Special bio-compound fertilizer for rice and production method thereof

A technology for biological compound fertilizer and rice, which is applied in the field of biological compound fertilizer production to achieve the effects of advanced production technology, reduction of poisoning caused by excessive chloride ion and salt concentration, and soil improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

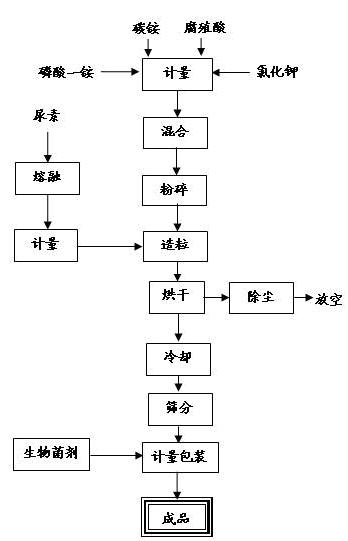

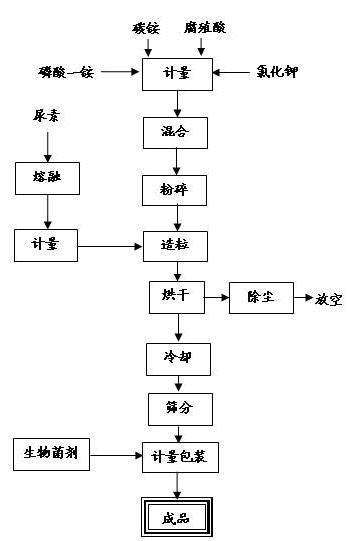

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: prepare special biological compound fertilizer for rice, nitrogen, phosphorus and potassium content are respectively 17%, 17%, 12%, all are percentage by mass, raw material components are as follows:

[0057] urea 280 copies potassium chloride 200 copies Monoammonium Phosphate 285 copies biological additives 70 copies humic acid 80 copies ammonium bicarbonate 50 copies calcium silicate 25 copies EDTA chelated zinc 10 copies

[0058] Melt 280 parts of urea in a drum granulator for spraying, and chelate with 200 parts of potassium chloride, 285 parts of monoammonium phosphate, 50 parts of biological additives, 50 parts of ammonium bicarbonate, 25 parts of calcium silicate and 10 parts of EDTA Zinc and returned materials are granulated, mixed evenly with 50 parts of pretreated humic acid, then granulated (40°C), dried (70°C), cooled, sieved, and packed after blending. Add 0.5kg of solid microbia...

Embodiment 2

[0059] Embodiment 2: prepare special biological compound fertilizer for rice, nitrogen, phosphorus and potassium content are respectively 16%, 12%, 18%, all are percentage by mass, raw material components are as follows:

[0060] urea 280 copies potassium chloride 300 copies Monoammonium Phosphate 200 copies biological additives 60 copies humic acid 65 copies ammonium bicarbonate 60 copies calcium silicate 25 copies EDTA chelated zinc 10 copies

[0061] Manufacturing process is the same as embodiment 1.

[0062] Comparative example: 54% ordinary potassium chloride compound fertilizer, the ratio of nitrogen, phosphorus and potassium is 18-18-18, and it is Sanan compound fertilizer produced by Stanley Fertilizer Co., Ltd.

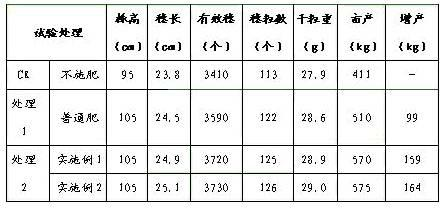

[0063] The application effect of above embodiment 1-2 and comparative example is as follows:

[0064]The applicant has specially set up an agrochemical service team, equipped with special agroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com