Stirring cylinder of cold-regeneration stirring apparatus for asphalt mixture

A kind of asphalt mixture, cold recycling technology, applied in the direction of road, road repair, road, etc., can solve the problems of non-continuous feeding, difficult production, increased production cost, etc., to reduce labor intensity, facilitate cleaning of residual materials, The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention is described in detail:

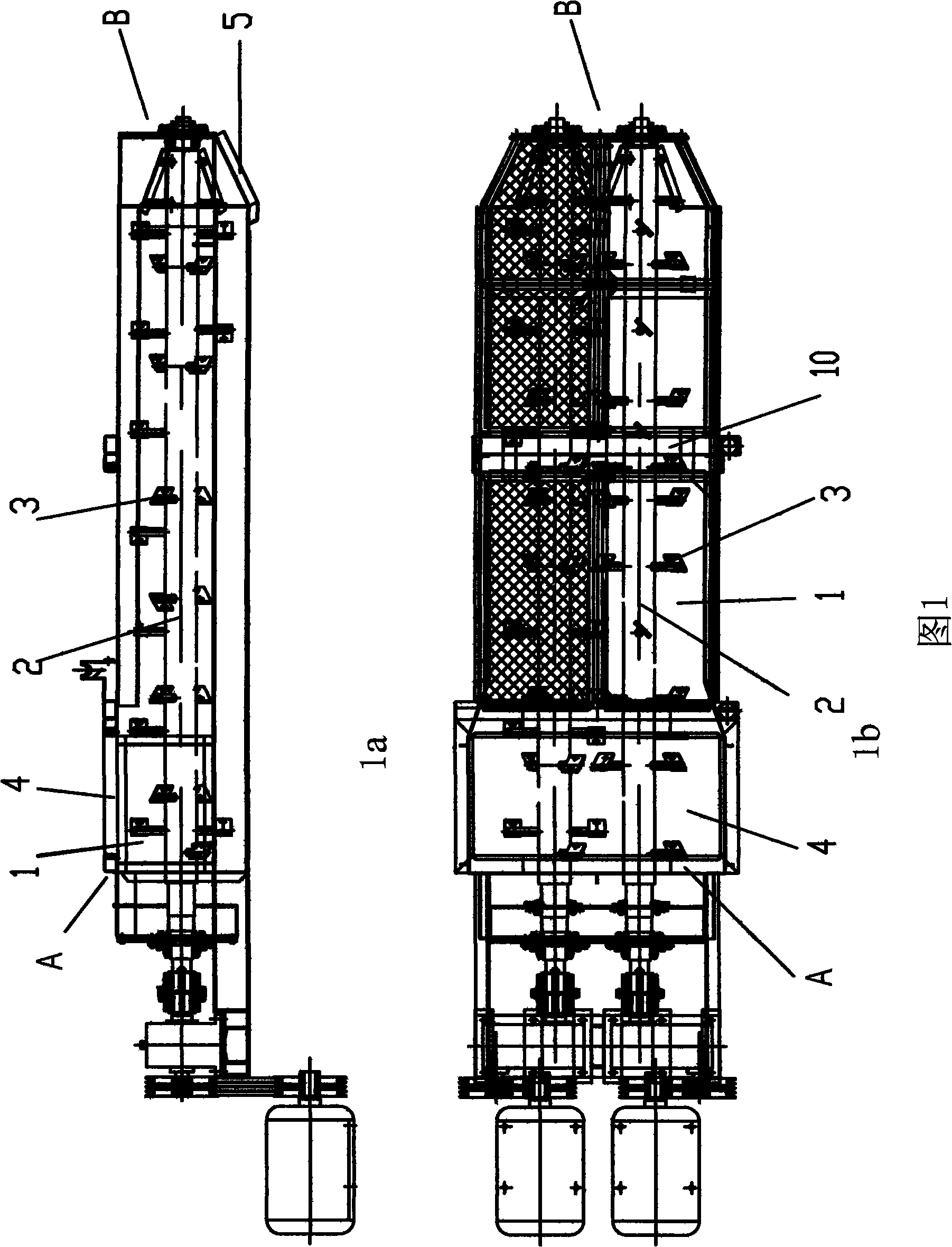

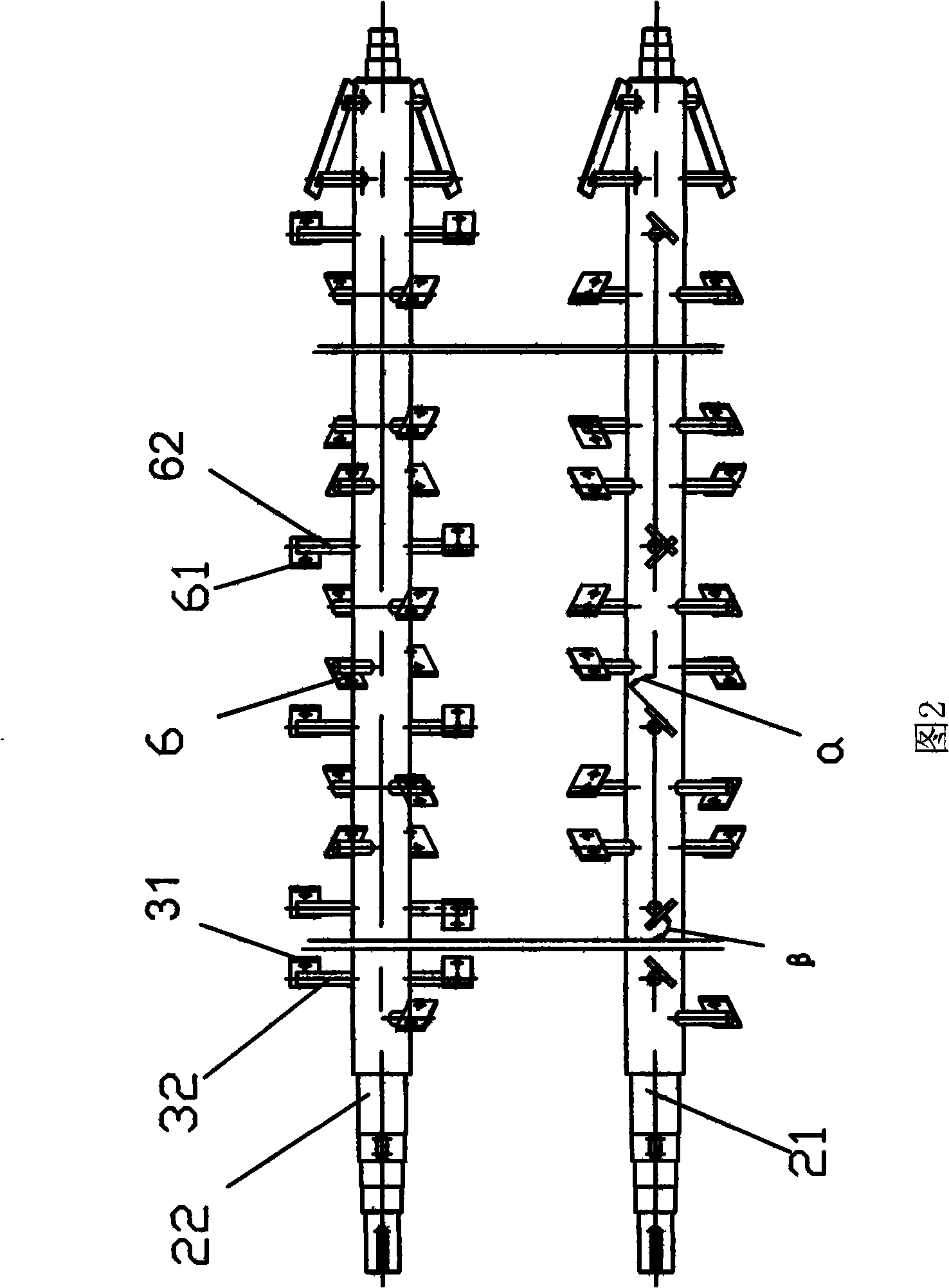

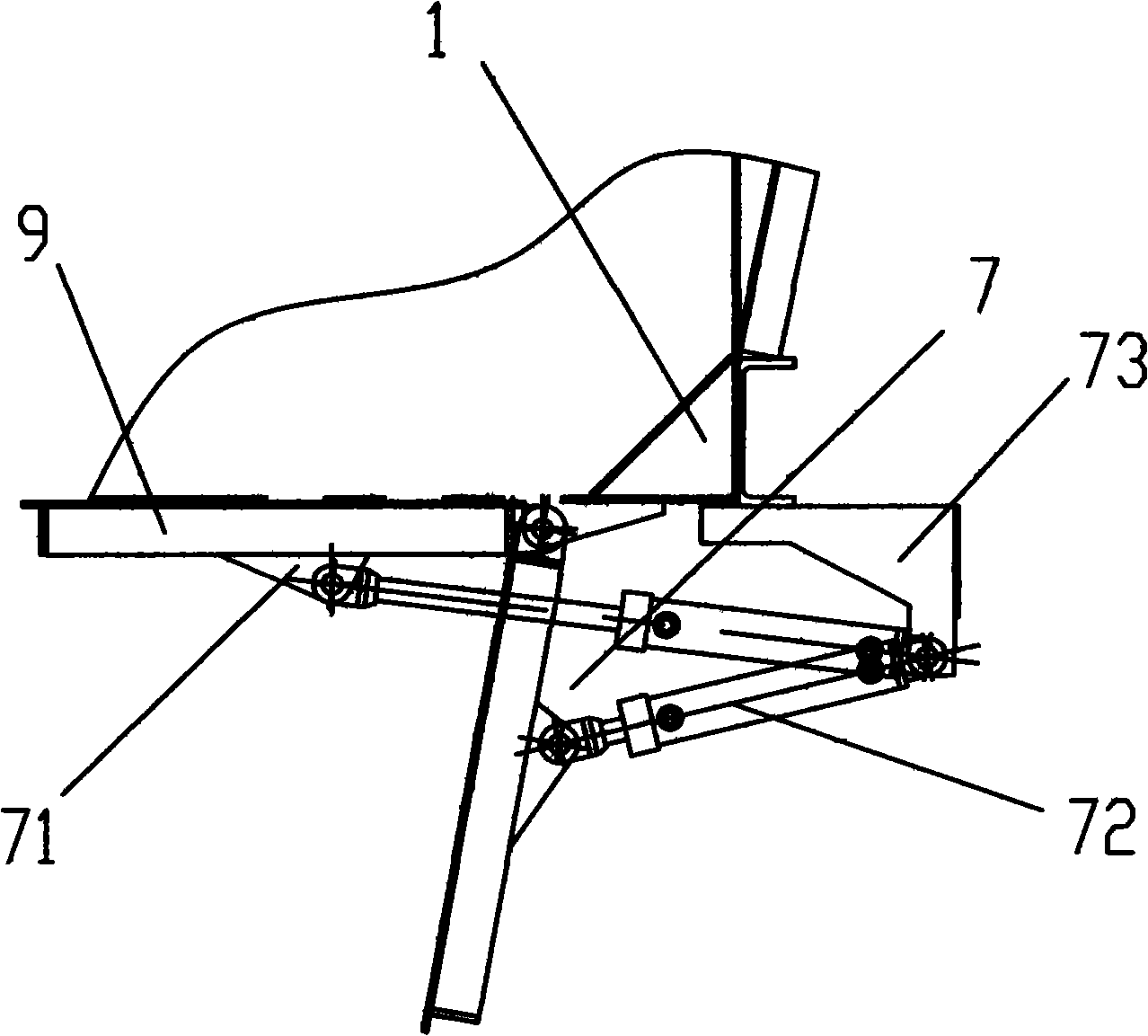

[0021] Referring to Figure 1- image 3 , the mixing tank of the present invention comprises a cylinder body 1, a material inlet 4 and a material outlet 5 are provided on the cylinder body 1, and the material inlet 4 is arranged on one axial end A of the cylinder body 1 stirring shaft 2 Above the end, the discharge port 5 is arranged below the other end B of the cylinder body 1 in the axial direction of the stirring shaft 2, and two rotatable stirring shafts 21, 22 are also arranged in the cylinder body 1, and the two stirring shafts 21, 22 Turning to the opposite, at least 3 stirring blade devices 3 are uniformly arranged respectively along the two stirring shafts 21, 22 axially, and the stirring blade device 3 includes a stirring blade 31 and a knife handle 32, and one end of the knife handle 32 is fixed on the stirring shaft On 21 and 22, the other end is connected to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com