Wire and cable horizontal combustion test device and test method thereof

A combustion test, wire and cable technology, applied in electrical program control, instrumentation, program control in sequence/logic controllers, etc., can solve problems such as low detection efficiency and inaccurate detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

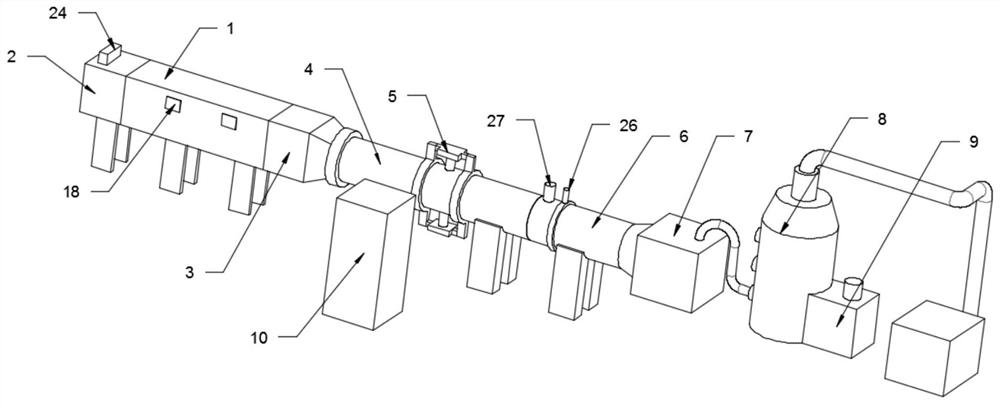

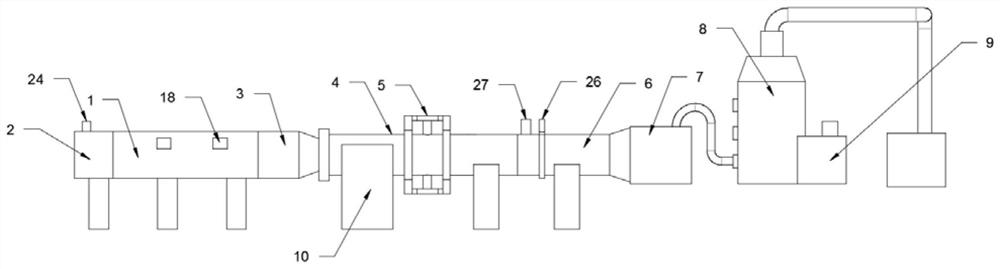

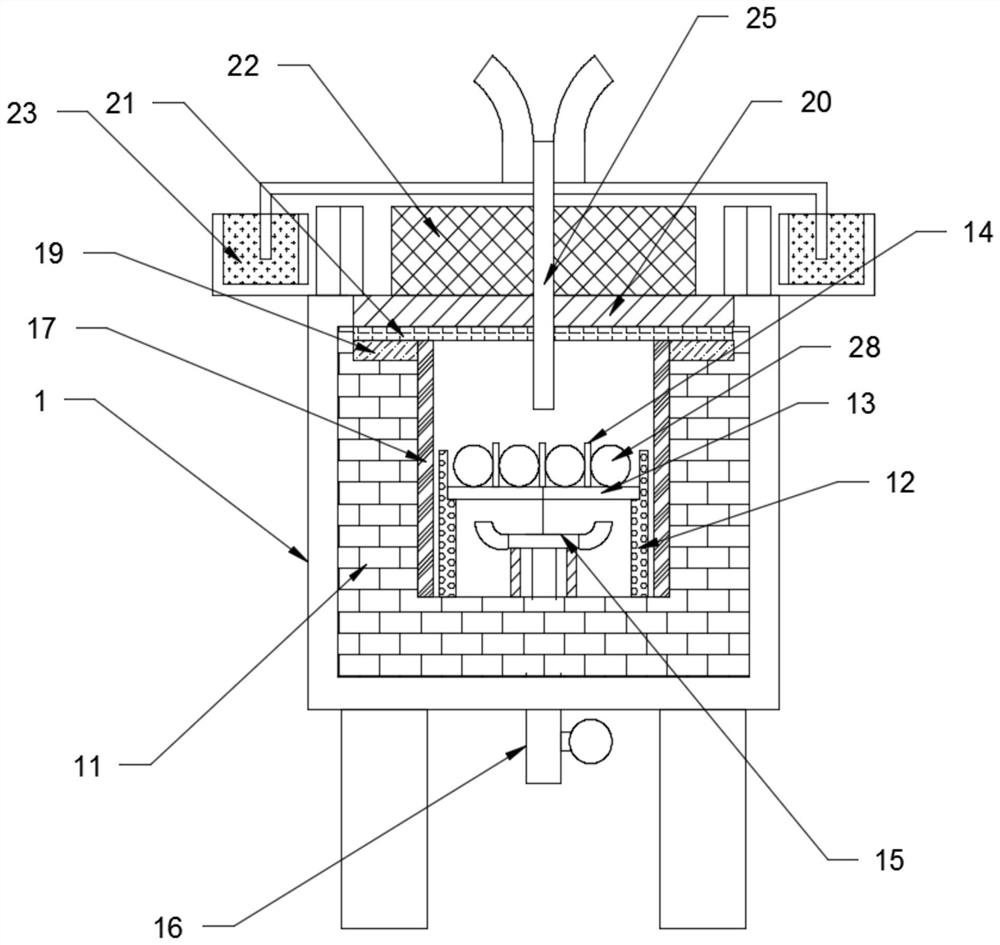

[0034] Refer to attached Figure 1-5, the wire and cable horizontal combustion test device provided by the present invention is used to measure and record the fire and smoke characteristics of insulated, jacketed or both insulated and jacketed wires, cables 28 and optical cables, including a combustion furnace 1 One side of the combustion furnace 1 is provided with an air intake chamber 2, the other end of the combustion furnace 1 is provided with an exhaust transition section 3, and the side of the exhaust transition section 3 away from the combustion furnace 1 is provided with an exhaust duct 4 , the exhaust duct 4 is provided with a smoke density measuring mechanism 5, and a gas analyzer 27 is arranged on one side of the smoke density measuring mechanism 5, and the end of the exhaust duct 4 away from the exhaust transition section 3 is connected with the flange through the The waste gas pipe 6 is fixedly connected, and the outside of one end of the waste gas pipe 6 is provi...

Embodiment 2

[0051] Embodiment 2: Wire and cable 28 horizontal combustion test method, to measure the flame propagation distance and optical density of insulated, jacketed or both insulated and jacketed wires, cables 28 and optical cables, including the air inlet chamber 2 , intake gate, combustion furnace 1, burner 15, movable cover plate 22, smoke exhaust transition section 3, exhaust duct 4, exhaust fan 7 and exhaust gas treatment mechanism 8 to establish a test device model that meets the requirements for use, and in the established The smoke exhaust duct speed measurement system and the smoke measurement system are set on the model, and the smoke exhaust duct speed measurement system and the smoke measurement system are connected with the computer client installed with the PLC control mechanism 10, and the smoke exhaust duct speed measurement system and the smoke measurement system are connected to each other. The system obtains test data such as oxygen concentration, carbon dioxide co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com