Preparation method of ZSM-35 molecular sieve

A technology of ZSM-35 and molecular sieve, applied in the field of preparation of ZSM-35 molecular sieve, can solve the problems of agglomeration and easy agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

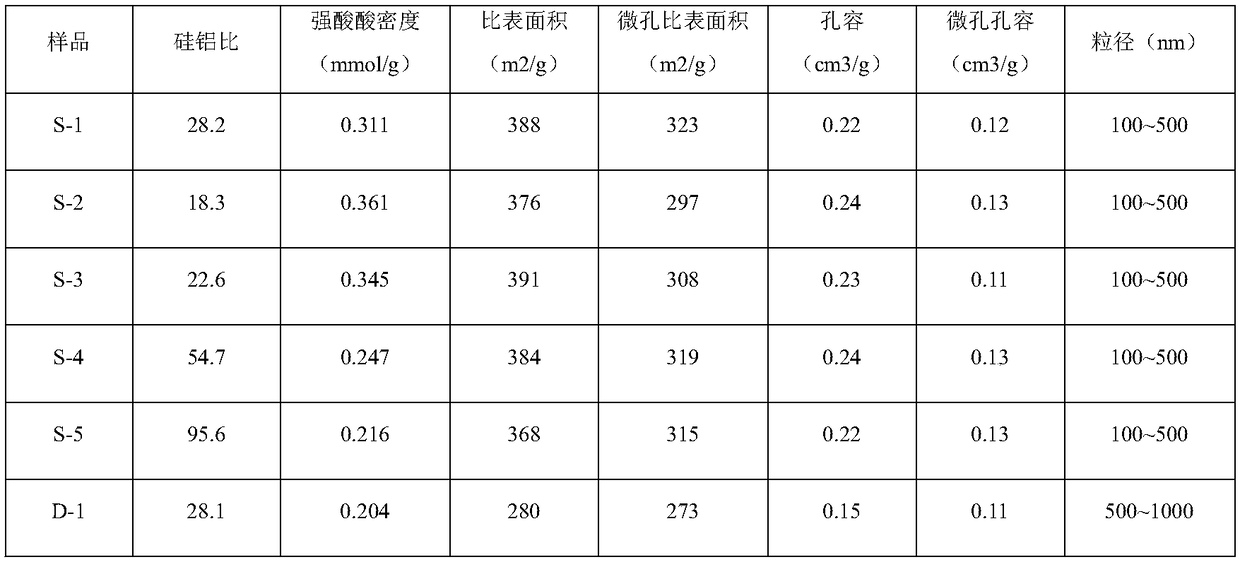

Embodiment 1

[0025] Aluminum sulfate (Al 2 o 3 7.08%) and ethylenediaminetetraacetic acid (CA) were mixed and stirred uniformly to obtain solution a. Solution a was aged at 60°C for 8h. The molar ratio of each component in solution a is H 2 O: Al 2 o 3 :CA=200:1.0:0.1.

[0026] Silica sol (SiO 2 25%), aluminum sulfate (Al 2 o 3 7.08%), liquid caustic soda (Na 2 (36.72%), cyclohexylamine, water and ZSM-35 molecular sieve seed crystals were mixed uniformly to obtain gel b. The molar ratio of each component in gel b is as follows: H 2 O:SiO 2 :Al 2 o 3 :Na 2 O: templating agent=10:1:0.01:0.1:0.3. The gel b was transferred to a crystallization kettle and crystallized at 120°C for 12h. After the crystallization is completed, add the solution a into the crystallization kettle. Crystallized at 170°C for 48h. After the crystallization is completed, a molecular sieve slurry is obtained. The ZSM-35 molecular sieve is obtained after separating the mother liquor, washing with wat...

Embodiment 2

[0028] Aluminum sulfate (Al 2 o 3 7.08%), disodium edetate (CA) were mixed and stirred uniformly to obtain solution a. Solution a was aged at 90°C for 18h. The molar ratio of each component in solution a is H 2 O: Al 2 o 3 :CA=100:1.0:0.001.

[0029] Silica sol (SiO 2 30%), aluminum sulfate (Al 2 o 3 7.08%), liquid caustic soda (Na 2 (36.72%), cyclohexylamine, water and ZSM-35 molecular sieve seed crystals were mixed uniformly to obtain gel b. The molar ratio of each component in gel b is as follows: H 2 O:SiO 2 :Al 2 o 3 :Na 2 O: templating agent=12:1:0.1:0.5:0.05. The gel b was transferred to a crystallization kettle and crystallized at 100°C for 36h. After the crystallization is completed, add the solution a into the crystallization kettle. Crystallized at 155°C for 72h. After the crystallization is completed, a molecular sieve slurry is obtained. The ZSM-35 molecular sieve is obtained after separating the mother liquor, washing with water, exchanging,...

Embodiment 3

[0031] Aluminum sulfate (Al 2 o 3 7.08%), citric acid (CA) and stir evenly to obtain solution a. Solution a was aged at 80°C for 24h. The molar ratio of each component in solution a is H 2 O: Al 2 o 3 :CA=1000:1.0:0.1.

[0032] Silica sol (SiO 2 30%), aluminum sulfate (Al 2 o 3 7.08%), liquid caustic soda (Na 2 (36.72%), cyclohexylamine, water and ZSM-35 molecular sieve seed crystals were mixed uniformly to obtain gel b. The molar ratio of each component in gel b is as follows: H 2 O:SiO 2 :Al 2 o 3 :Na 2 O: templating agent=40:1:0.025:0.05:1. The gel b was transferred to a crystallization kettle and crystallized at 140°C for 10h. After the crystallization is completed, add the solution a into the crystallization kettle. Crystallized at 165°C for 48h. After the crystallization is completed, a molecular sieve slurry is obtained. The ZSM-35 molecular sieve is obtained after separating the mother liquor, washing with water, exchanging, drying and roasting. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com