Control method for reducing cold start emission based on hybrid electric vehicle

A technology of hybrid electric vehicles and control methods, which is applied in the direction of exhaust treatment, exhaust devices, engine components, etc., which can solve the problems of increasing HC and CO emissions, catalyst aging, and large power consumption, so as to reduce vehicle emissions , the effect of accelerating ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

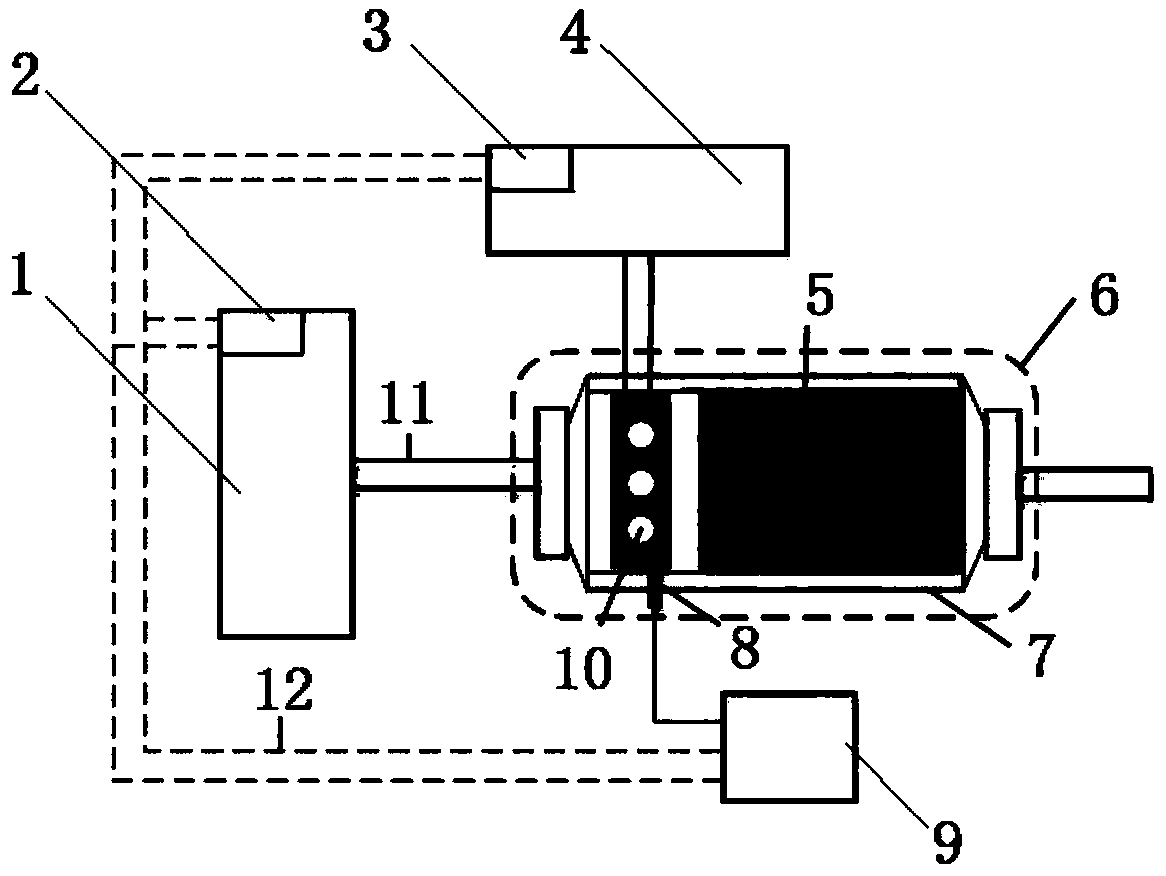

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

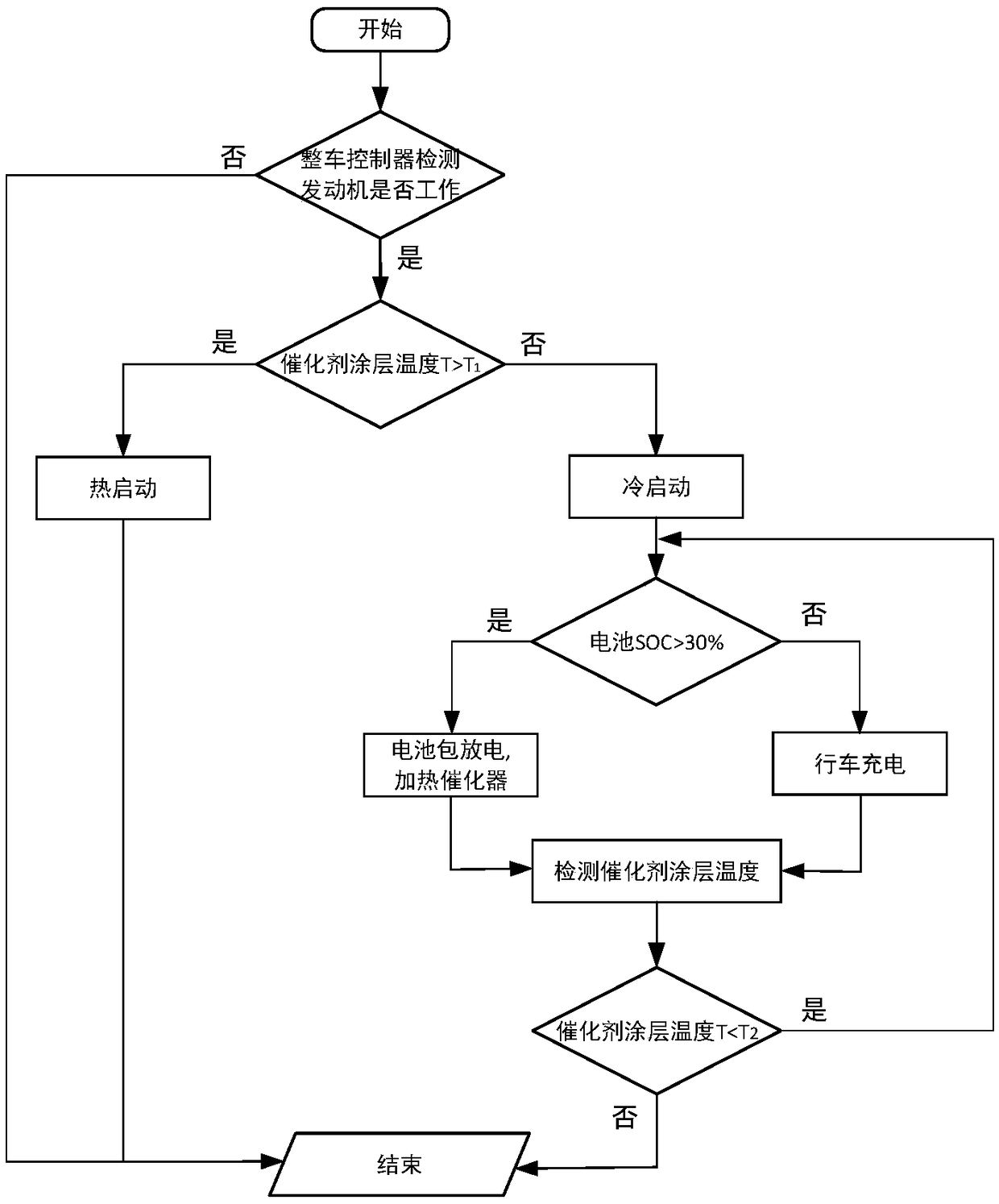

[0021] like figure 2 As shown, a control method for reducing cold start emissions based on hybrid electric vehicles, including three-way catalytic converter 6 heating control methods:

[0022] First, the vehicle controller 9 detects whether the ECU2 controls the start of the engine 1 through the CAN bus. If it detects that the engine 1 is started, the vehicle controller 9 reads the current catalytic converter temperature T and the battery SOC as a judgment for the electric heating type. The basis for whether the three-way catalytic converter reaches the light-off temperature is to compare with the set light-off temperature T1;

[0023] If it is greater than the light-off temperature T1, it is determined that the engine 1 is in a hot start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com