A miniature gate valve device for high vacuum

A flapper valve and high-vacuum technology, applied in the direction of valve devices, laboratory containers, chemical instruments and methods, etc., can solve the problems of poor versatility and inability to meet the increasingly diverse microscopic analysis requirements, and achieve universal Strong performance, high cost performance, and the effect of improving reliability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

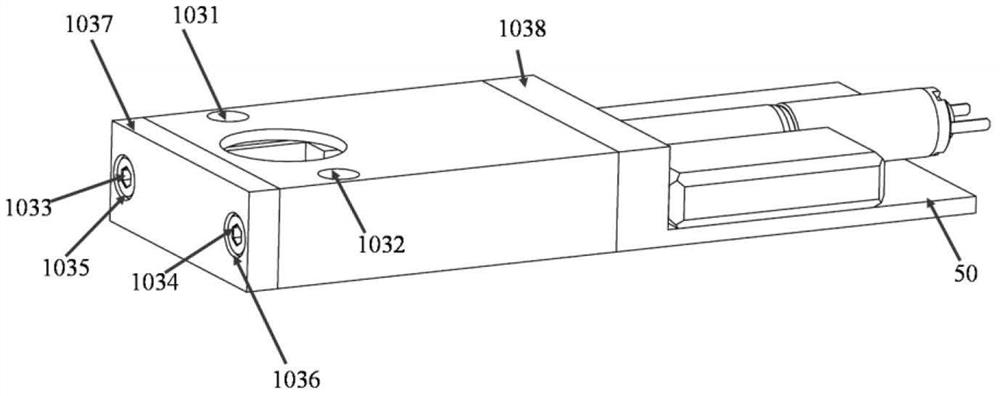

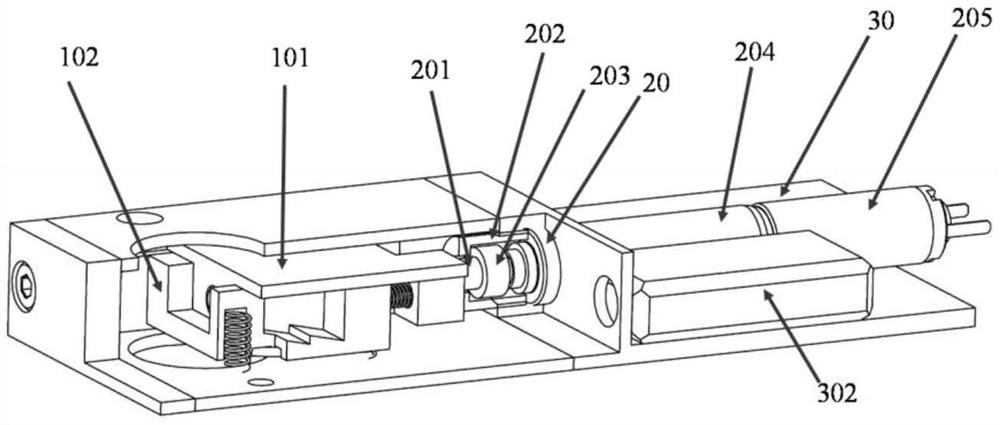

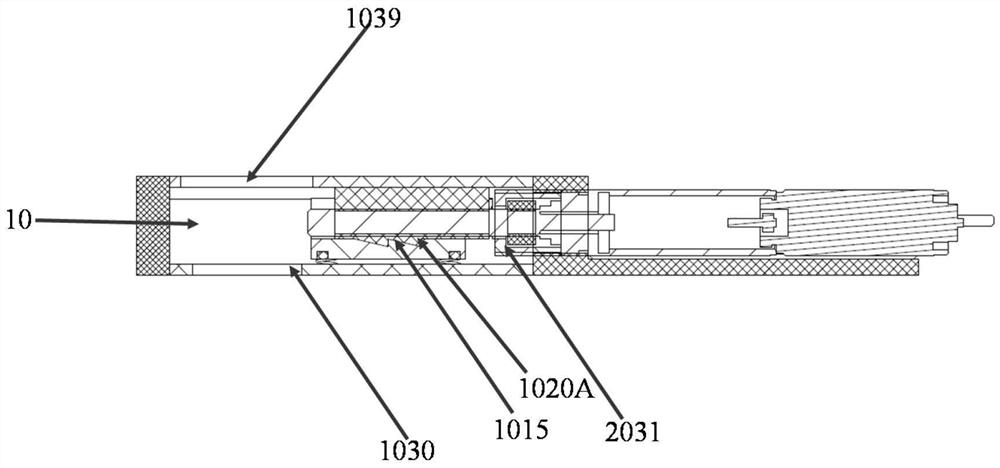

[0056] Such as figure 1 , figure 2 and Figure 5As shown, the high vacuum micro gate valve of the present invention includes a sealed chamber 10 for sealing samples, a transmission mechanism 20 connected to the sealed chamber 10, the transmission mechanism 20 can drive the sealed chamber 10 to move, and is used to control the transmission mechanism. 20 movement and stop control mechanism 30 and the fixing mechanism 50 that connects and fixes the sealed chamber 10, the transmission mechanism 20 and the control mechanism 30; Vacuum environment for sample recovery and transfer.

[0057] In the miniature gate valve device for high vacuum of the present invention, the sealed chamber 10 is a closed chamber formed by the first sealed slider 101 and the second sealed slider 102, and the two pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com