Reduction of cold-start emissions and catalyst warm-up time with direct fuel injection

a technology of direct fuel injection and catalyst, which is applied in the direction of electric control, ignition automatic control, machines/engines, etc., can solve the problems of insufficient temperature of catalyst material in the catalytic converter in order to sufficiently process the unwanted, uncombusted, by-products of combustion, and inhibit the proper vaporization of fuel. , to achieve the effect of reducing hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

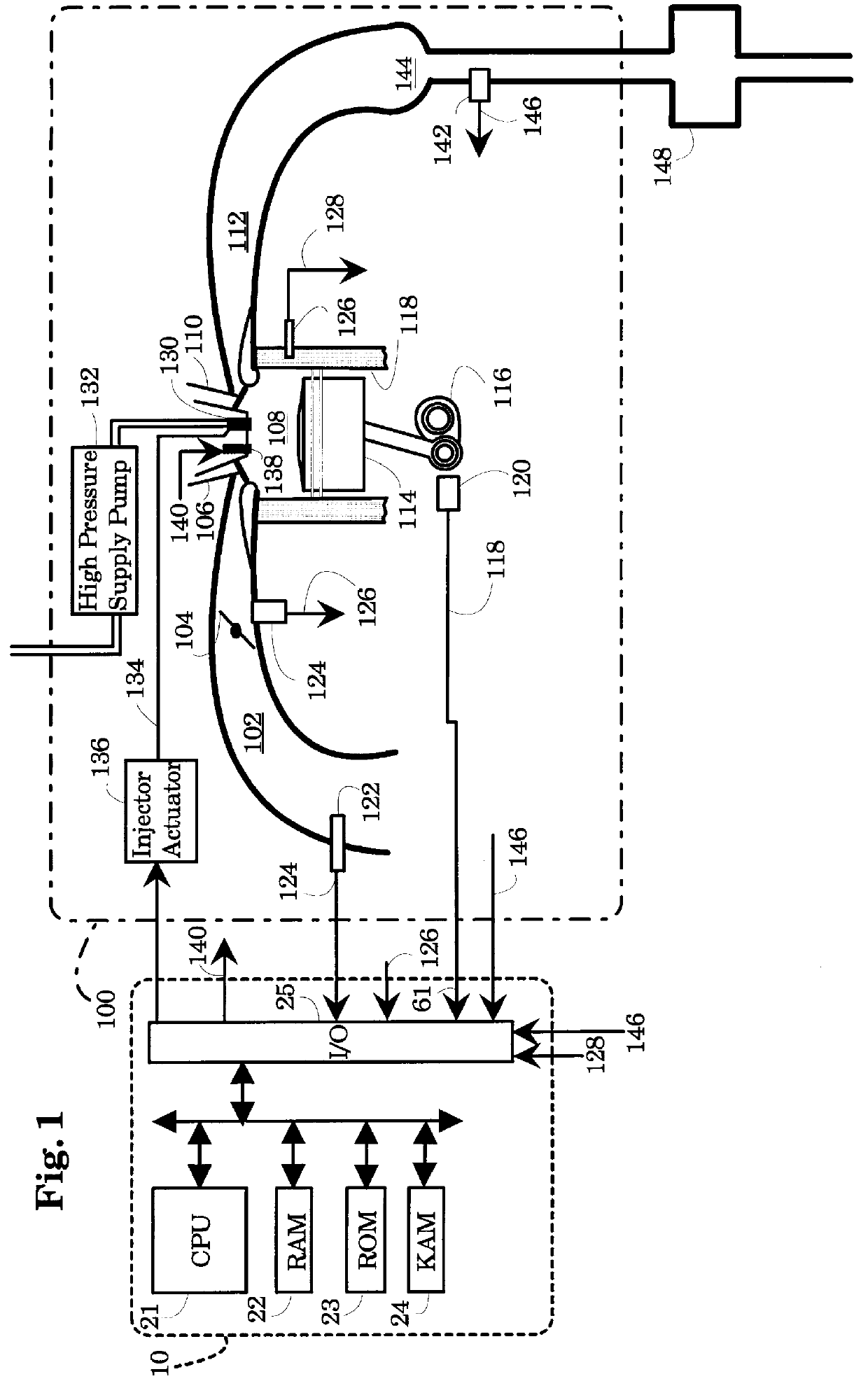

FIG. 1 of the drawings shows an Electronic Engine Controller (EEC) 10 and an internal combustion engine 100, which comprises a plurality of cylinders, one of which is shown in FIG. 1. Engine 100 draws an aircharge through an intake manifold 102, past a throttle plate 104, and intake valve 106 and into combustion chamber 108. An air / fuel mixture which consists of the aircharge and fuel injected by fuel injector 130, is ignited in combustion chamber 108, and exhaust gas produced from combustion of the air / fuel mixture is transported past exhaust valve 110 through exhaust manifold 112. A piston 114 is coupled to a crankshaft 116, and moves in a linear fashion within a cylinder defined by cylinder walls 118.

A crankshaft position sensor 120 detects the rotation of crankshaft 116 and transmits a crankshaft position signal 118 to EEC 10. Crankshaft position signal 118 preferably takes the form of a series of pulses, each pulse being caused by the rotation of a predetermined point on the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com