Laser pulse sequence silicon hole processing system with adjustable sub-pulse time interval

A laser pulse sequence, sub-pulse time technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the performance and life impact of core components, ablation accuracy and flatness decline, high-energy femtosecond Laser processing quality cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

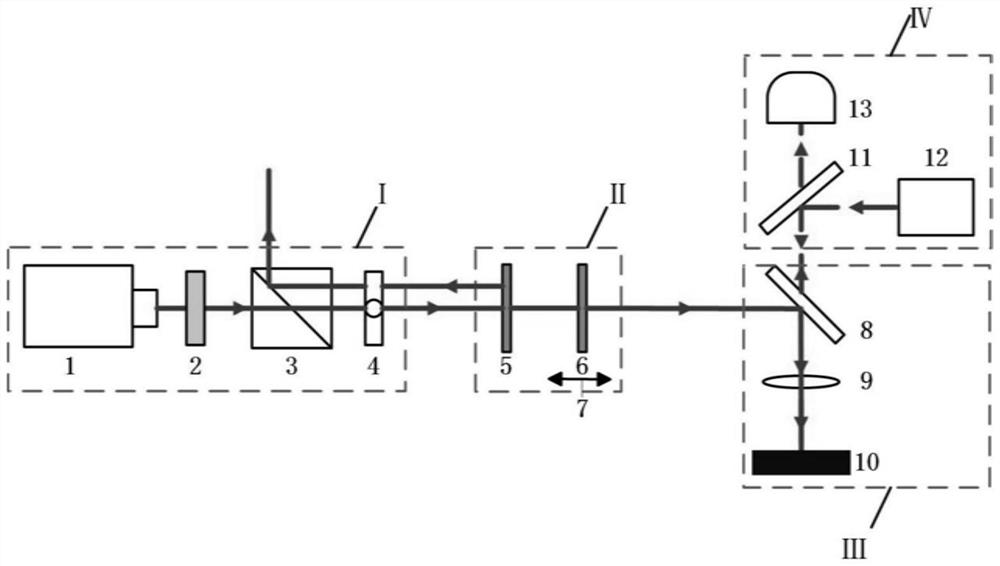

[0026]The laser 1 used is the PHAROS series product of Light Conversion Company. The central wavelength of the outgoing pulse is 1030 nm, the pulse width is 169 fs, the repetition frequency is set to 1 kHz, the light field distribution is Gaussian distribution, and the output horizontal linearly polarized light passes through the laser 1. The number of pulse sequences can be adjusted by selecting the output function; the circular gradient neutral filter 2 is the CVND30-B100A model of Huibo Optical Company; the polarization beam splitter cube 3 used is the MPBS24-1030-HP model of Lubang Technology Company ; Quarter wave plate 4 is the AQWP05M-980 model of Thorlabs Company; The first beam splitter 5 and the second beam splitter 6 are the GCC-4111 model of Daheng Optoelectronics Company; Objective lens 9 is that the numerical aperture of Nikon Company is NA = 0.25, the spot diameter converging on the silicon sample surface is 8.3 μm; the sample three-dimensional translation stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com