Coal powder pressurizing oxygen-enriched combustion settling furnace experimental device

A technology of oxygen-enriched combustion and experimental device, applied in the direction of material thermal development, investigation stage/state change, etc., can solve the problems of inability to study pulverized coal combustion, error, low pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

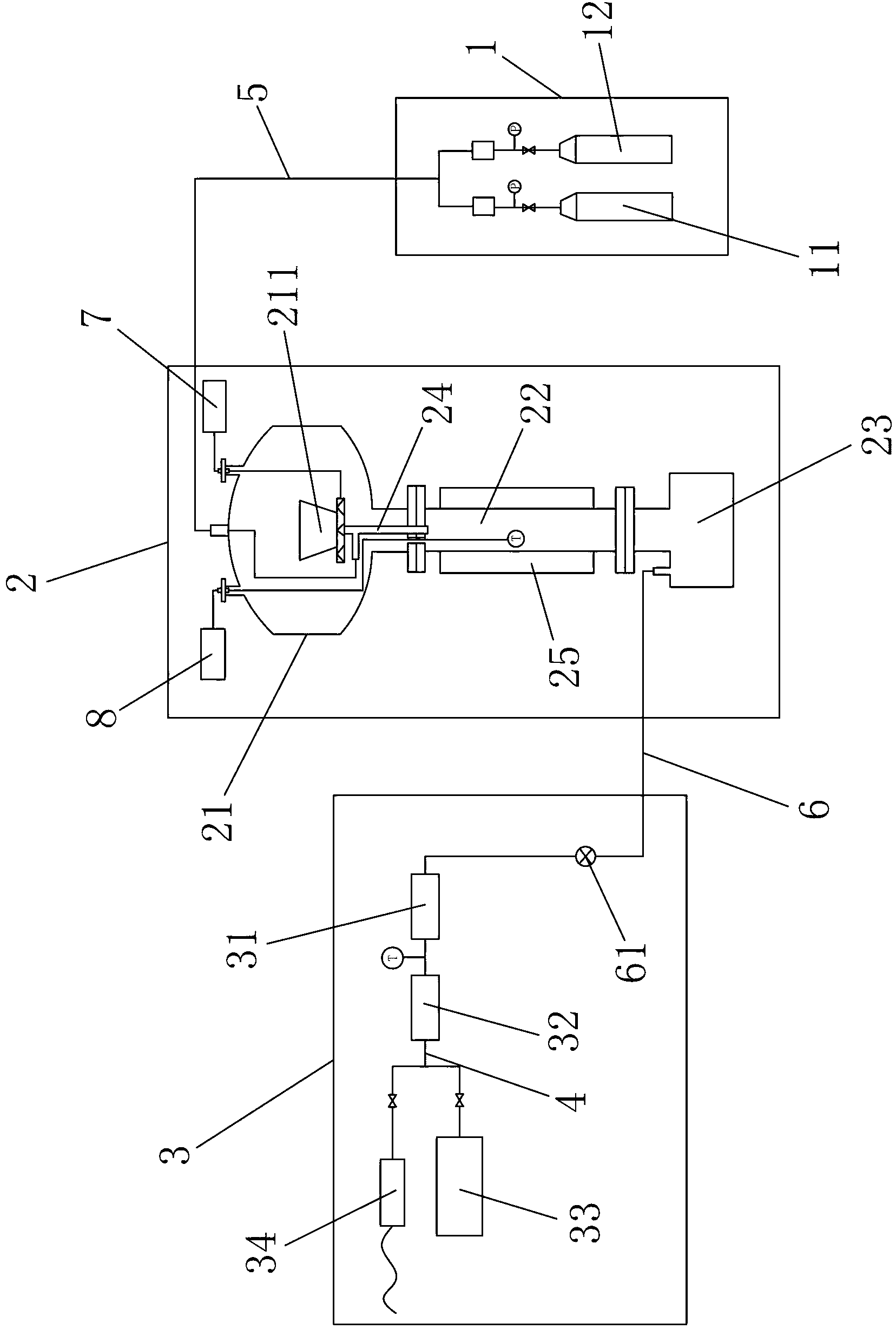

[0035] Such as Figures 1 to 4 Shown, a pulverized coal pressurized oxygen-enriched combustion settling furnace experimental device, said experimental device includes an air intake system 1, a settling furnace 2 and a flue gas analysis system 3;

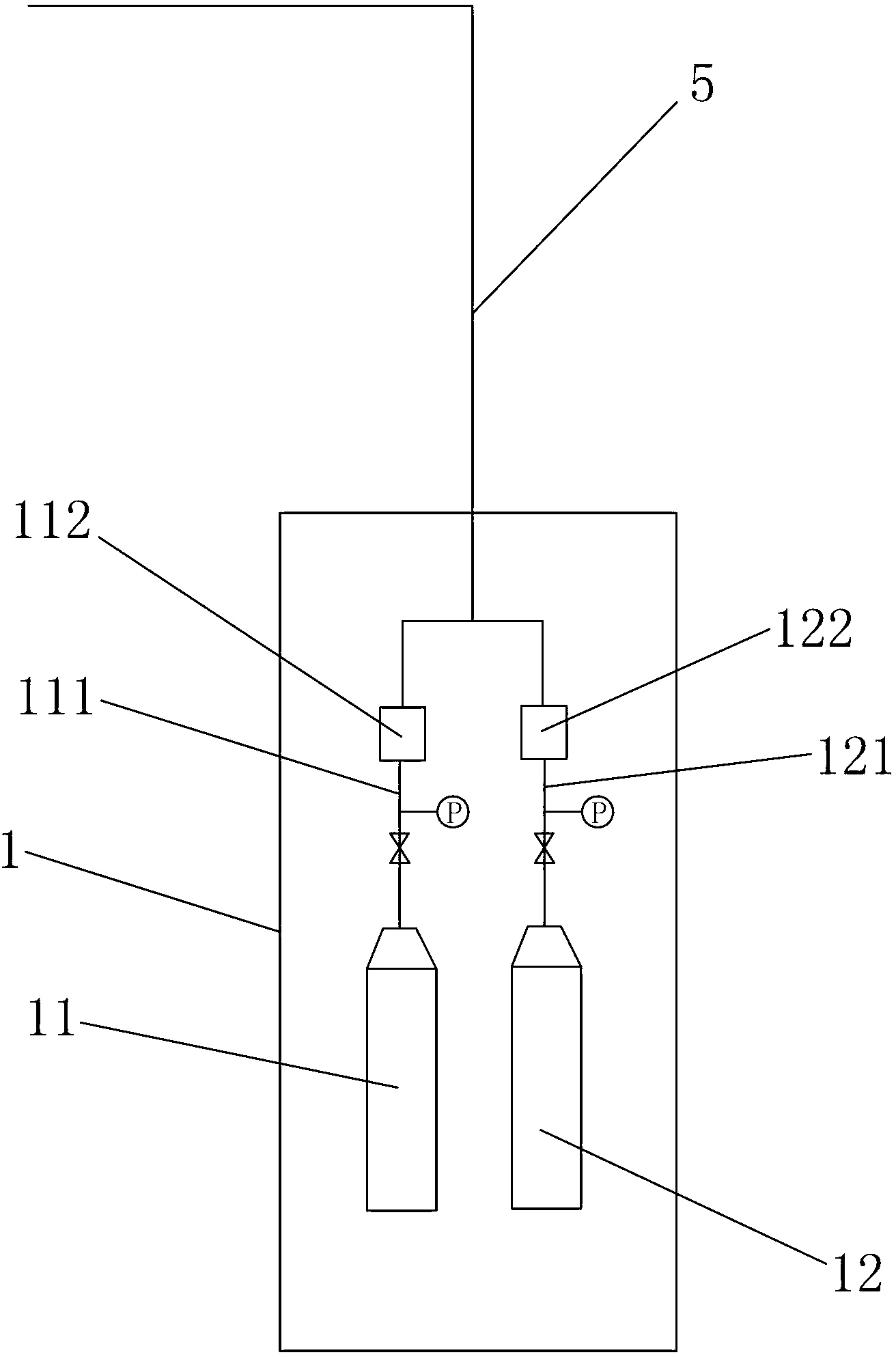

[0036] The intake system 1 includes an oxygen supply unit 11 and a carbon dioxide supply unit 12; the oxygen supply unit 11 communicates with the intake pipeline 5 through a pipeline A111, and the pipeline A111 is provided with a mass flow meter 112; the carbon dioxide supply unit 12 passes through a pipe The road B121 communicates with the intake pipe 5, and a mass flow meter 122 is provided on the pipe B121.

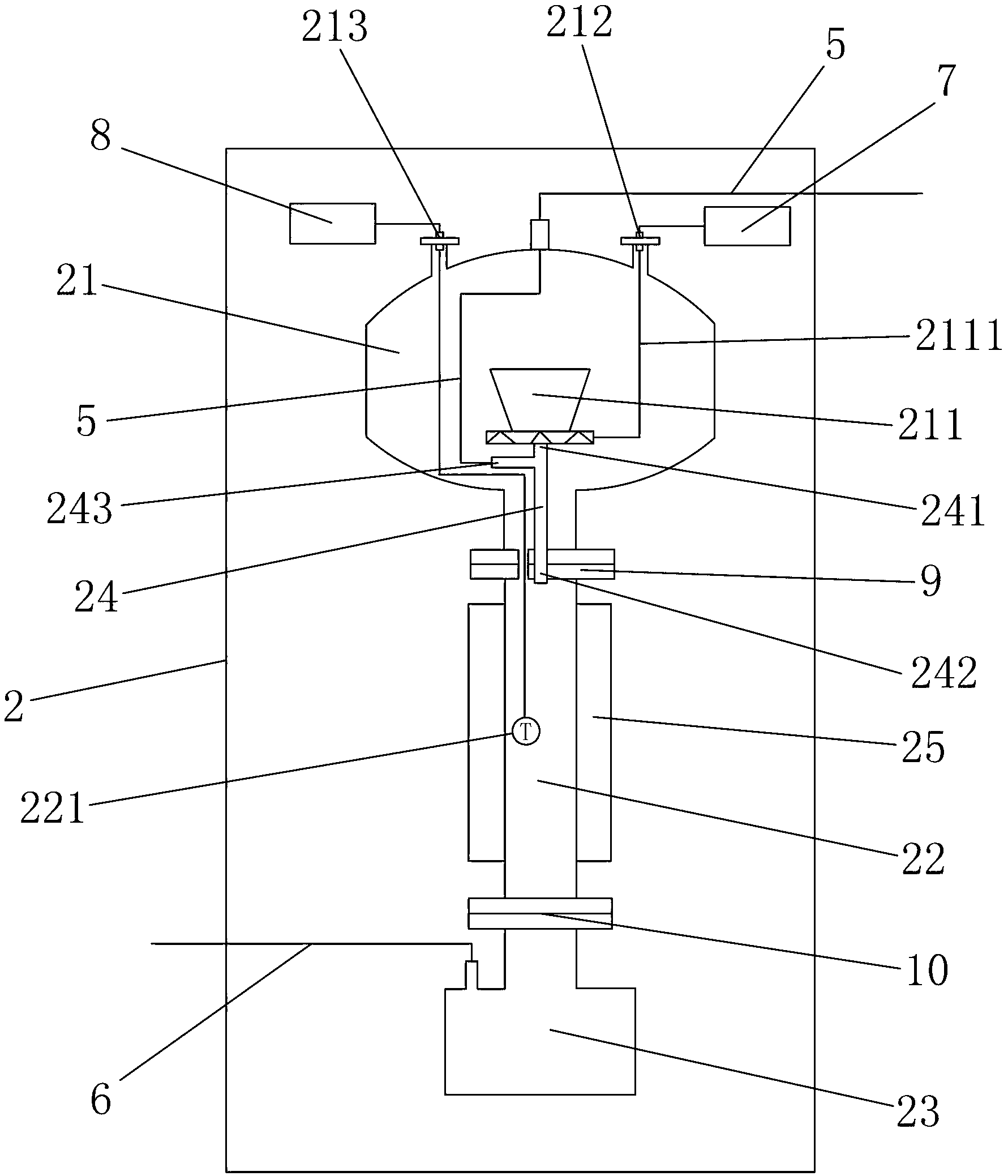

[0037]The settling furnace 2 includes a pressure vessel 21, a reaction tube 22 and a slag storage tank 23 connected in sequence from top to bottom; the upper part of the reaction tube 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com