Distillation system and method for separating liquid product

A technology of distillation system and fraction, applied in the field of distillation system, can solve the problems of poor repeatability and reproducibility of the device, affect the product separation effect, and the device is prone to fluctuations, etc., achieve good repeatability and reproducibility of results, wide application range, The effect of high precision pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

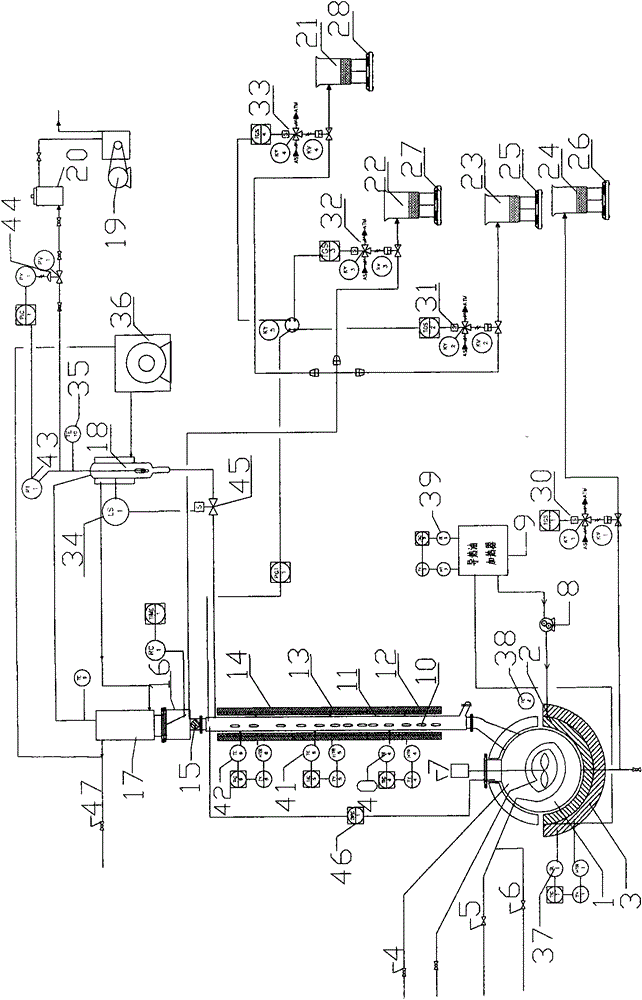

[0054] Such as figure 1 Shown is the pot distillation system of the present invention, which realizes normal and reduced pressure distillation, can cut raw materials from the initial boiling point to 530°C, and has a processing capacity of 200-500L, through highly automated distributed control The system can continuously distill the required fractions; the whole distillation system includes distillation kettle, distillation tower, pressure control system, fraction collection system, cooling system, distillation tower reflux distributor, and control system.

[0055] The still 1 is composed of a spherical kettle body, a heat transfer oil jacket 2, an electric heating jacket 3, a raw material feed pipe 4, a steam coil 5, a cooling water coil 6, a mixer 7 and a heat transfer oil system; the above heat transfer oil The system includes a heat transfer oil pump 8 and a heat transfer oil electric heater 9, both of which are connected with the heat transfer oil jacket 2 to form a close...

Embodiment 2

[0064] The specific steps of the coal liquefied oil distillation separation method using the device of the present invention are as follows.

[0065] Add 250L coal liquefied oil into the spherical still body 1 through the raw material feed pipe 4, start the mixer 7, adjust the frequency conversion of the motor to control the stirring speed, so that the coal liquefied oil can be heated evenly in the still; open the cooling system flow, and start the refrigeration Machine 36; open the upper hand valve of the steam coil 5, and pass steam to quickly heat the coal liquefied oil in the still 1; start the electric heating jacket 3 at the bottom of the still 1 for auxiliary heating; open the flow of the heat transfer oil system, start the heat transfer oil pump 8, and establish heat conduction Oil circulation, start the heat conduction oil electric heater, set the heating temperature and heating temperature rise speed on the control system; start the distillation tower 11 electric heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com