Patents

Literature

64results about How to "Lower hydrocarbon emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

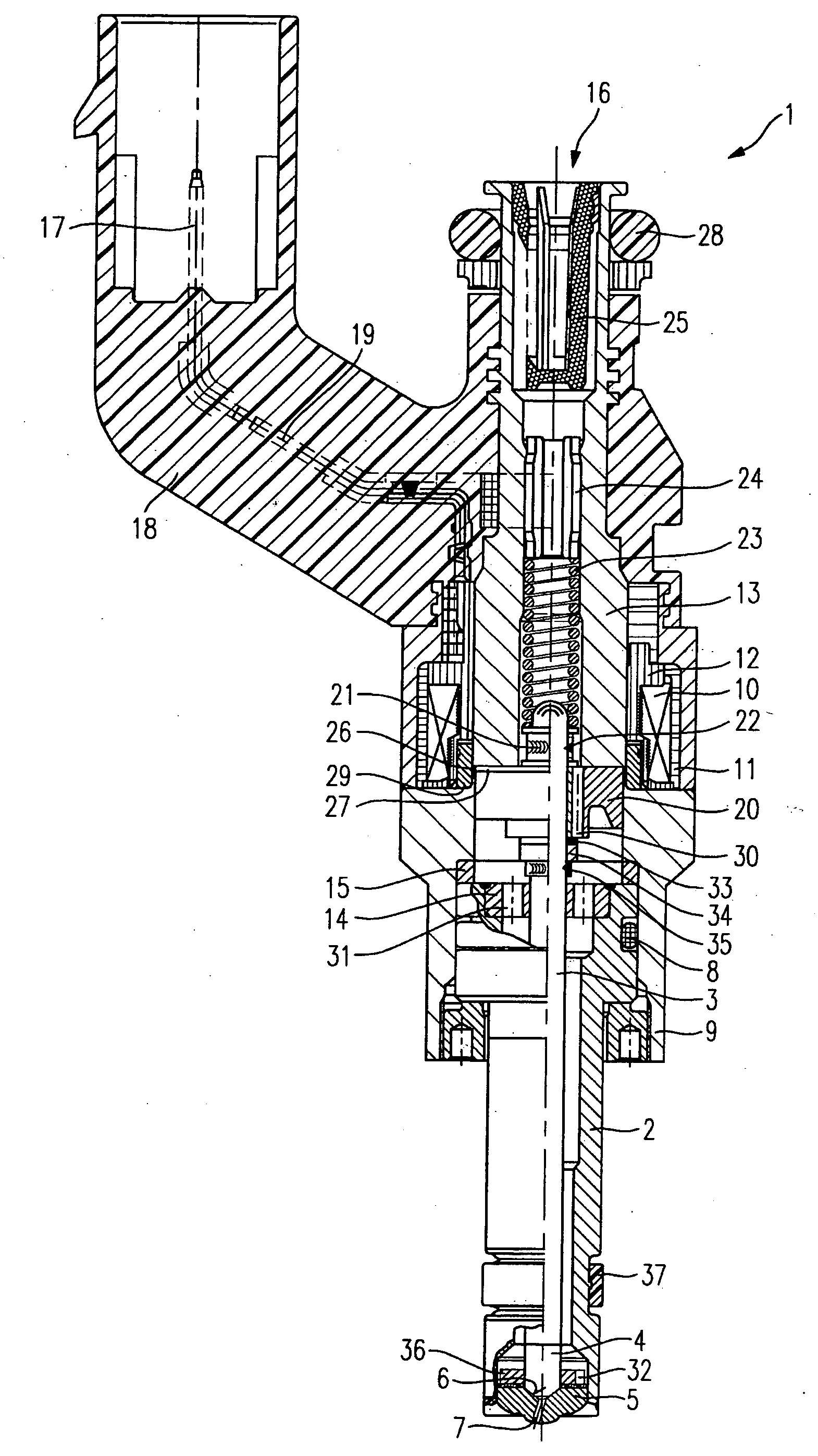

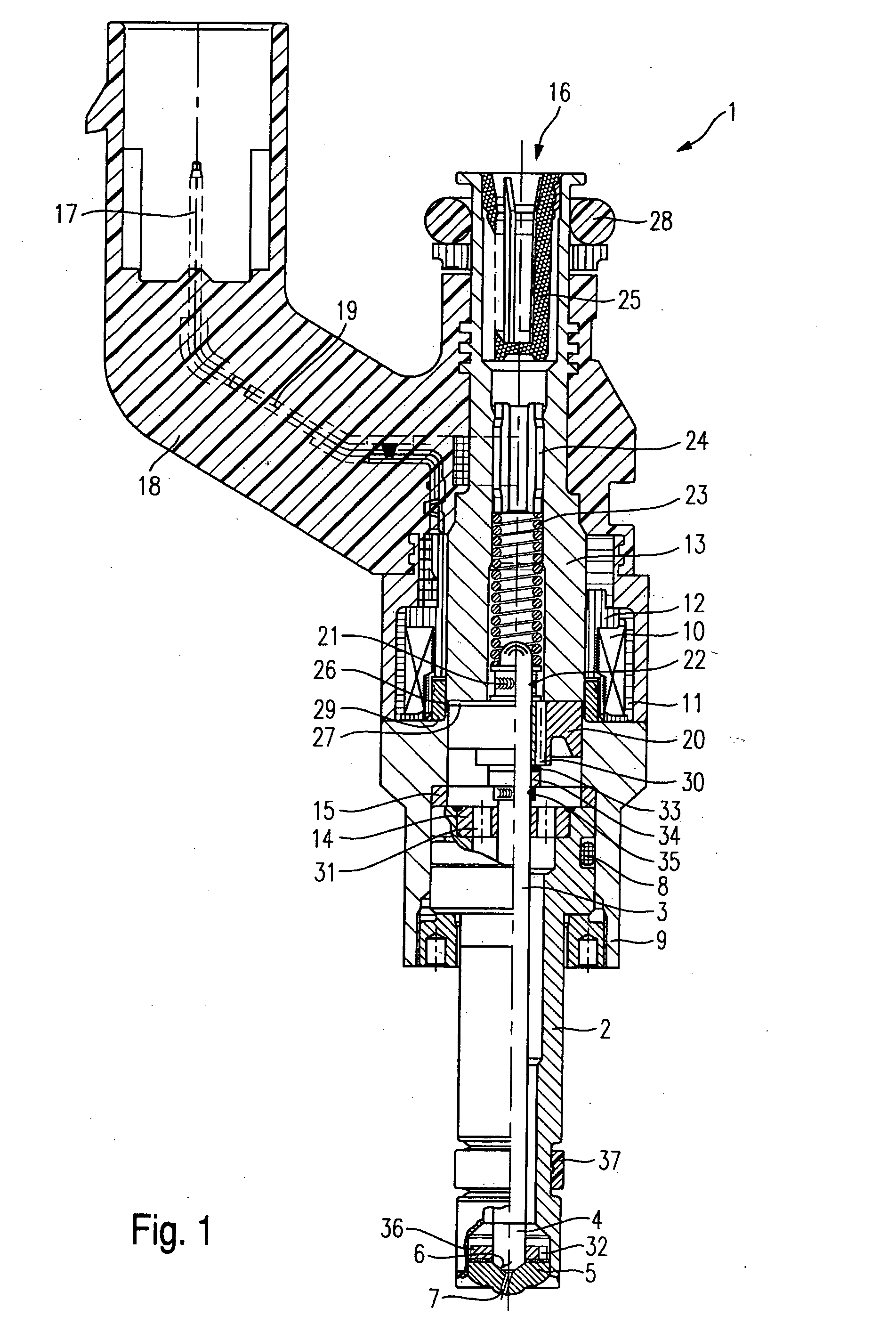

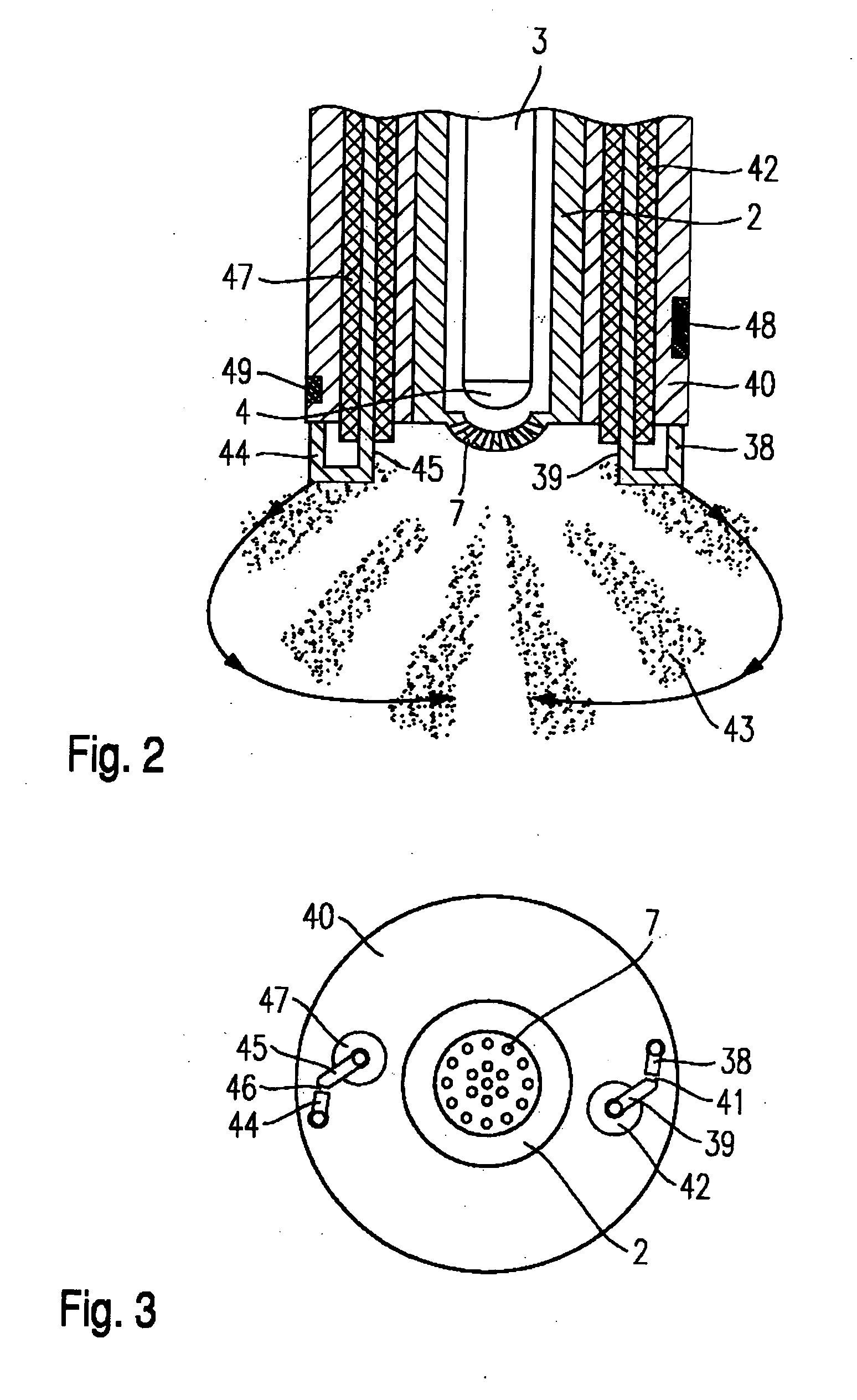

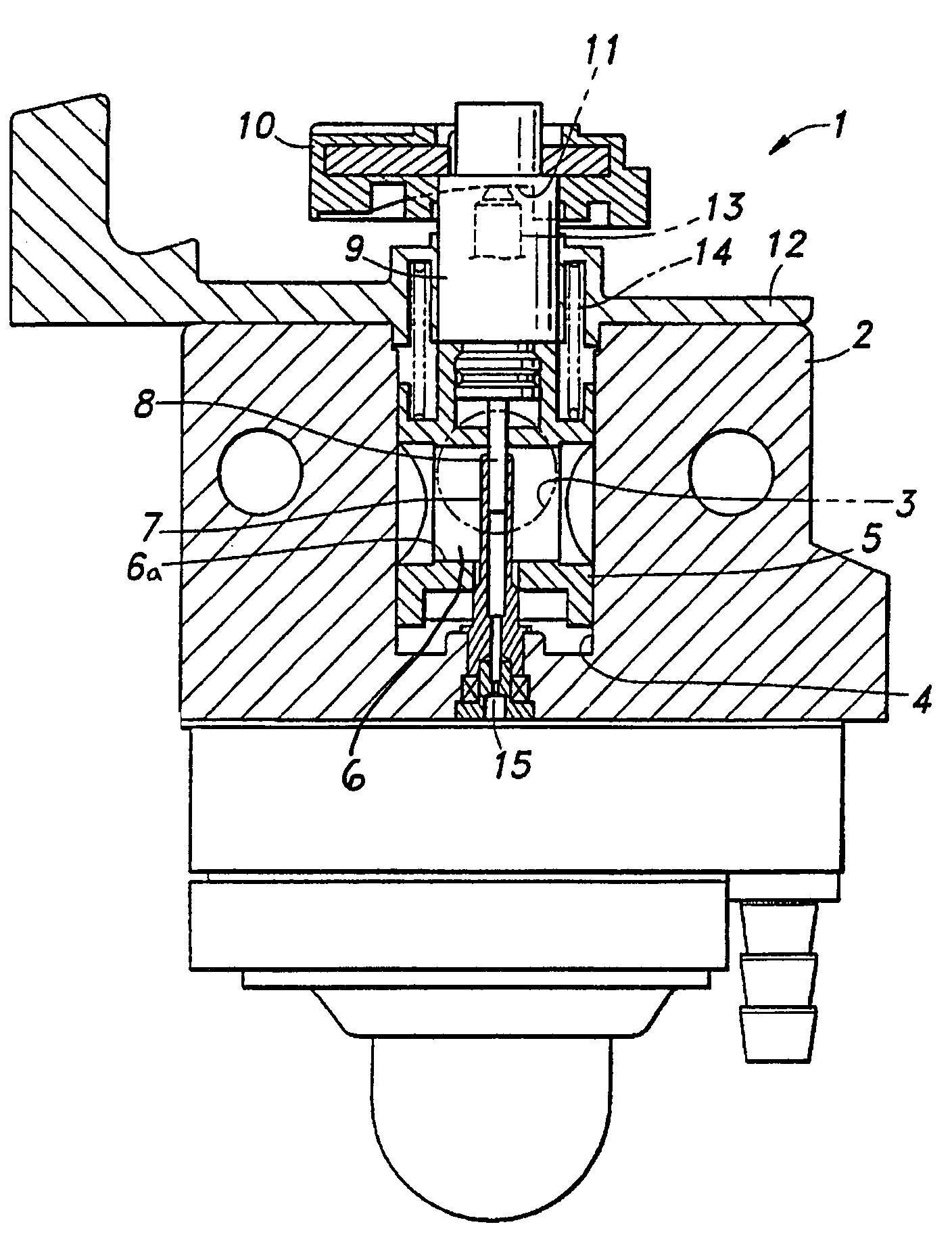

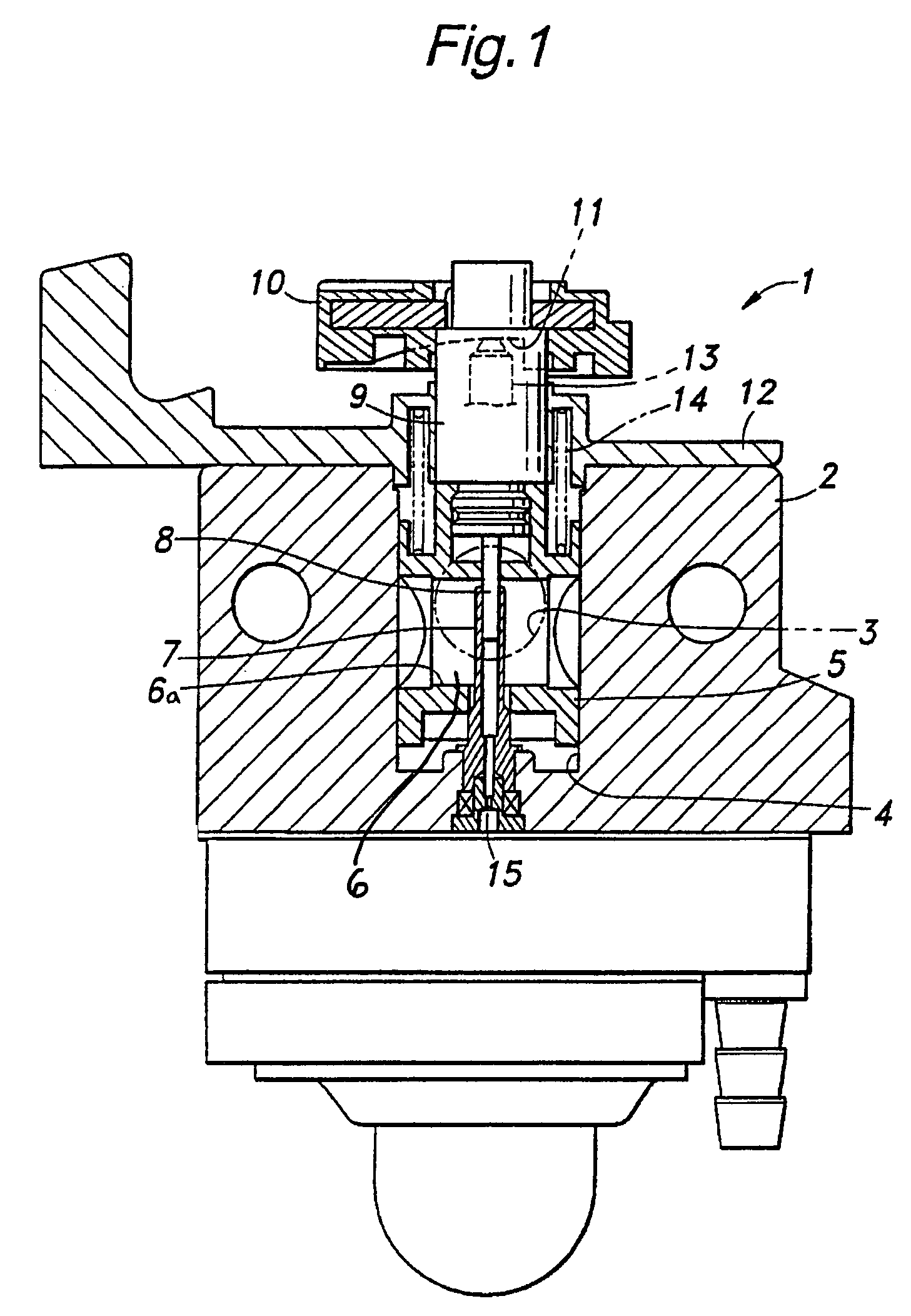

Fuel Injector Having an Integrated Ignition Device

InactiveUS20080072871A1Reduce thicknessEasy to monitorMachines/enginesFuel injection with sensorsCombustion chamberElectrode pair

A fuel injector having an integrated ignition device includes a first electrode pair for igniting fuel which is injected directly into a combustion chamber of an internal combustion chamber through spray-discharge orifices of the fuel injector. The first electrode pair is made up of a ground electrode and a center electrode which are set apart by a spark gap. The fuel injector and the ignition device are situated in a shared housing. The ignition device has at least one additional spark gap and / or an additional electrode pair.

Owner:ROBERT BOSCH GMBH

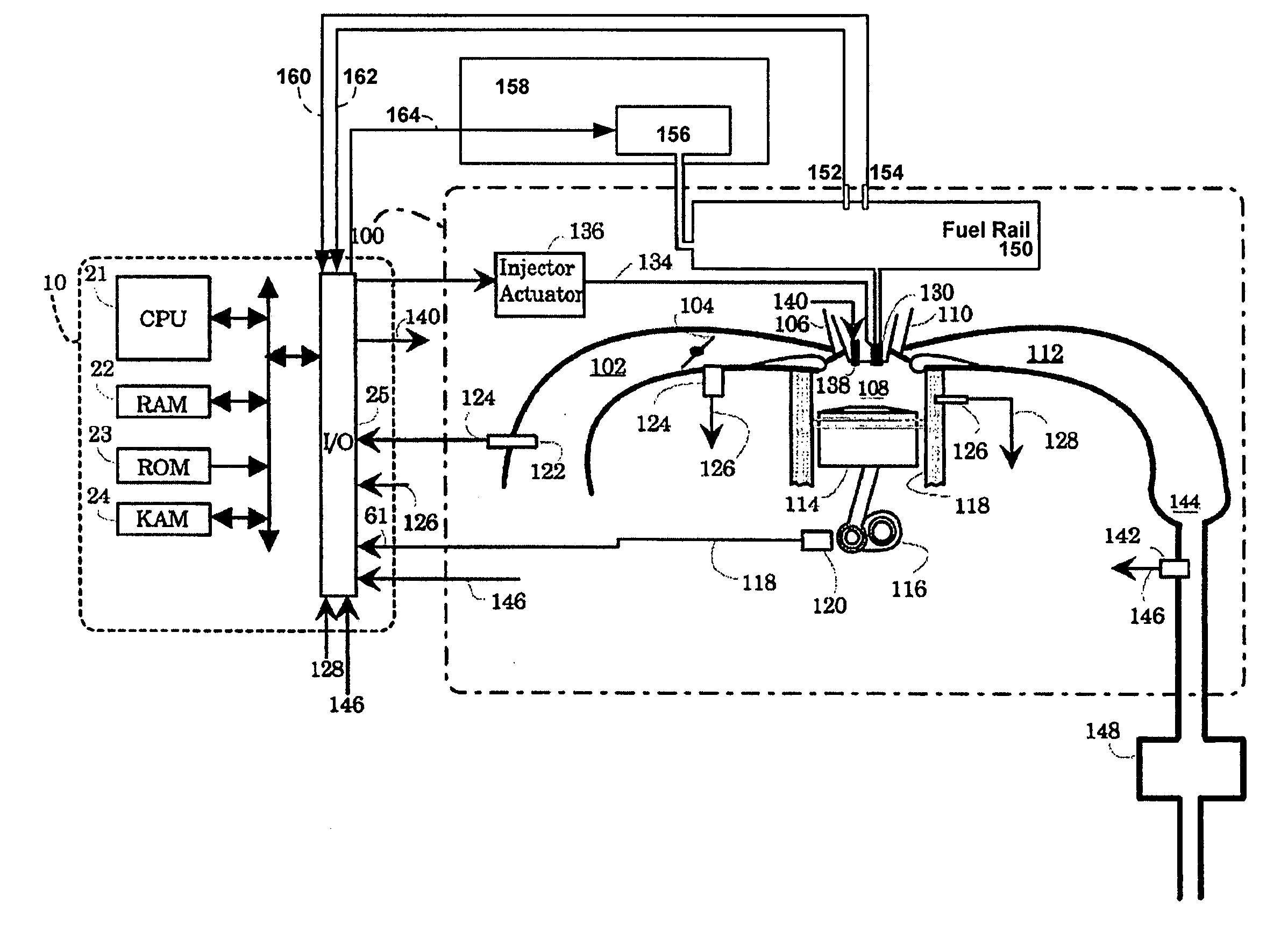

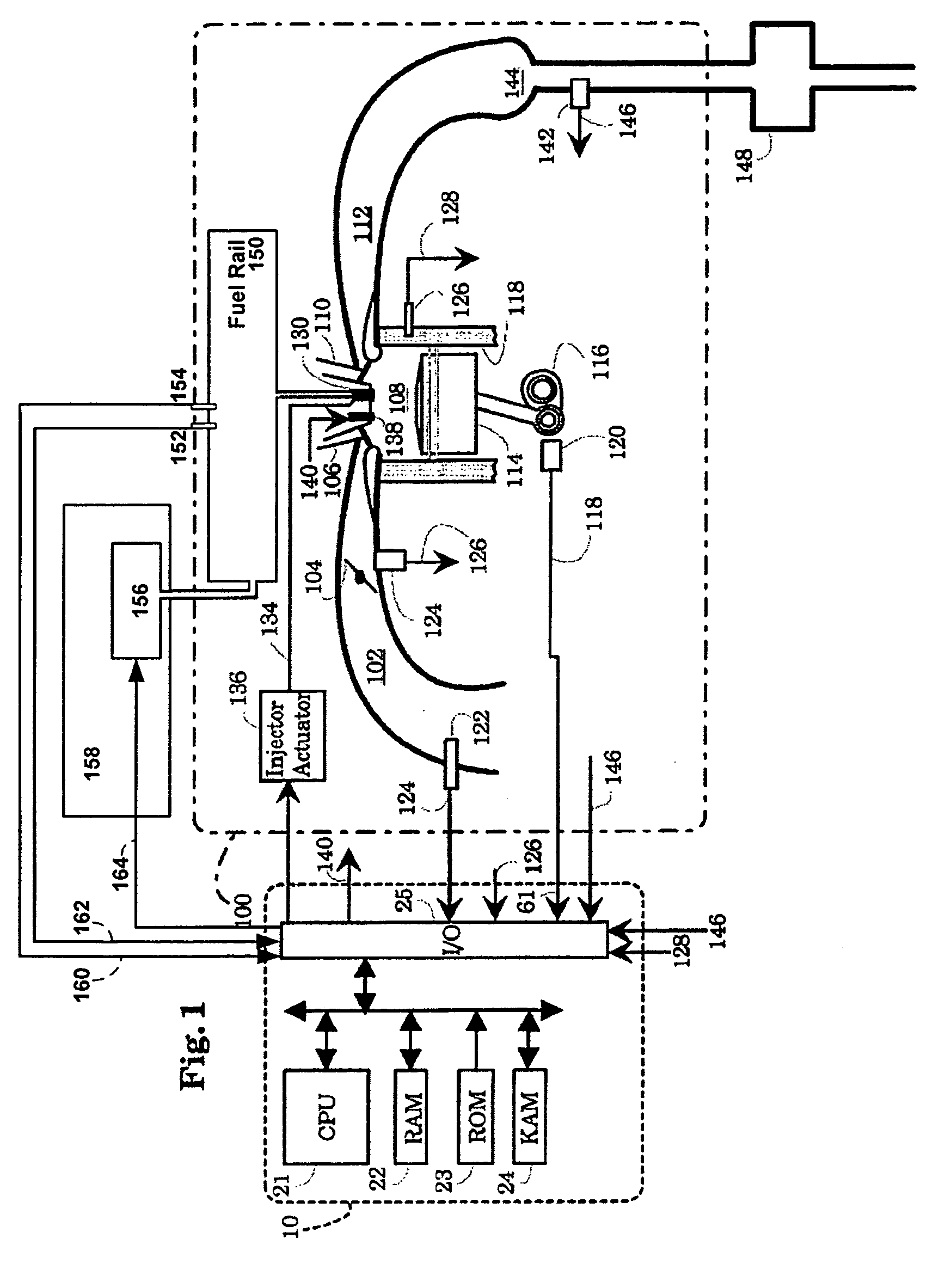

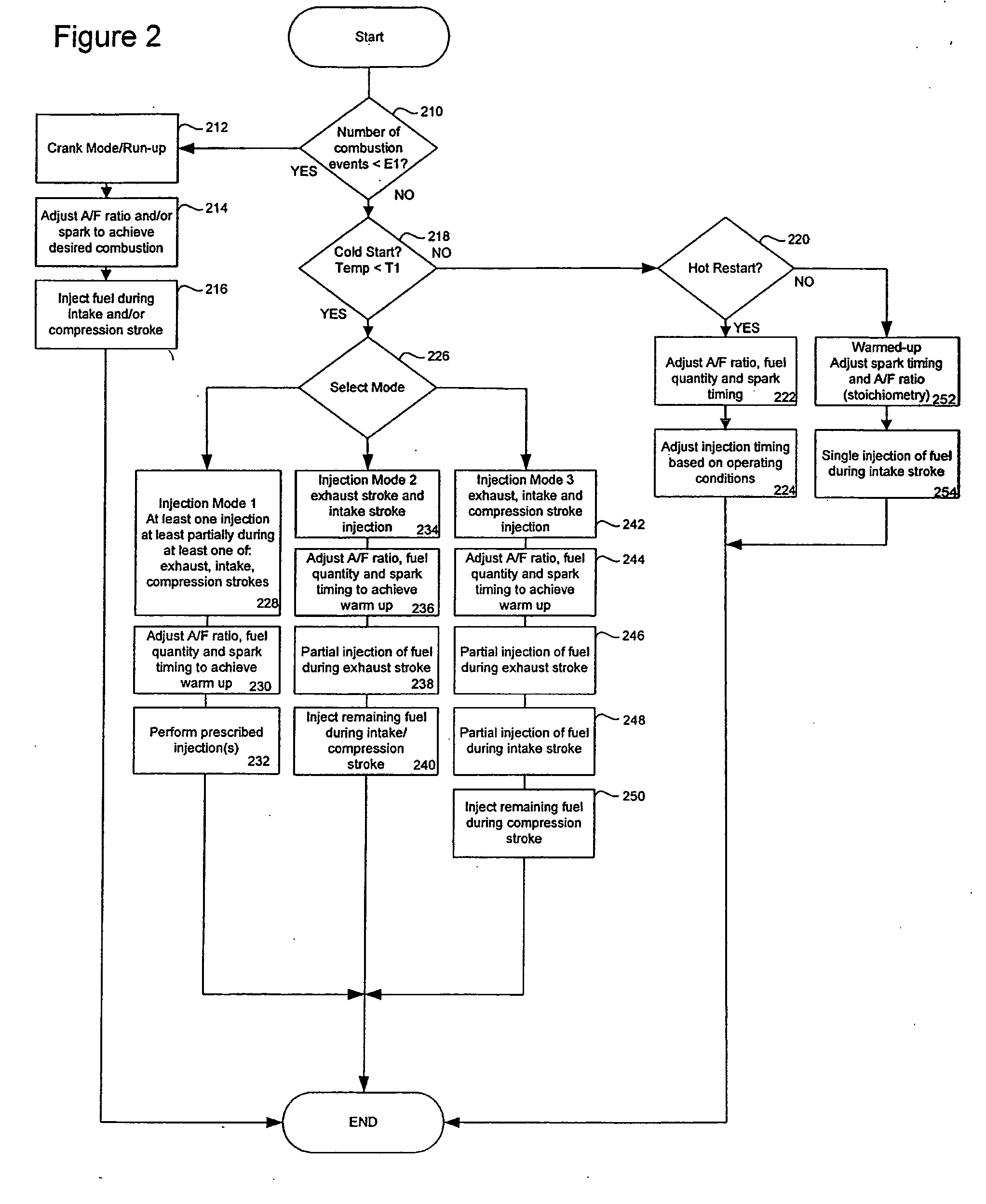

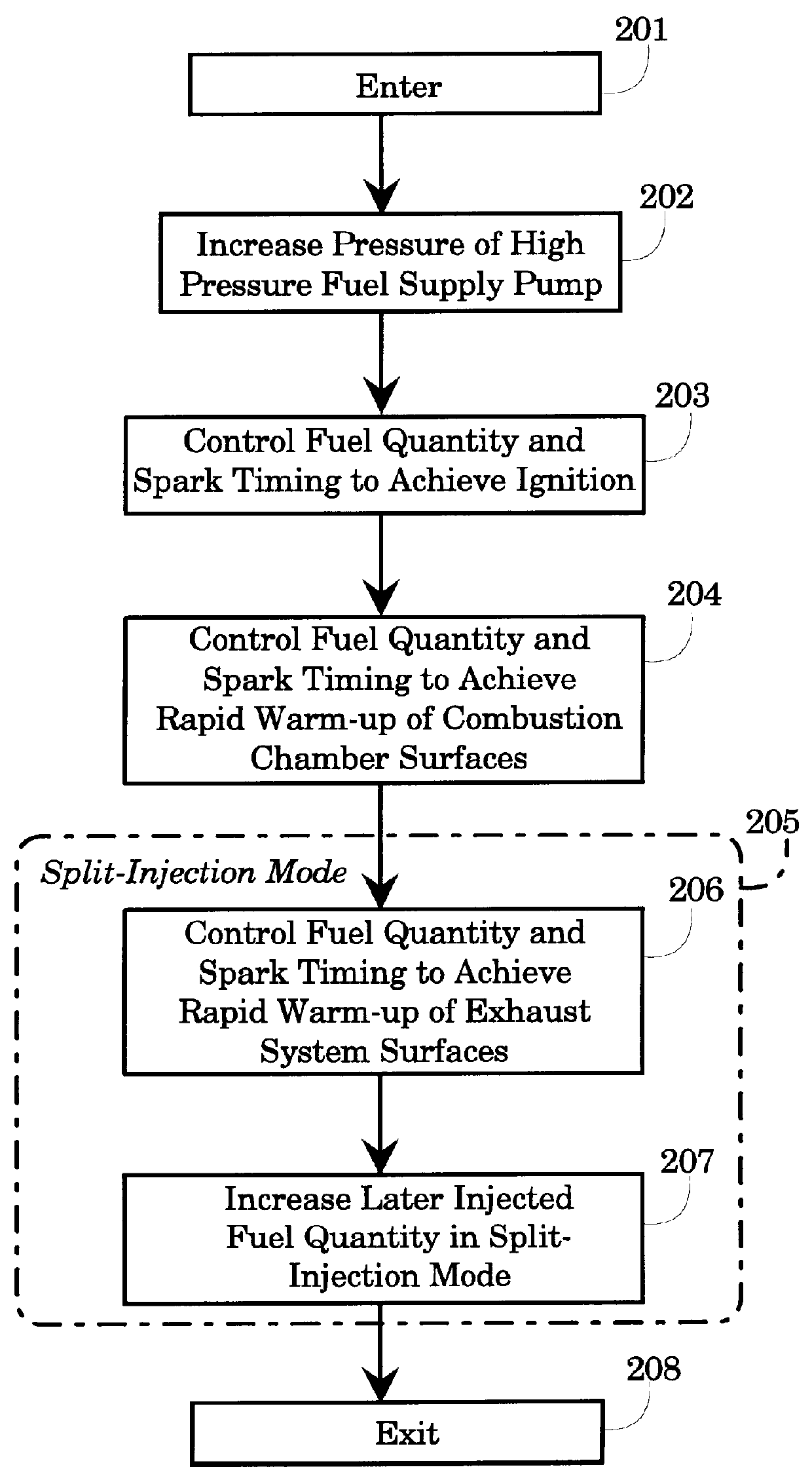

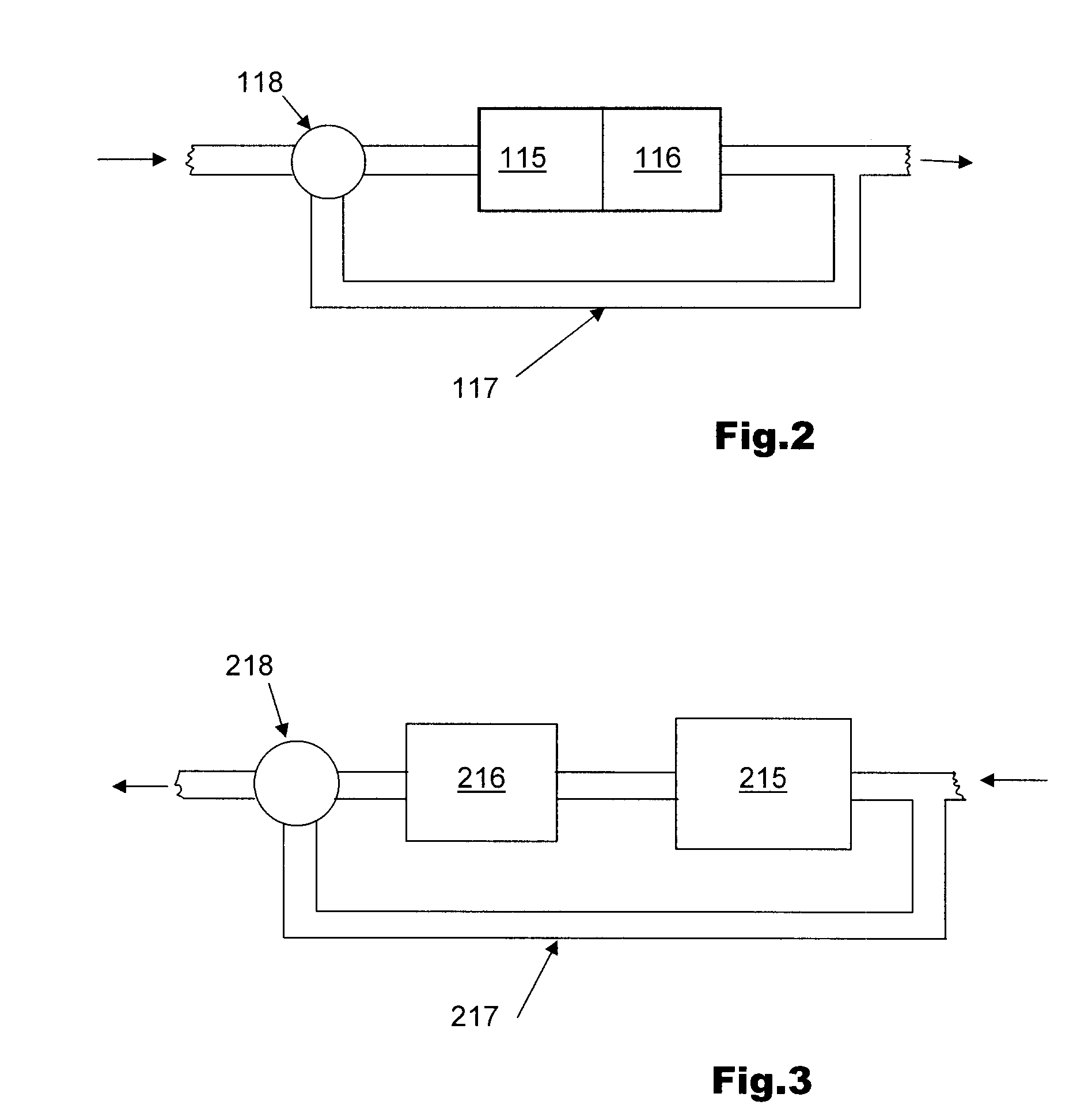

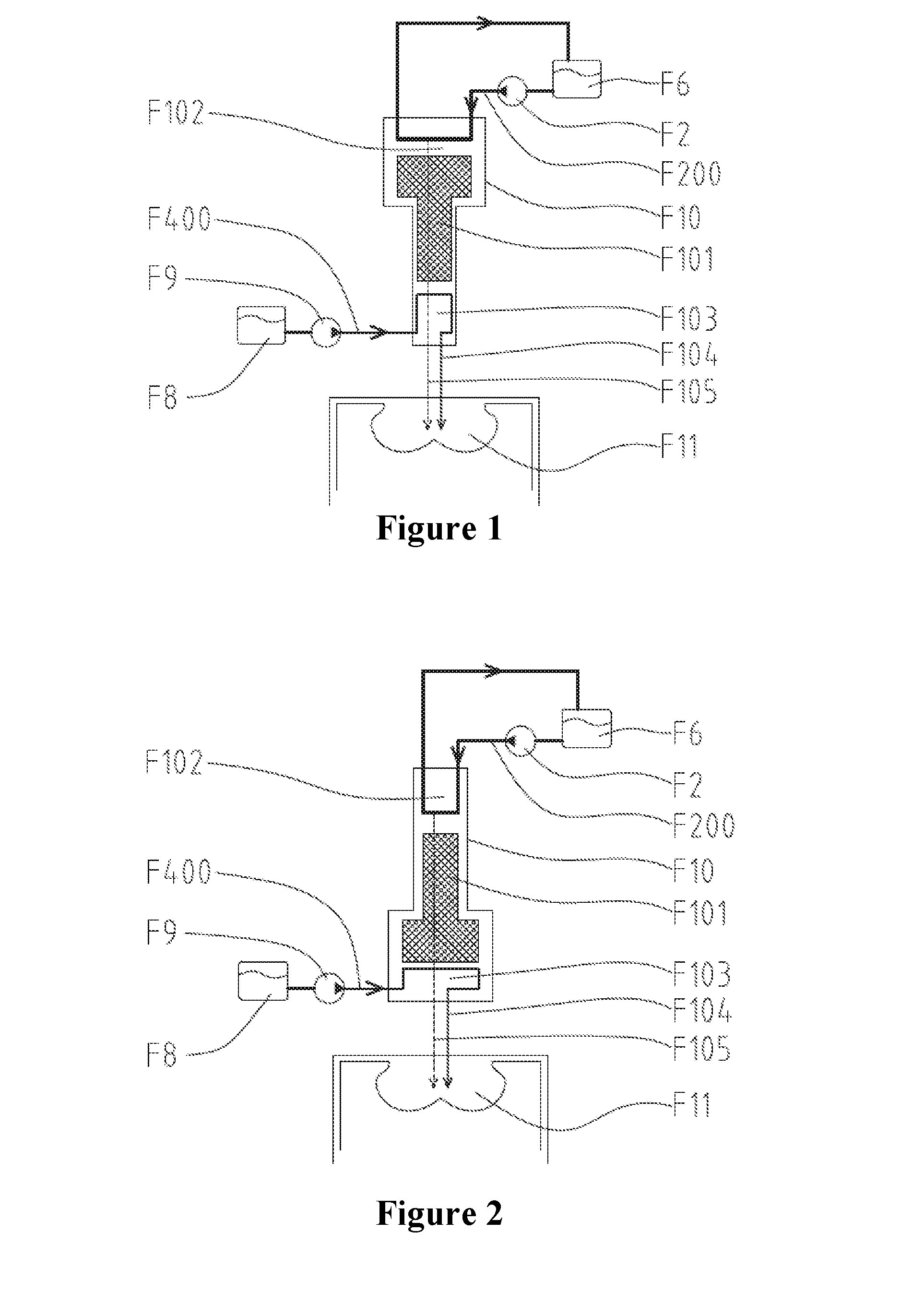

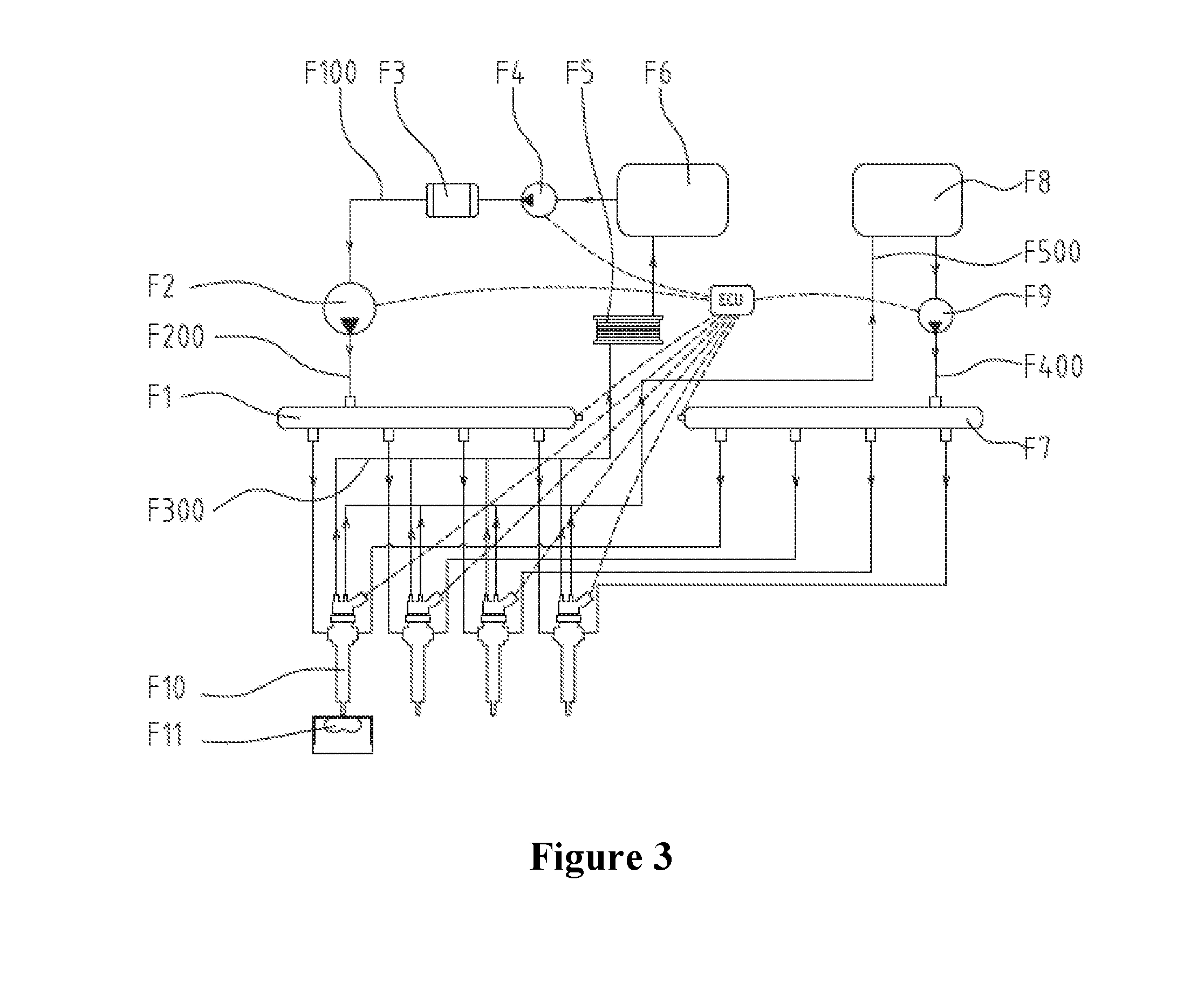

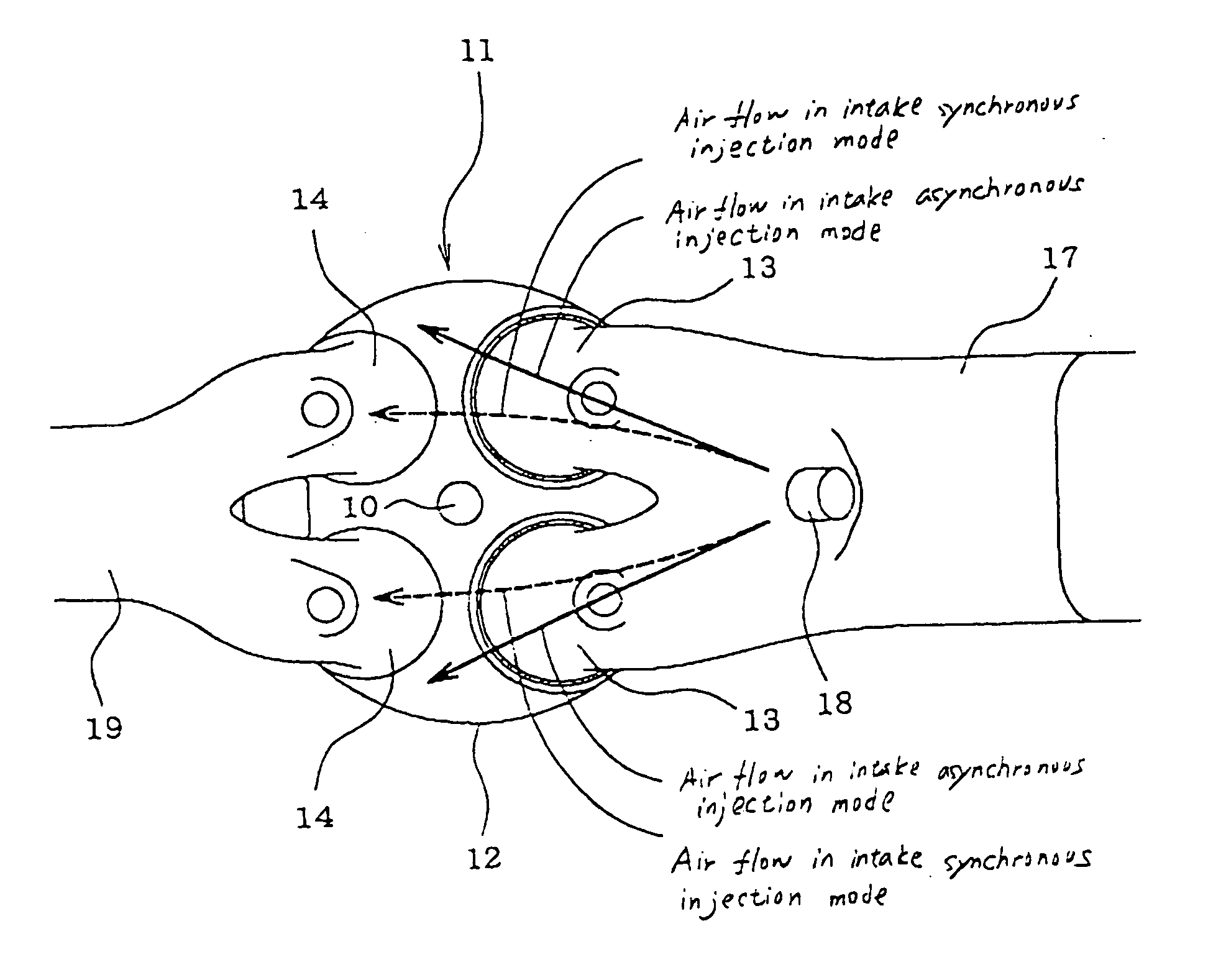

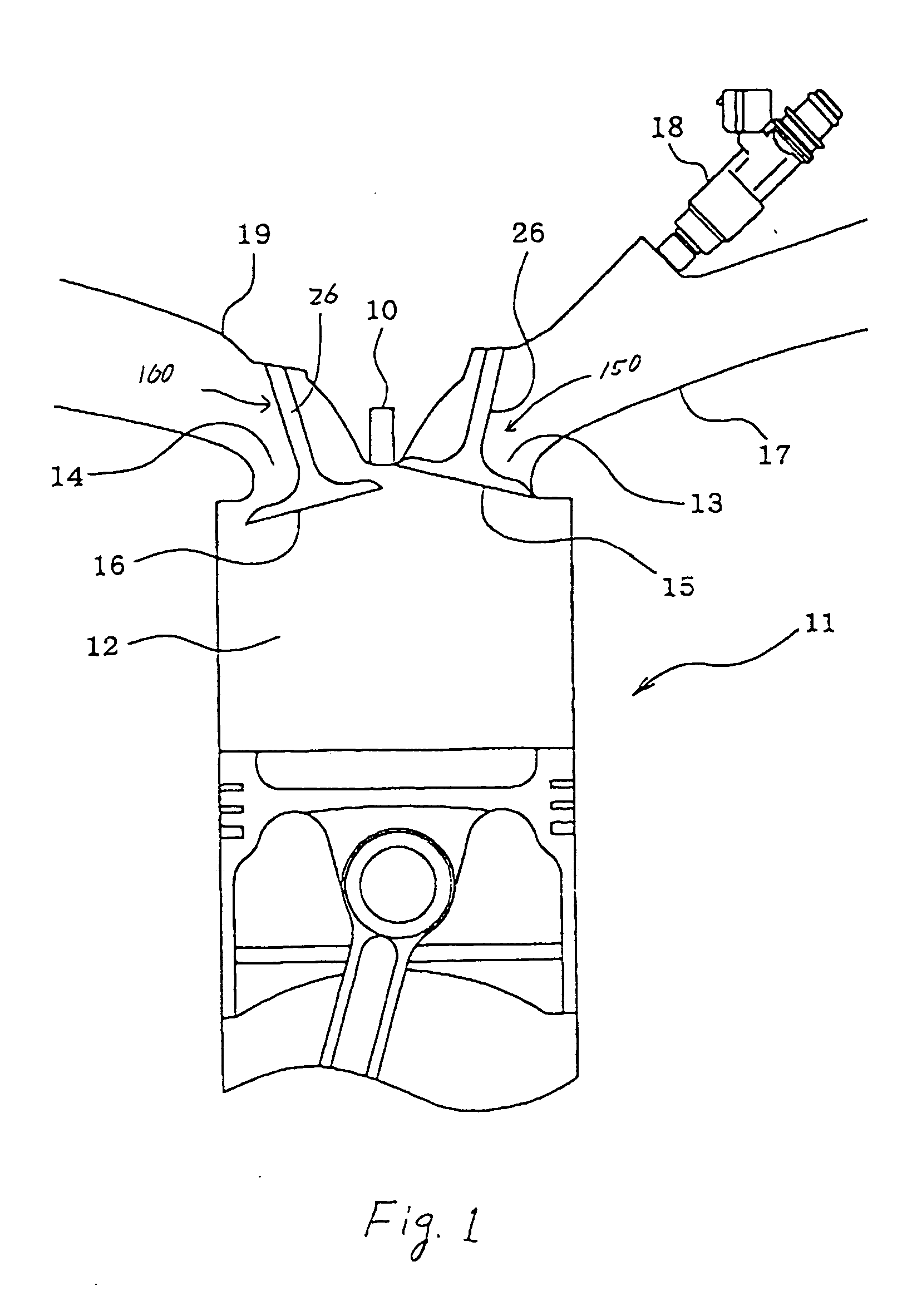

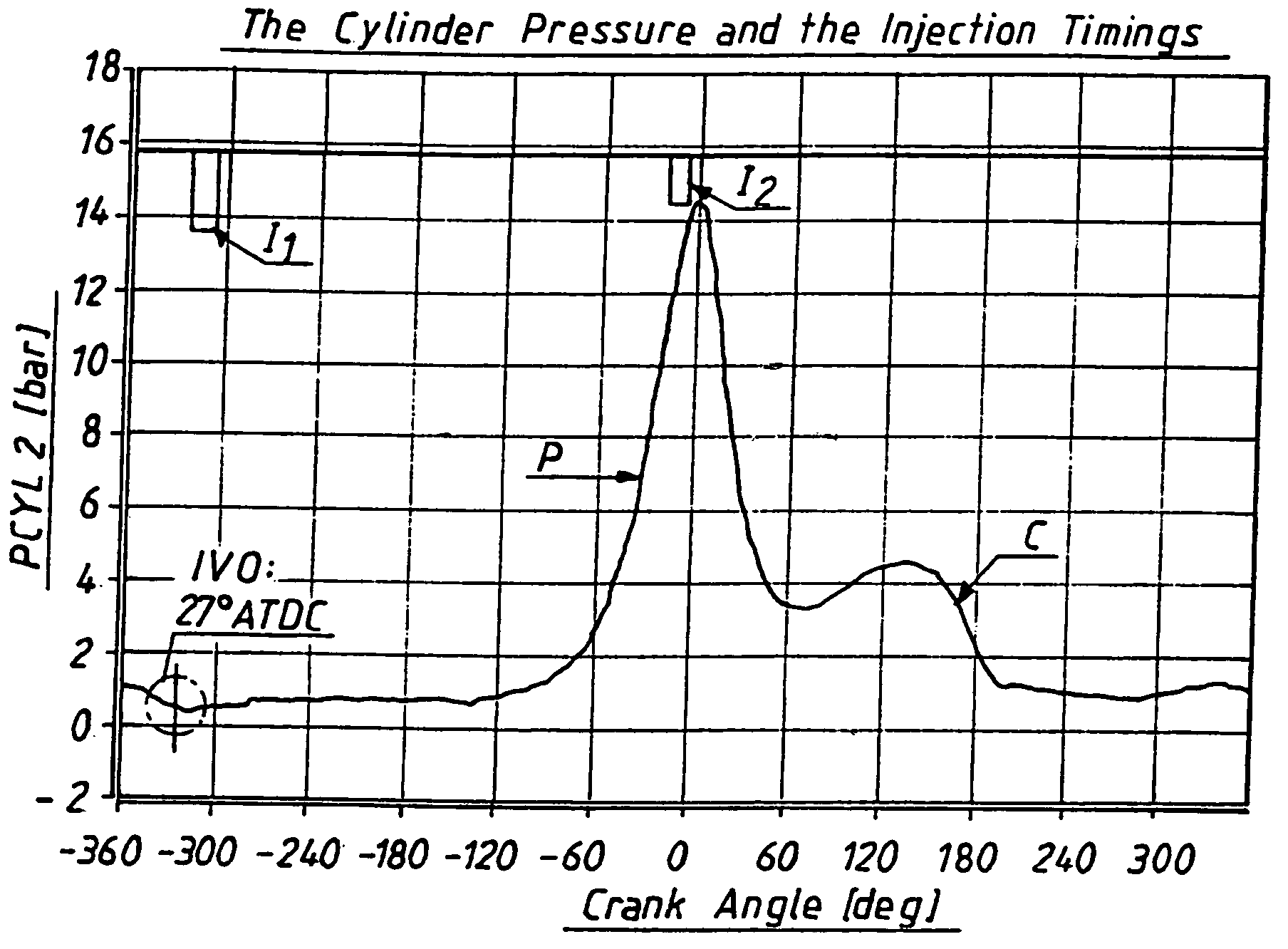

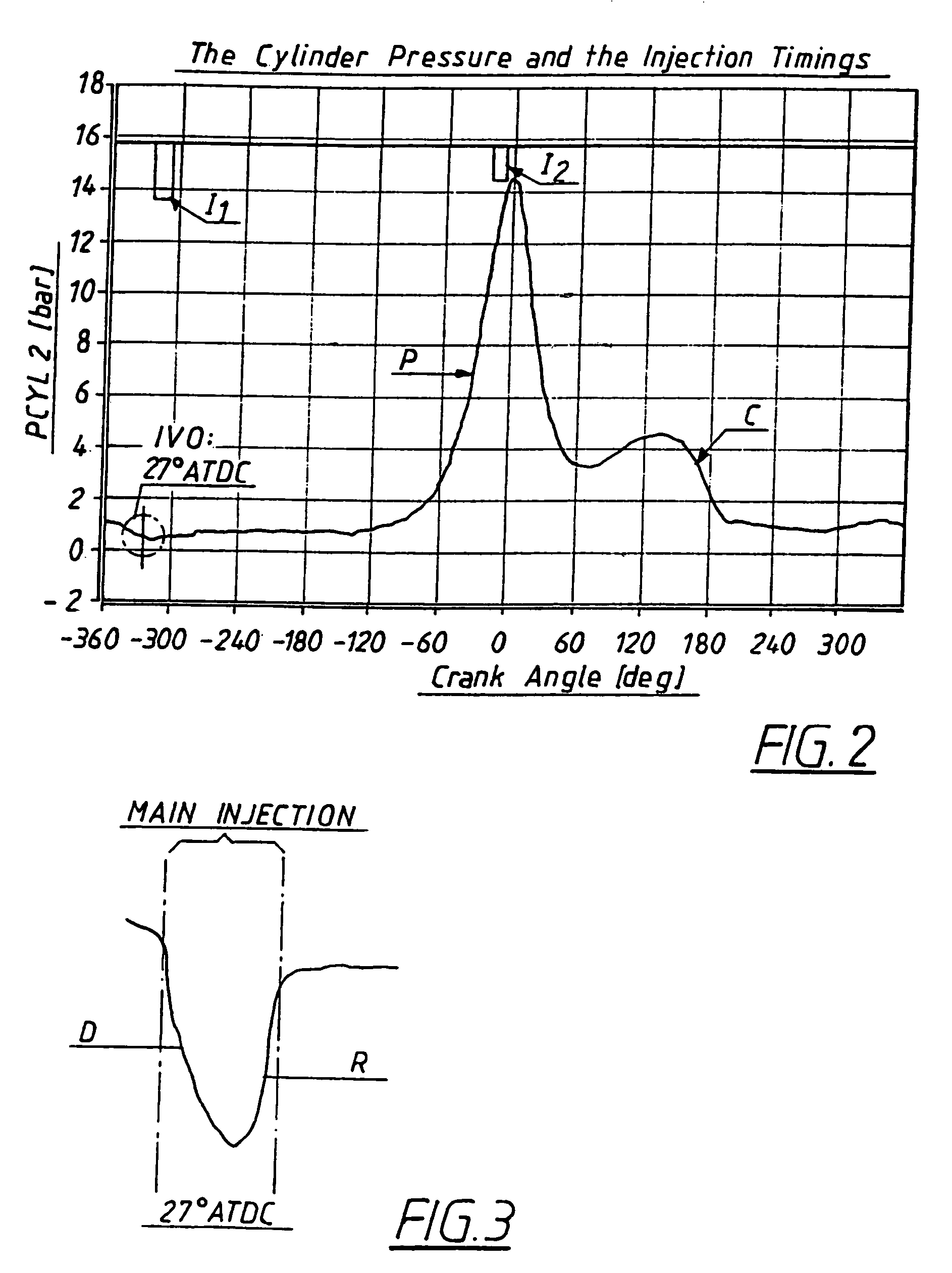

Fuel injection strategy for reduced cold start emission from direct injection gasoline engines

ActiveUS20070068485A1Improved vaporizationReducing piston wettingElectrical controlInternal combustion piston enginesCombustionGasoline

A system, comprising of an engine having a cylinder therein, a fuel injector coupled to said cylinder and configured to directly inject fuel into said cylinder, a fuel system coupled to said injector, and a controller configured to control engine starting operation, wherein during a start, said fuel injector performs a first fuel injection at least partially during an exhaust stroke of said cylinder, where fuel from said first fuel injection is mixed with air inducted at least during an intake stroke following said exhaust stroke, said fuel injector performing a second fuel injection after said first fuel injection, and combusting fuel from said first and second fuel injections to perform a combustion event in said cylinder.

Owner:FORD GLOBAL TECH LLC

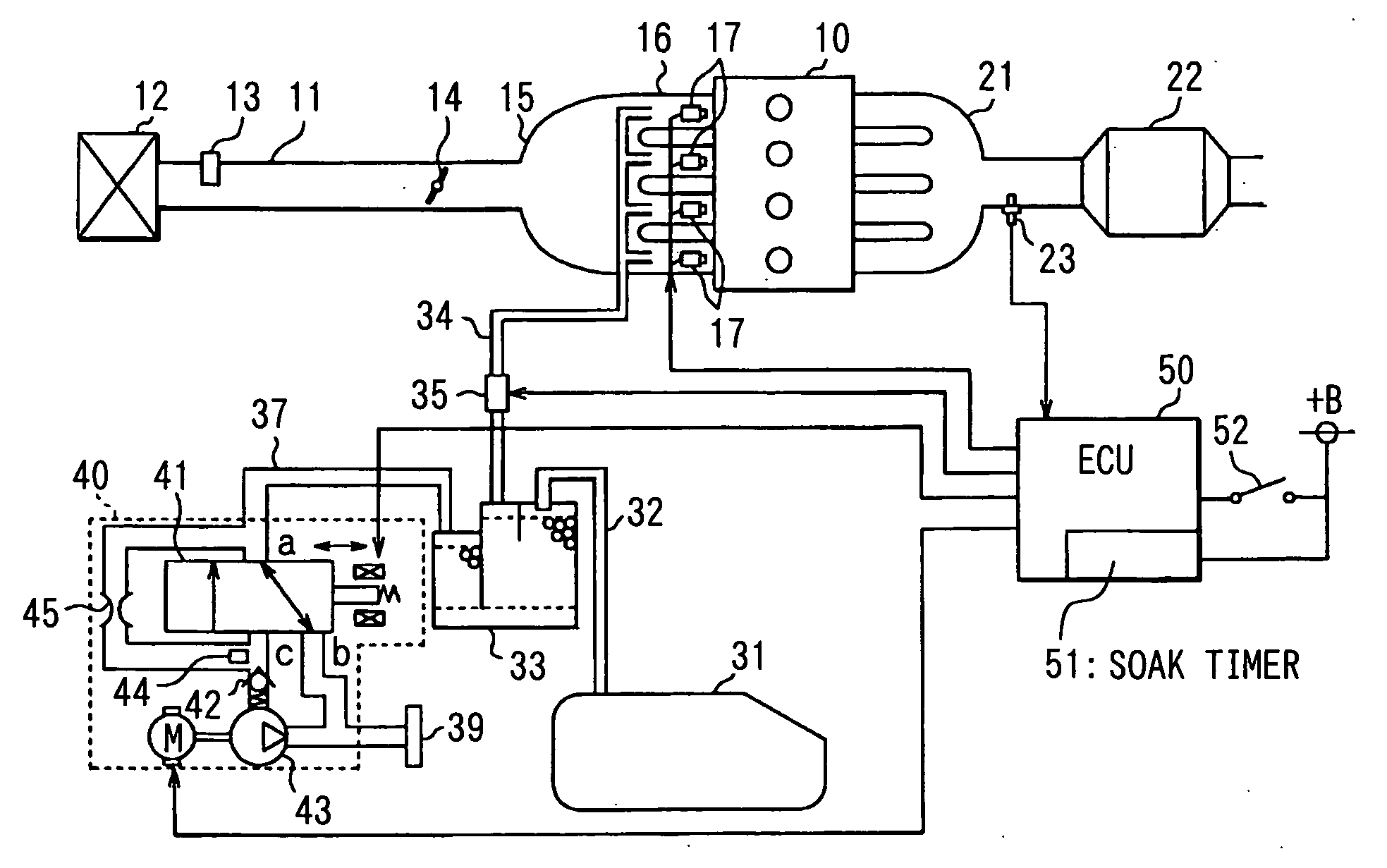

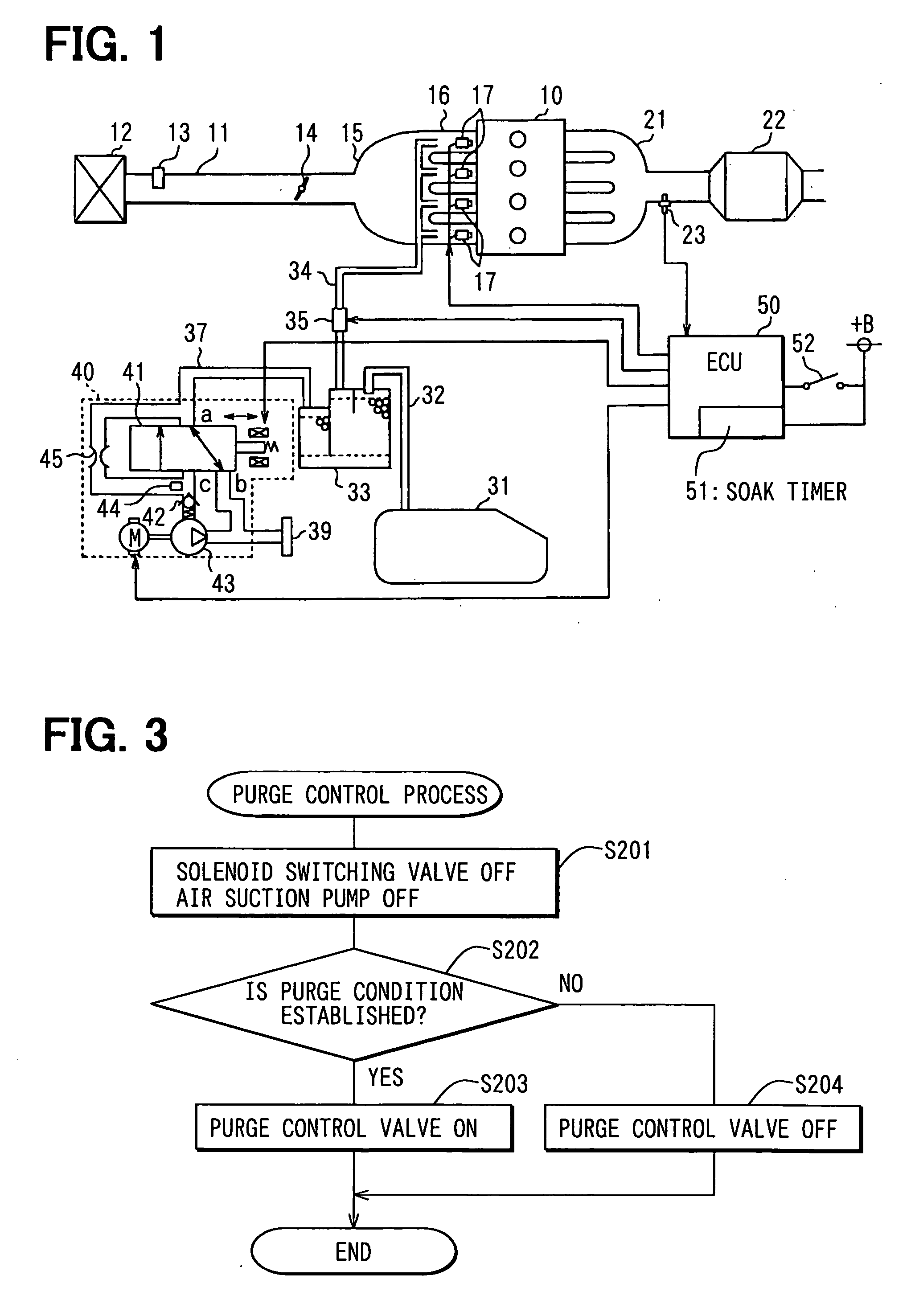

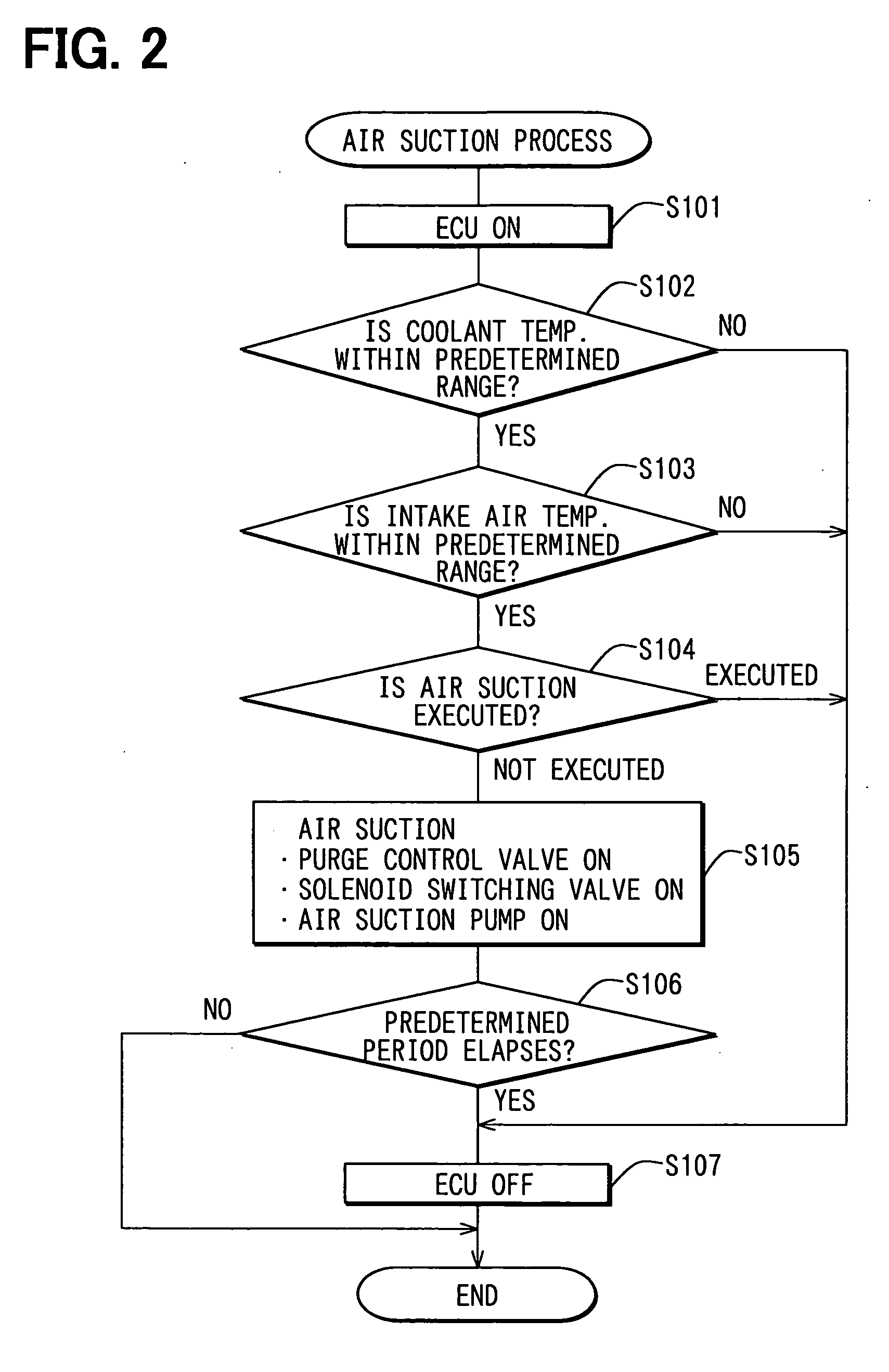

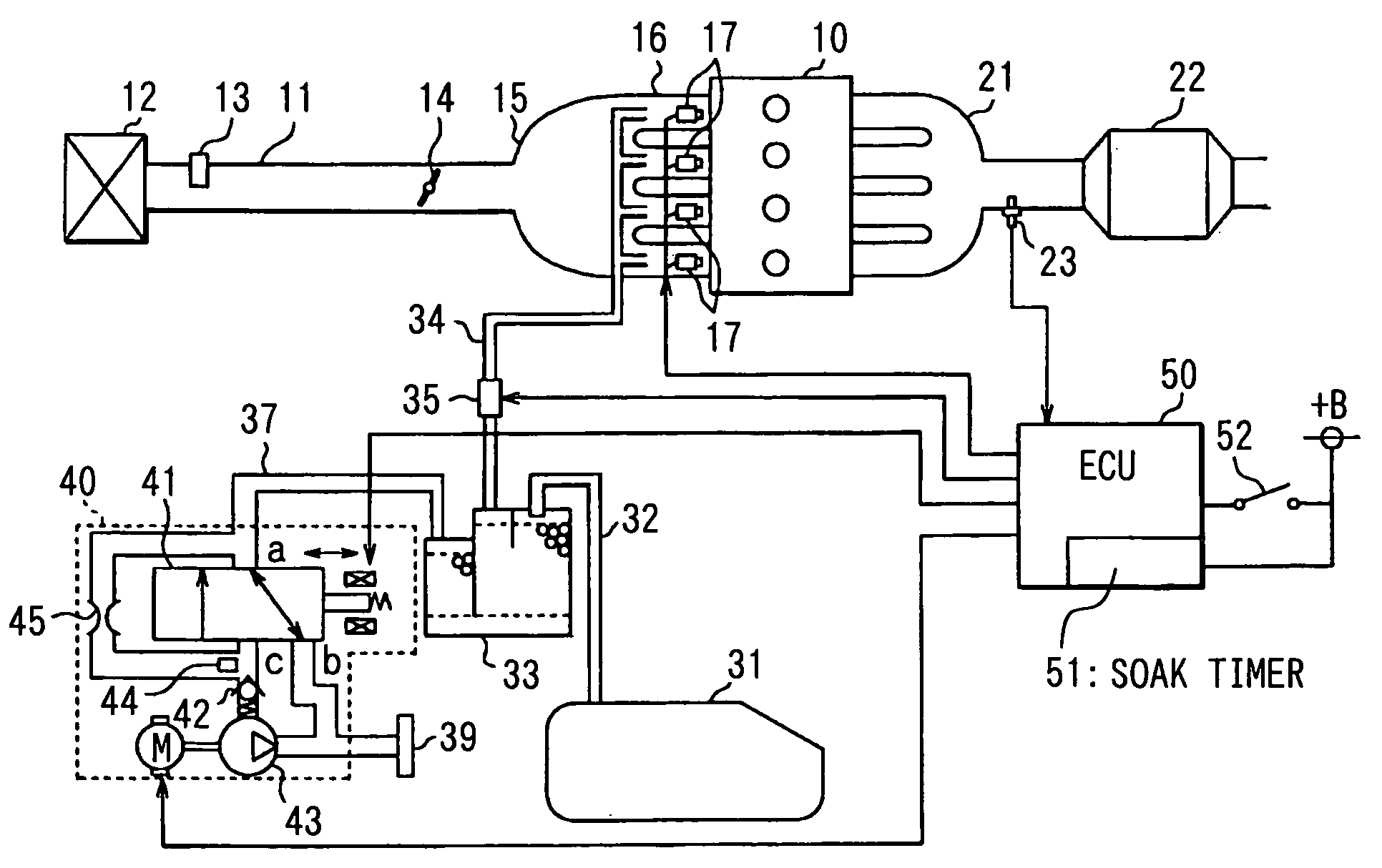

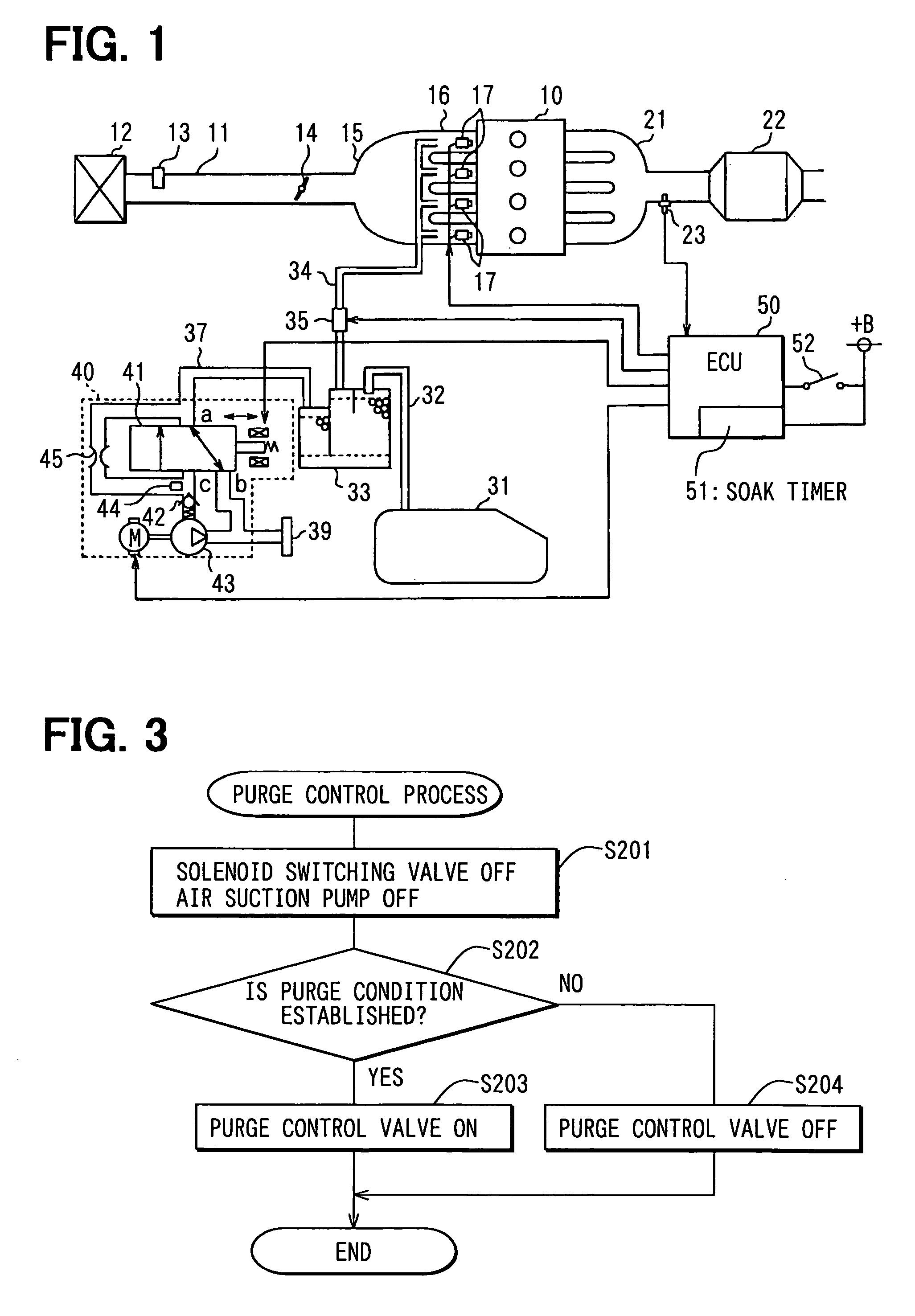

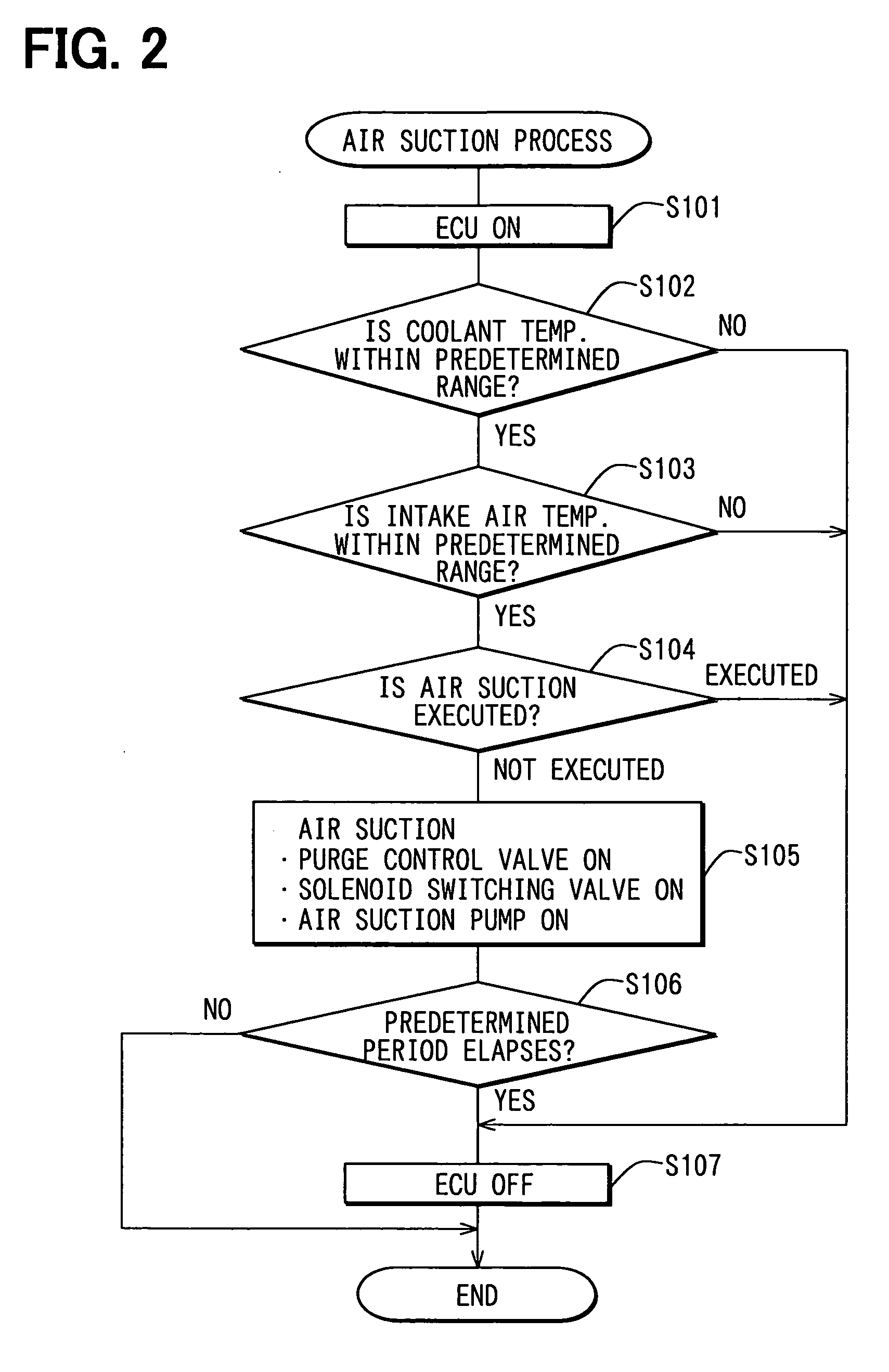

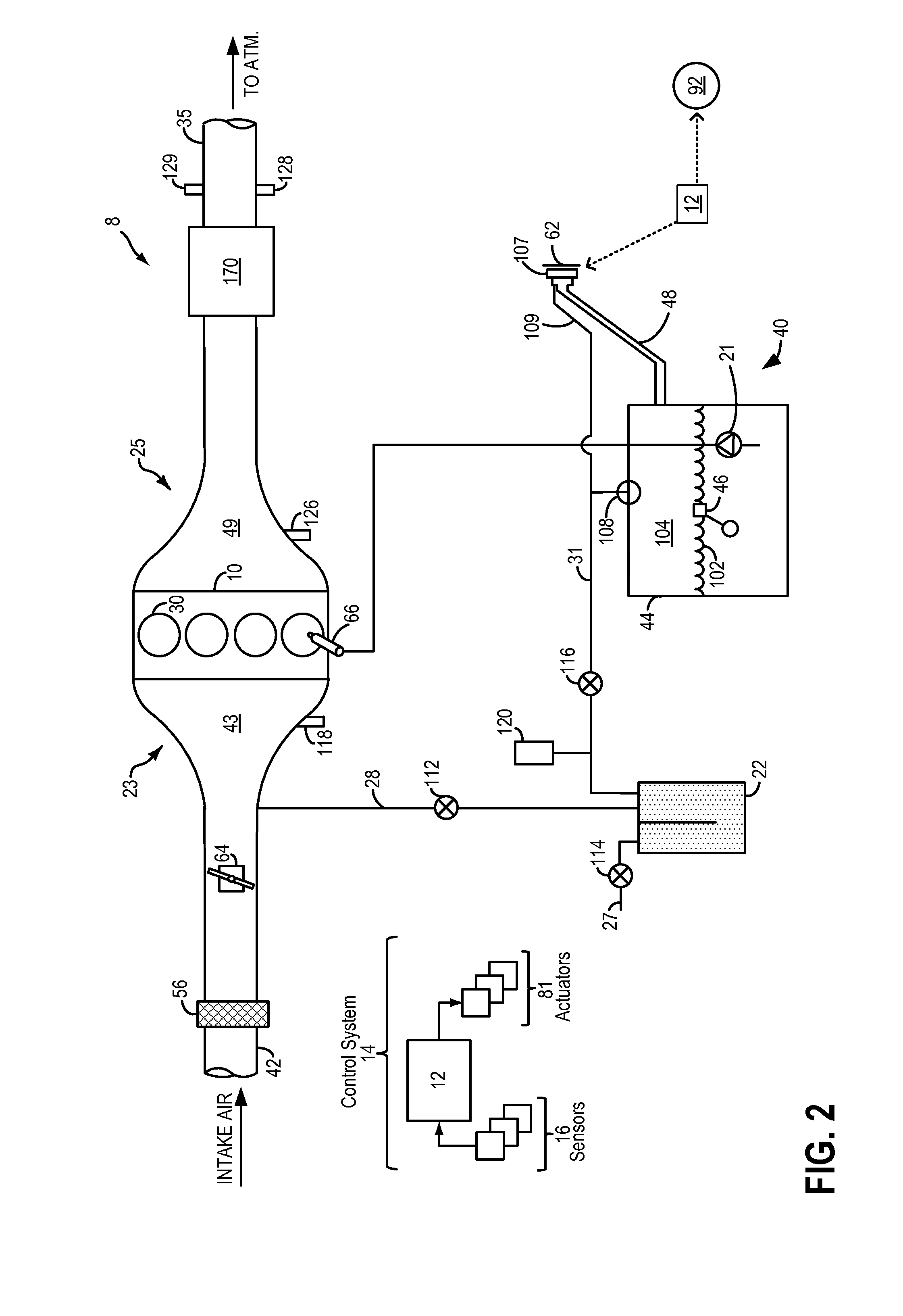

Apparatus for reducing hydrocarbon emission of internal combustion engine

InactiveUS20050011185A1Restrain deteriorationReduce emissionElectrical controlNon-fuel substance addition to fuelEngineeringFuel vapor

A canister communicates with an intake manifold of an internal combustion engine through a purge pipe. The canister absorbs fuel vapor evaporated in a fuel tank. The absorbed fuel vapor is purged into the intake manifold when the engine is on. A gas leak check module communicates with the canister for drawing air by an air suction pump 43. When the engine is off, the air suction pump is driven and draws hydrocarbon floating at a vicinity of an intake port through the purge pipe. Thus, the hydrocarbon floating at the vicinity of the intake port is absorbed in the canister so that emission of hydrocarbon is reduced.

Owner:DENSO CORP +1

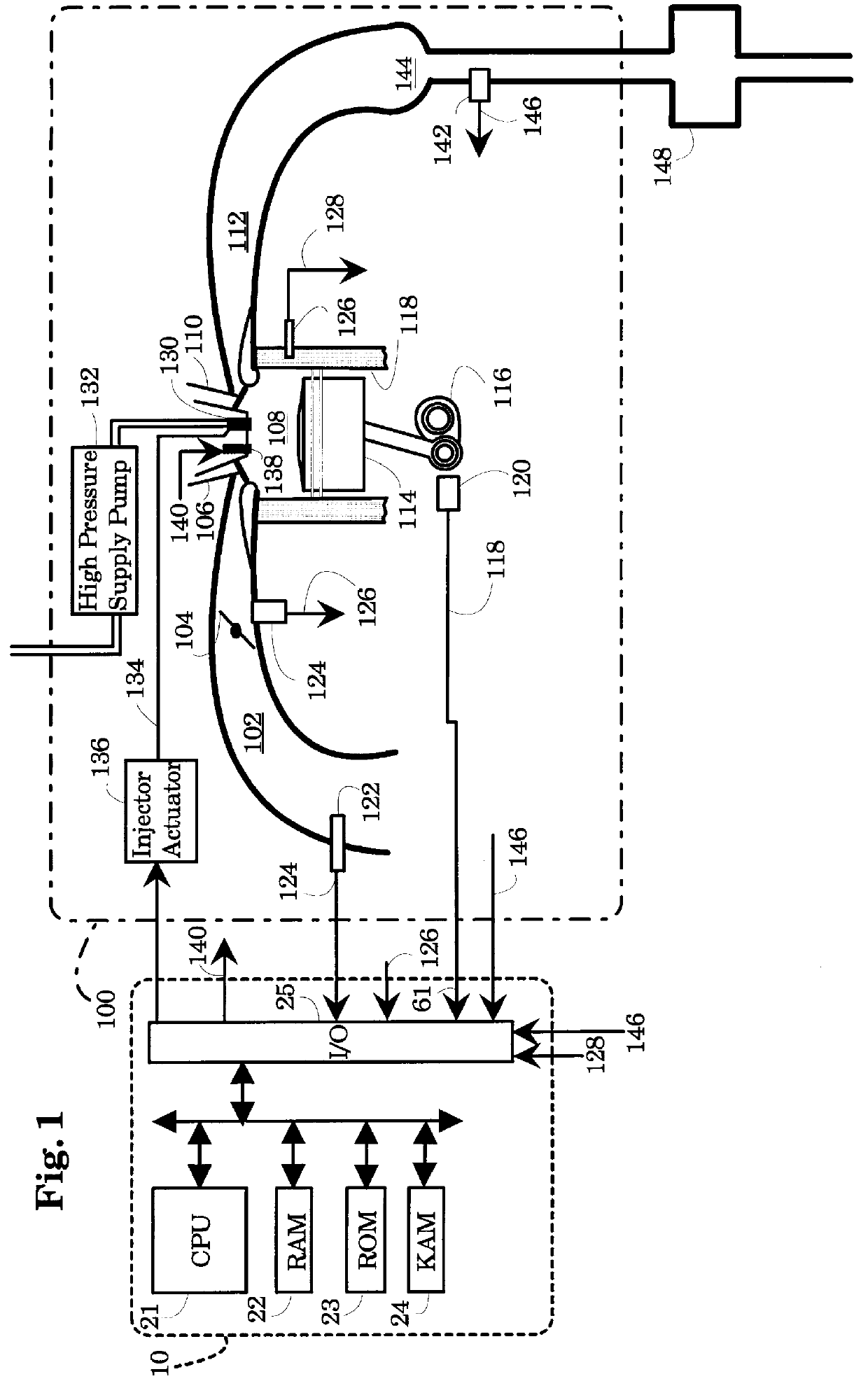

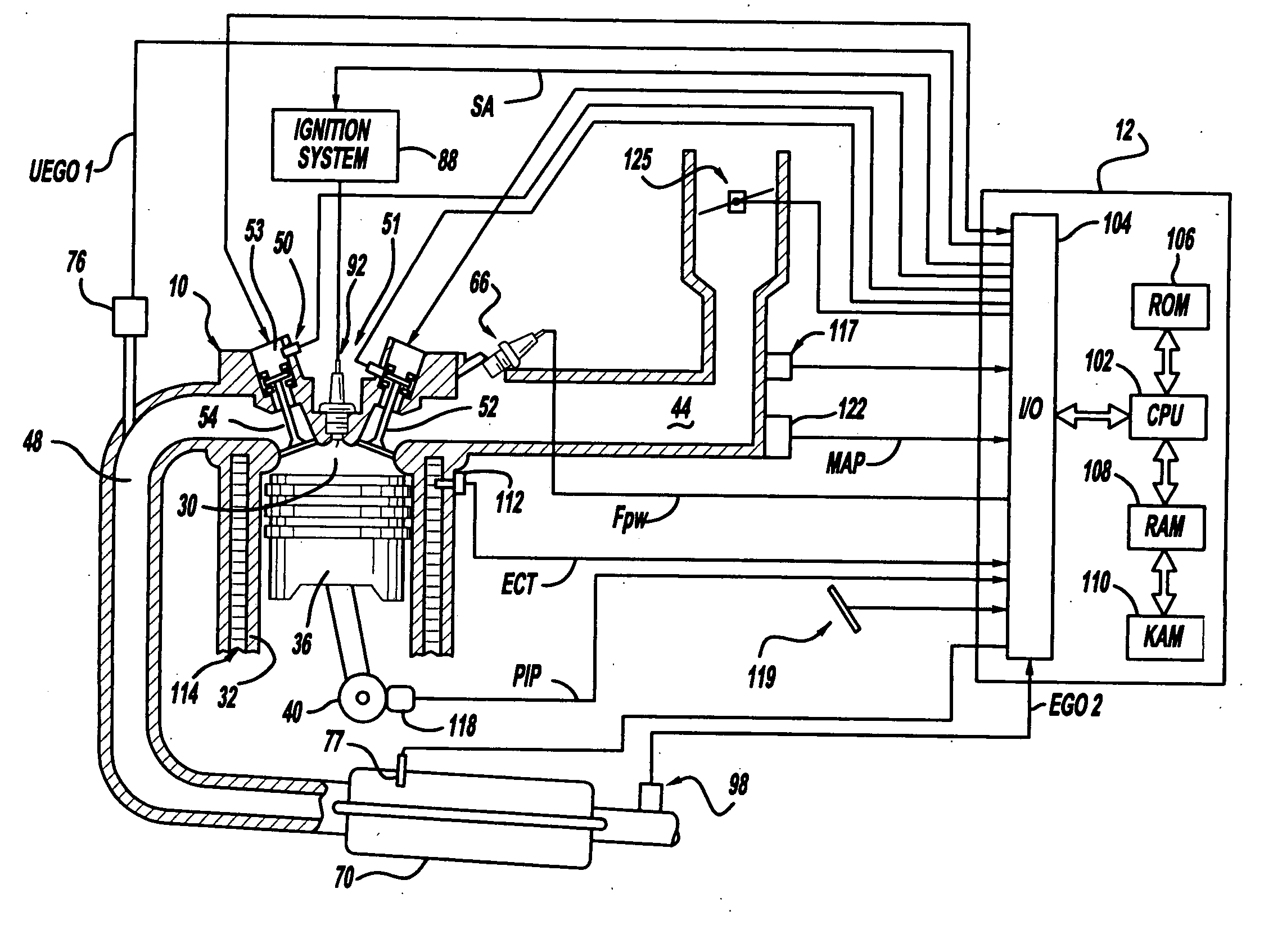

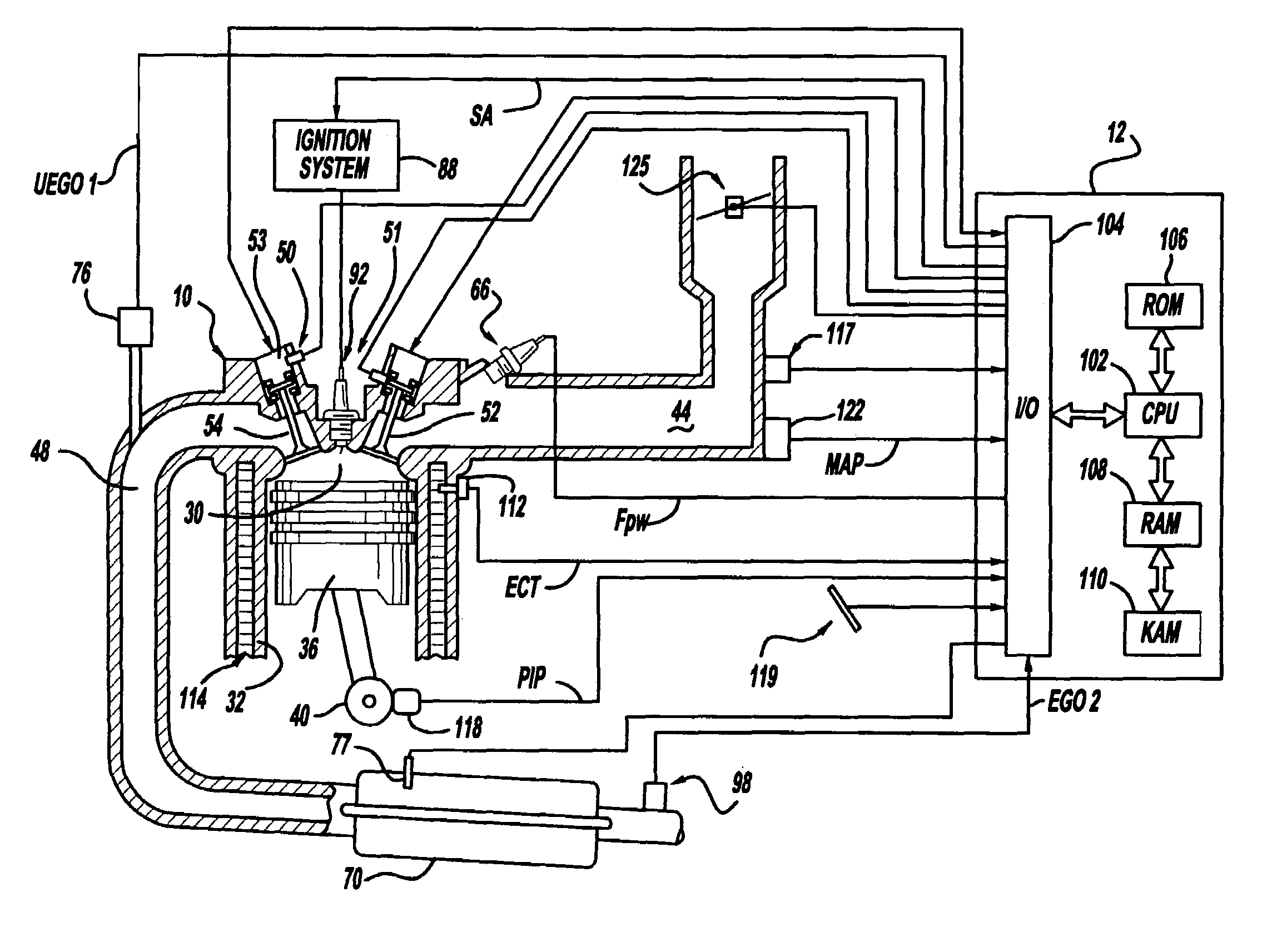

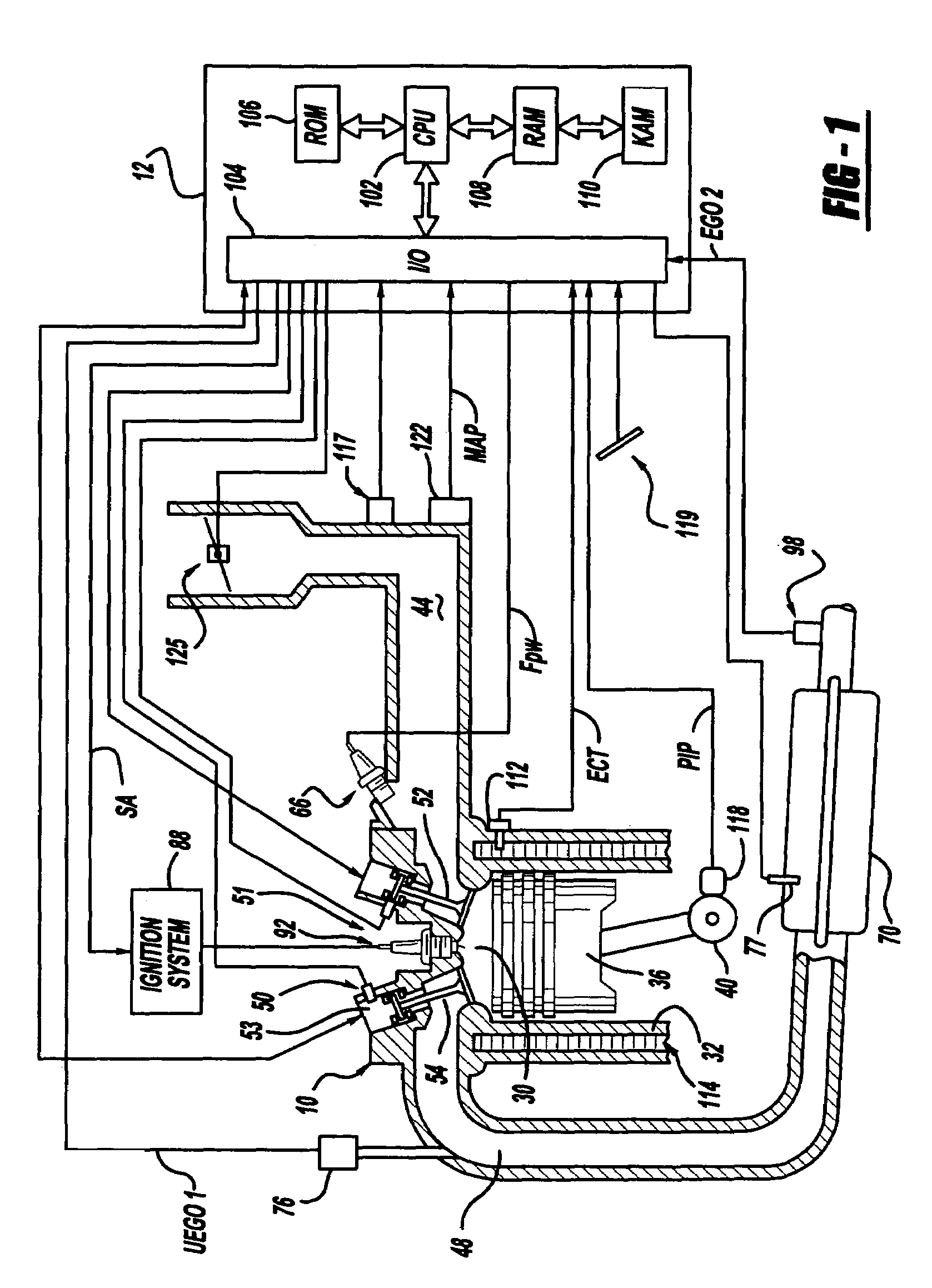

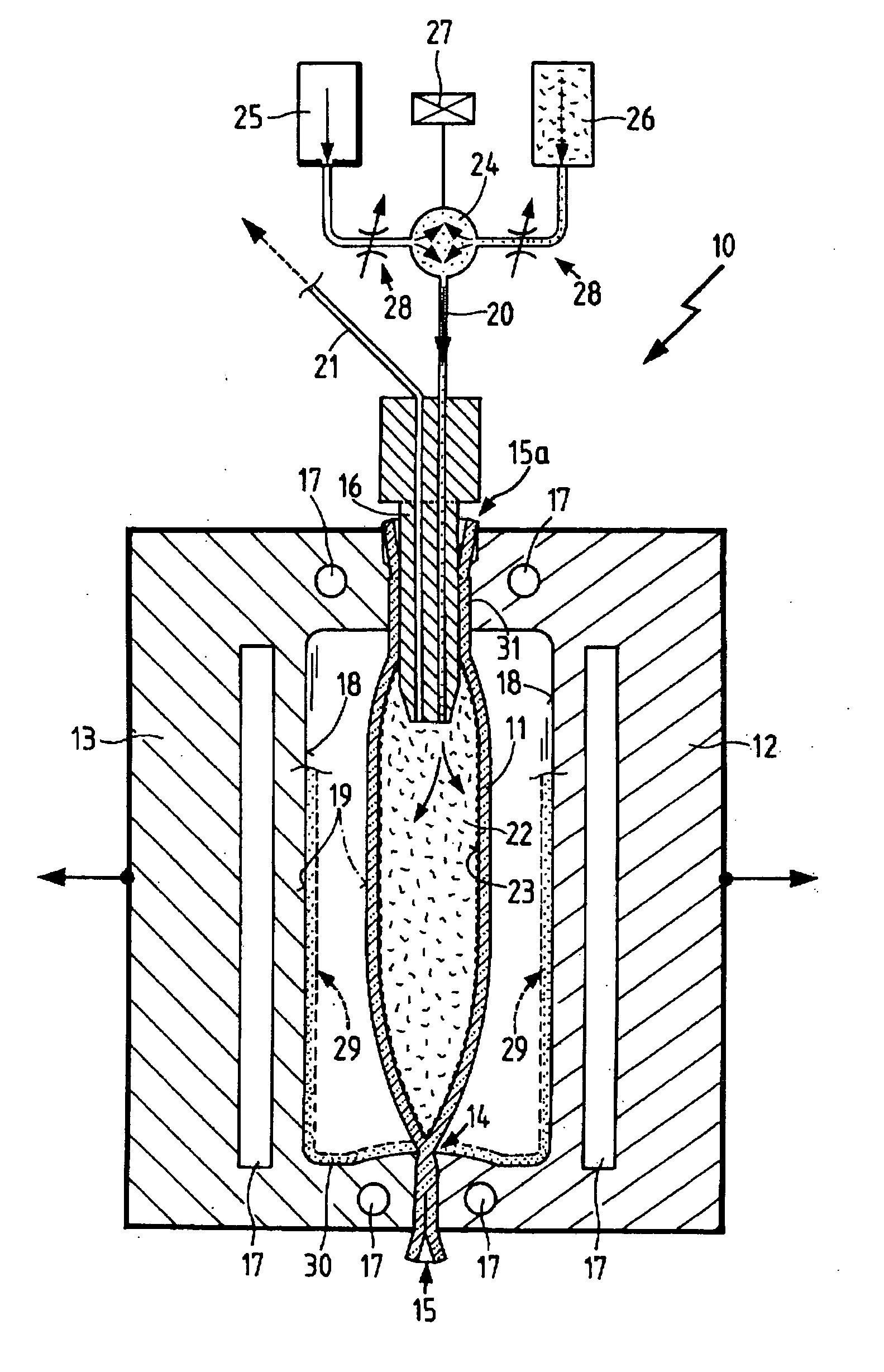

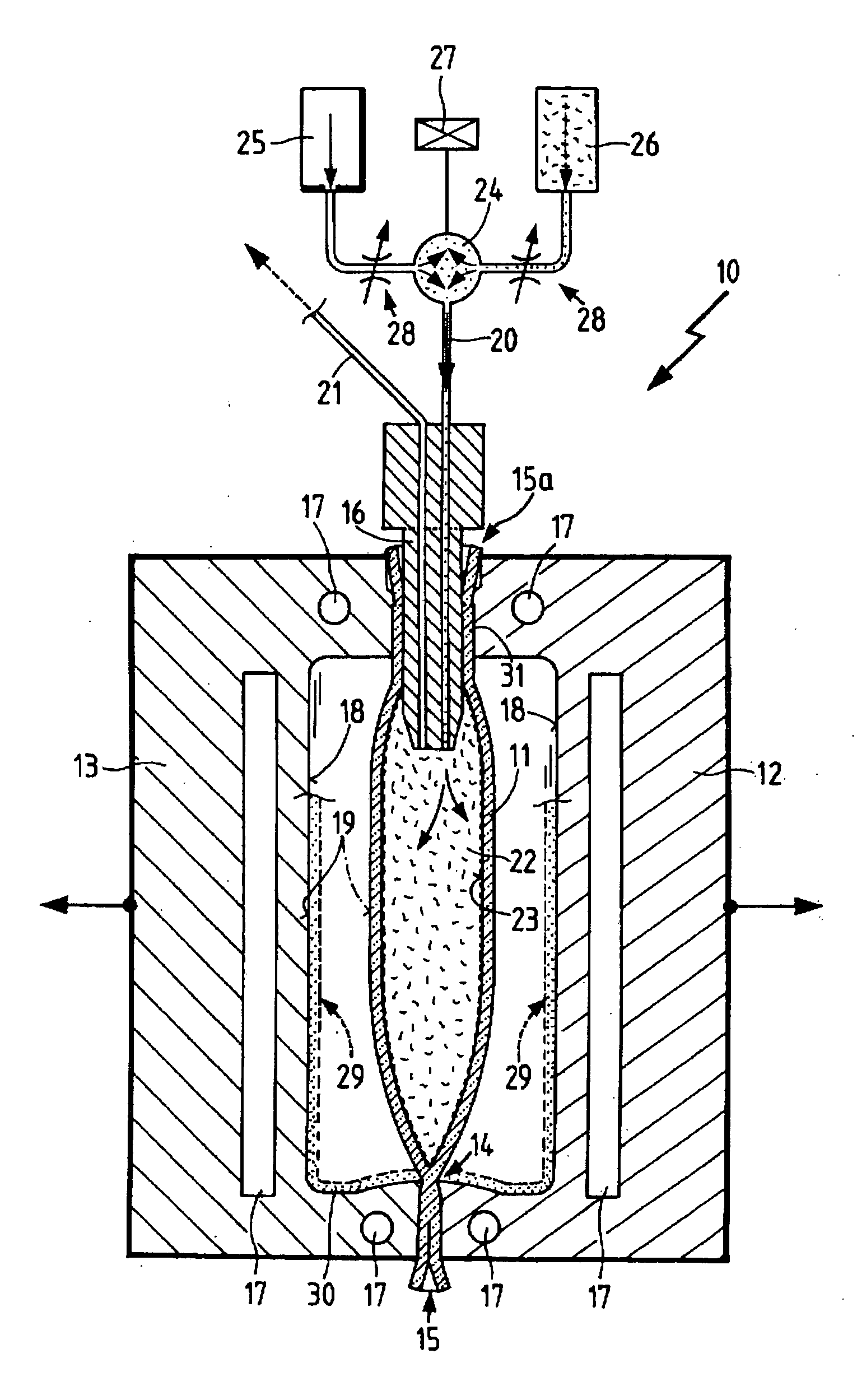

Reduction of cold-start emissions and catalyst warm-up time with direct fuel injection

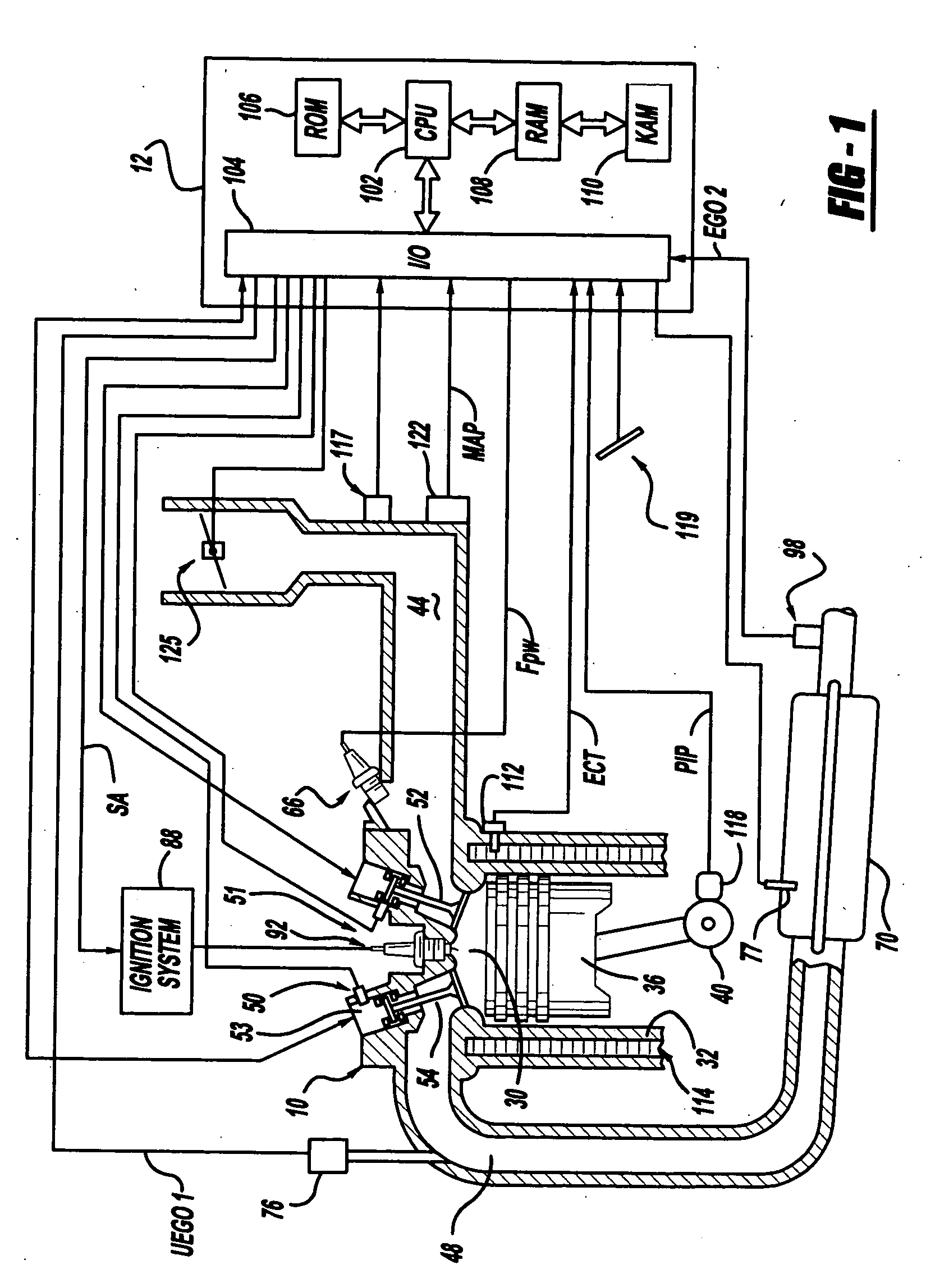

InactiveUSRE36737E1Reduce decreaseReduce hydrocarbonElectrical controlInternal combustion piston enginesCombustion chamberInternal combustion engine

An internal combustion engine employs fuel injectors positioned to inject fuel directly into combustion chambers of the engine, and an electronic engine controller (EEC) to control operation of the engine. The EEC implements a cold start routine which controls the amount of fuel injected, the time at which the fuel is injected and spark timing to achieve a rapid increase in temperature of the engine and the exhaust system components, thereby decreasing tailpipe hydrocarbon emissions during cold start.

Owner:FORD GLOBAL TECH LLC

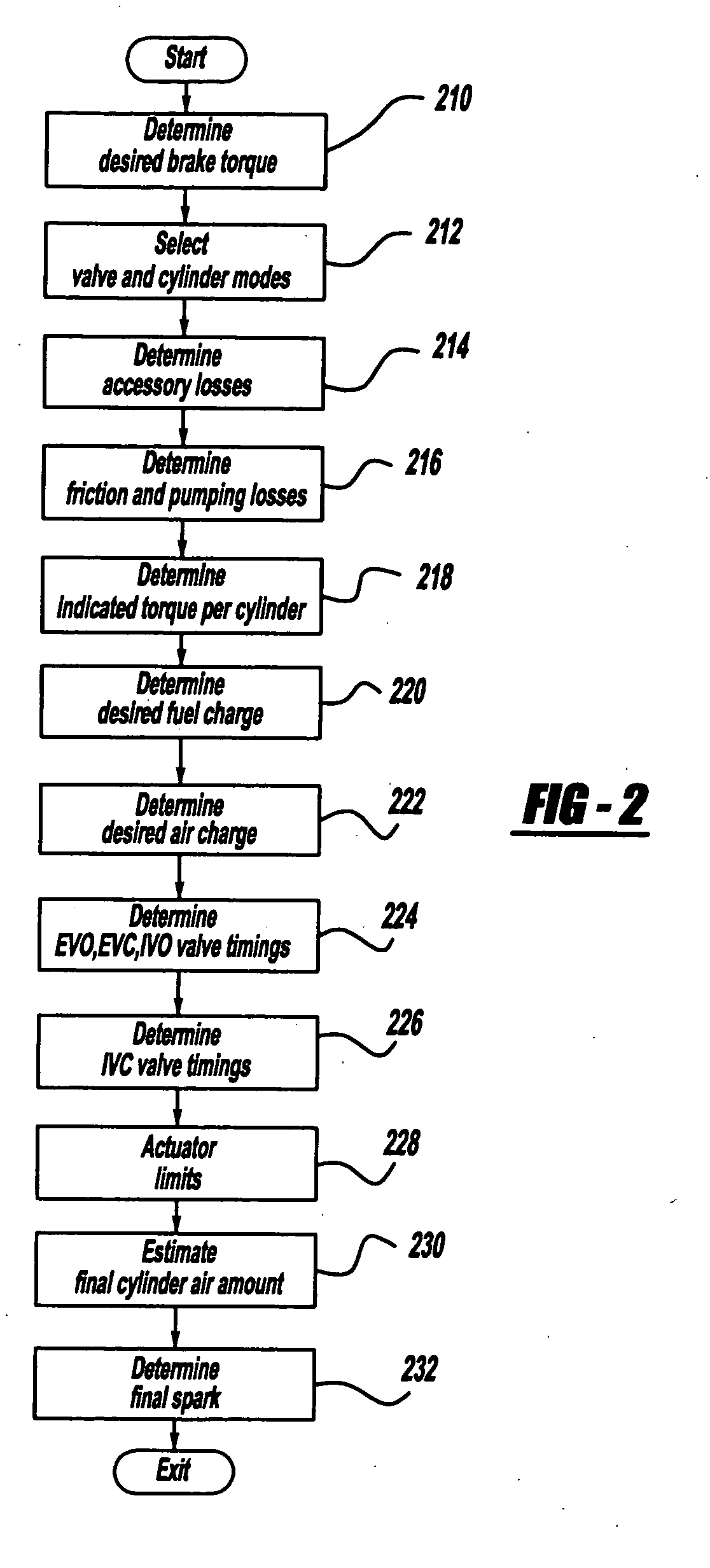

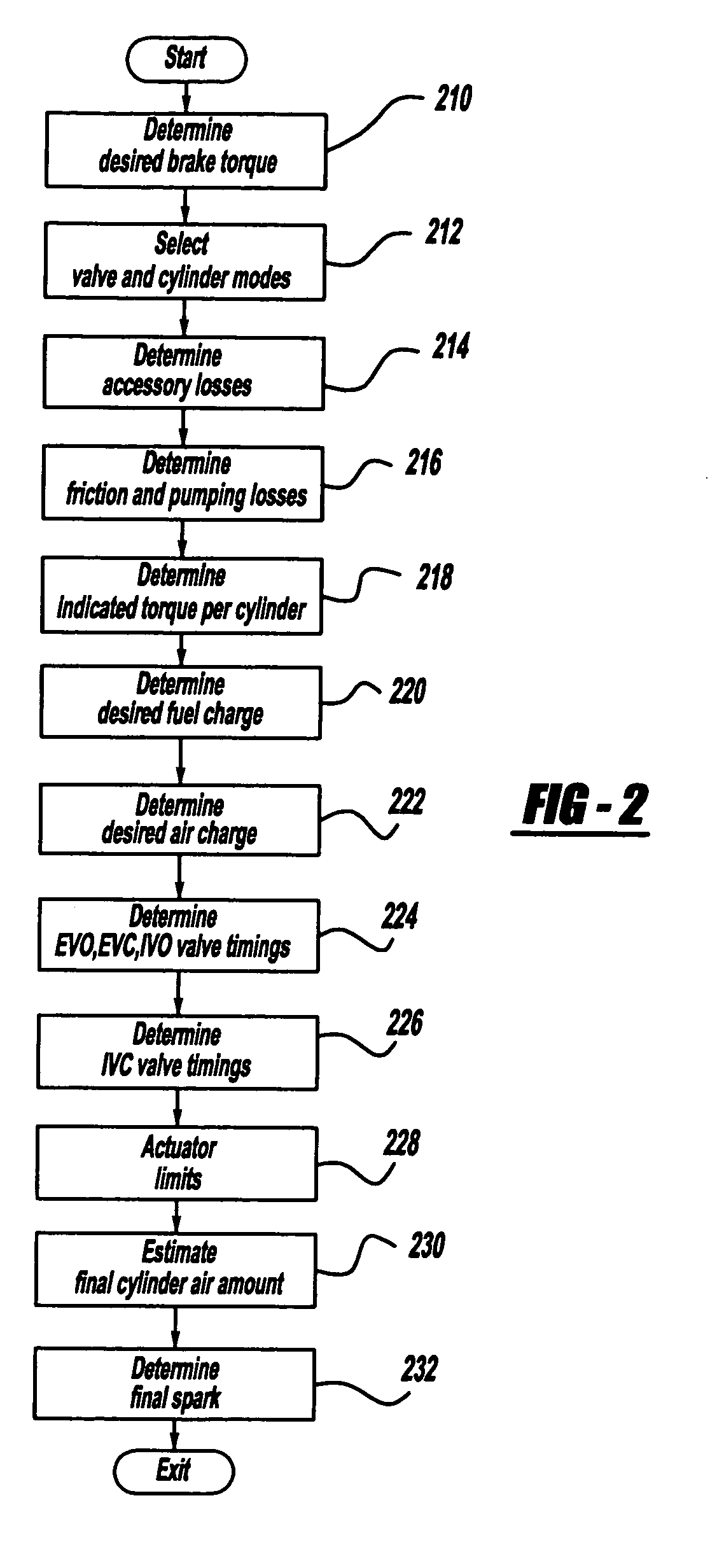

Starting an engine with valves that may be deactivated

ActiveUS20050205037A1Reduce engine emissionsReduce vibrationHybrid vehiclesElectrical controlEngine valveInternal combustion engine

A system and method to control engine valve timing to during the start of an internal combustion engine. Valves that may be deactivated are controlled in a manner to reduce hydrocarbon emissions during the start of an internal combustion engine.

Owner:FORD GLOBAL TECH LLC

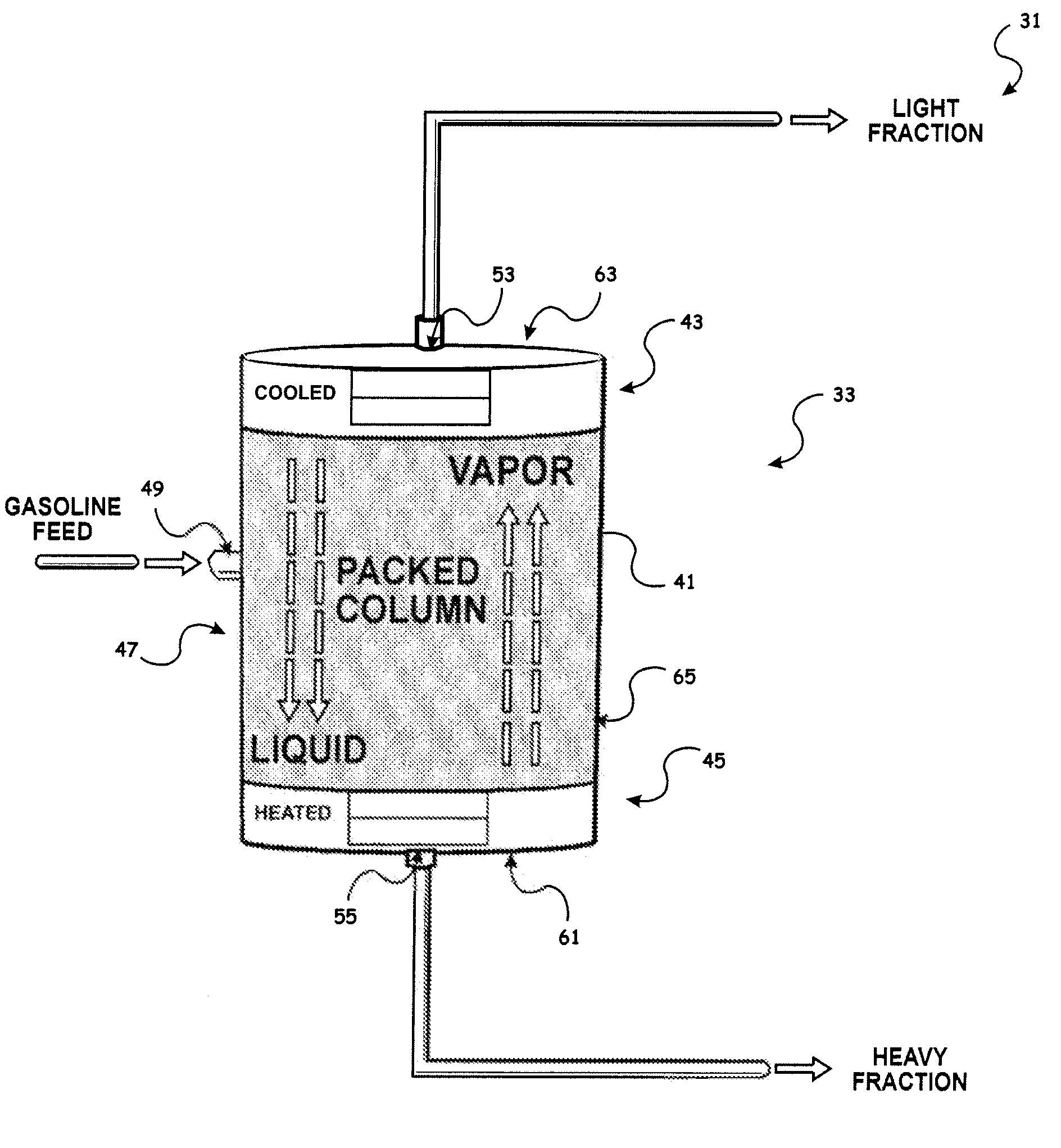

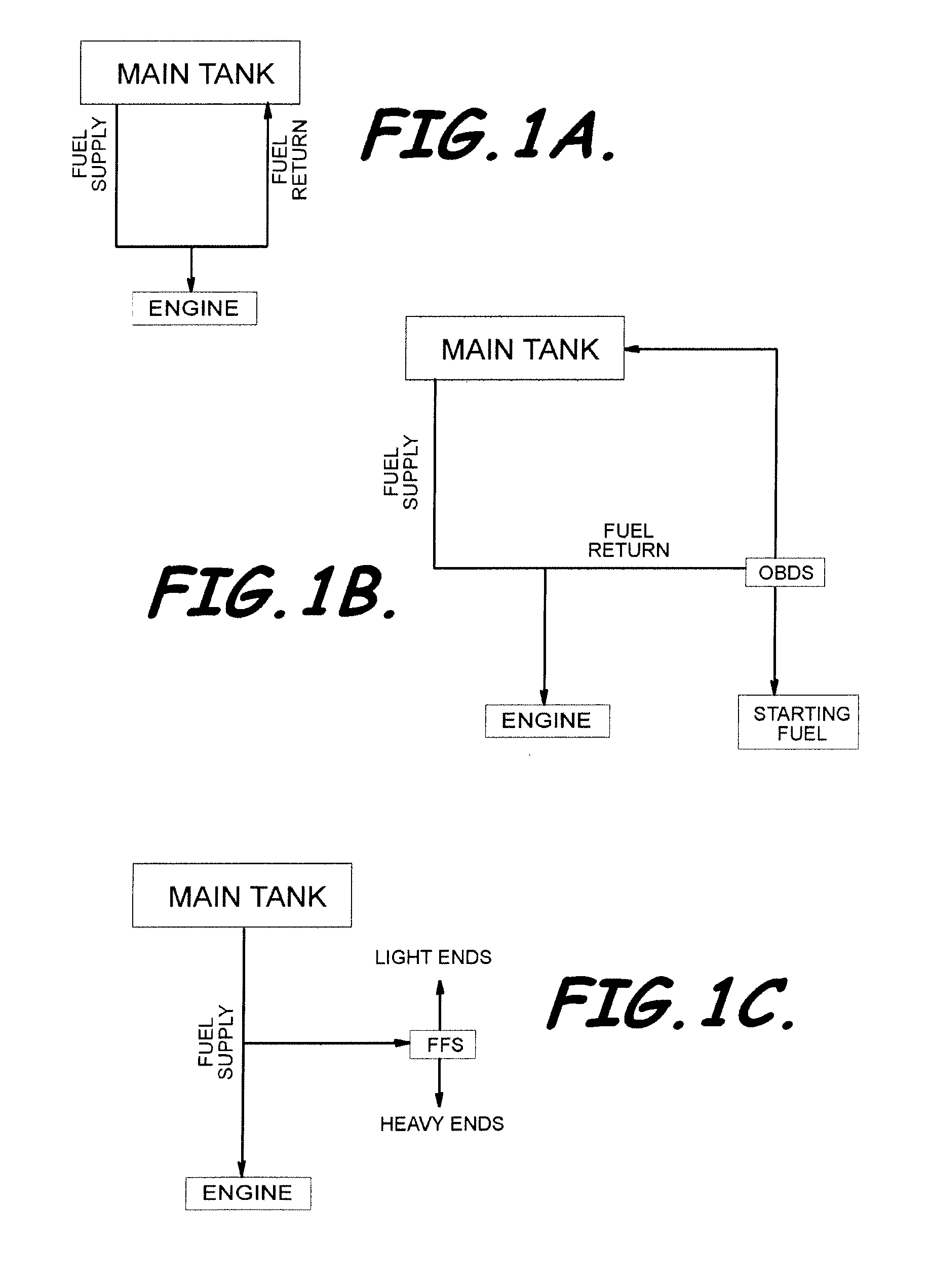

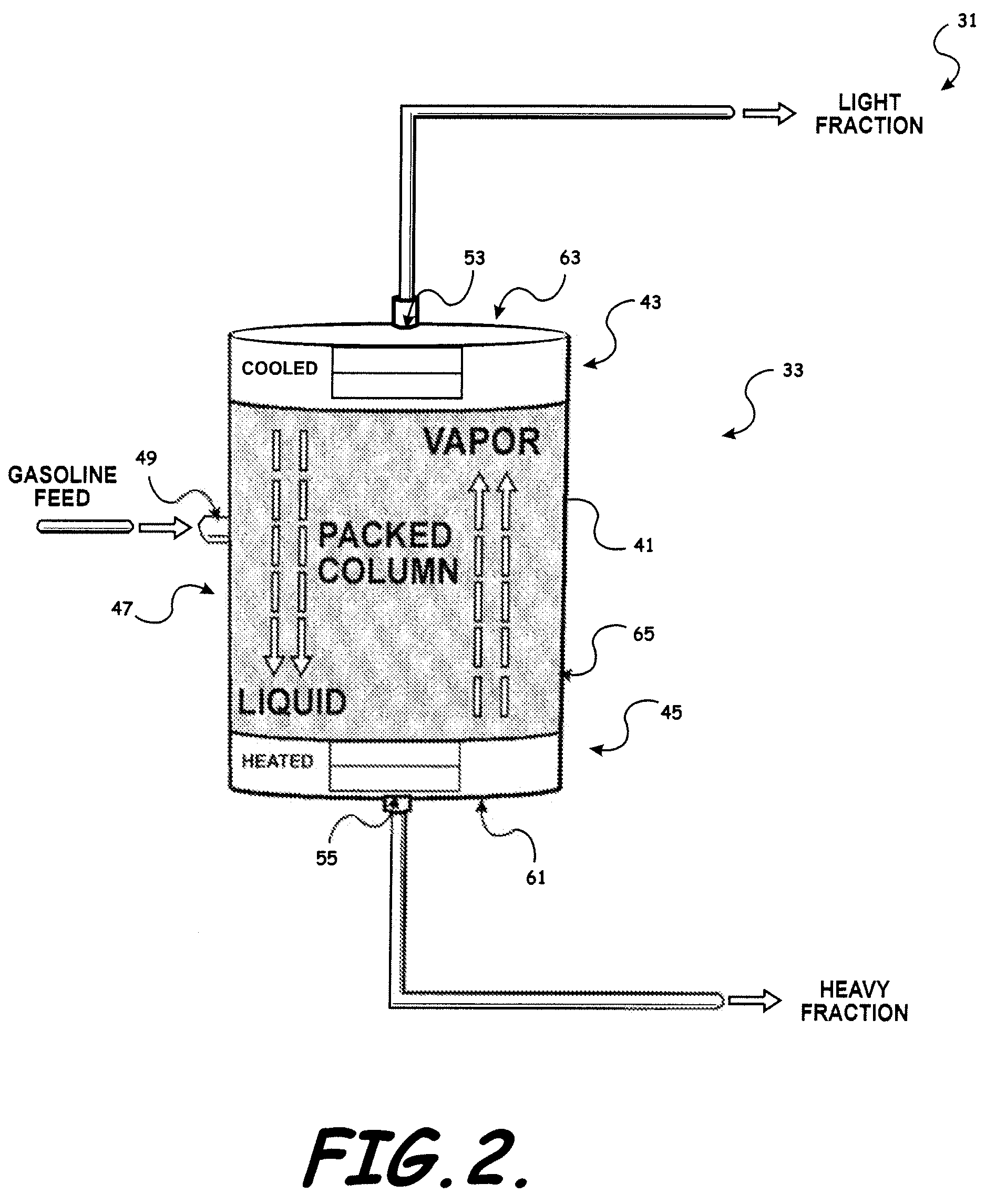

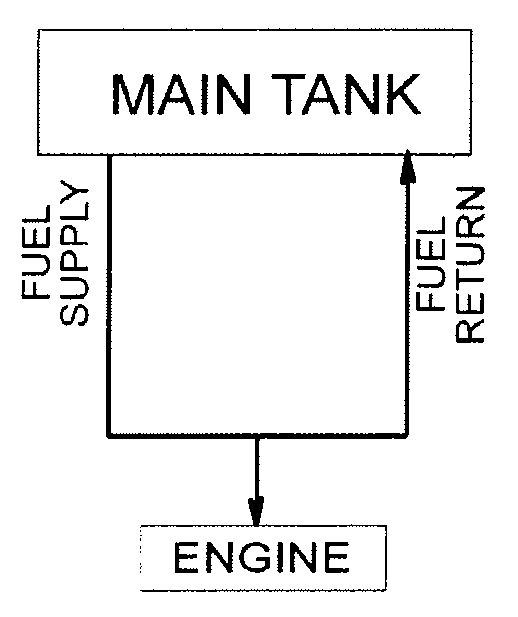

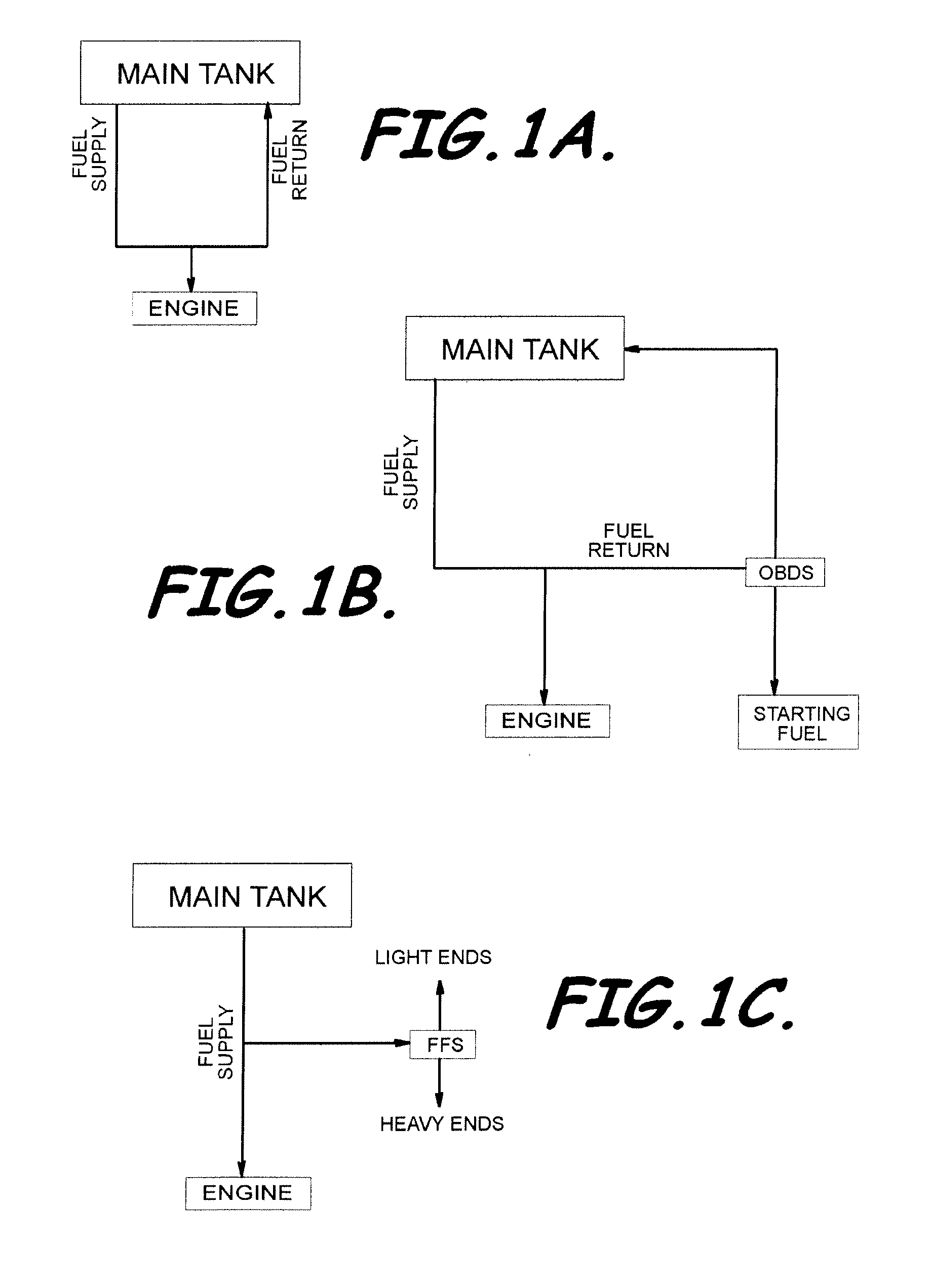

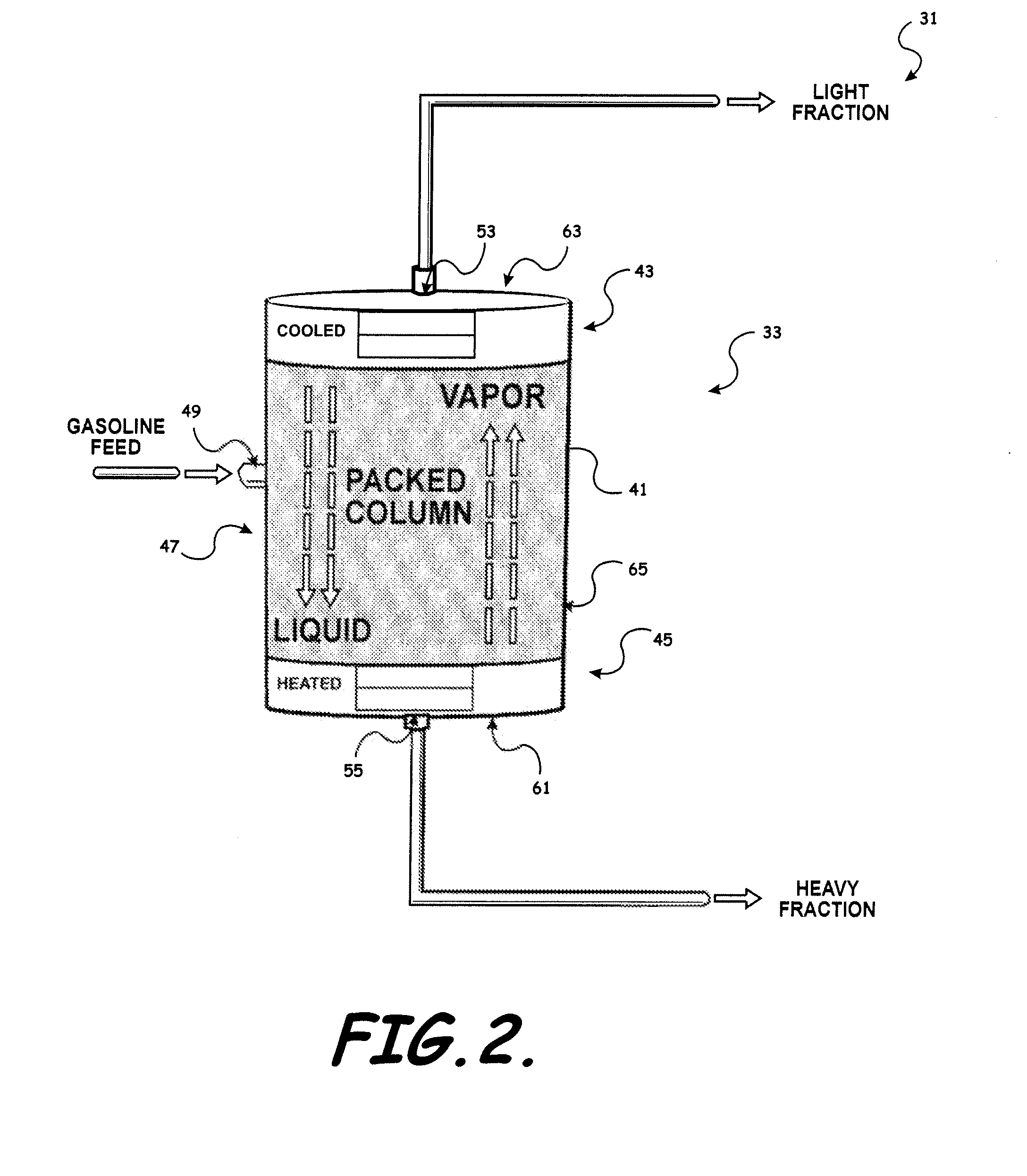

On-board fuel fractionation system and methods to generate an engine starting fuel

InactiveUS7370610B2Efficient separationAccelerate emissionsThermal non-catalytic crackingDistillation regulation/controlDistillationFractionation

A Fuel Fractionation System (FFS) and associated methods to generate and store a fuel for internal combustion engines is provided. FFS provides a distillation column assembly to distill liquid fuel to form a volatile light fraction secondary fuel. The distillation column assembly includes a vaporization module to vaporize a feed fuel in the distillation column and includes a condensation module to condense heavy fraction components of the vaporized feed fuel. FFS also provides a controller positioned to control the vaporization of feed fuel in the distillation column to thereby control the separation of the feed fuel into light fraction fuel and heavy fraction fuel components, and positioned to control the condensation of the heavy fraction components so that fuel exiting a light fraction output port in the distillation column is substantially light fraction fuel components by volume.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Apparatus for reducing hydrocarbon emission of internal combustion engine

InactiveUS7107759B2Lower hydrocarbon emissionsDeterioration of characteristic is restrictedElectrical controlNon-fuel substance addition to fuelExternal combustion engineInlet manifold

A canister communicates with an intake manifold of an internal combustion engine through a purge pipe. The canister absorbs fuel vapor evaporated in a fuel tank. The absorbed fuel vapor is purged into the intake manifold when the engine is on. A gas leak check module communicates with the canister for drawing air by an air suction pump 43. When the engine is off, the air suction pump is driven and draws hydrocarbon floating at a vicinity of an intake port through the purge pipe. Thus, the hydrocarbon floating at the vicinity of the intake port is absorbed in the canister so that emission of hydrocarbon is reduced.

Owner:DENSO CORP +1

Starting an engine with valves that may be deactivated

ActiveUS7194993B2Increase flexibilityReduce the amount requiredHybrid vehiclesElectrical controlEngine valveInternal combustion engine

A system and method to control engine valve timing to during the start of an internal combustion engine. Valves that may be deactivated are controlled in a manner to reduce hydrocarbon emissions during the start of an internal combustion engine.

Owner:FORD GLOBAL TECH LLC

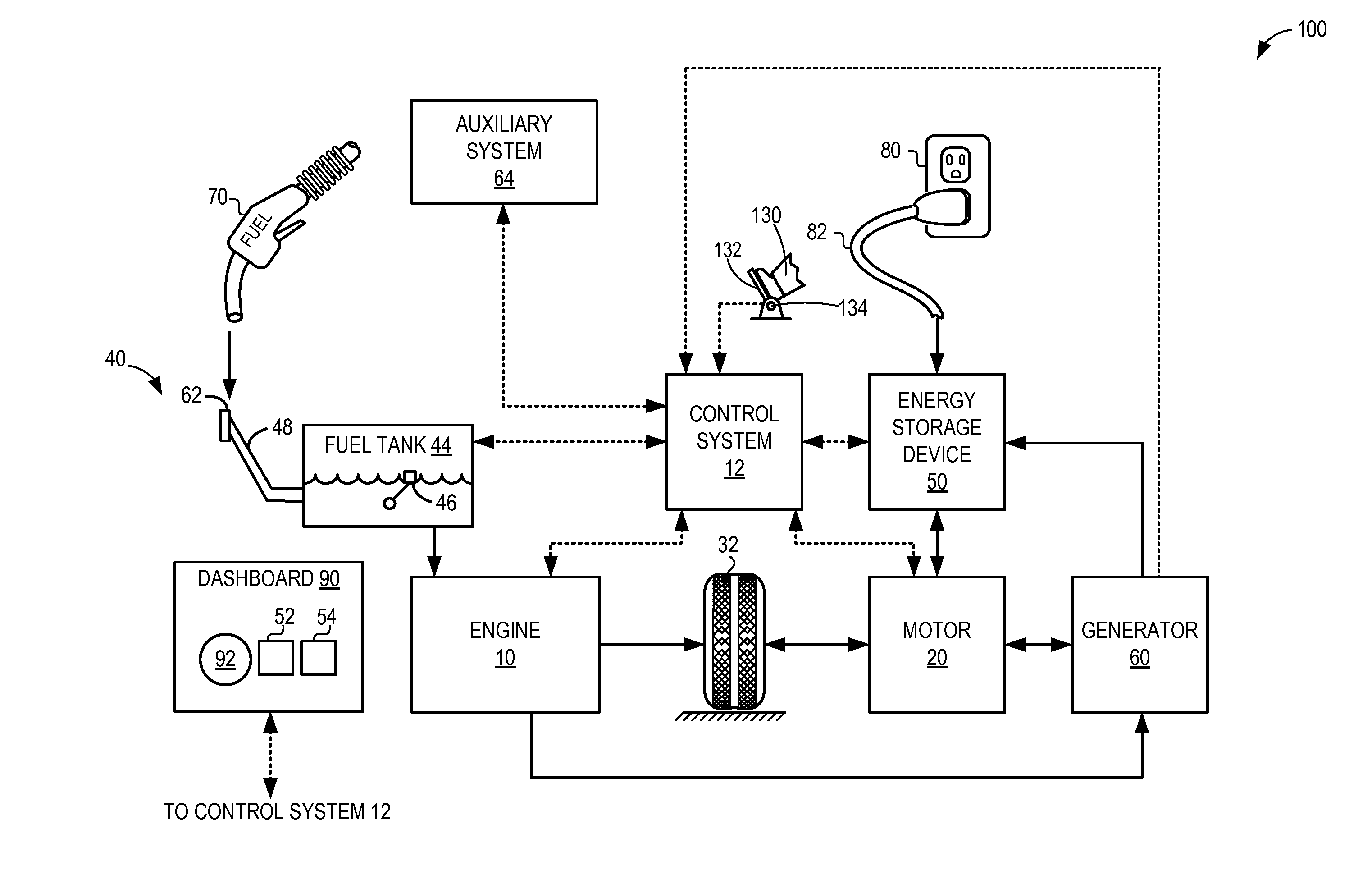

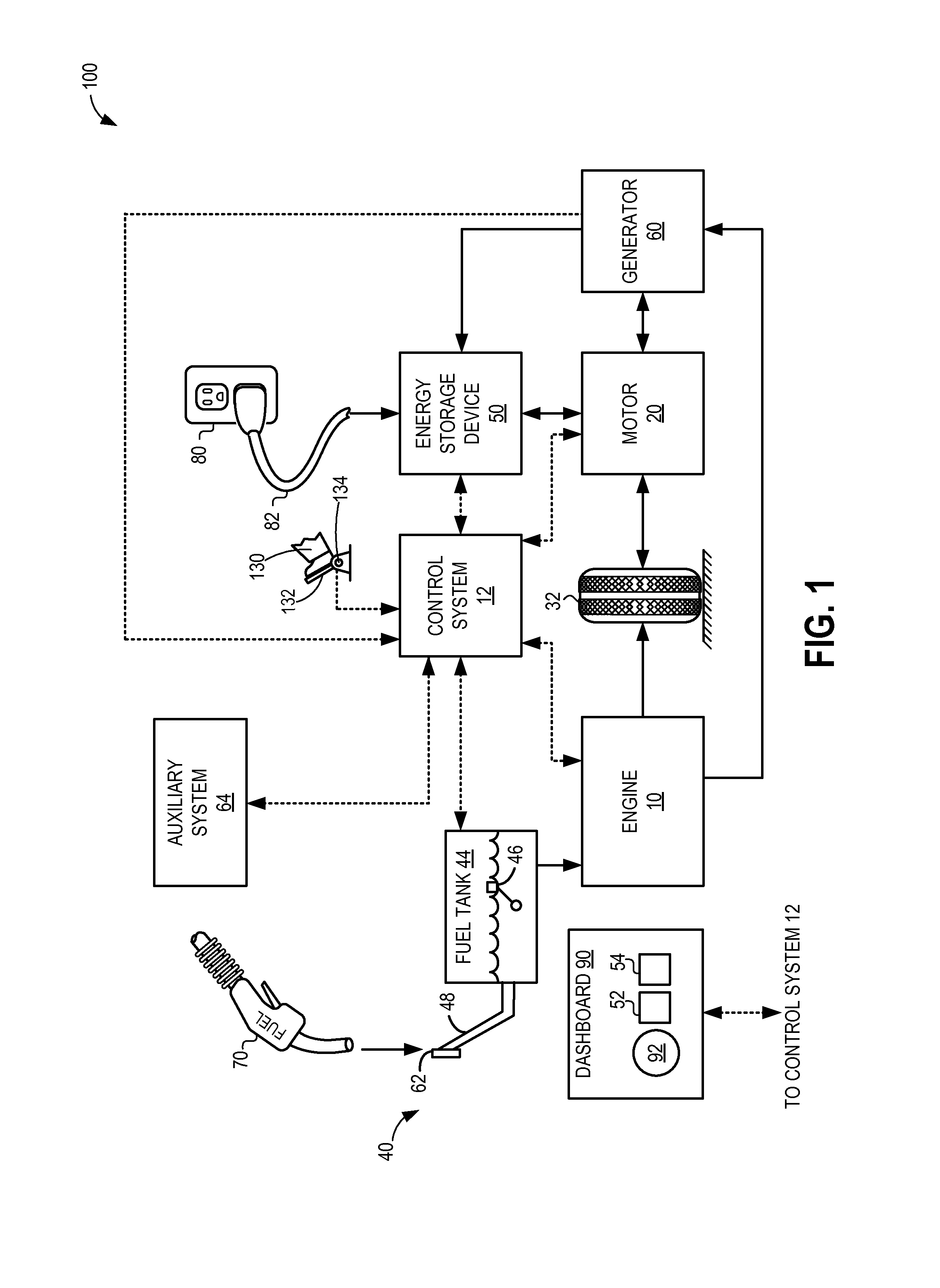

Fuel system control

ActiveUS20140374177A1Reliably determinedAccurate identificationHybrid vehiclesNon-fuel substance addition to fuelFuel tankAtmosphere

Methods and systems are provided for accurately confirming fuel tank depressurization before unlocking a fuel door to enable refueling. Following a refueling request, a fuel system may be sealed from the atmosphere while one or more fuel system valves are adjusted to divert fuel tank pressure or vacuum to an engine intake. Depressurization may be inferred based on the presence of air or vapor flow into the intake as sensed by a manifold airflow sensor.

Owner:FORD GLOBAL TECH LLC

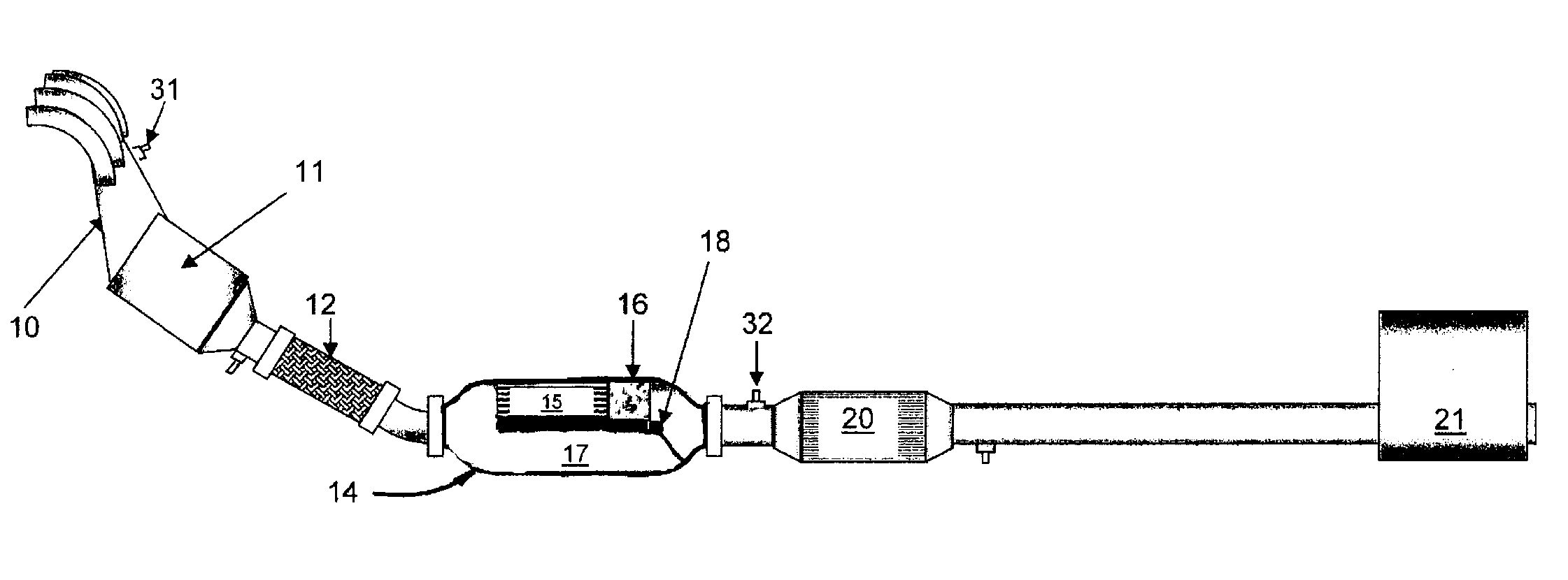

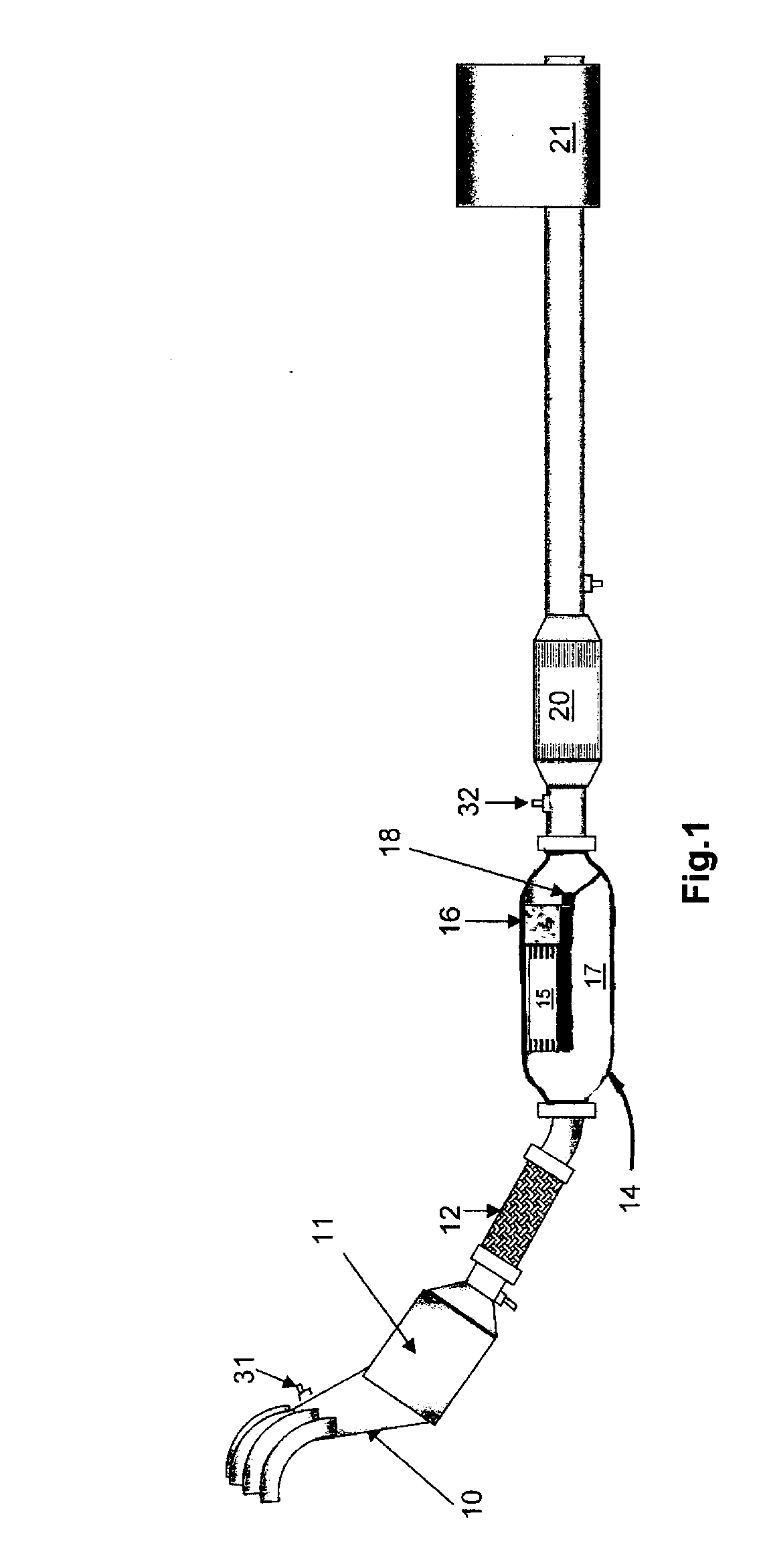

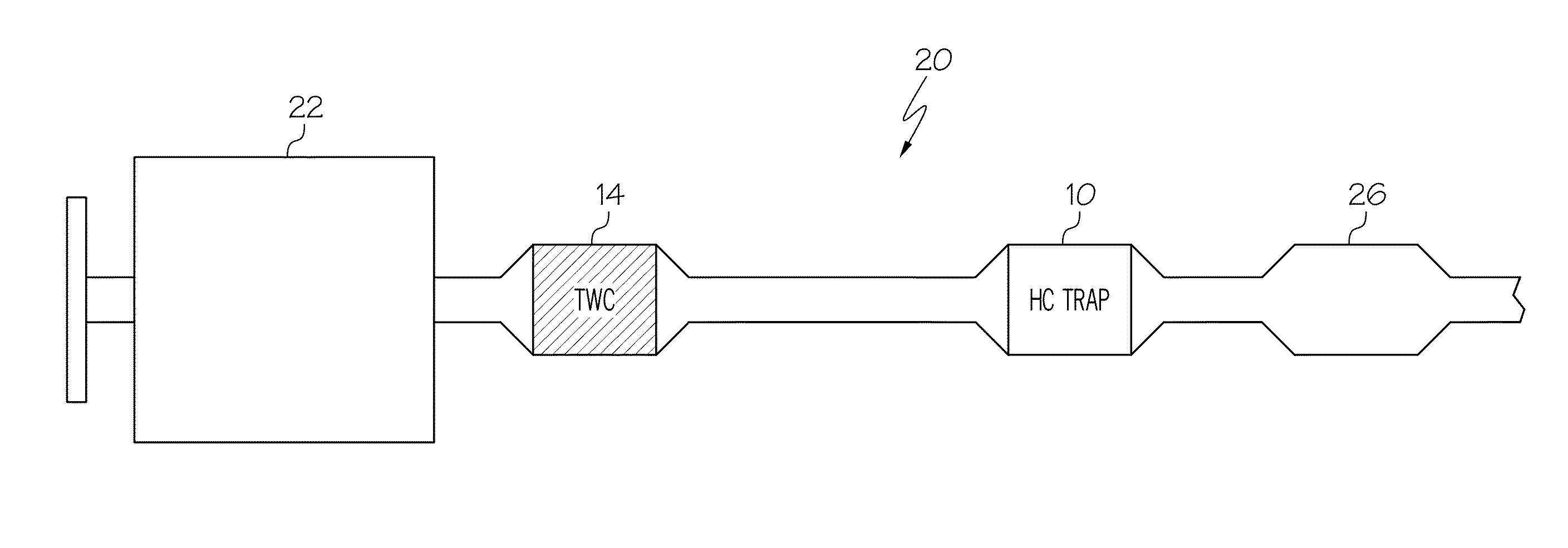

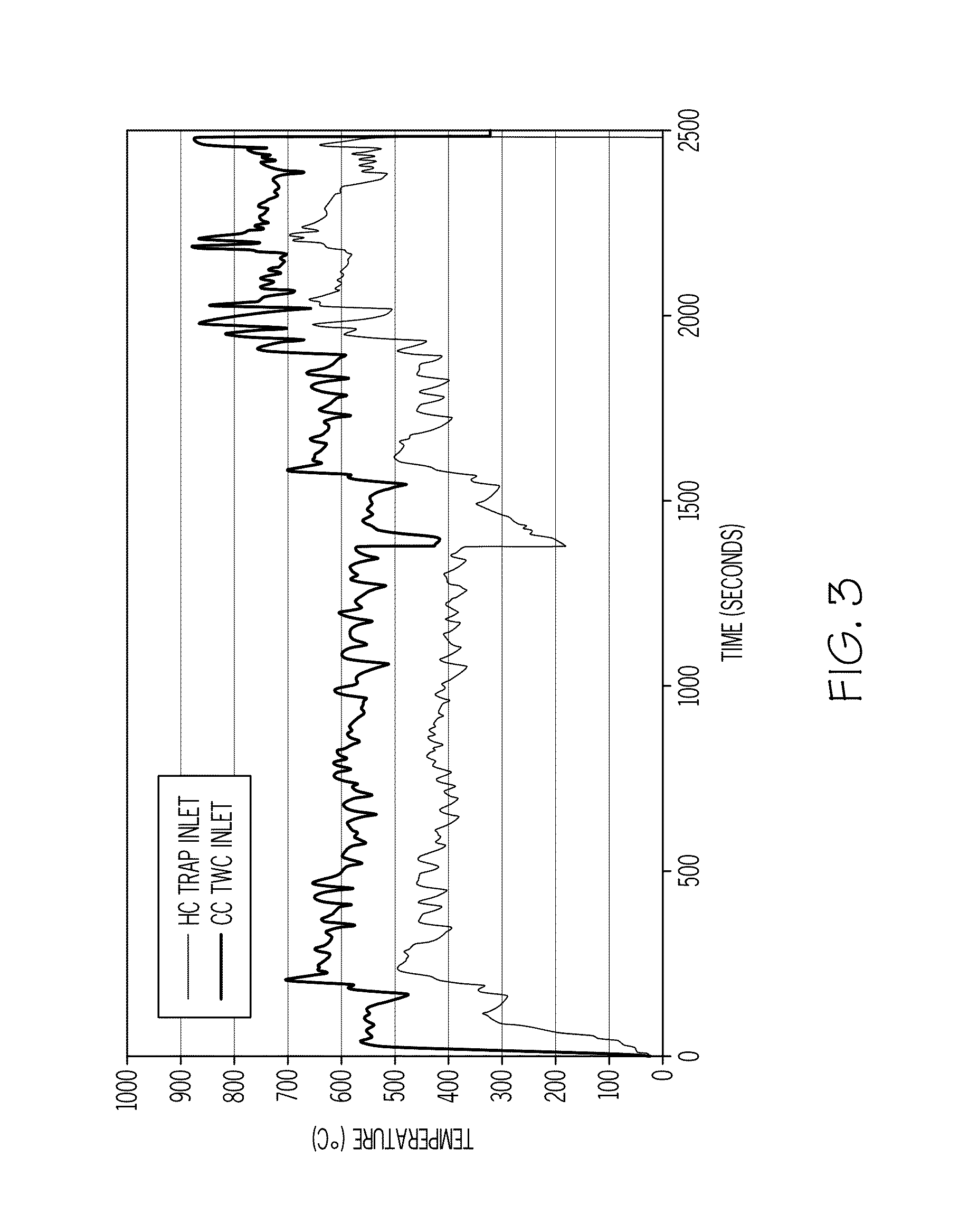

Emission Control System For An Engine

InactiveUS20060242947A1Lower hydrocarbon emissionsInternal combustion piston enginesNon-fuel substance addition to fuelControl systemHydrocotyle bowlesioides

An emission control system for an engine is disclosed in which an exhaust gas cooler is positioned upstream from a hydrocarbon trap in order to prevent premature desorbtion of hydrocarbons from the hydrocarbon trap. A bypass passage is also provided to allow the exhaust gas cooler to be bypassed to speed up the activation of a lean NOx trap positioned downstream from the hydrocarbon trap prior to hydrocarbon release.

Owner:FORD GLOBAL TECH LLC

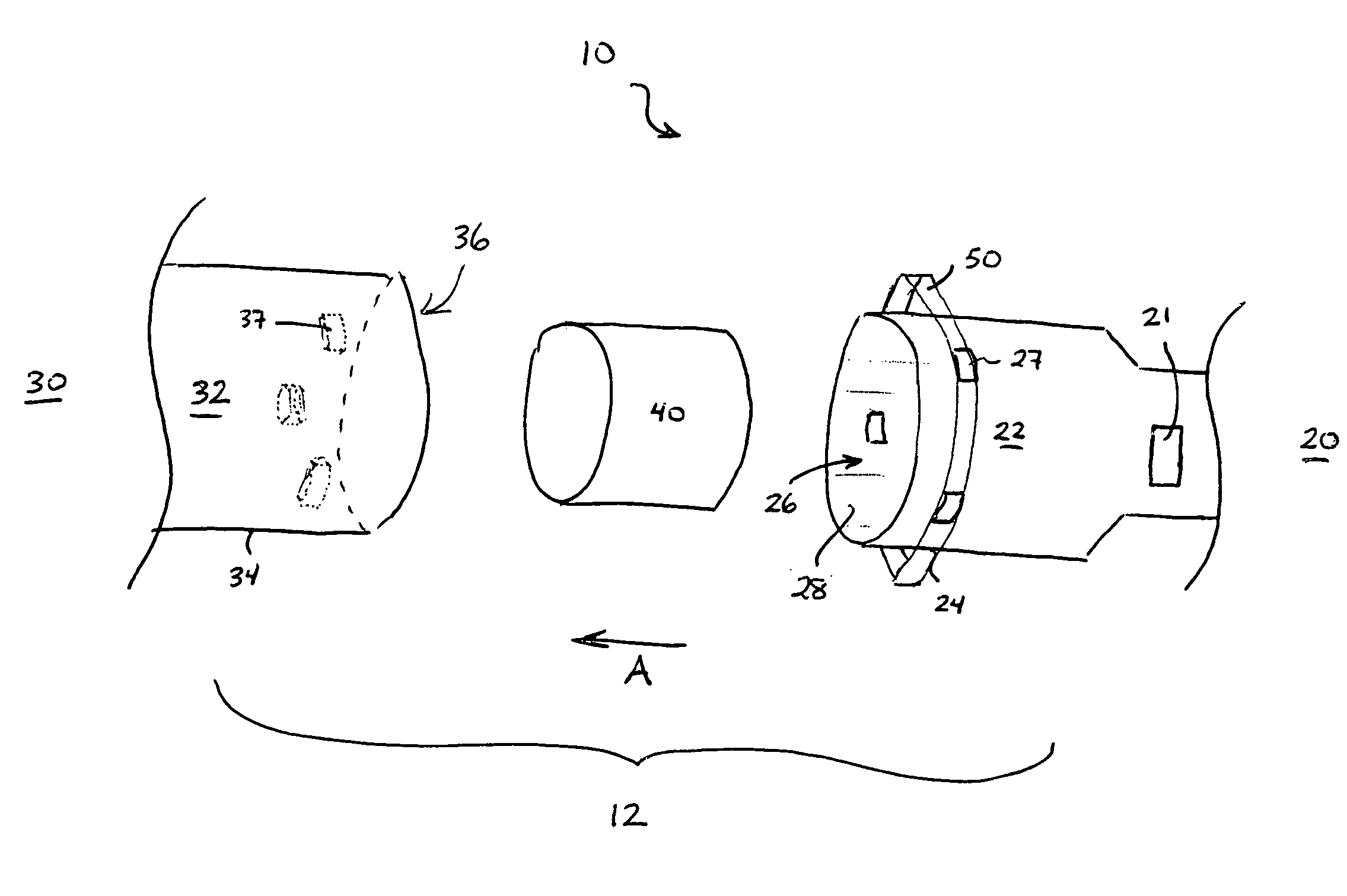

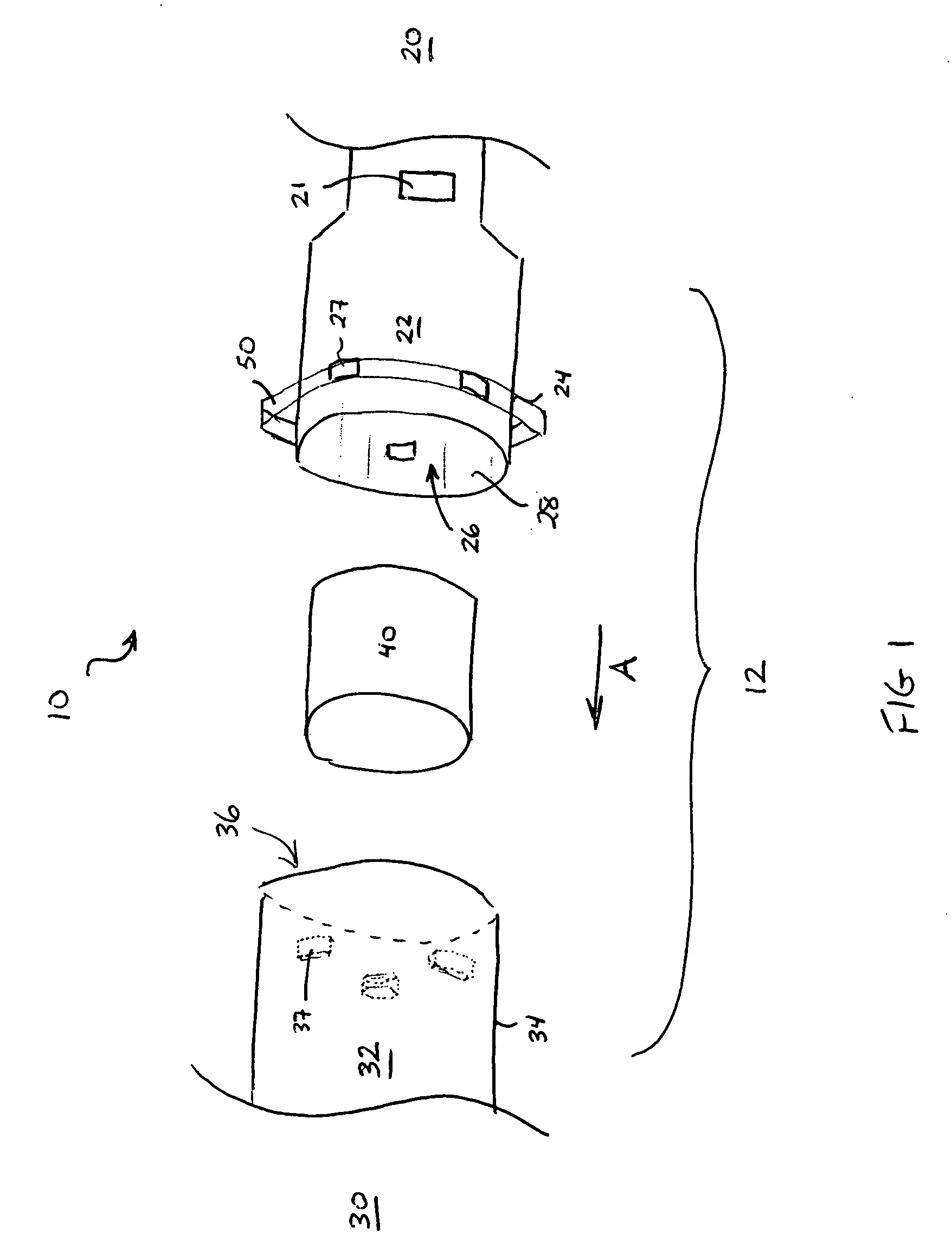

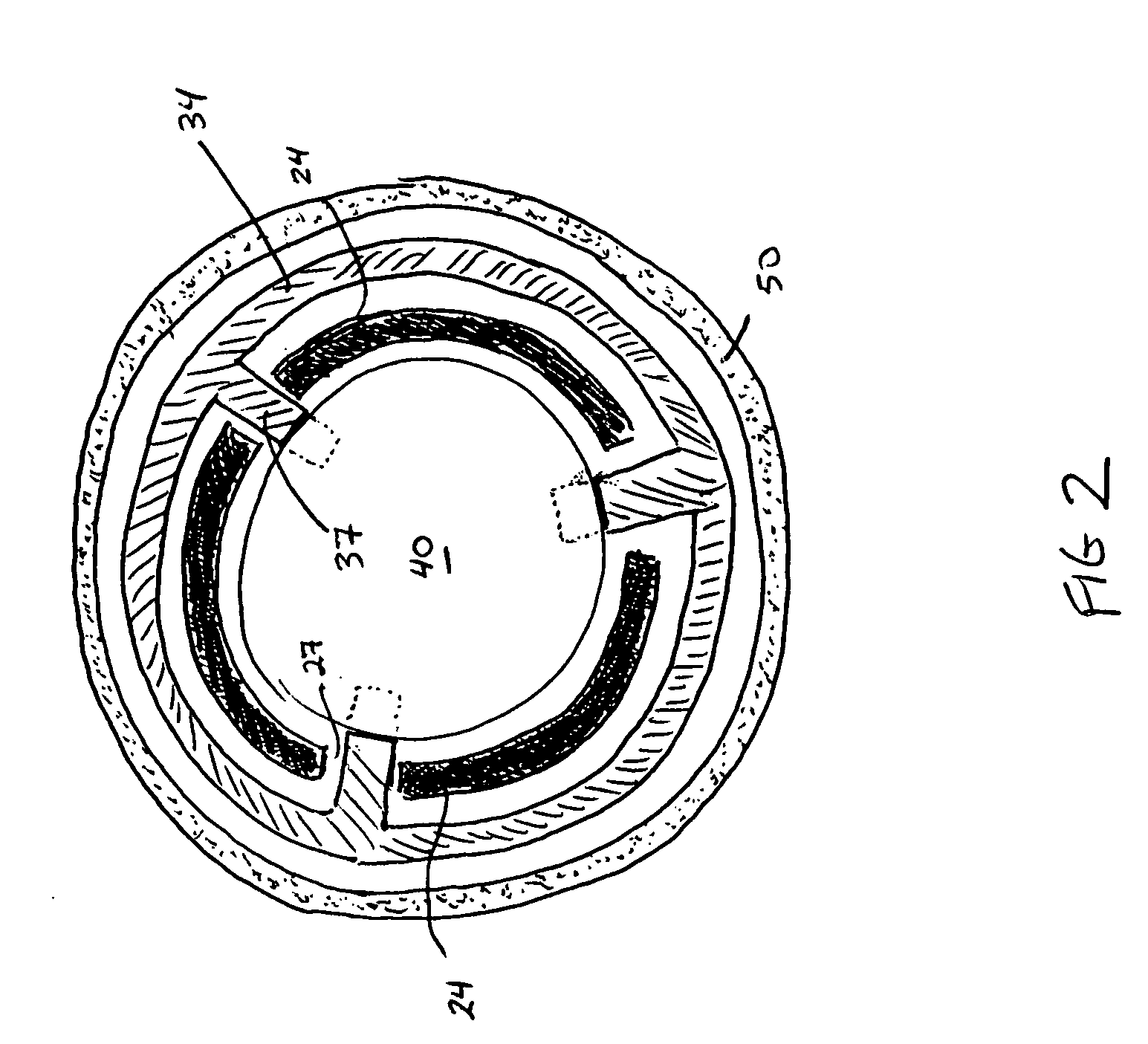

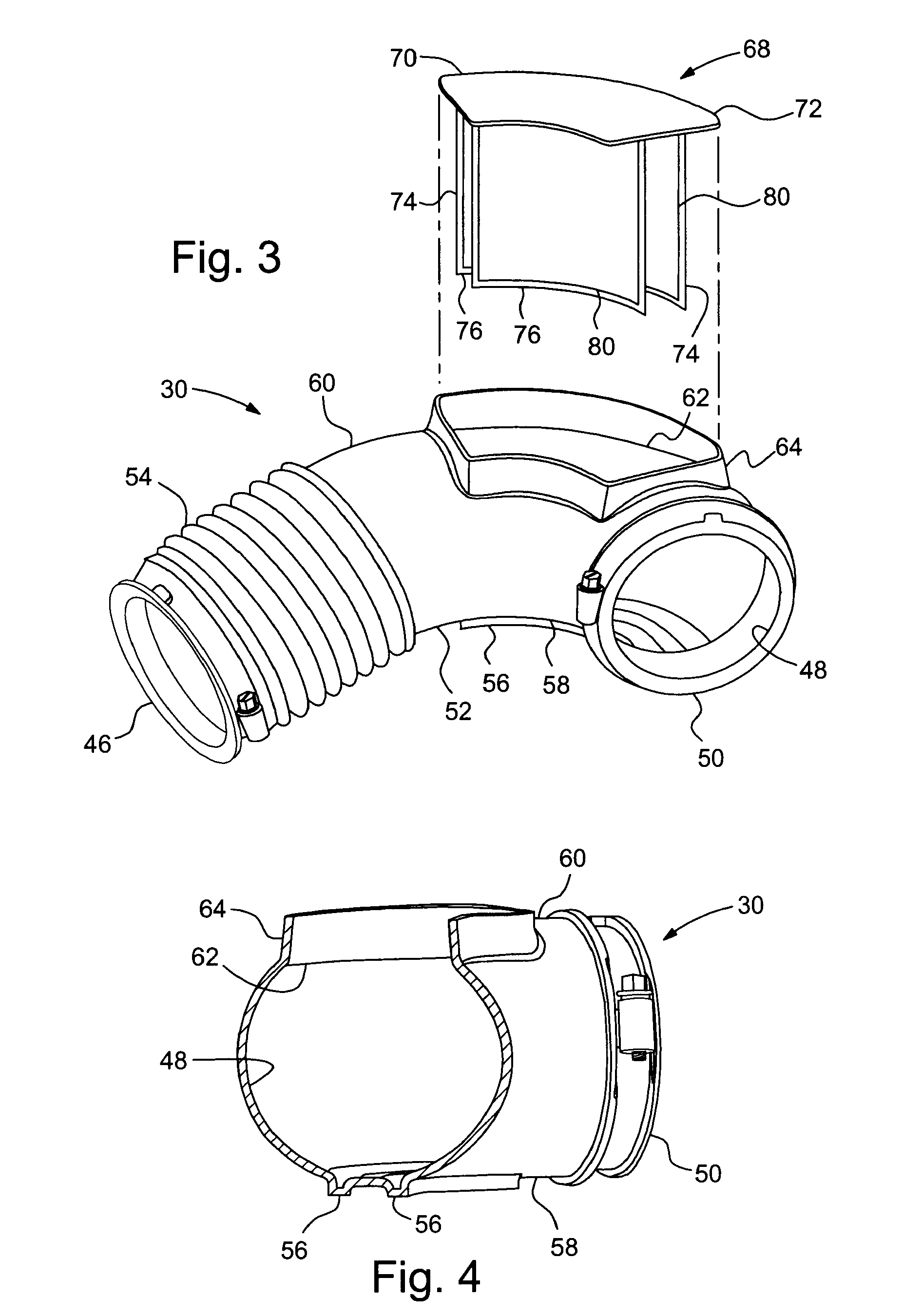

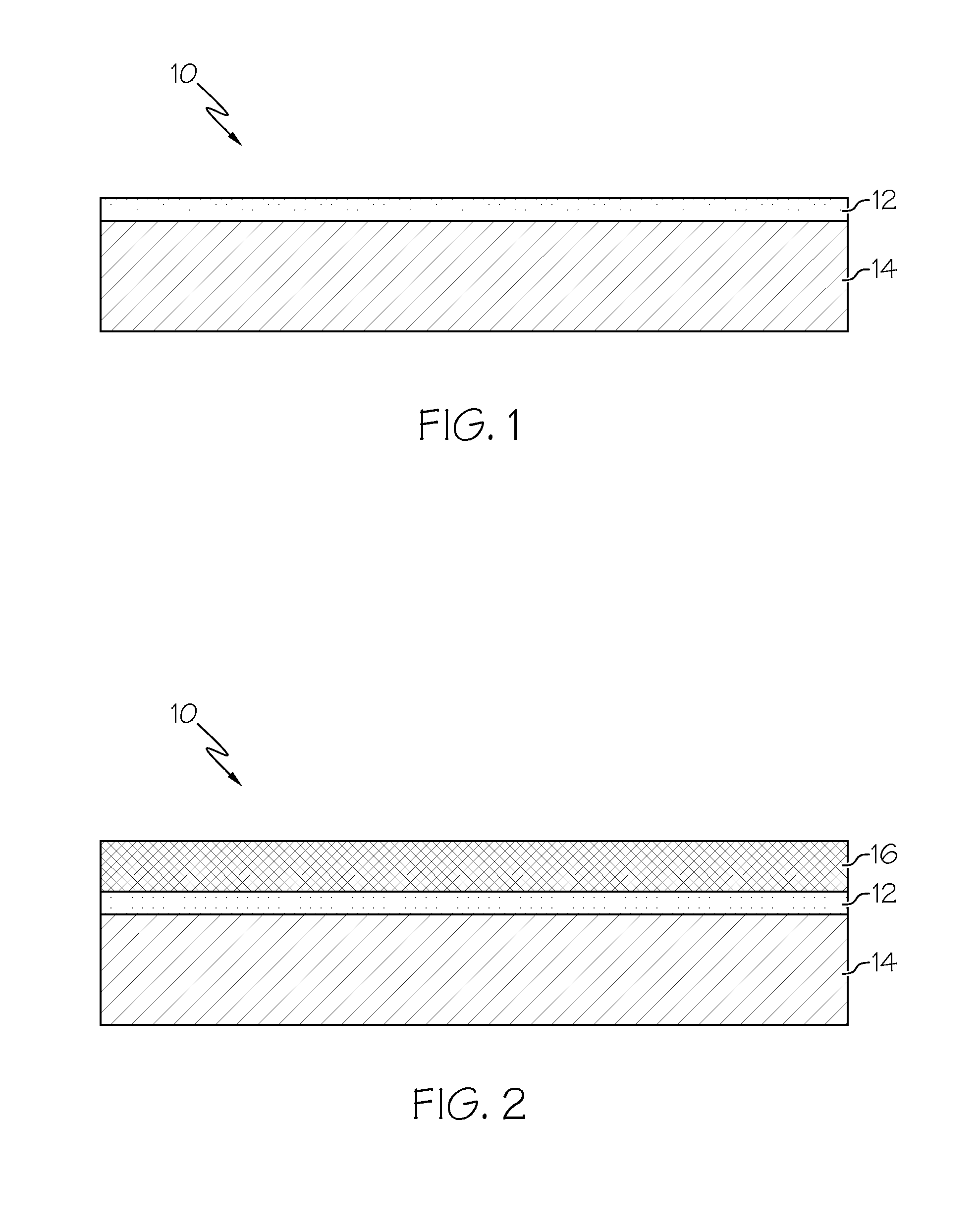

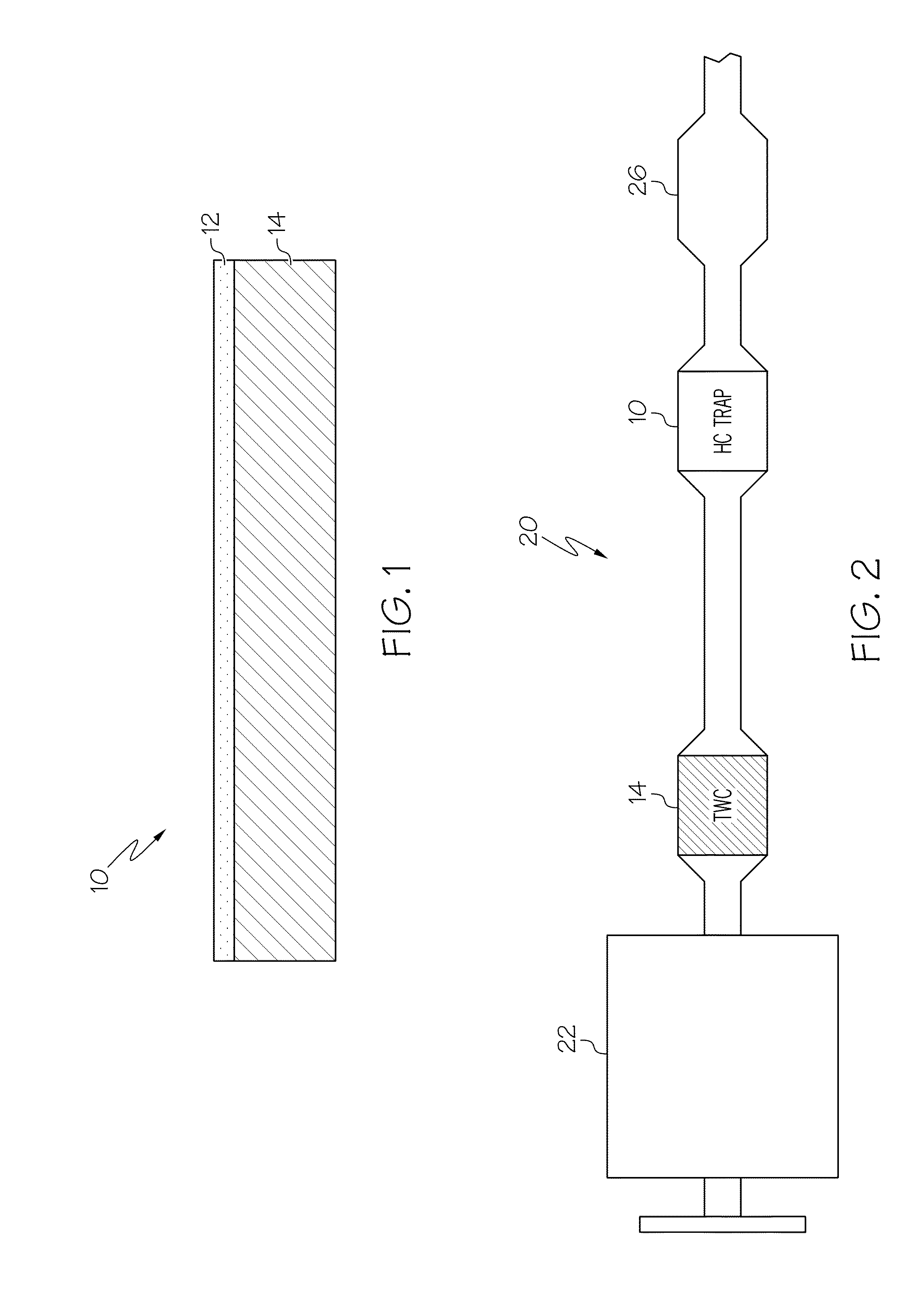

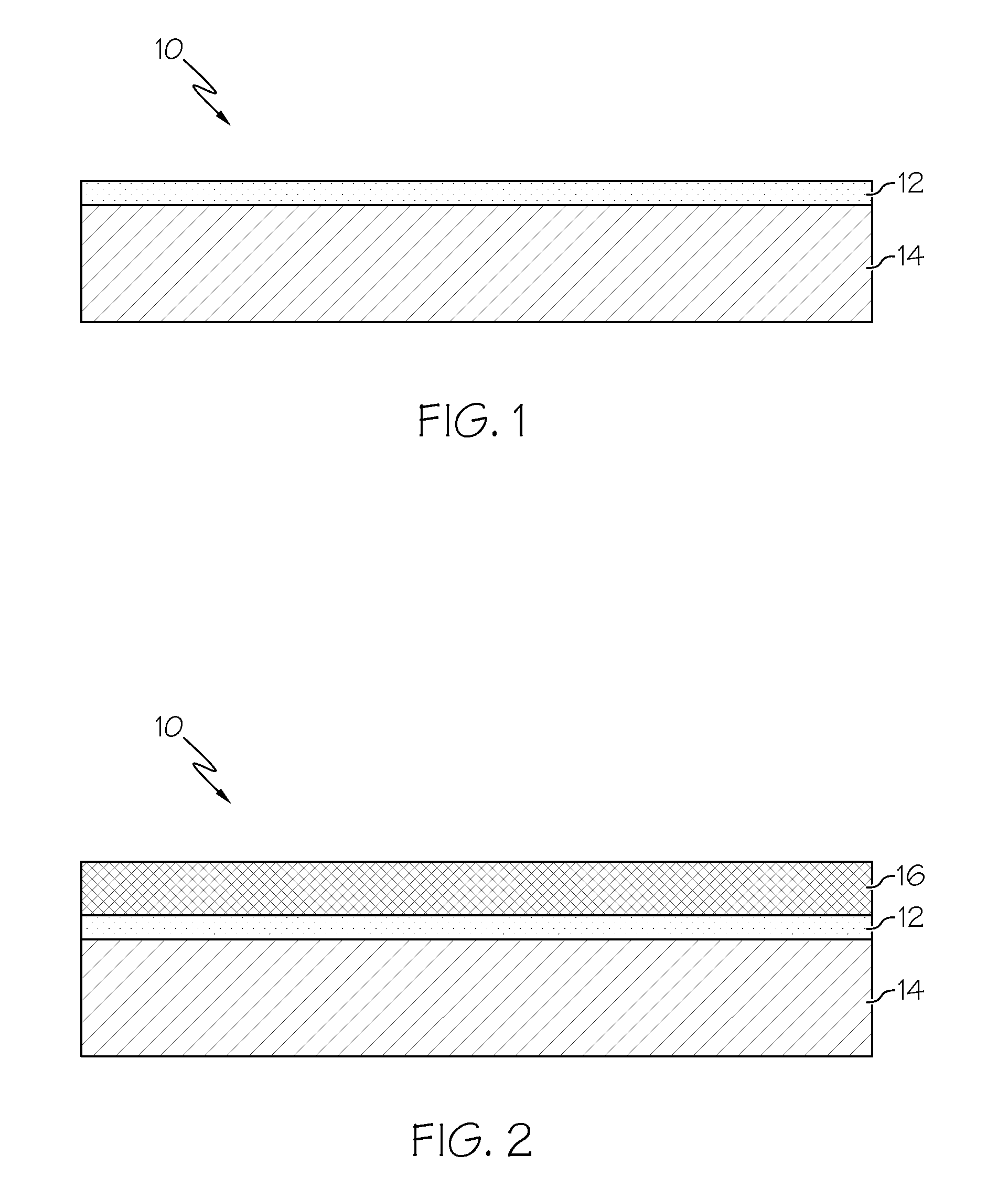

Retention assembly for a hydrocarbon trap

ActiveUS20070186904A1Lower hydrocarbon emissionsEasy to insertIsotope separationPipe elementsAir filterHydrocotyle bowlesioides

A retention assembly secures a hydrocarbon trap within an air intake path of an internal combustion engine. The hydrocarbon trap is positioned within a first air tube, such as an outlet duct of a clean air filter. A second air tube, such as an inlet portion of a clean air duct assembly, is fitted over a portion of the first air tube to enclose the hydrocarbon trap within the first air tube. A clamp is fitted over both the first and second air tubes. A plurality of radially-extending, circumferentially-spaced protrusions that are formed on an inner surface of the second air tube pass through a respective plurality of apertures formed in the first air tube and, under radial compression exerted by the clamp, engage an outer surface of the hydrocarbon trap, thereby securing the trap within the first air tube.

Owner:MANN HUMMEL GMBH

Iron oxide nanoparticle dispersions and fuel additives for soot combustion

ActiveUS20130337998A1Reducing carbonaceous soot light-offLower hydrocarbon emissionsMaterial nanotechnologyIron oxides/hydroxidesEmulsionIron oxide nanoparticles

Aqueous and substantially crystalline iron oxide nanoparticle dispersions and processes for making them are disclosed. The nanoparticle size and size distribution width are advantageous for use in a fuel additive for catalytic reduction of soot combustion in diesel particulate filters. Nanoparticles of the aqueous colloid are transferred to a substantially non-polar liquid comprising a carboxylic acid and one or more low-polarity solvents. The transfer is achieved by mixing the aqueous and substantially non-polar materials, forming an emulsion, followed by a phase separation into a substantially metal-free remnant polar phase and a substantially non-polar organic colloid phase. A method for rapid and substantially complete transfer of non-agglomerated nanoparticles to the low polarity phase in the presence of an organic amine, and a rapid phase separation of the substantially non-polar colloid from a remnant aqueous phase, are provided.

Owner:CERION

Close coupled catalyst for purification of exhaust gas and the preparation thereof

ActiveUS20100048383A1High activityImprove stabilityGas treatmentInternal combustion piston enginesCeriumCordierite

A close coupled three-way catalyst for purification of exhaust gas of motor vehicle and the preparation thereof. The support is selected from cordierite honeycomb ceramic materials having a pore volume of 0.25-0.35 ml / g. The coating layer is the mixture of hexaaluminate and perovskite-type composite oxide, cerium-zirconium solid solution, rare-earth oxide and alumina, alkali-earth oxide and zeolite having a high Si / Al ratio. The active components are palladium-rhodium, rare-earth oxide and transition metal in the hexaaluminate and perovskite-type composite oxide. The catalyst has not only the function of low-temperature catalytic oxidation of hydrocarbons, but also the function of reduction of nitrogen oxides, and can be used for purifying the exhaust gas of motor vehicles using gasoline, liquid gas, or CNG as fuel.

Owner:EAST CHINA UNIV OF SCI & TECH

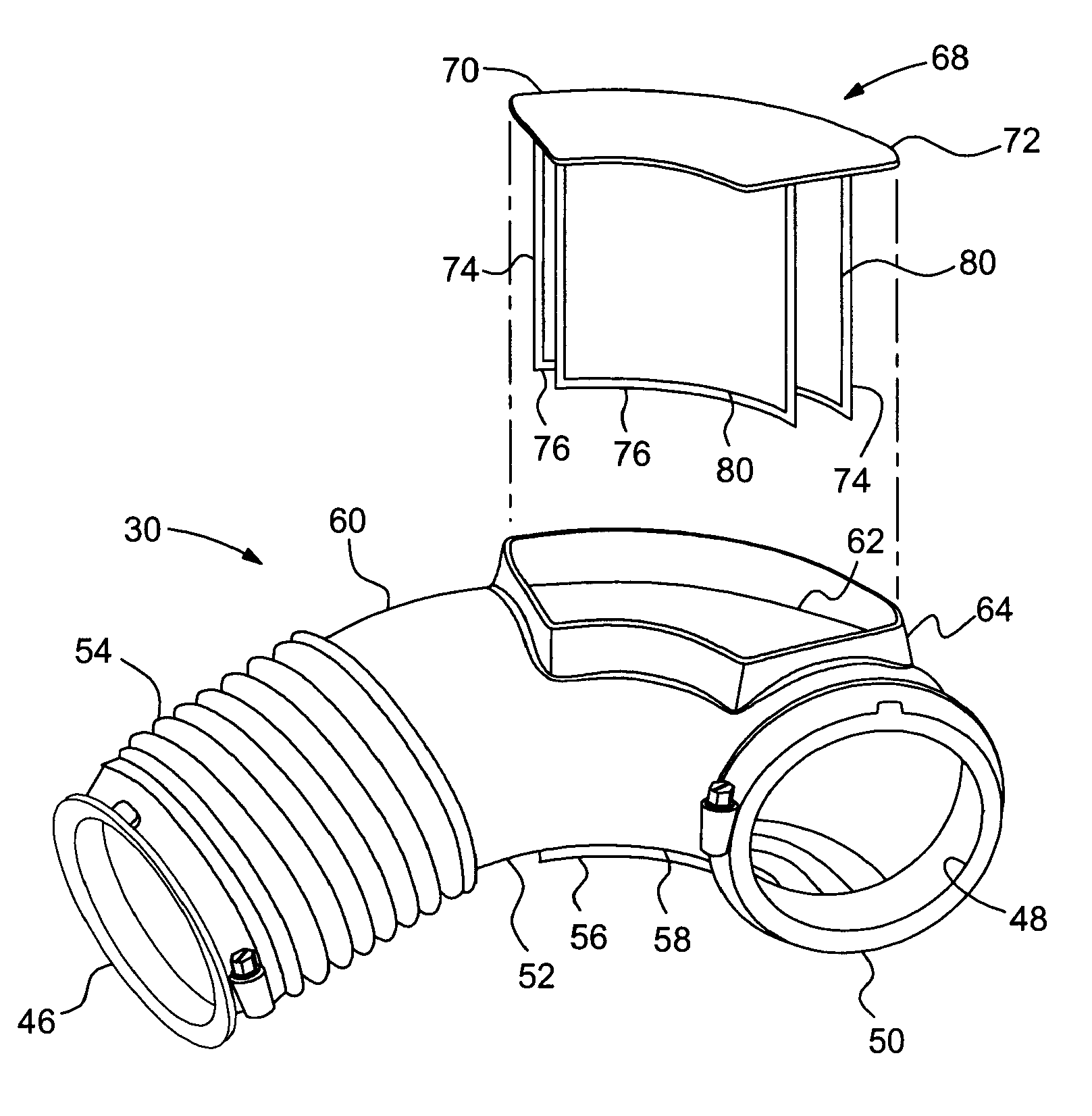

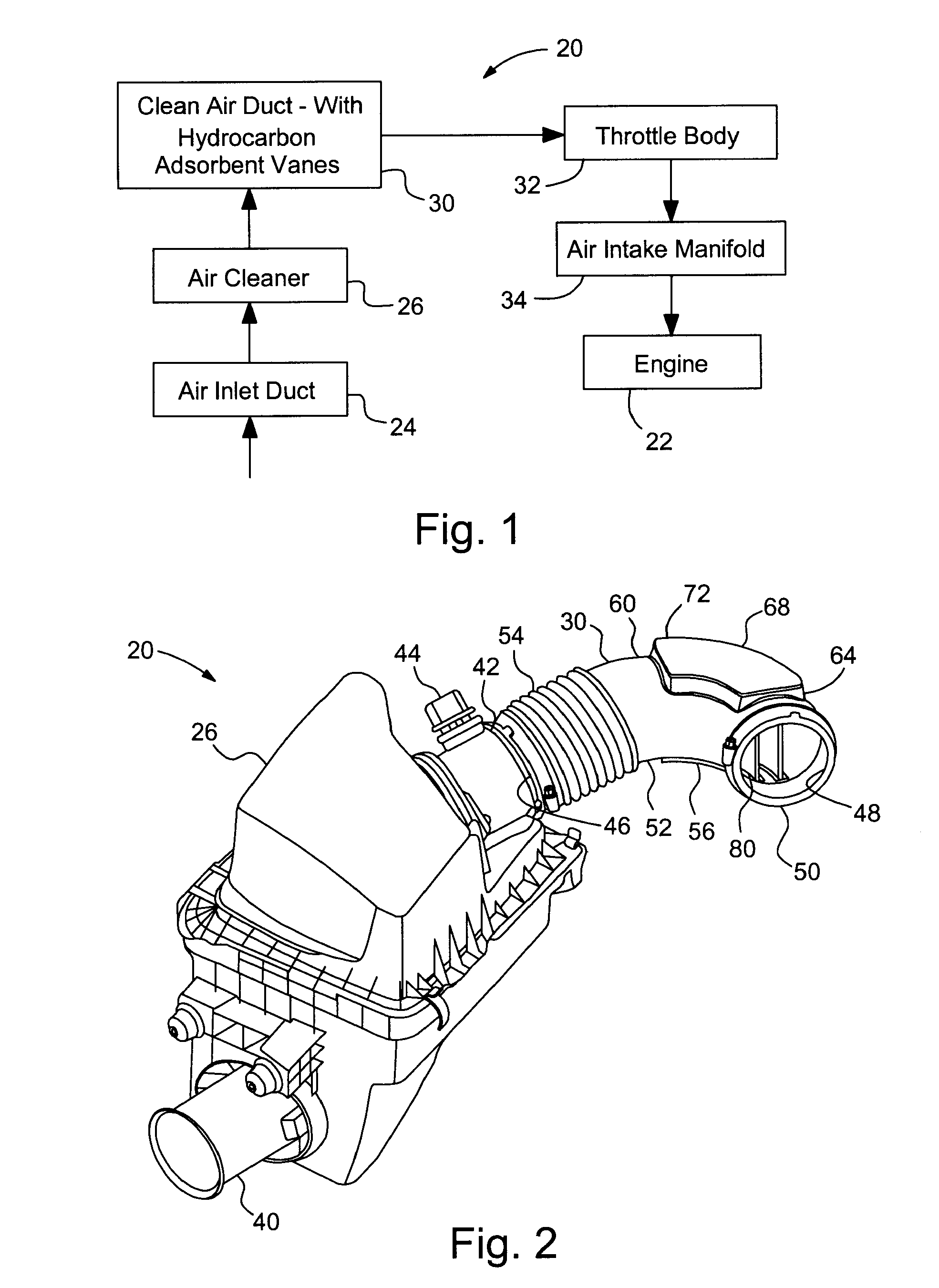

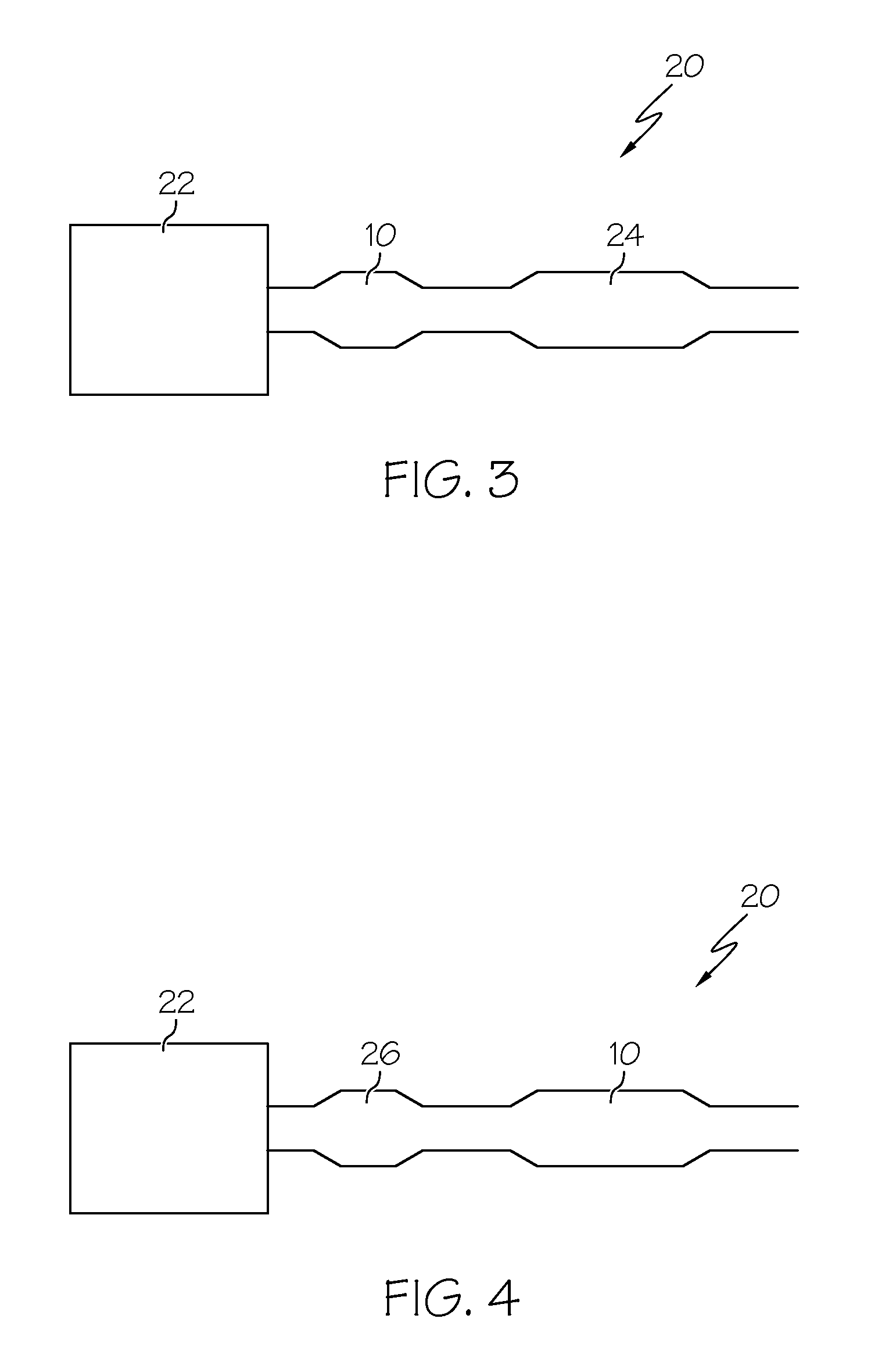

Flow turning vane assembly with integrated hydrocarbon adsorbent

InactiveUS7641720B2Lower hydrocarbon emissionsImprove capture abilityInternal combustion piston enginesNon-fuel substance addition to fuelCurve shapeEngineering

The invention concerns a flow turning vane assembly for use in a duct bend portion of a clean air duct of an air induction system for a vehicle engine. The flow turning vane assembly may have a vane support housing, and a hydrocarbon adsorbent vane mounted to the vane support housing. The hydrocarbon adsorbent vane has a curved shape complimentary to the duct bend portion and includes a hydrocarbon adsorbent layer.

Owner:GM GLOBAL TECH OPERATIONS LLC

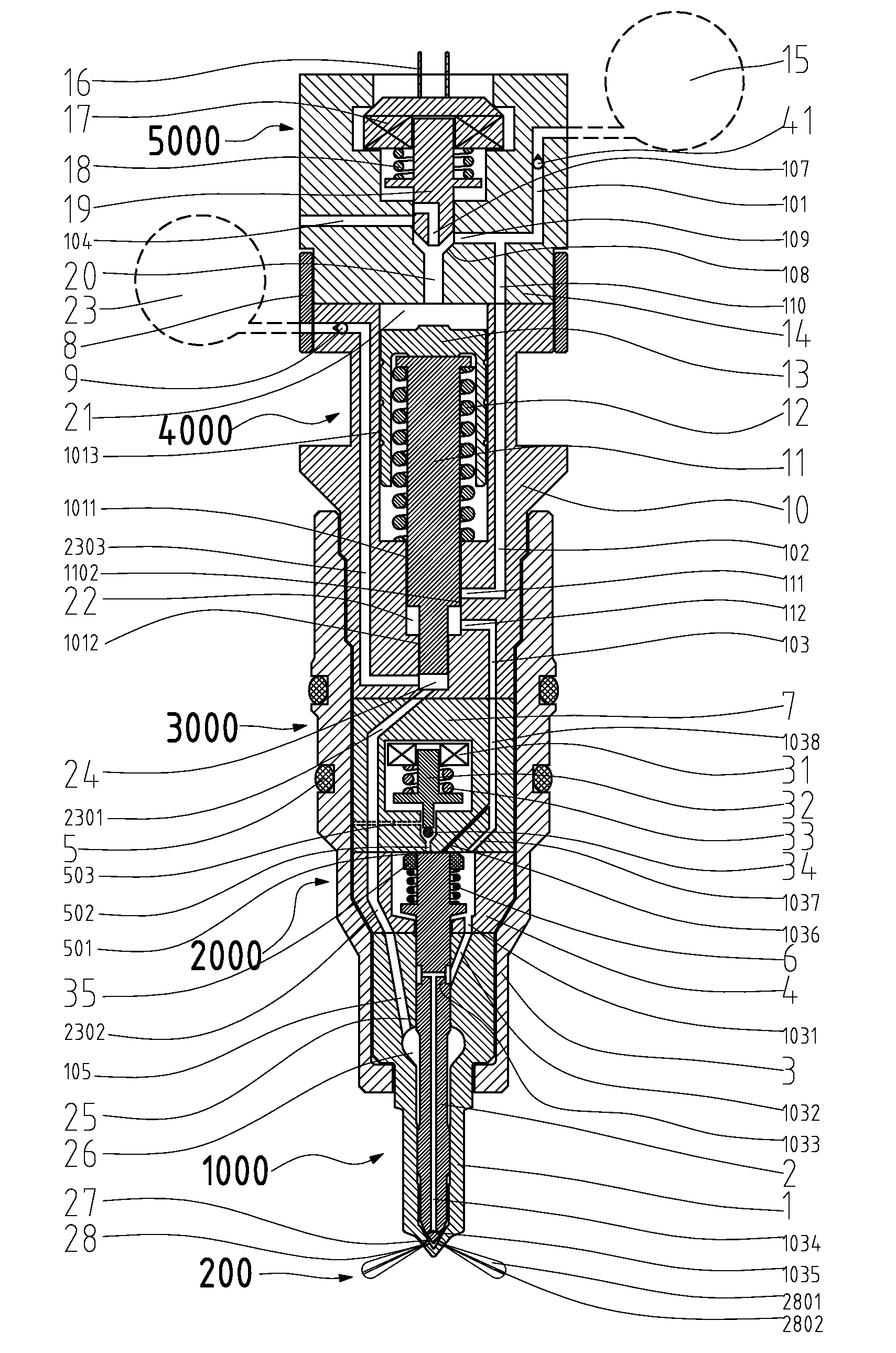

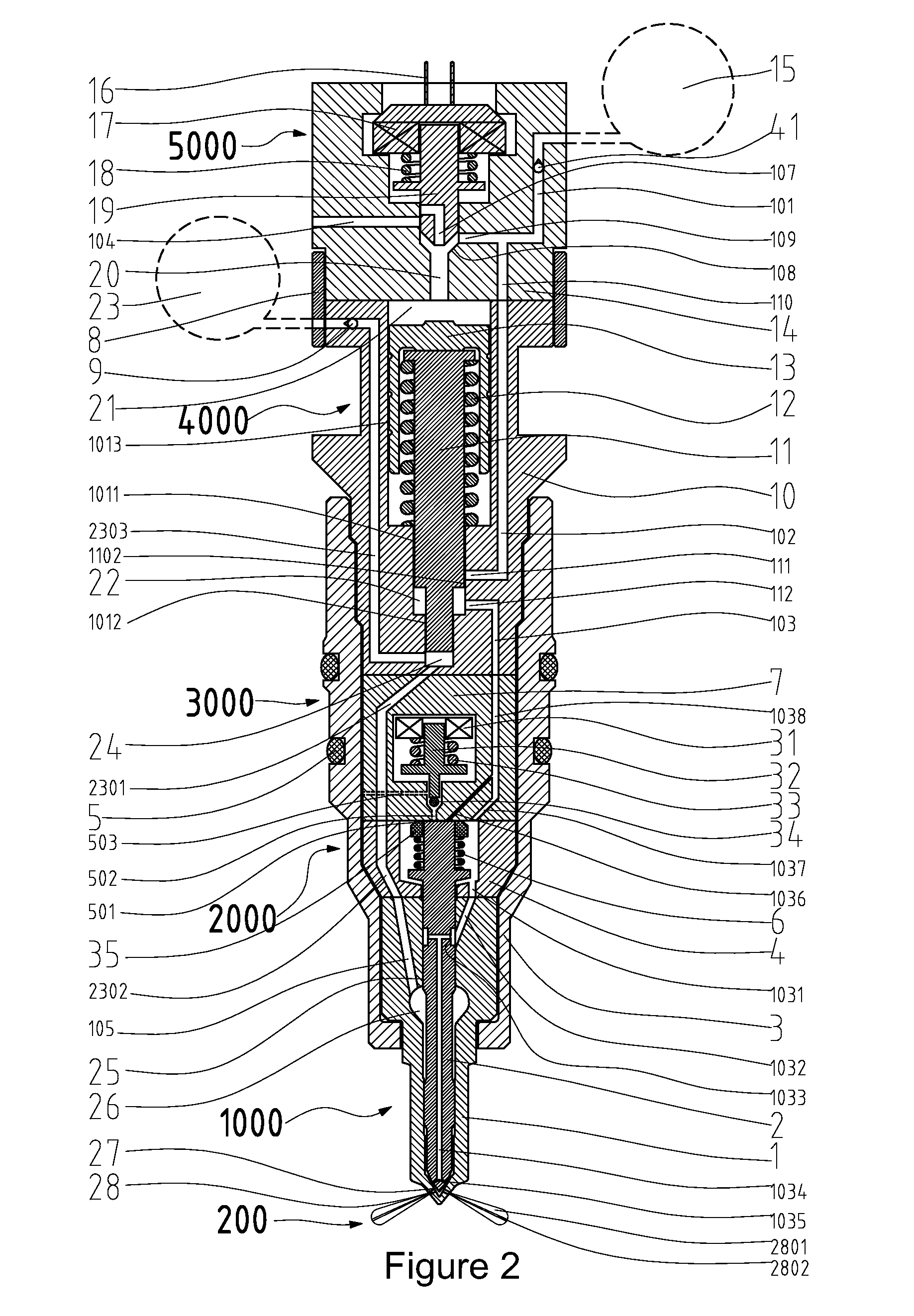

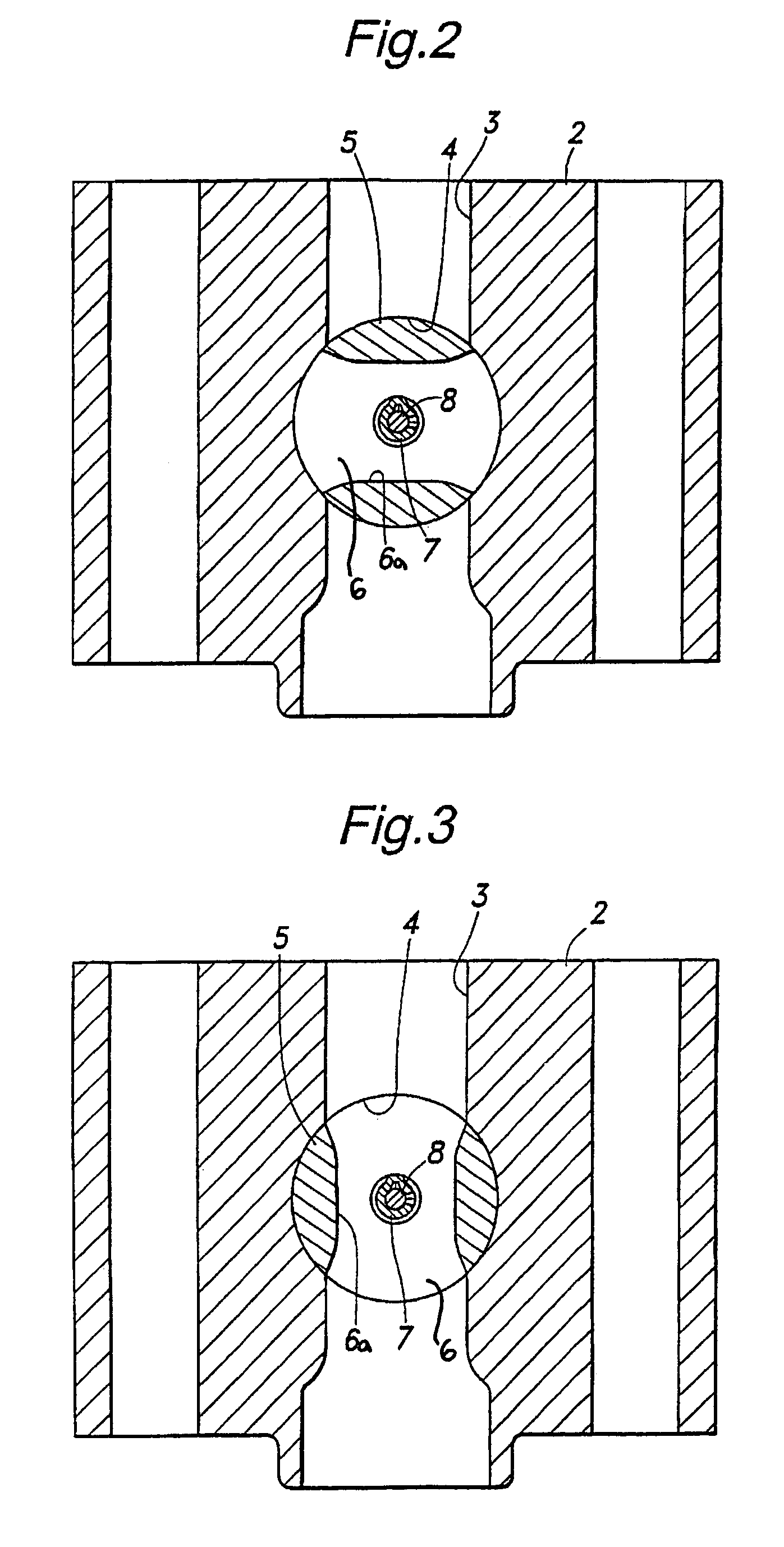

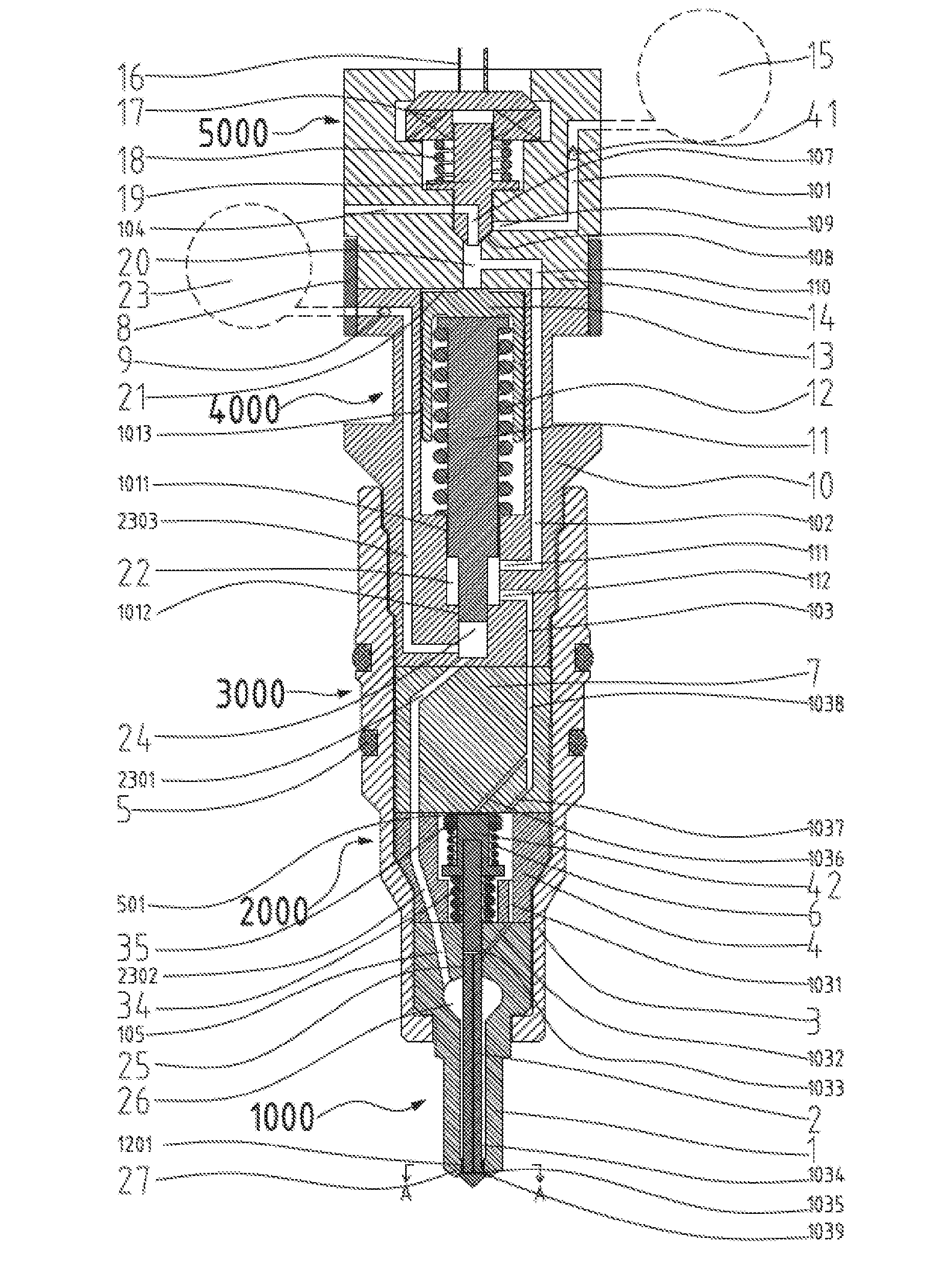

Fuel injector for multi-fuel injection with pressure intensification and a variable orifice

InactiveUS20140373806A1Facilitate pressureLow viscosityExhaust gas recirculationCombustion enginesCombustion chamberEngineering

A multi-fuel injector has an internal pressure intensifier which has means to intensify fuels with different viscosities, cetane or octane numbers, with high viscosity fuel being used to intensify both itself and low viscosity fuels to high pressure for direct injection into combustion chamber. A combustion method using such a method of fuel injection is also disclosed. A multi-fuel injector with variable orifice nozzle and variable spray patterns is also disclosed.

Owner:HOU DEYANG +1

Close coupled catalyst for purification of exhaust gas and the preparation thereof

ActiveUS8207078B2High activityImprove stabilityGas treatmentMolecular sieve catalystsCeriumCordierite

A close coupled three-way catalyst for purification of exhaust gas of motor vehicle and the preparation thereof. The support is selected from cordierite honeycomb ceramic materials having a pore volume of 0.25-0.35 ml / g. The coating layer is the mixture of hexaaluminate and perovskite-type composite oxide, cerium-zirconium solid solution, rare-earth oxide and alumina, alkali-earth oxide and zeolite having a high Si / Al ratio. The active components are palladium-rhodium, rare-earth oxide and transition metal in the hexaaluminate and perovskite-type composite oxide. The catalyst has not only the function of low-temperature catalytic oxidation of hydrocarbons, but also the function of reduction of nitrogen oxides, and can be used for purifying the exhaust gas of motor vehicles using gasoline, liquid gas, or CNG as fuel.

Owner:EAST CHINA UNIV OF SCI & TECH

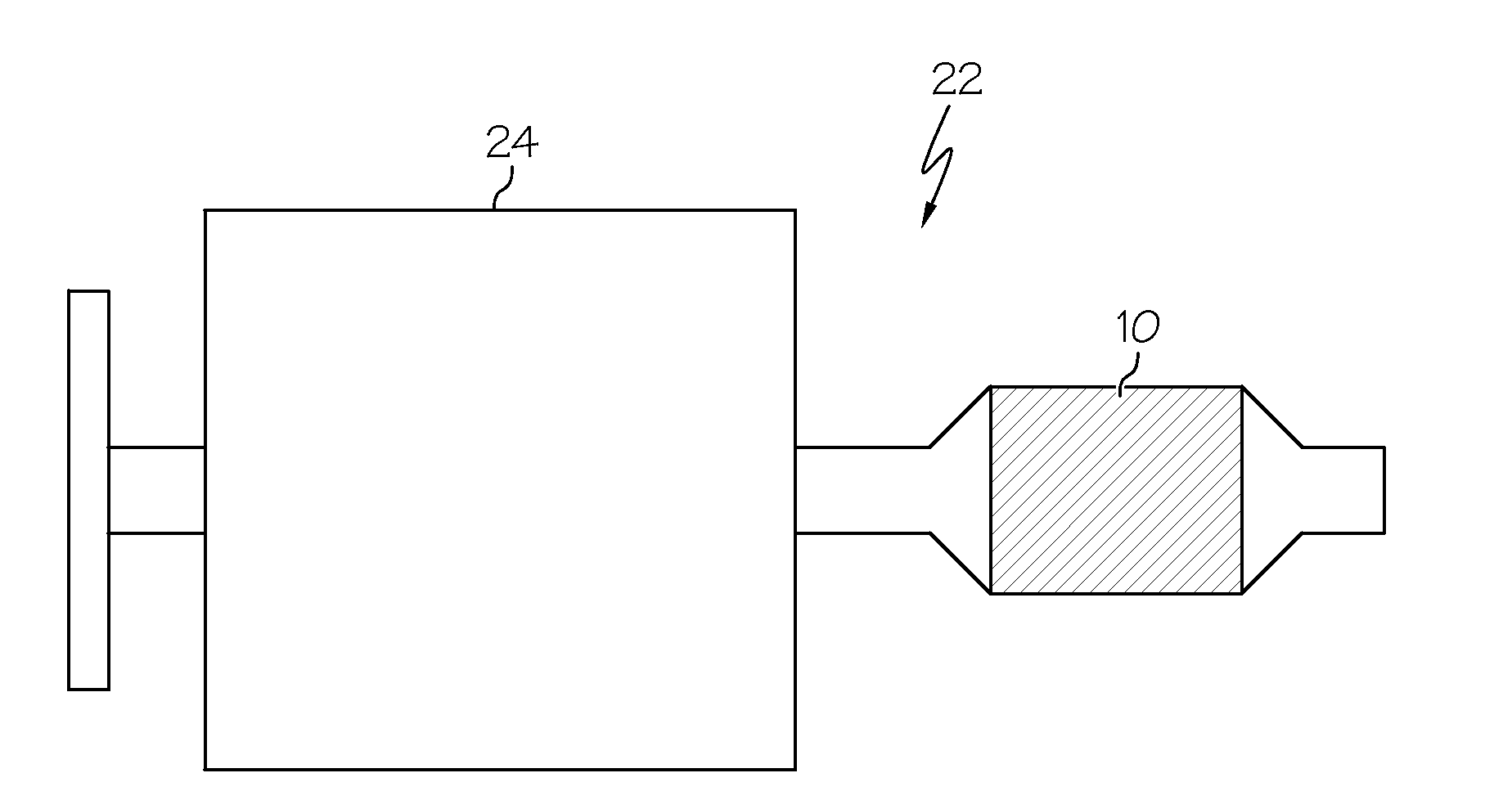

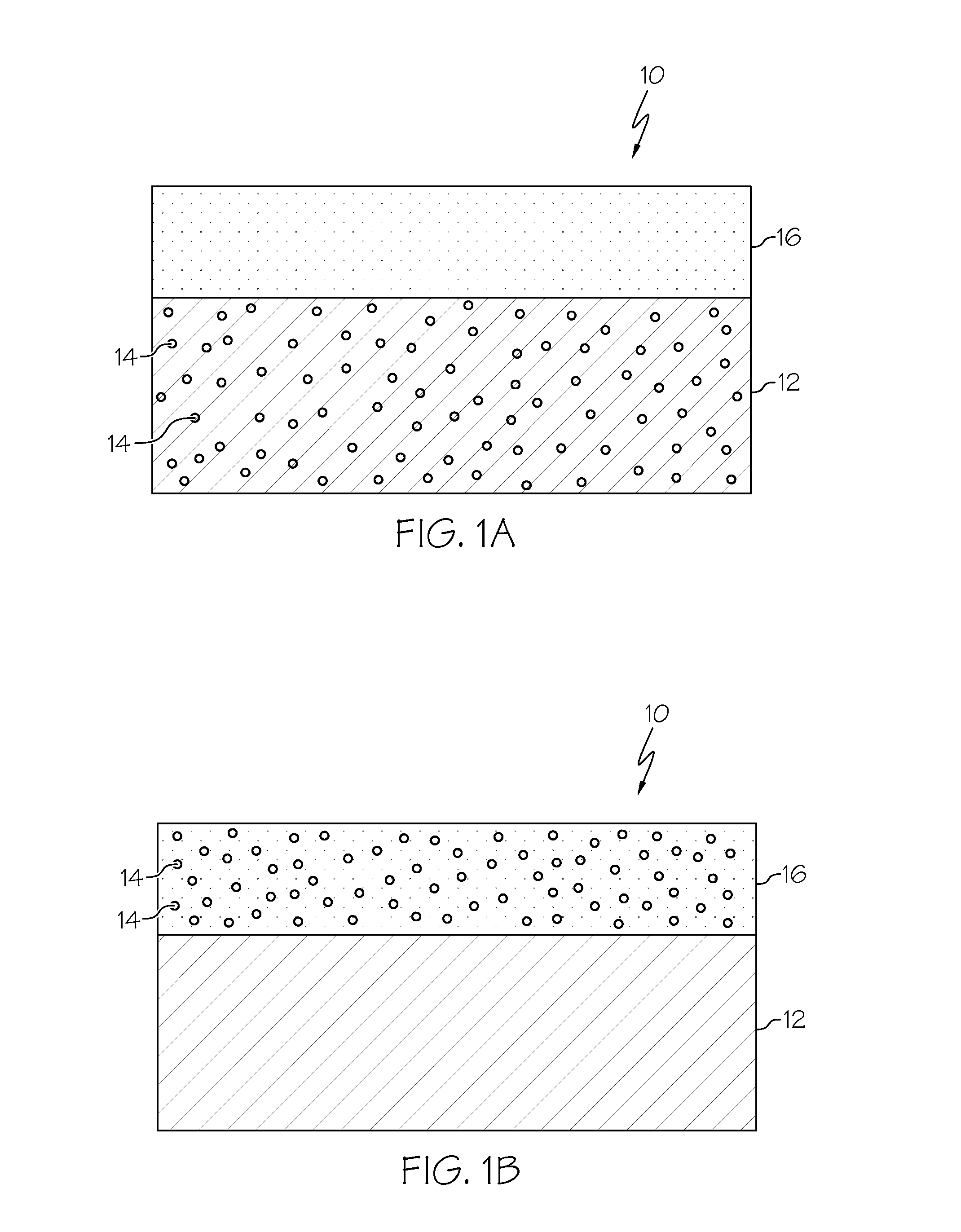

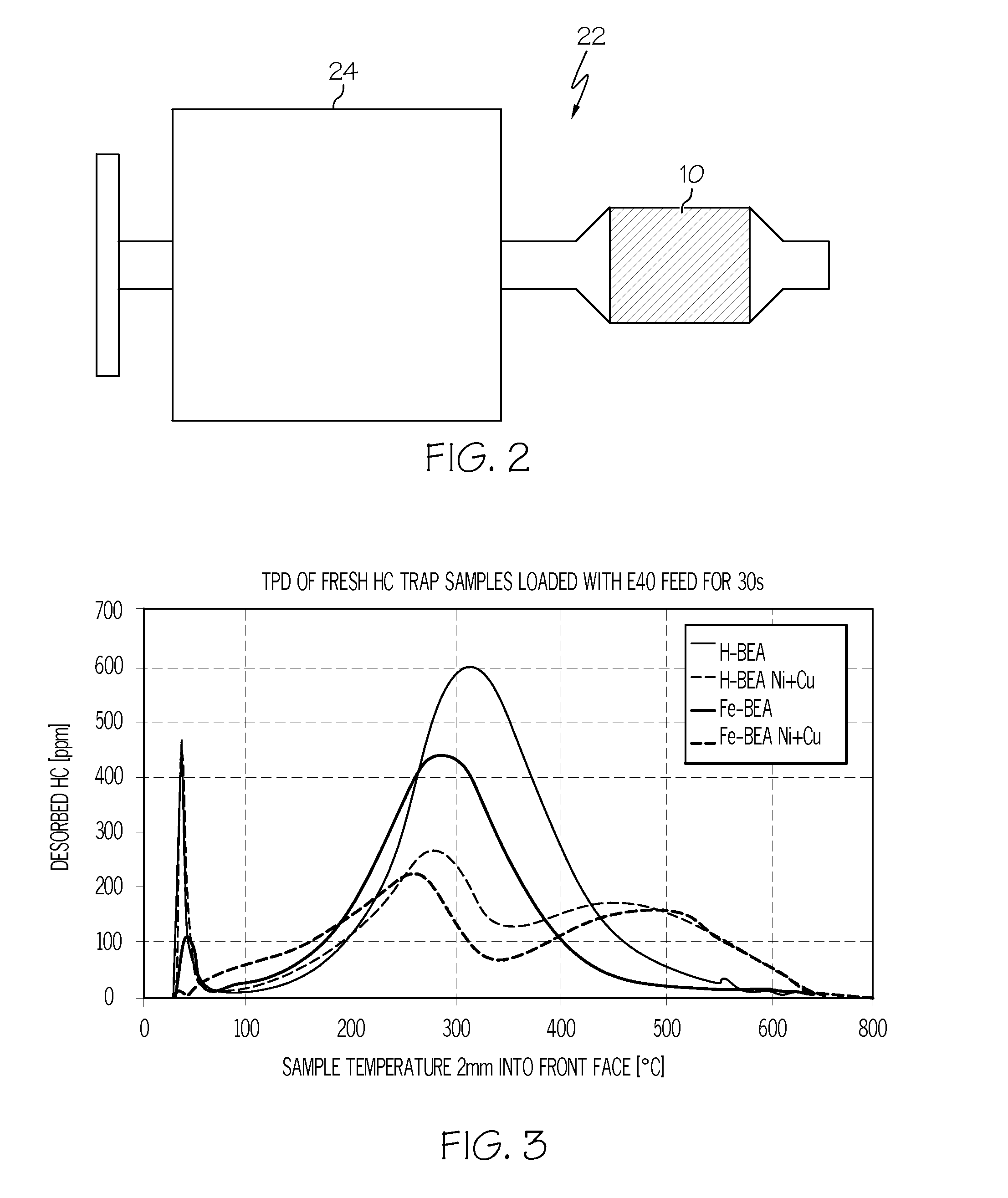

Combined hydrocarbon trap and catalyst

InactiveUS20130287659A1Reducing cold start hydrocarbon emissionReduce exhaust emissionsCombination devicesNitrogen compoundsDesorptionCopper

A combined hydrocarbon trap / oxidation catalyst system is provided for reducing cold-start hydrocarbon emissions. The hydrocarbon trap includes a monolithic substrate containing zeolite and a catalyst including a mixture of nickel and copper which is impregnated into or washcoated onto the substrate. The hydrocarbon trap may be positioned in the exhaust gas passage of a vehicle such that hydrocarbons are adsorbed on the trap and stored until the engine and exhaust reach a sufficient temperature for desorption and oxidation of the hydrocarbons.

Owner:FORD GLOBAL TECH LLC

Air conducting channel

InactiveUS20060107835A1Space saveSimplify assemblyDucting arrangementsIsotope separationEngineeringInternal combustion engine

A channel for conducting a gaseous medium, particularly an air conducting channel for an internal combustion engine, having at least one channel section that is produced in an extrusion blow molding process. The blow-molded channel section has adsorption particles on its inside walls, which are attached in an interlocked manner to the inside wall of the channel section in the blow molding process.

Owner:MANN HUMMEL GMBH

Rotary throttle valve carburetor

InactiveUS7114708B2Easy to controlEasy flow controlLighting and heating apparatusUsing liquid separation agentEngineeringCarburetor

A rotary throttle valve carburetor includes a body having a fuel and air mixing passage and a throttle valve movable between idle and wide open positions. A valve bore is increasingly aligned with the fuel and air mixing passage as the throttle valve is moved from idle toward its wide open position. A fuel metering needle is responsive to movement of the throttle valve so that the needle moves relative to the body in response to movement of the throttle valve. A fuel nozzle extends into the valve bore, is associated with the fuel metering needle, and has a fuel ejection passage with an effective flow area controlled by movement of the fuel metering needle relative to the fuel nozzle and includes a portion with a cross-sectional area that gradually increases in the direction of fuel metering needle movement corresponding to throttle valve movement toward its wide open position.

Owner:NIPPON WALBRO KK

On-board fuel fractionation system and methods to generate an engine starting fuel

InactiveUS20070193852A1Improve performance and usabilityEngine power output can be increasedThermal non-catalytic crackingDistillation regulation/controlOn boardDistillation

A Fuel Fractionation System (FFS) and associated methods to generate and store a fuel for internal combustion engines is provided. FFS provides a distillation column assembly to distill liquid fuel to form a volatile light fraction secondary fuel. The distillation column assembly includes a vaporization module to vaporize a feed fuel in the distillation column and includes a condensation module to condense heavy fraction components of the vaporized feed fuel. FFS also provides a controller positioned to control the vaporization of feed fuel in the distillation column to thereby control the separation of the feed fuel into light fraction fuel and heavy fraction fuel components, and positioned to control the condensation of the heavy fraction components so that fuel exiting a light fraction output port in the distillation column is substantially light fraction fuel components by volume.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

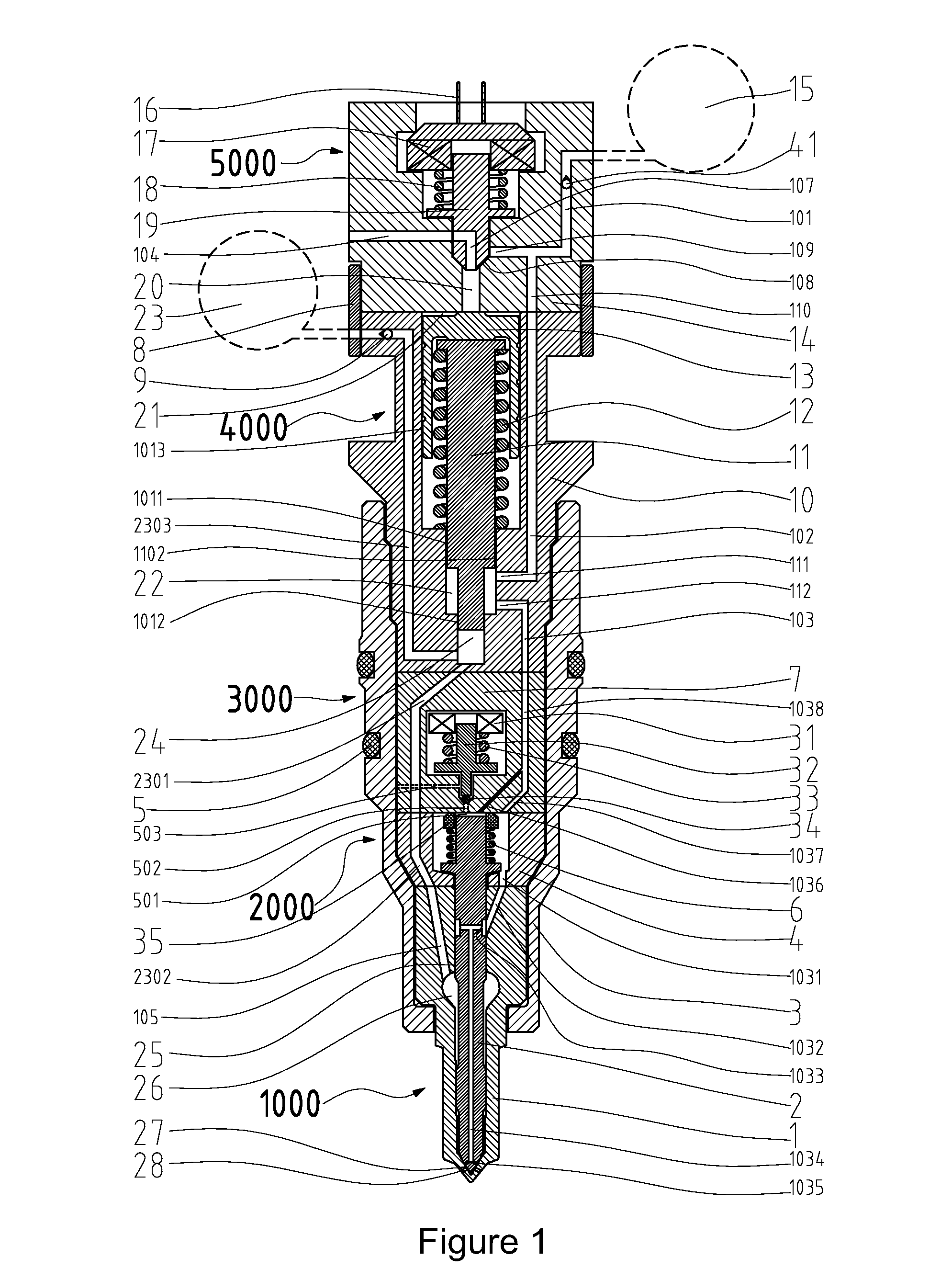

Method, system, and fuel injector for multi-fuel injection with pressure intensification and a variable orifice

InactiveUS20160123286A1Extends Brake Mean Effective Pressure (BMEP) mapHigh viscosityInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberHigh pressure

A multi-fuel injector has an internal pressure intensifier which has means to intensify fuels with different viscosities, cetane or octane numbers, with high viscosity fuel being used to intensify itself and low viscosity fuels to high pressure for direct injection into combustion chamber. A fuel injection method and fuel system using such a method of fuel injection is disclosed. A multi-fuel injector with a variable orifice nozzle and variable spray patterns is also disclosed.

Owner:QUANTLOGIC CORP +1

High cetane petroleum fuels

ActiveUS20120132182A1Decrease in nitrogen oxide (NOX) emissionEfficient combustionNon-fuel substance addition to fuelSolid fuelsHomogeneous charge compression ignitionTop dead center

A high-efficiency diesel fuel and method of combustion that reduces emissions. The diesel engine can operate in pre-mixed charge compression ignition (PCCI) combustion. The method can involve injecting high-efficiency diesel fuel at from −8 to 0 degrees After Top Dead Center (ATDC), combusting the fuel, and operating the engine with an exhaust gas recirculation (EGR) of from 20 to 60%.

Owner:PHILLIPS 66 CO

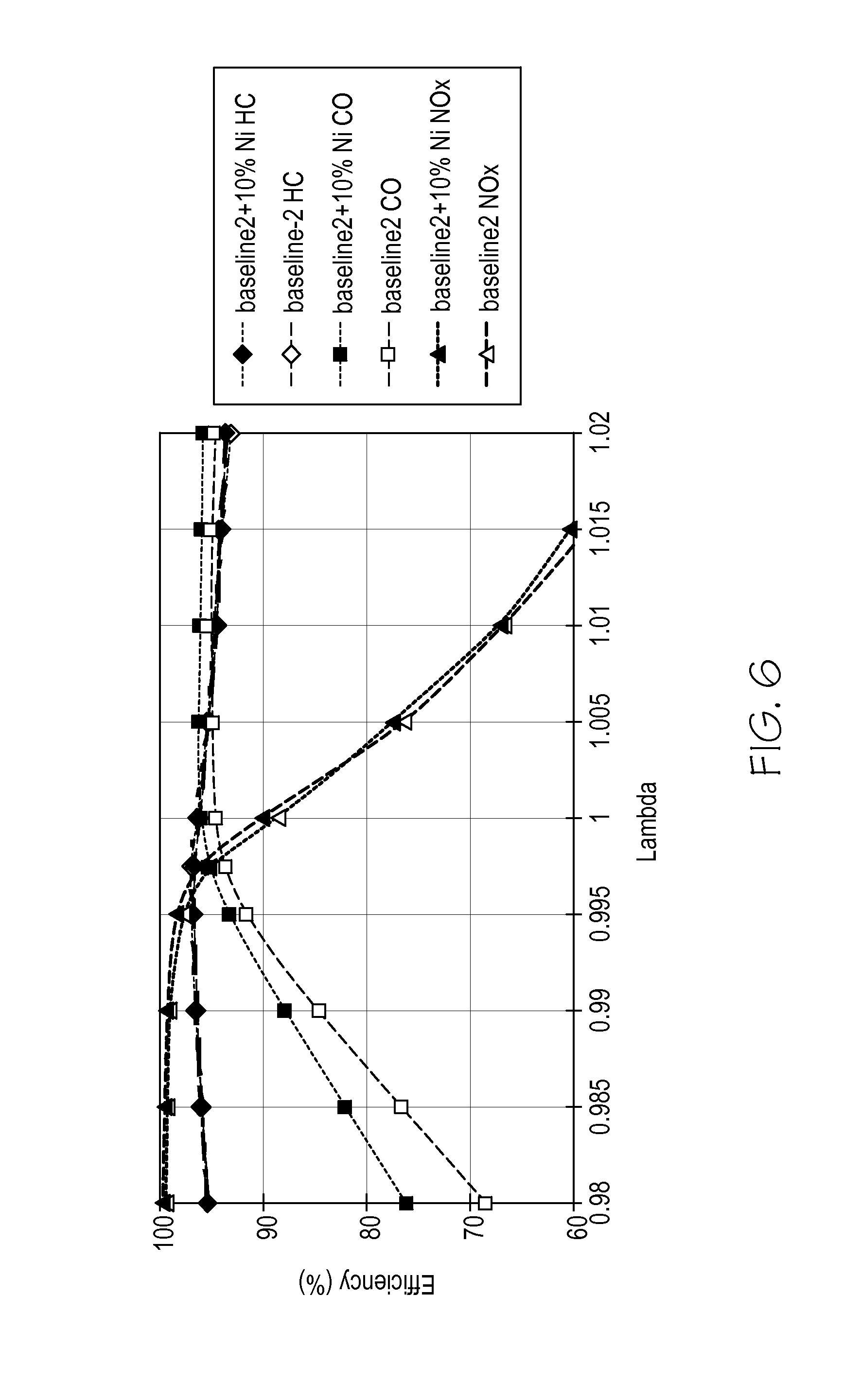

Exhaust treatment system including a nickel-based catalyst

ActiveUS8506912B1Reducing carbon monoxide and hydrocarbon emissionReduce functionCombination devicesNitrogen compoundsCompound (substance)Nitrogen oxide

A nickel-based catalyst is provided for reducing carbon monoxide, hydrocarbon emissions, and nitrogen oxides from vehicle exhausts. The catalyst is impregnated directly onto a carrier which is non-reactive with nickel. The nickel is contained on said carrier at a loading of between about 2 to about 20 wt %. When used in a vehicle exhaust gas treatment system, the catalyst provides improved efficiency in reducing CO, HC, and NOx emissions over the use of conventional three-way-catalysts.

Owner:FORD GLOBAL TECH LLC

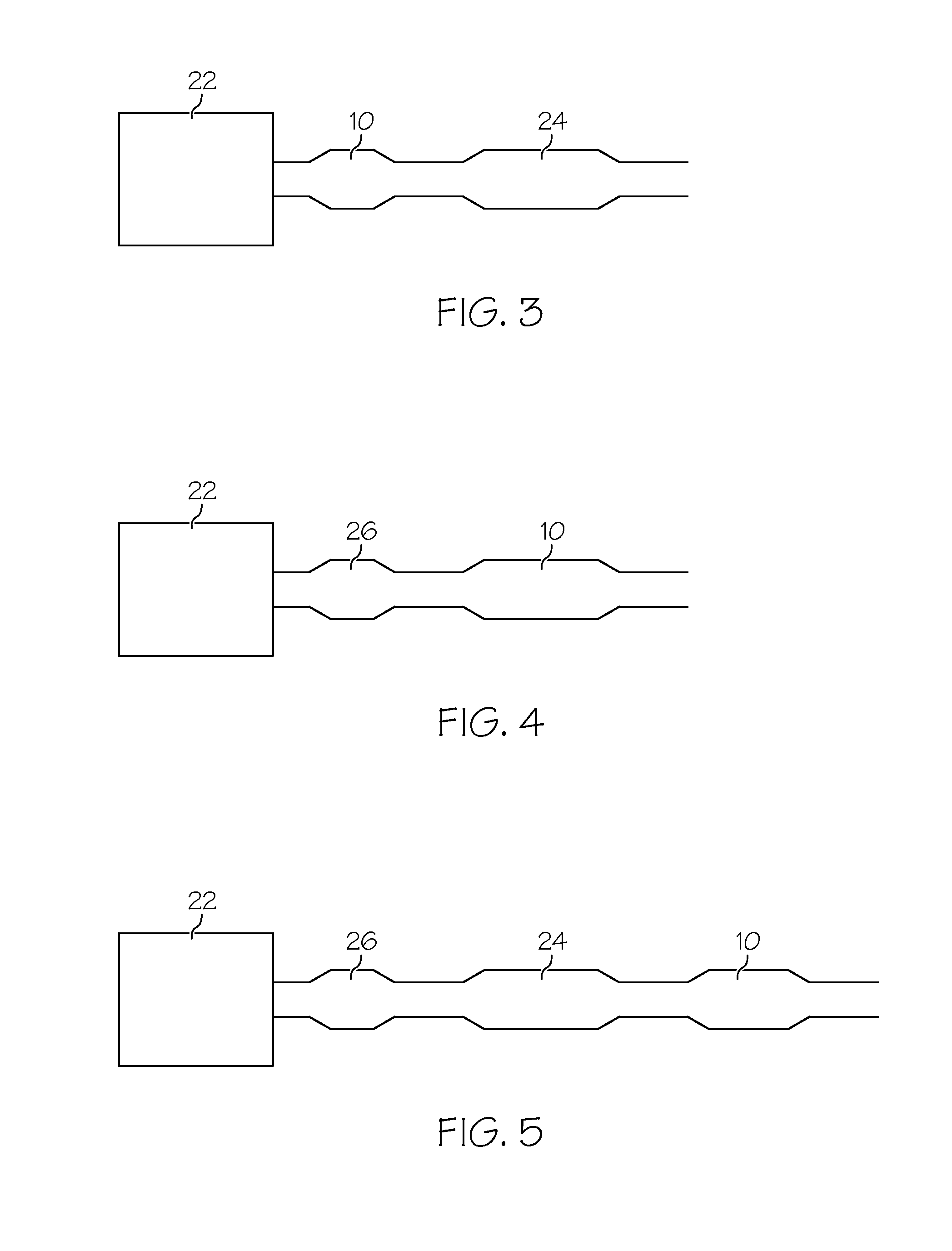

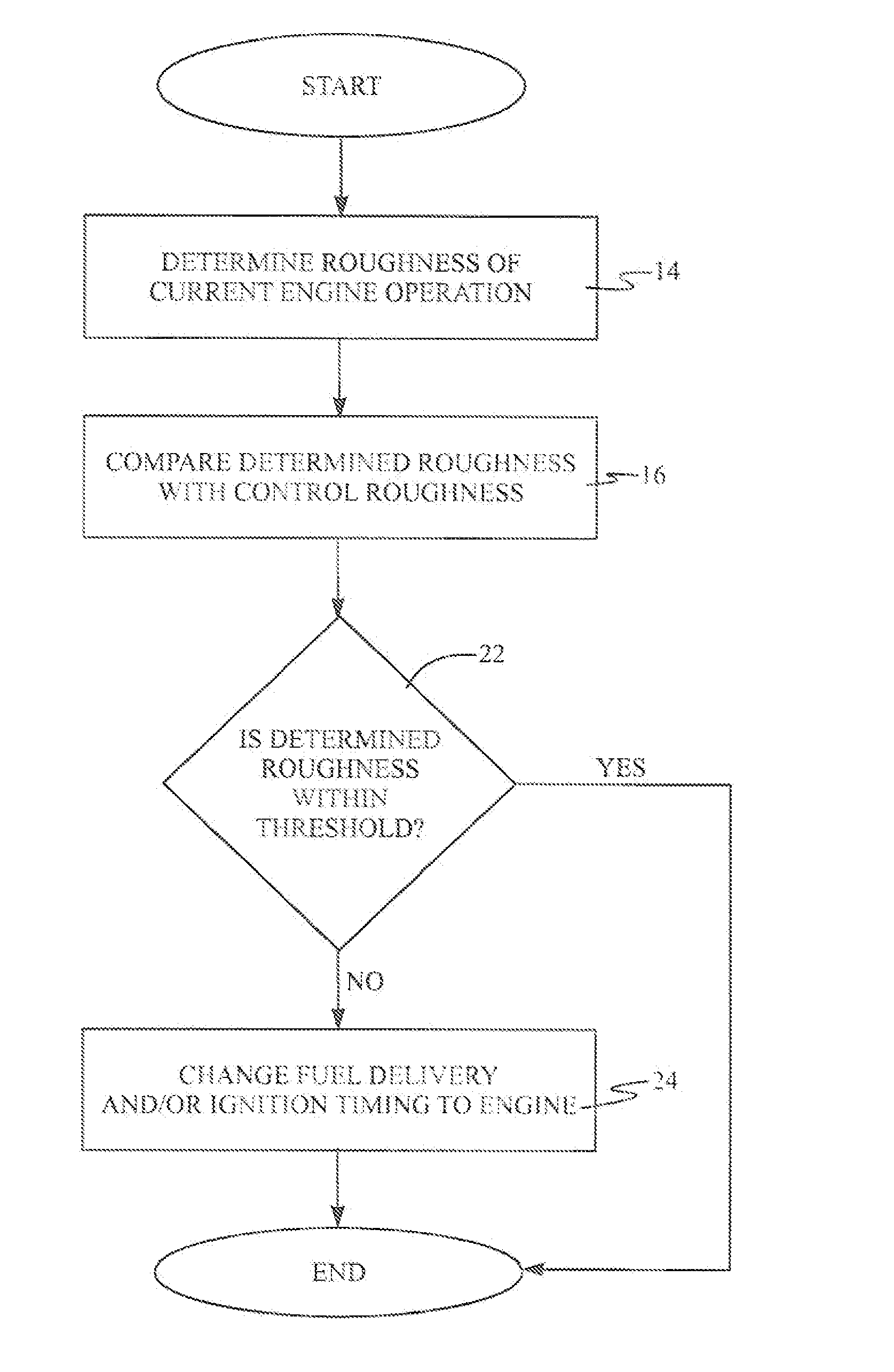

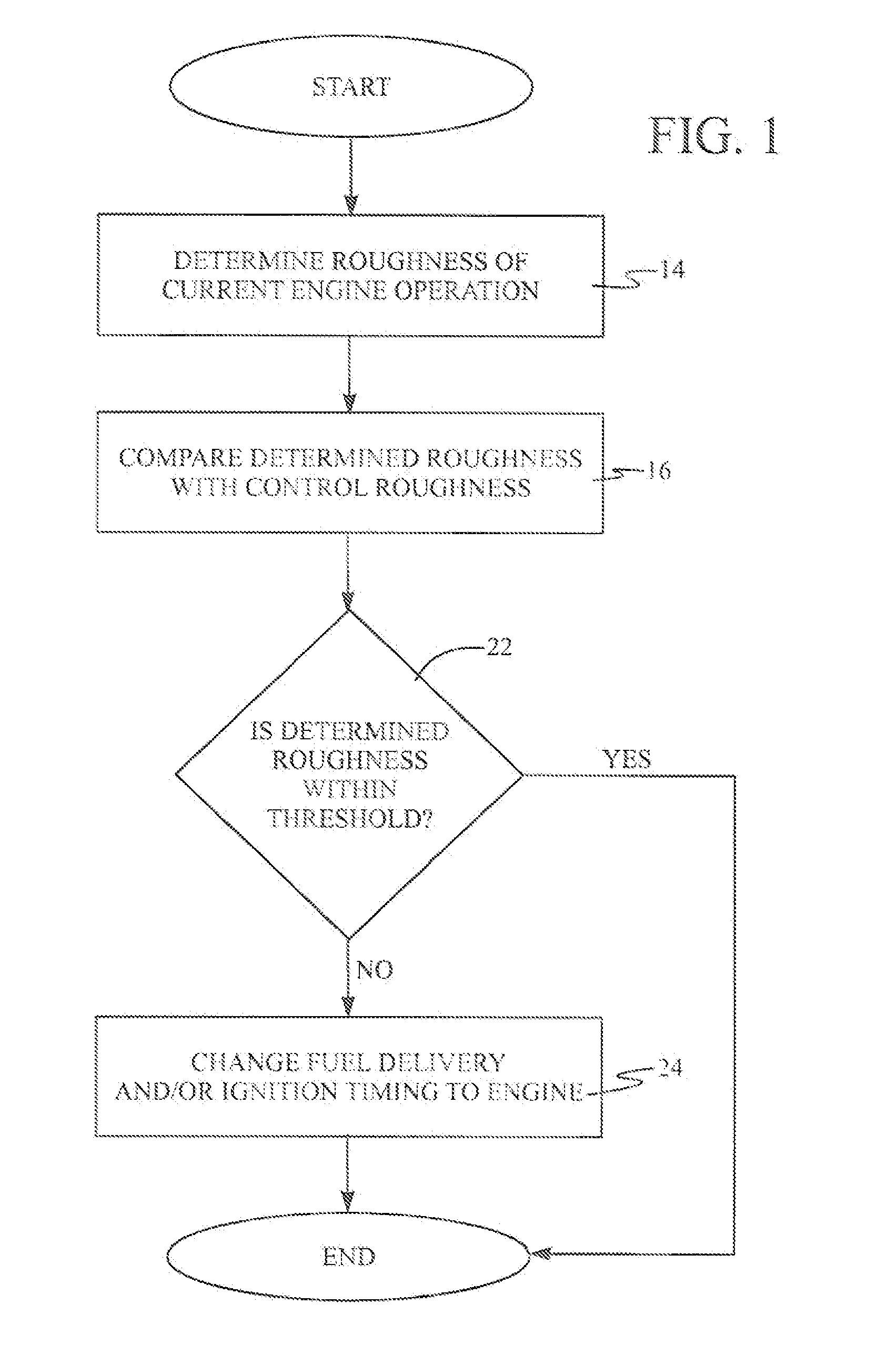

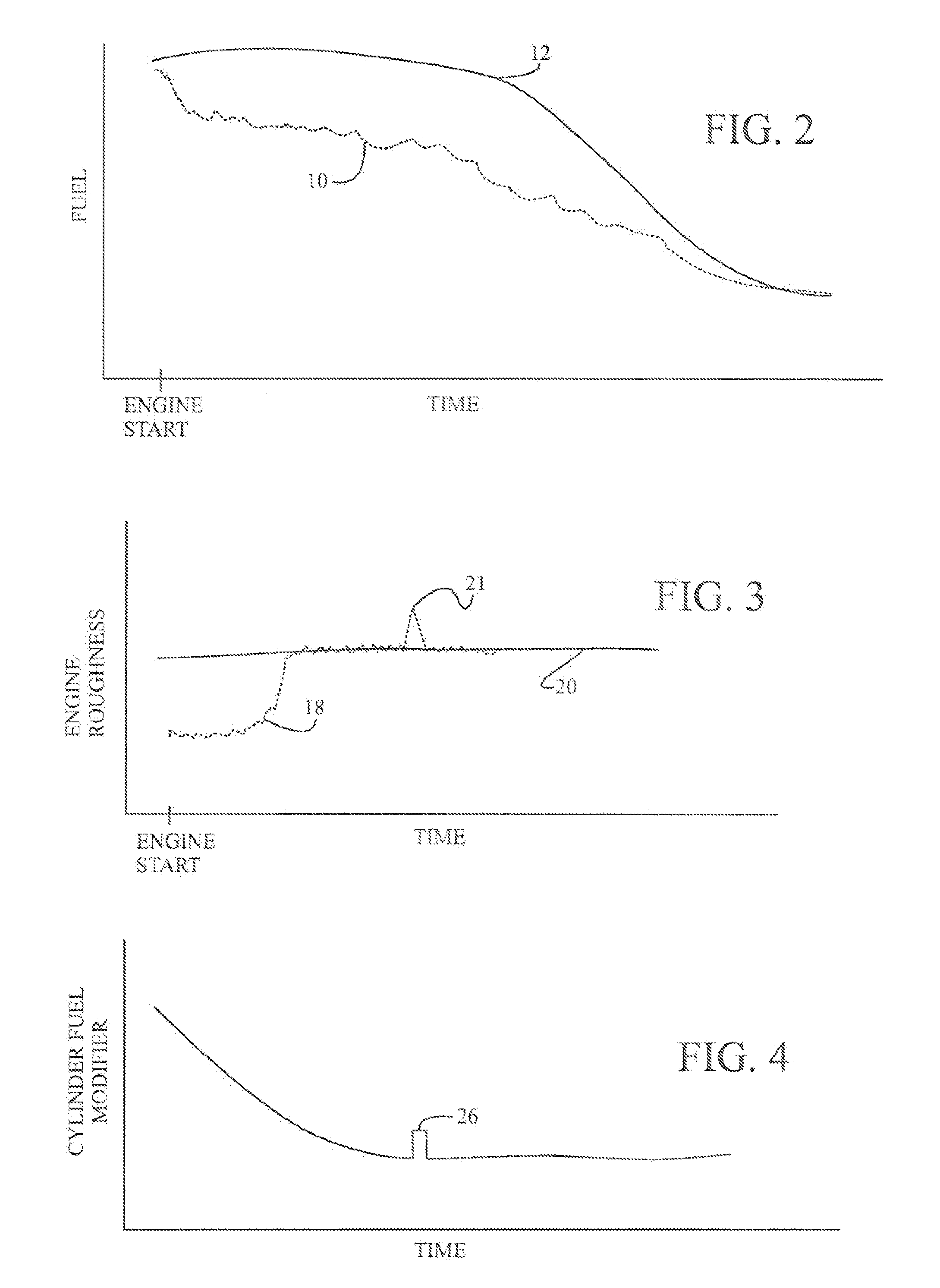

Engine event-based correction of engine speed fluctuations

ActiveUS20080302331A1Engine roughness during initial operationLower hydrocarbon emissionsAnalogue computers for vehiclesElectrical controlEngineeringIgnition timing

Ignition timing for a combustion engine may be controlled by determining the roughness of current engine operation, comparing the determined roughness with a control roughness to determine if the determined roughness is within a threshold limit of the control roughness, and changing the ignition timing in a subsequent fuel delivery event as a function of the difference between the determined roughness and the control roughness. Preferably, the ignition timing is changed at least when the determined roughness is not within the threshold limit, although other factors may be taken into account when changing the ignition timing.

Owner:FCA US

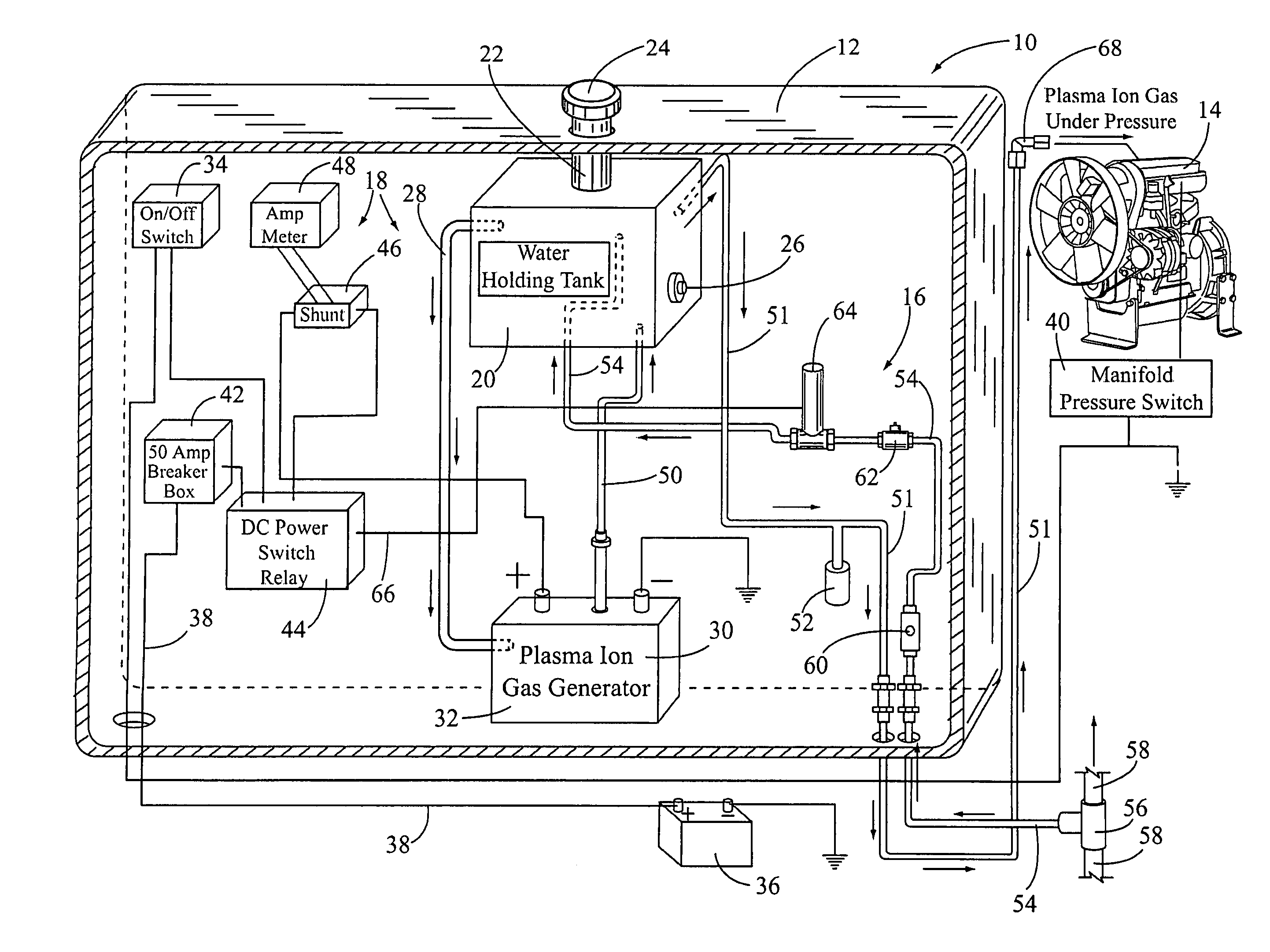

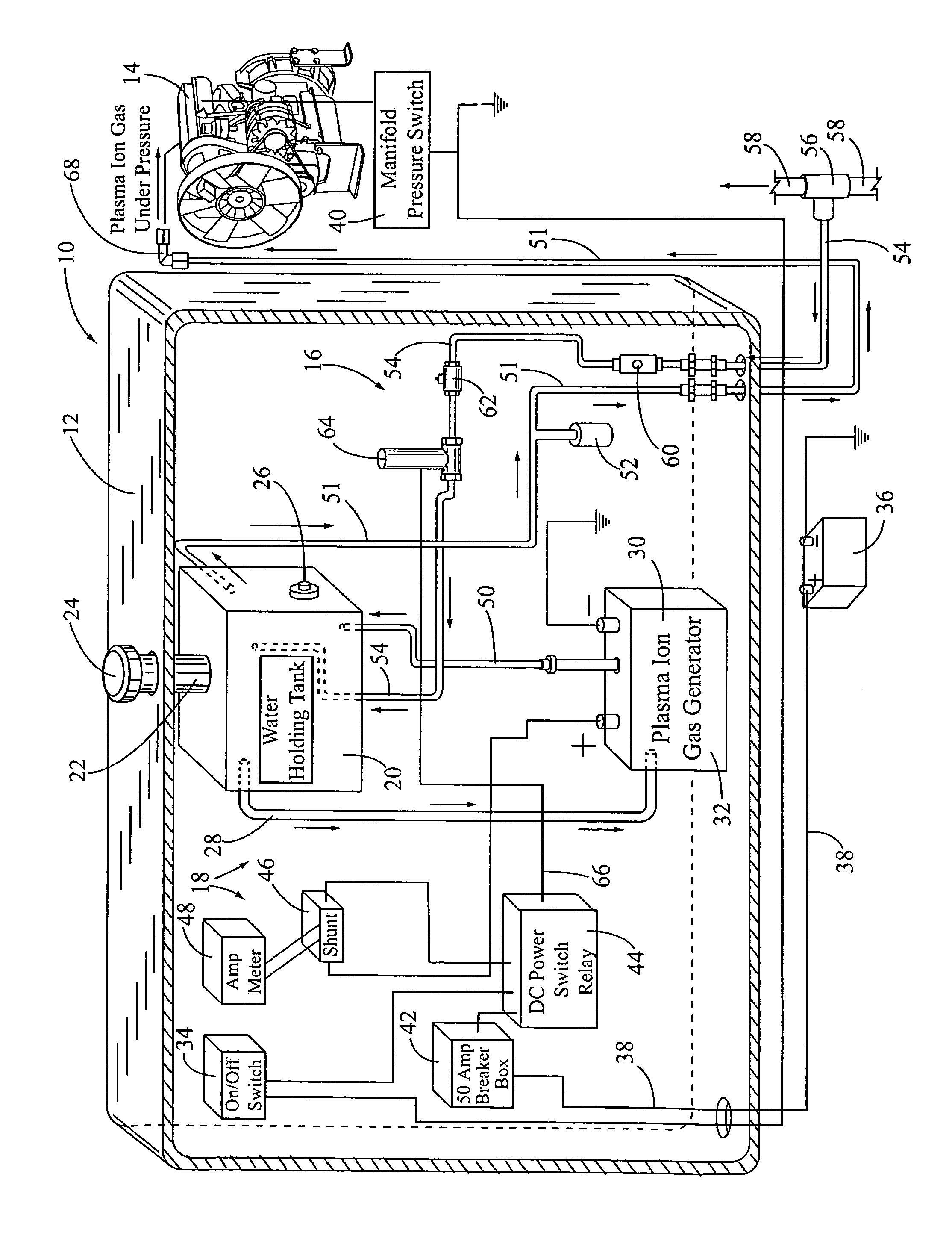

Combination air pressure system and plasma ion gas generator system for turbocharged diesel engine

InactiveUS8544452B1Easy to installIncreasing mileage per gallonInternal combustion piston enginesNon-fuel substance addition to fuelPressure systemCombustible gas

A combination air pressure system and a plasma ion gas generator system adapted for mounting next to an intake manifold of a turbocharged diesel engine. The system includes a water holding tank for supplying water to a plasma ion gas generator. The gas generator includes a housing with a plurality anode and cathode electrode plates. The system also includes an on / off switch and amp meter. The on / off switch is connected to the vehicle's battery. When the system is turned “on”, power is supplied to the gas generator for generating combustible gases. The air pressure system includes an air line connected to a vehicle's high pressure air line. The system's air line is connected to the water holding tank for pressurizing the gas mixture before it's introduced in the intake manifold.

Owner:CFT GLOBAL

Low temperature catalyst/hydrocarbon trap

ActiveUS20150231566A1Emission reductionImprove adsorption capacityCombination devicesNitrogen compoundsPlatinum groupMetal

A low-temperature catalyst is provided for reducing cold-start hydrocarbon emissions. The catalyst comprises a platinum group metal impregnated onto an oxygen storage material. The catalyst may be used alone or may be included in a hydrocarbon trap containing a hydrocarbon adsorption material therein. The catalyst / hydrocarbon trap is positioned in the exhaust system of a vehicle downstream from a close-coupled catalyst such that the exhaust temperature at the catalyst location does not exceed 850° C. during normal vehicle operation and when combined with a hydrocarbon adsorption material in a trap, the exhaust temperature does not exceed 700° C.

Owner:FORD GLOBAL TECH LLC

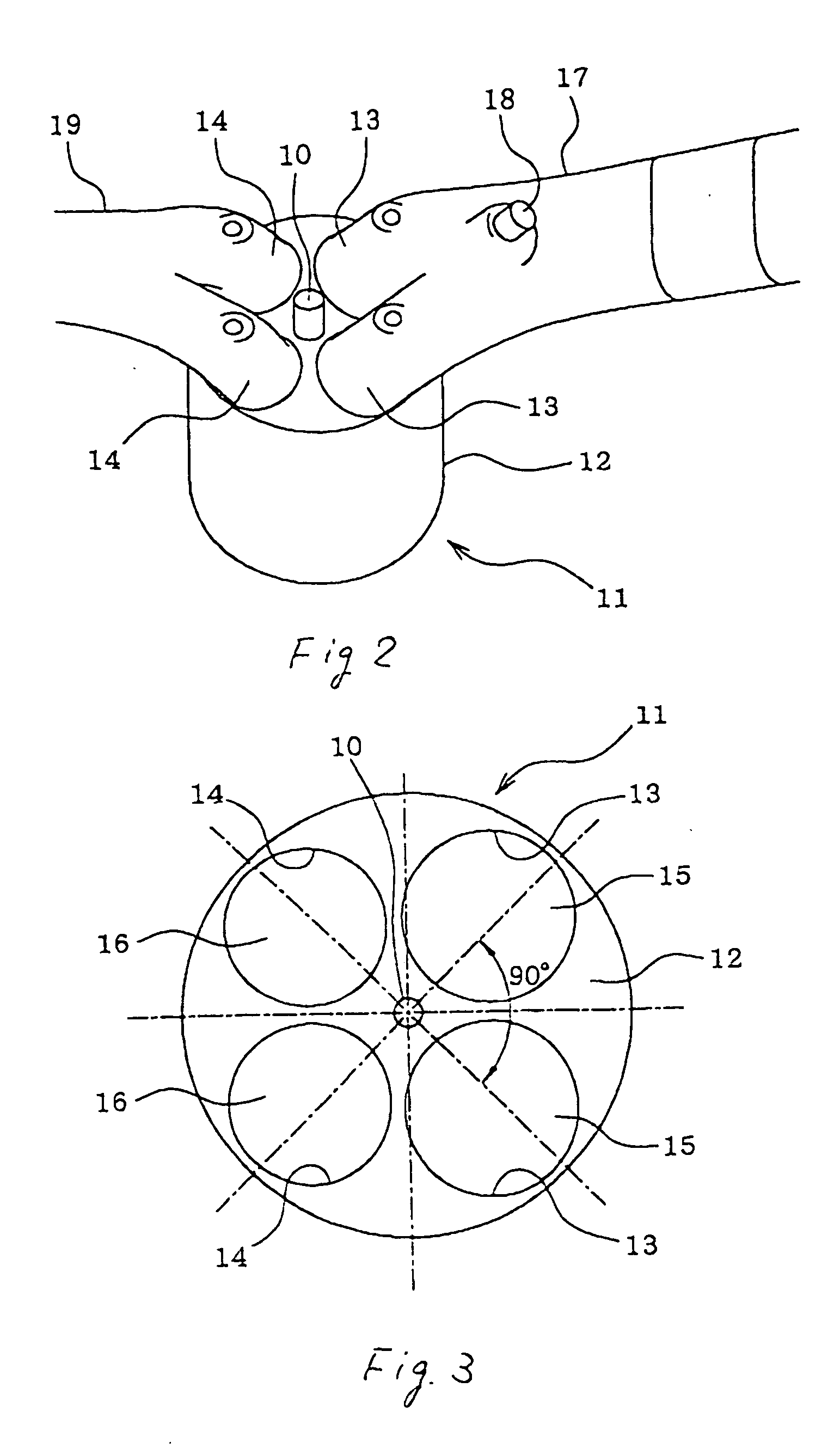

Fuel injector designed to optimize pattern of fuel spray

ActiveUS20050235961A1Lower hydrocarbon emissionsSimple and inexpensive structureElectrical controlInternal combustion piston enginesInjectorHead parts

A fuel injector for an internal combustion engine which has a spray hole designed geometrically to produce a spray of fuel so that substantially 70% or more of an amount of the spray hits a preselected area of a head of an intake valve of the engine when the intake valve is closed. The preselected area is one of a first and a second area of the intake valve head which are defined by a reference boundary line extending through a base end of a stem of the intake valve. The preselected area is the first area closer to an intake manifold, while the second area is closer to an exhaust valve. This avoids rich misfire and reduces HC emissions from the engine regardless of the intake valve is in a closed state or in an open state.

Owner:DENSO CORP

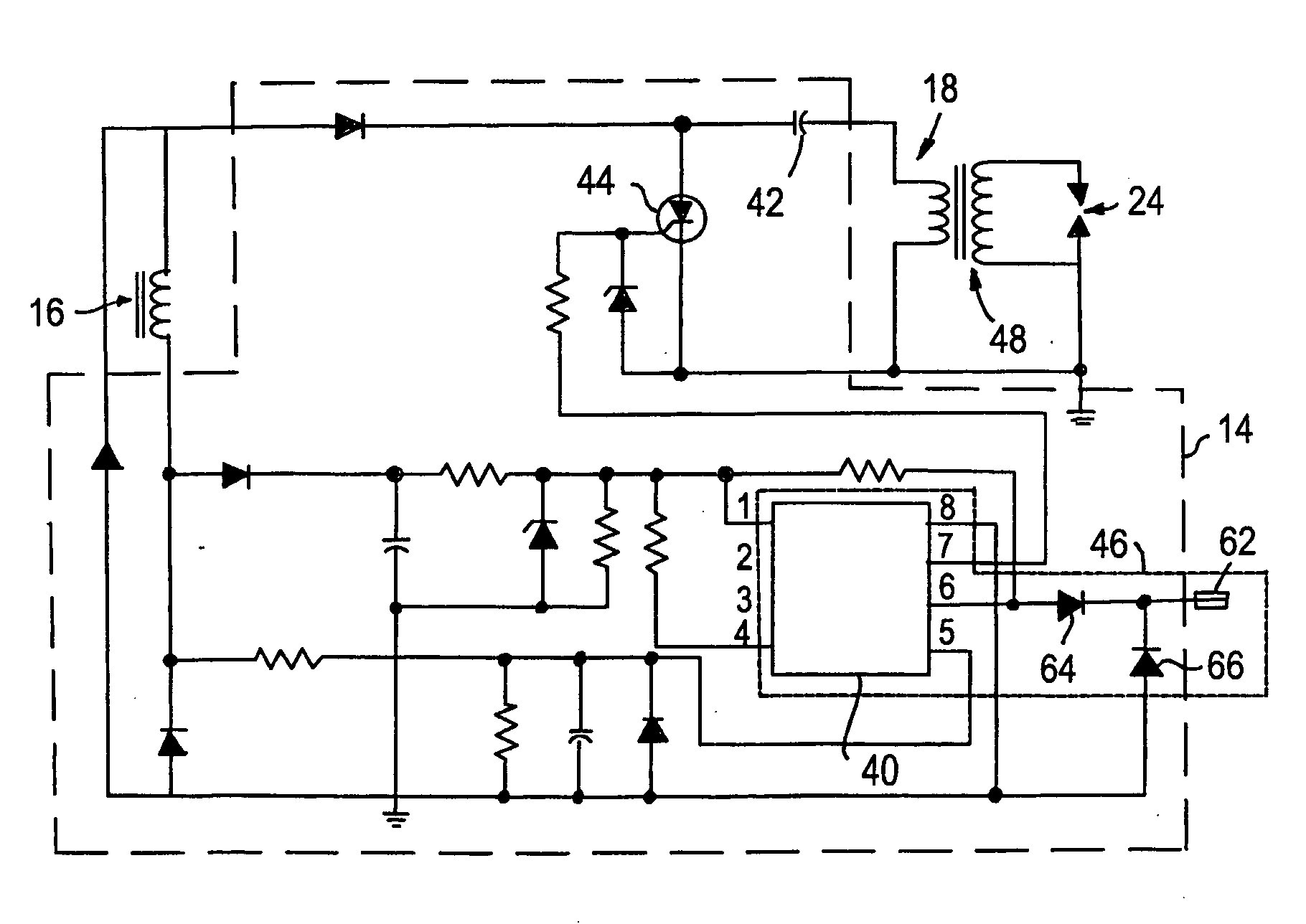

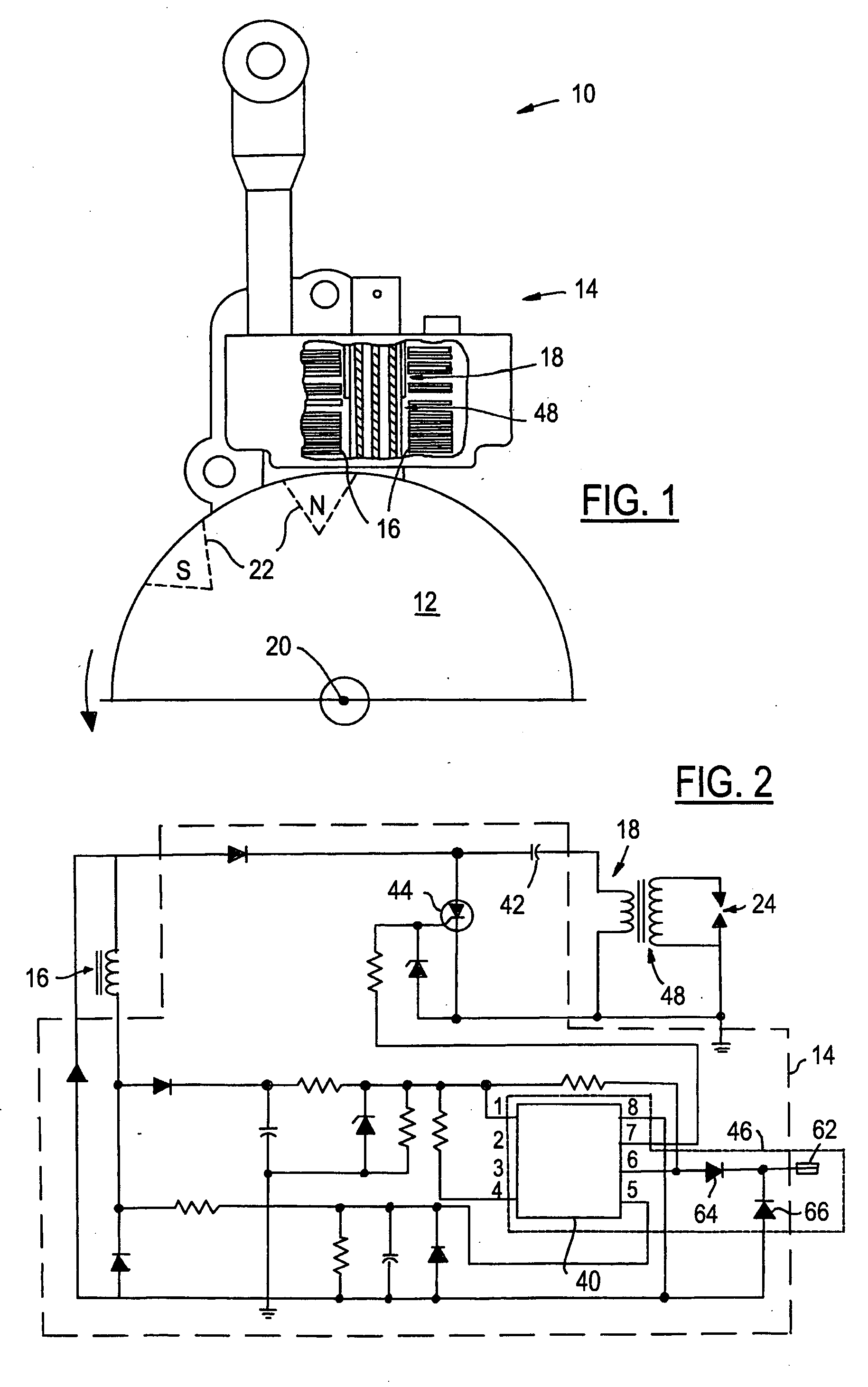

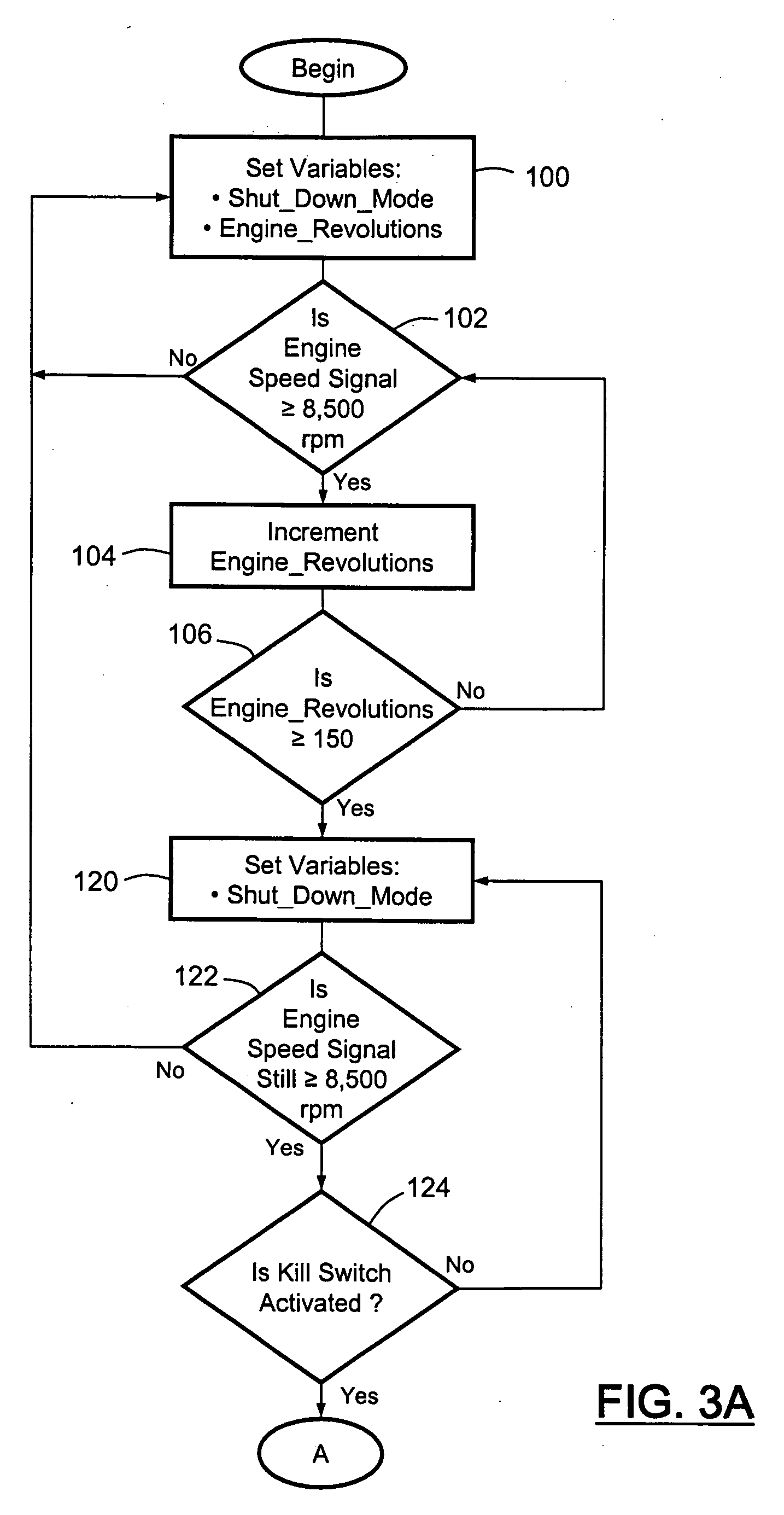

Engine kill-switch control circuit and method of operating the same

ActiveUS20060069495A1Lower hydrocarbon emissionsPrevent backfireAnalogue computers for vehiclesElectrical controlControl mannerKill switch

A kill-switch control circuit for use with a light-duty combustion engine determines whether to execute a controlled shut down method or an immediate shut down method in response to kill-switch activation. The selection of a shut down method is made, at least in part, by using engine speed readings and by counting engine revolutions. The controlled shut down method utilizes ignition timing delay and / or spark ratio techniques to quickly bring the engine to a stop, yet does so in a controlled manner that avoids backfiring and other undesirable effects. Conversely, the immediate shut down method abruptly stops sending a current to the spark plug.

Owner:WALBRO LLC

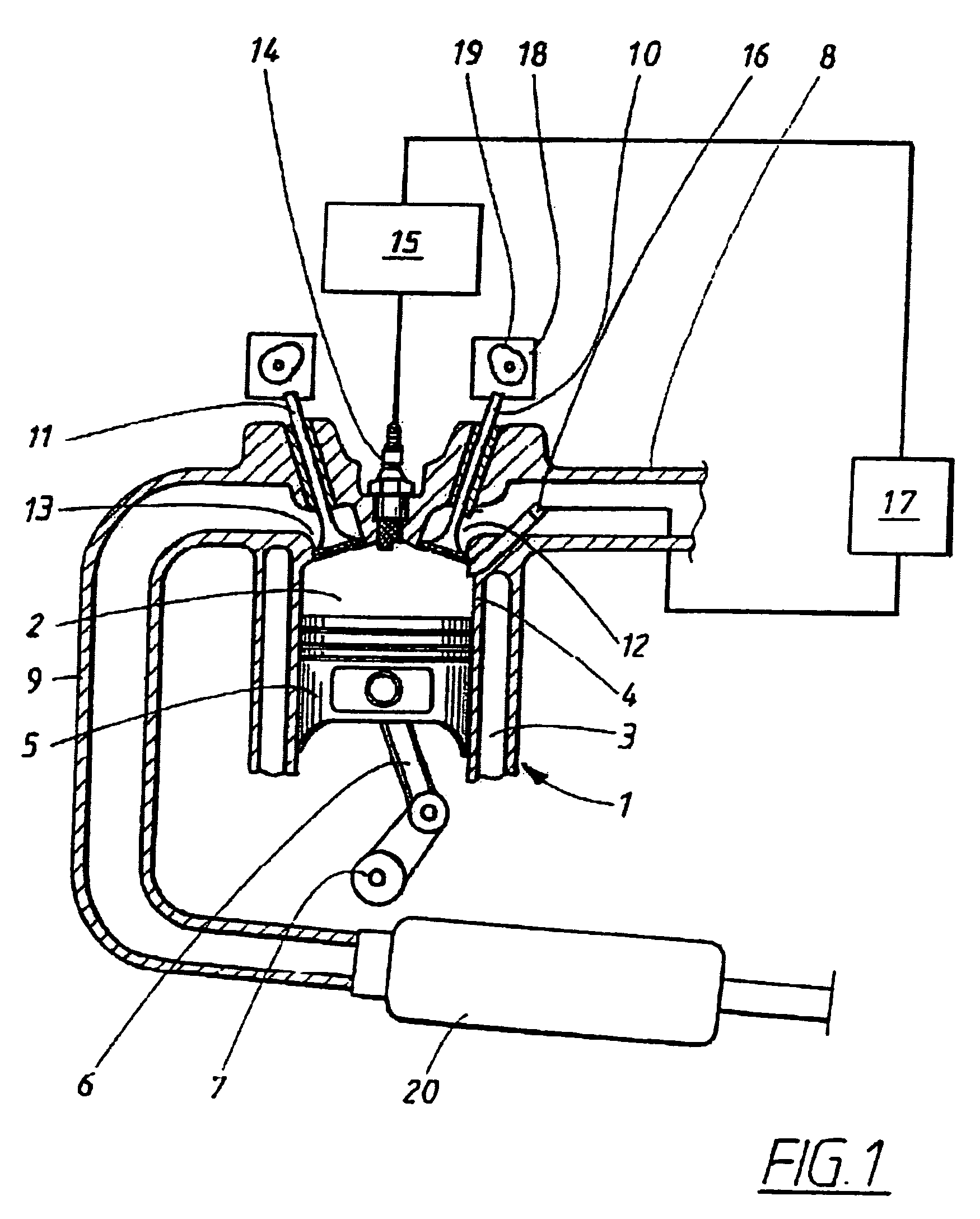

Method of reducing exhaust gas emissions during cold start conditions and an internal combustion engine in which the method is used

InactiveUS7124734B2Well mixedIncrease the differential pressureValve arrangementsElectrical controlTop dead centerExternal combustion engine

An internal combustion engine and a method of reducing hydrocarbon emissions of an internal combustion engine during cold start conditions in disclosed. The engine has at least one cylinder provided with a piston which reciprocates between a top dead-center and a bottom dead-center, at least one intake valve through which intake air is provided, a fuel injector assembly arranged to inject atomised fuel particles directly into the cylinder and means for controlling the opening and closing of the intake valve. According to the invention, intake valve opening is adjusted to occur after top dead center of the piston. When the intake valve opens, a pressure differential exists across the valve. Fuel is injected directly into the cylinder during the time of the pressure differential.

Owner:FORD GLOBAL TECH LLC

Three-way catalyst comprising mixture of nickel and copper

ActiveUS9403157B2Enhanced oxygen storage capacity (OSC)Lower hydrocarbon emissionsMolecular sieve catalystsInternal combustion piston enginesNitrogen oxideCopper

A three-way catalyst including a mixture of nickel and copper is provided for reducing carbon monoxide, hydrocarbon emissions, and nitrogen oxides from vehicle engine exhausts. The catalyst is impregnated onto a carrier substrate which is non-reactive with nickel and copper. When used in a vehicle exhaust gas treatment system, the nickel-copper catalyst provides improved efficiency in reducing CO, HC, and NOx emissions over the use of conventional three-way-catalysts and provides enhanced oxygen storage capacity (OSC) and water-gas-shift (WGS) functions.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com