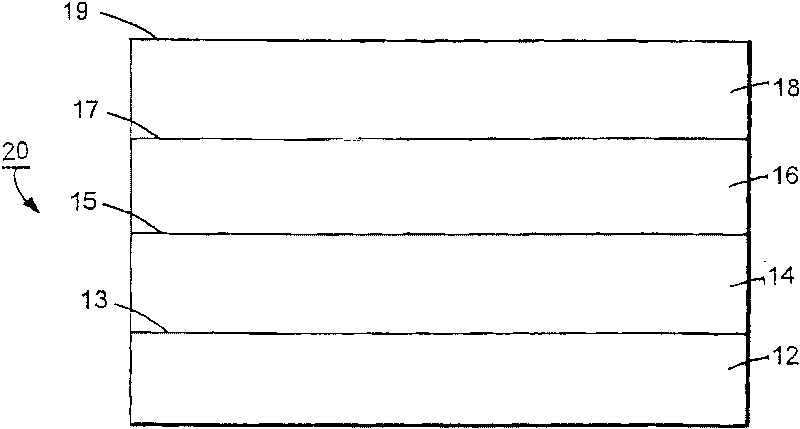

[0166] A multilayer article was prepared as follows. The precursor solution prepared in Example 1 was spin-coated on a CeO 2 / YSZ / CeO 2 / Ni buffered substrate.

[0167] The buffered substrate was prepared by rotationally deforming a nickel sample to over about 97% to form a ribbon. Annealing the ribbon at about 1000°C for about 1 hour forms a fine cubic textured material. Using electron beam evaporation and at a temperature of about 625 °C, a CeO with a thickness of about 30 nm 2 Layers were deposited on the textured nickel surface at a rate of about 1 Angstrom / sec. A ~300 nm thick layer of YSZ was deposited at a rate of ~0.5 Å / s on CeO using RF sputtering at a temperature of ~725 °C. 2 layer. Using radio frequency sputtering and at a temperature of about 725 °C, a CeO with a thickness of about 20 nm 2 Layers were deposited on the YSZ layer at a rate of about 0.7 Angstroms / sec. The buffered CeO 2 / YSZ / CeO 2 / Ni substrate cut into two parts.

[0168] The spin coating...

Embodiment 3

[0173] A multilayer article was prepared as follows. The unused part of CeO prepared in embodiment 2 2 / YSZ / CeO 2 The Ni / Ni buffered substrate was incubated at 900° C. for about 1 hour in a gaseous environment with a nominal total gas pressure of forming gas (about 4 vol% hydrogen in argon) of about 760 Torr. The gas environment has approximately 1 x 10 -12 Hold to about 1×10 -16 Torr's nominal oxygen pressure. The precursor solution prepared according to Example 1 was spin-coated on CeO 2 / YSZ / CeO 2 / Ni buffer substrate on the conditioned surface, decomposed and further heated according to Example 2. The resulting YBa was determined by transmission measurements at 77 K in a self-field using a 1 µV / cm standard 2 Cu 3 o 7-x layer has approximately 1.34 x 10 6 The critical current density in amperes / cm².

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com