Rotary-type smart automatic manufacturing apparatus for planar coil antenna

A flat coil, coil antenna technology, applied in coil manufacturing, antenna support/installation device, antenna, etc., can solve problems such as long operation time, uneven antenna height, and reduced antenna performance, and achieve uniform surface and labor costs. saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Next, preferred embodiments according to the present invention will be described with reference to the drawings.

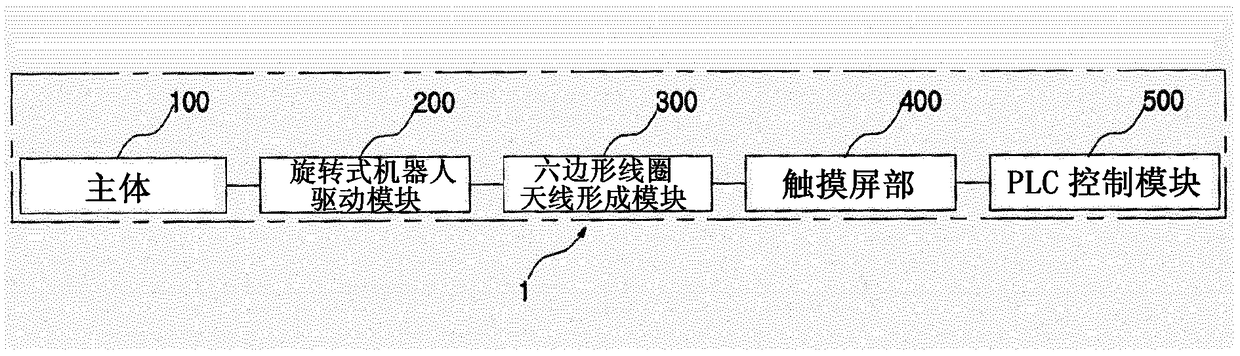

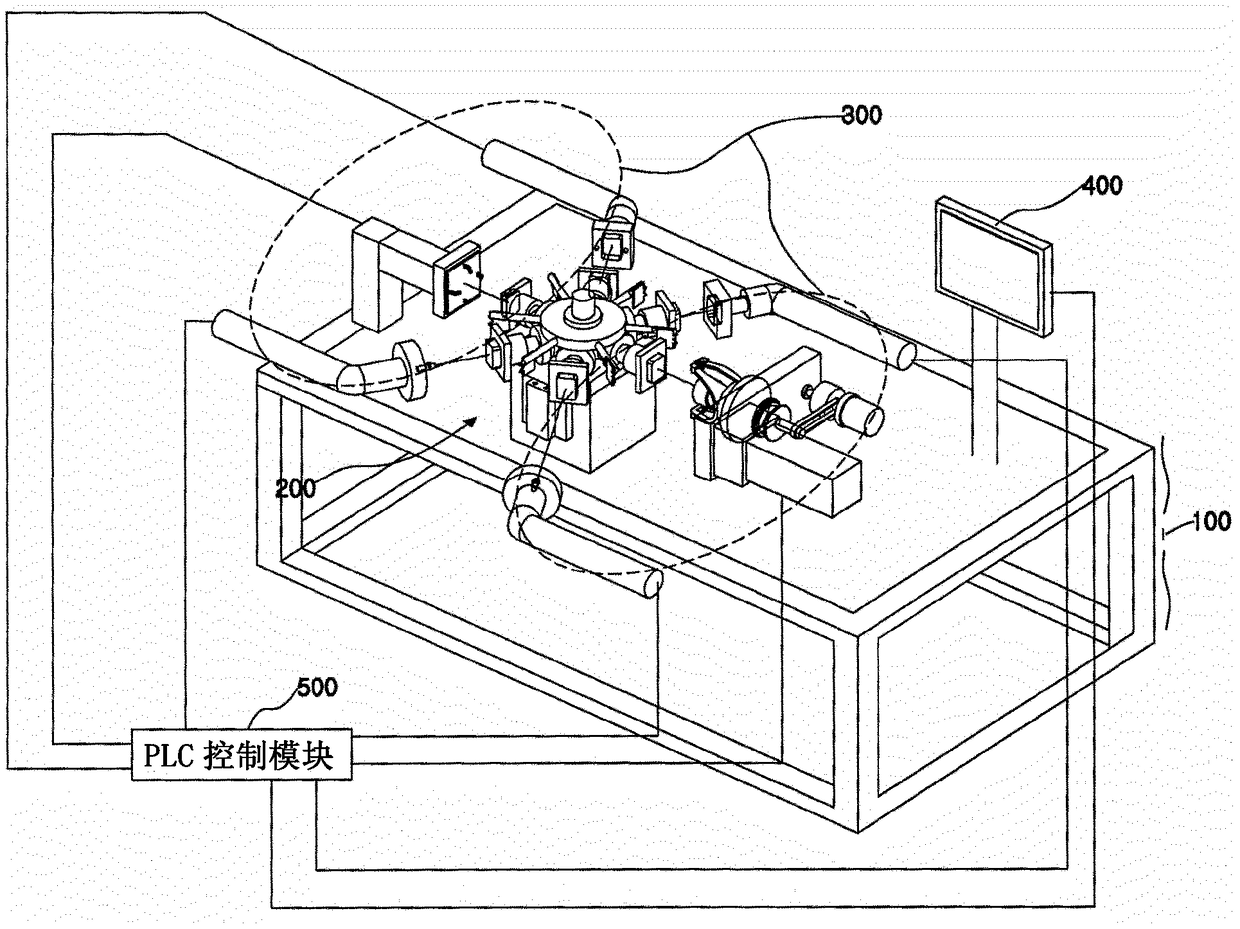

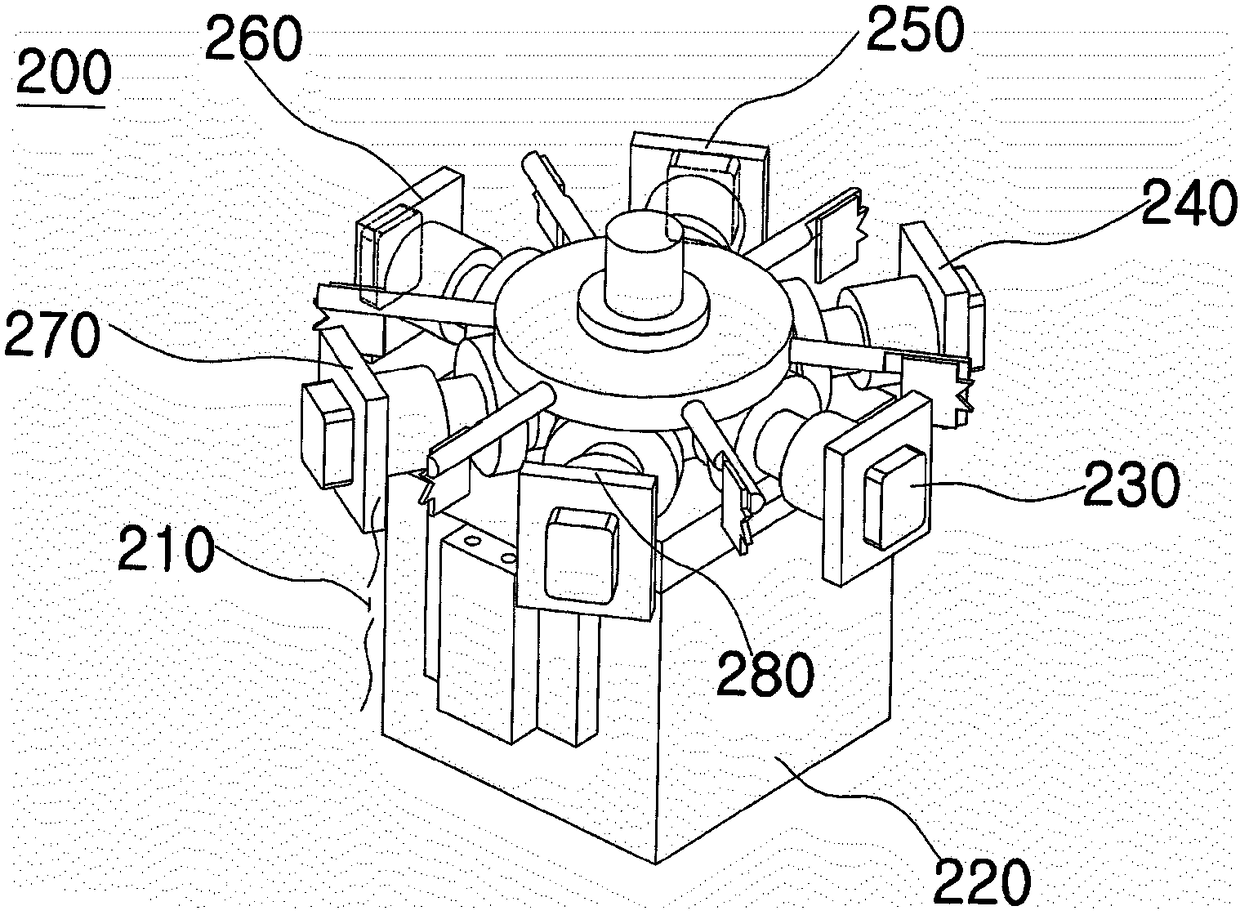

[0055] figure 1 It is a structural diagram showing the constituent elements of the rotary planar coil antenna intelligent automatic manufacturing device 1 according to the present invention, figure 2 It is a perspective view showing the constituent elements of the rotating planar coil antenna intelligent automatic manufacturing device 1 according to the present invention, which is configured to perform planar coil winding and punching while rotating in turn at one position after receiving a quadrangular planar wire , Cooling stamping, conveying, air injection, preheating, so as to automatically form a planar coil antenna with a flat surface.

[0056] More specifically, as figure 2 It is shown that the above-mentioned rotating planar coil antenna intelligent automatic manufacturing device 1 includes a main body 100 , a rotating robot driving module 200 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com