Implantation system for bone implants

A technology of bone filler and capsule, applied in the field of bone filler implantation system, can solve the problems of many operation steps, long operation time, difficult to control flow, etc., to simplify operation, reduce operation risk, and avoid complicated operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

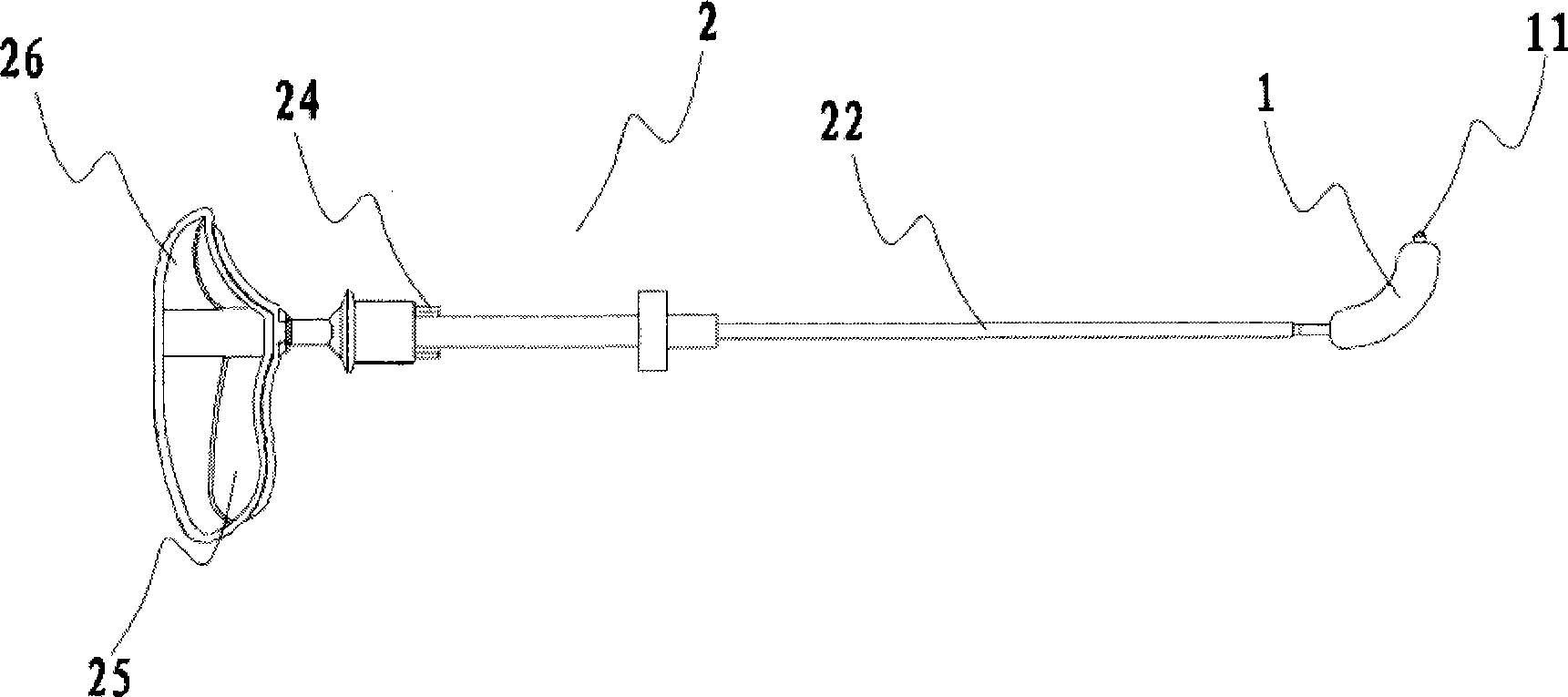

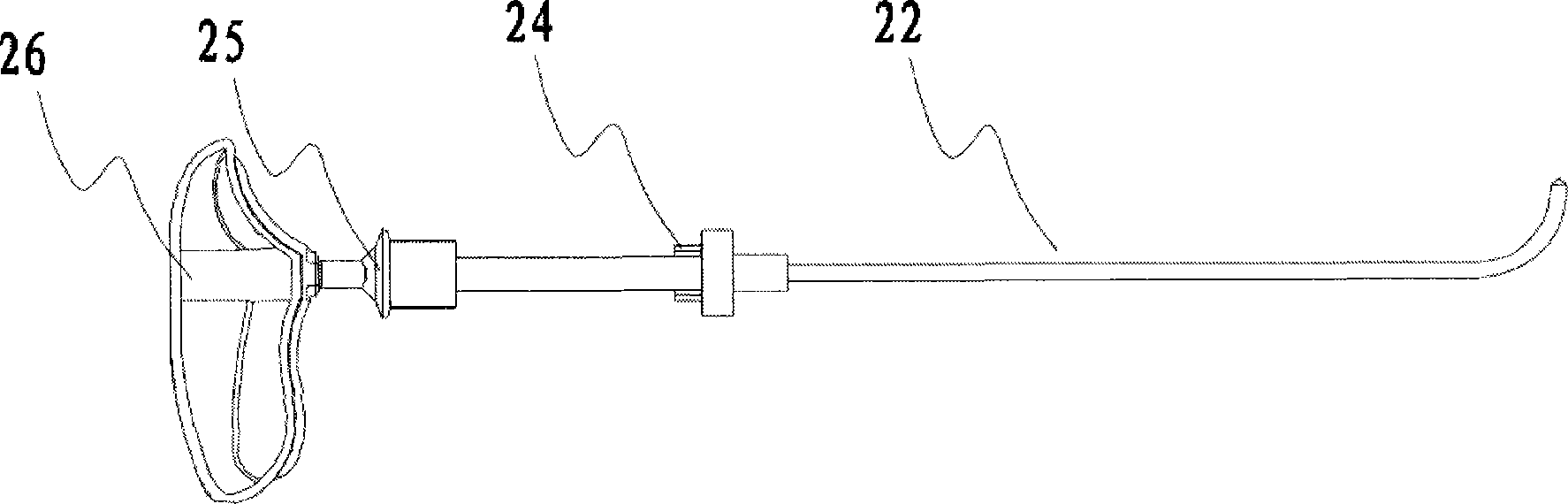

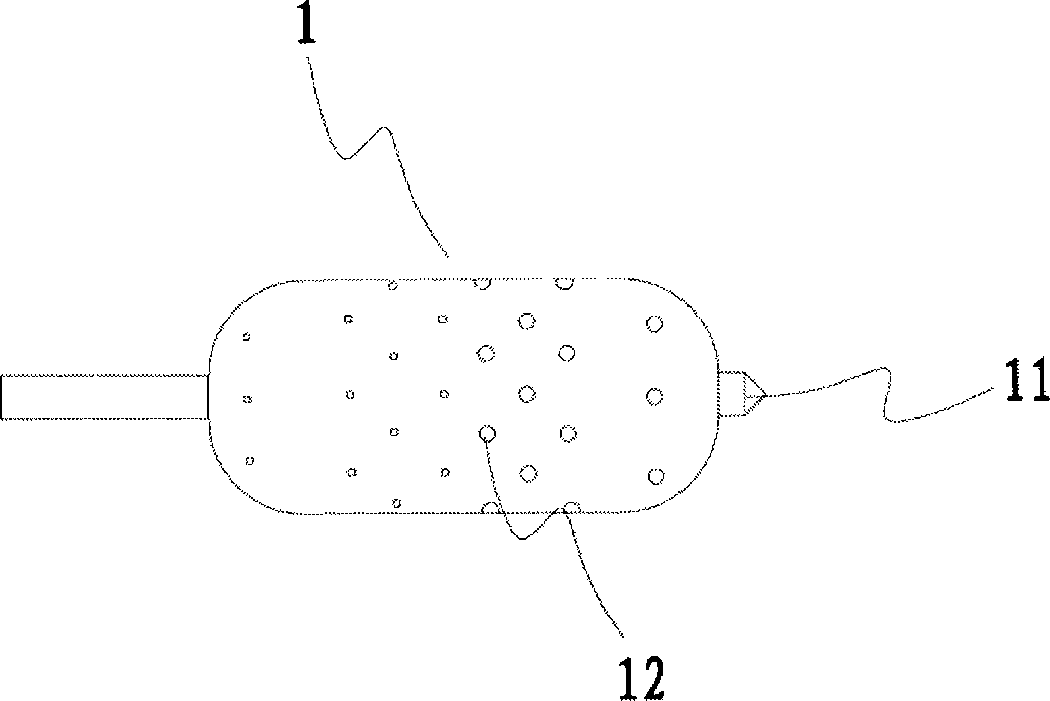

[0046] Figure 1 to Figure 8 As shown, a bone filler implantation system includes a capsule body 1 and a delivery device 2, the distal end of the capsule body 1 is fixedly connected with a distally closed cap 11, and the proximal end of the cap 11 is There is a blind hole 111 opening toward the inside of the capsule body 1, the capsule body 1 has a microhole 12, the delivery device 2 includes a delivery tube 21, a sleeve 22, a lining core 23, the delivery tube 21 It is a rigid tube, the distal end of the delivery tube 21 is detachably connected to the proximal end of the bladder 1, the lining core 23 is slidably inserted into the delivery tube 21, the distal part of the lining core 23 It is a curved section 231, and the curved section 2311 protrudes from the distal end of the delivery tube 21, and the distal end of the lining core 23 is inserted into the head through the delivery tube 21 and the inside of the bladder 1 In the blind hole 111 of 11, the bladder 1 wraps the curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com