Biomass boiler monitoring system

A biomass boiler and monitoring system technology, applied in lighting and heating equipment, fluid heaters, water heaters, etc., can solve the problems of reduced combustion efficiency, high labor intensity of operators, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

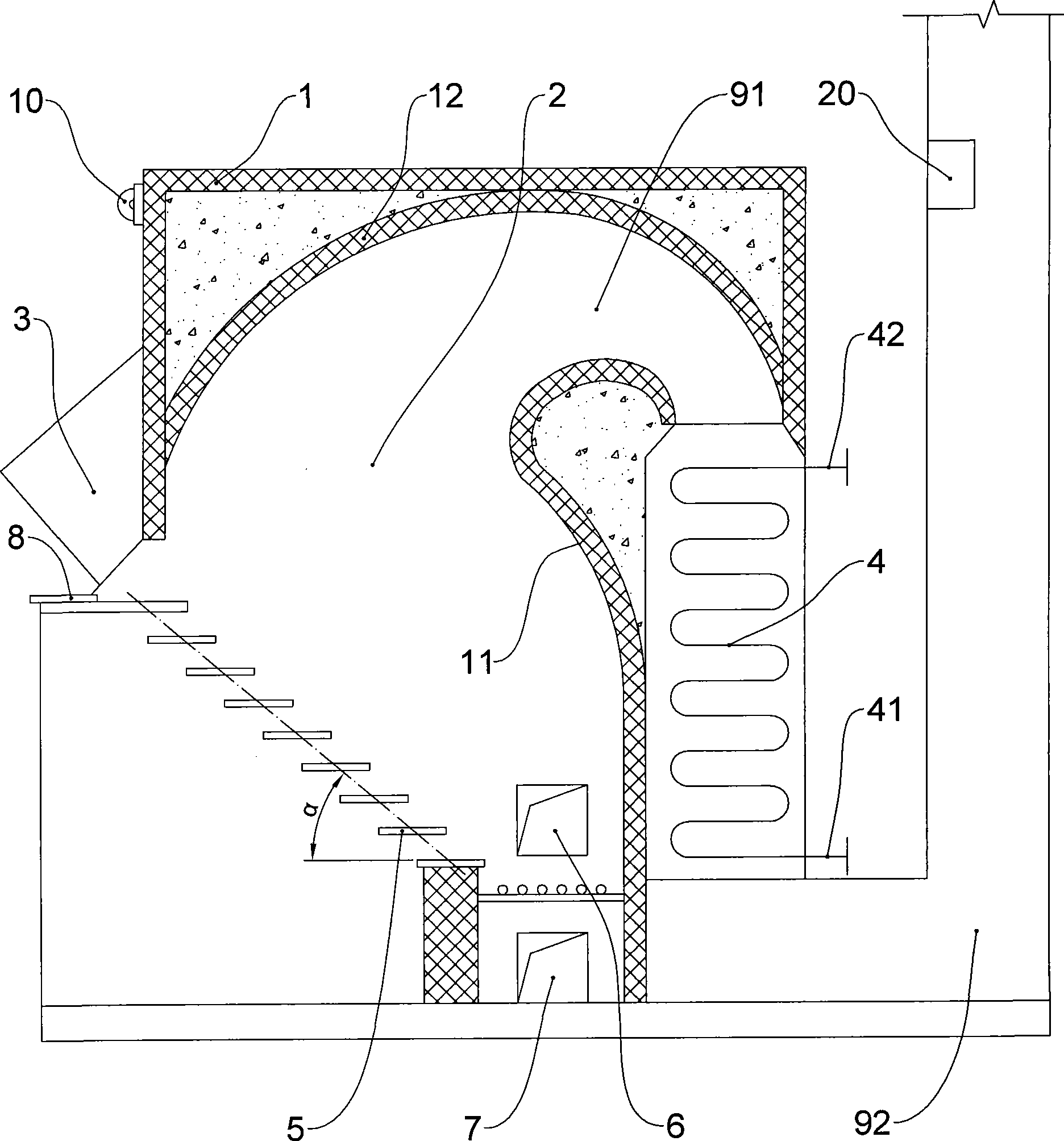

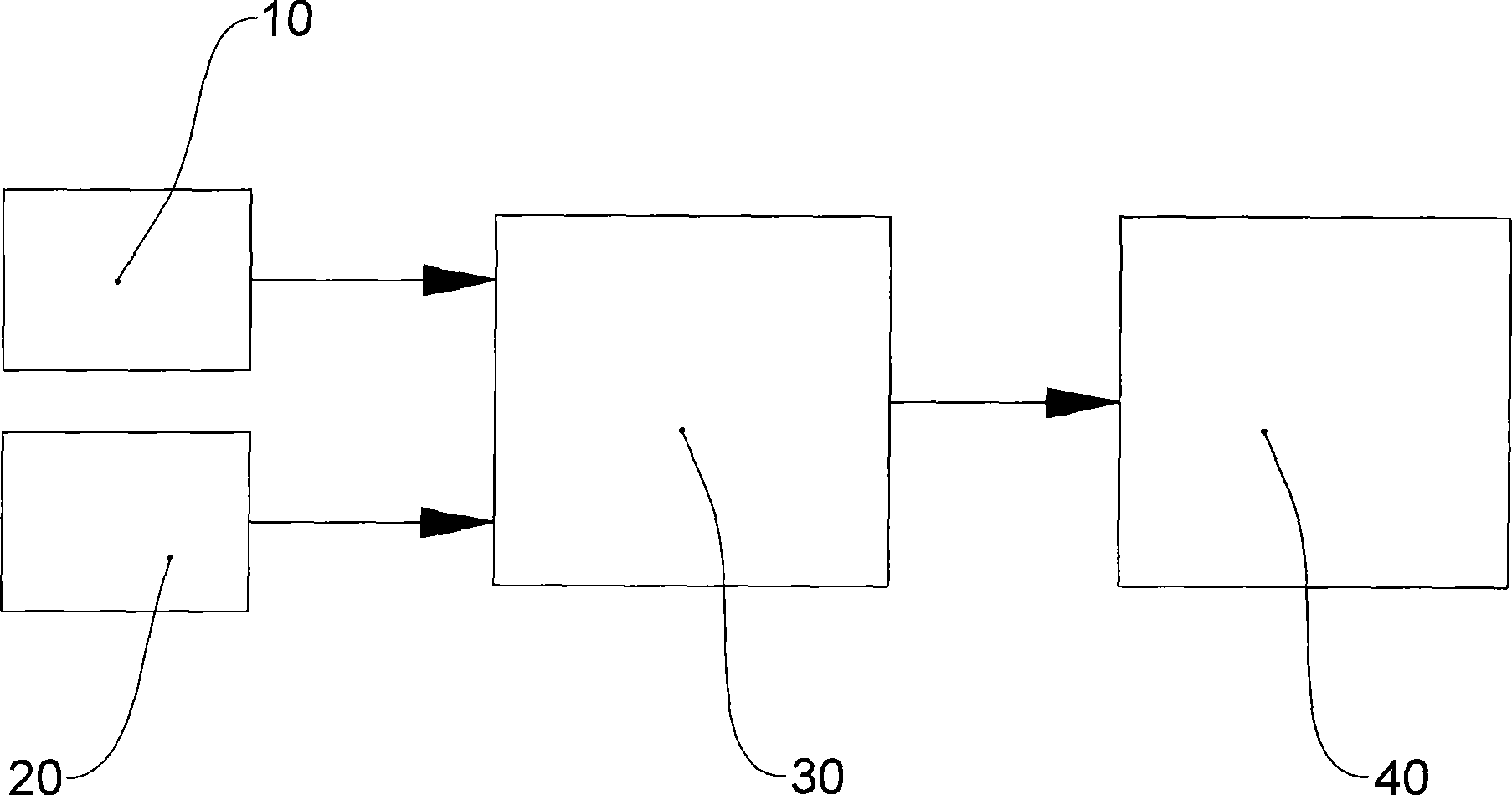

[0026] Such as figure 1 , image 3 As shown, the present invention includes a biomass boiler body and a smoke exhaust channel 92. The biomass boiler body is provided with a camera 10 for monitoring the feed port, and a gas induction monitor 20 is provided in the smoke exhaust channel 92. The camera 10, the gas induction monitor 20 are connected to the signal receiver 30, the signal receiver 30 is connected to the signal recorder 40, and the signal receiver 30 and the signal recorder 40 are placed in the environment Regulatory department, described camera 10, described gas induction monitor 20 are connected with the described signal receiver 30 that is positioned at remote by the wireless network such as GPRS or CDMA, and described signal receiver 30 is positioned at local signal record by wired network Instrument 40 is connected.

[0027] The biomass boiler in this embodiment is a hot water boiler. The biomass boiler body includes a furnace body 1, a furnace 2, a hopper 3, ...

Embodiment 2

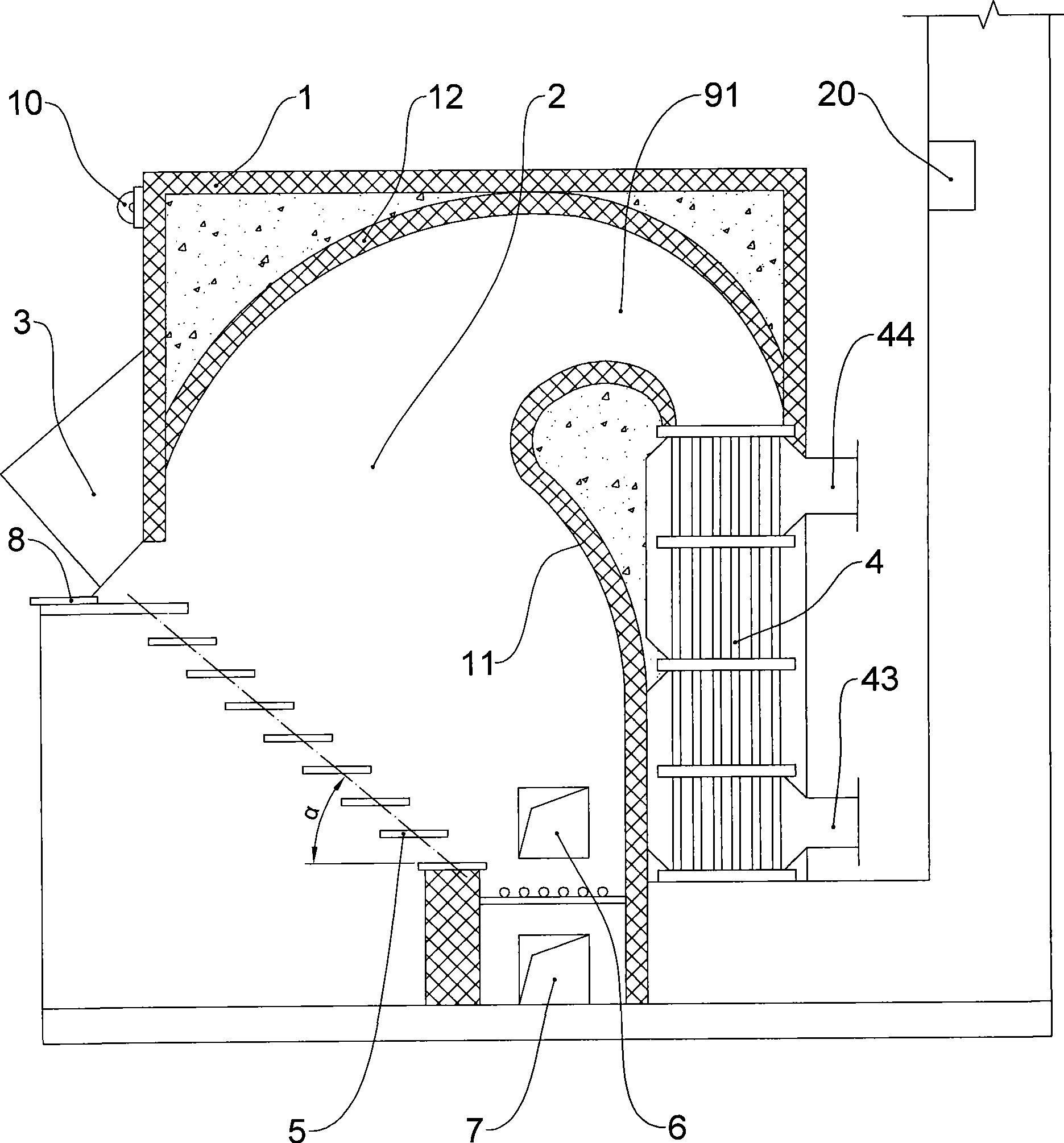

[0030] Such as figure 2 , image 3As shown, the difference between this embodiment and Embodiment 1 is that the biomass boiler in this embodiment is a hot blast stove, the heat exchanger 4 in this embodiment is a gas-gas heat exchanger, and the cooling of the heat exchanger 4 The cold air inlet 43 and the hot air outlet 44 are respectively provided on the two sides, and the hot side of the heat exchanger 4 communicates with the smoke passage 91 and the smoke exhaust passage 92 respectively.

[0031] The present invention monitors the feeding situation of the feed port through the camera 10 at all times, and can accurately identify the type of fuel, thereby preventing coal with high pollution emissions from being used as fuel, and the camera 10 obtains the signal through the signal recorder 40 The real-time image signal of the real-time video signal is recorded for future viewing; meanwhile, the harmful gas in the smoke exhaust channel 92 is monitored in real time through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com