Automatic code spraying and stacking machine for spandex filament paper pipes and use method of automatic code spraying and stacking machine

A technology of stacker and spandex yarn, which is applied to the stacking of objects, conveyors, conveyor objects, etc., which can solve the problems of low production efficiency, high labor cost, and unstable stacking quality, and achieve stable operation and low cost. Inexpensive, institutionally reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

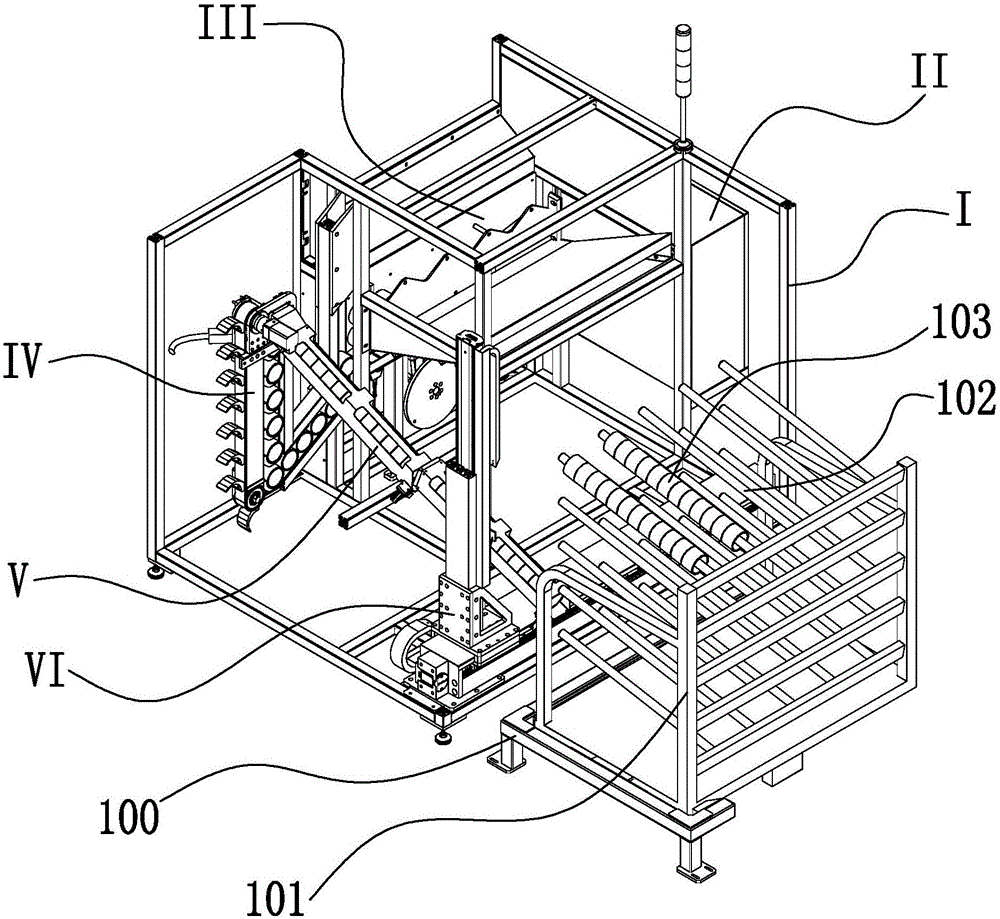

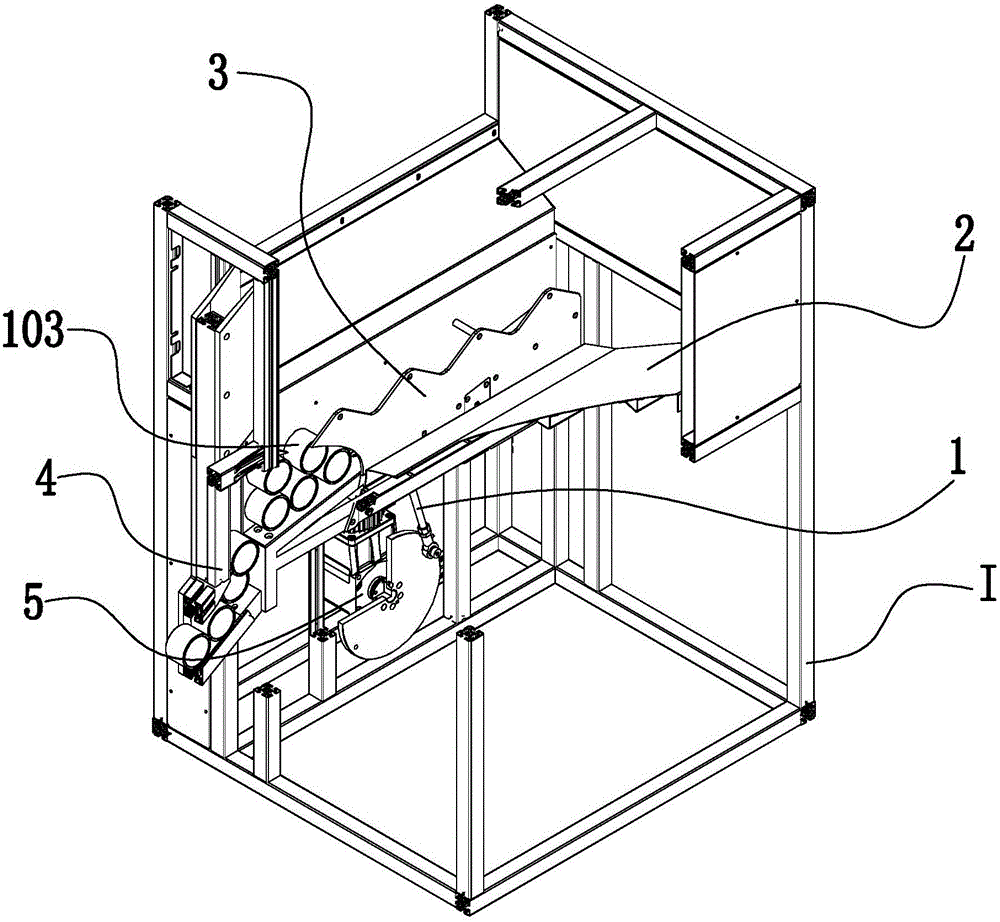

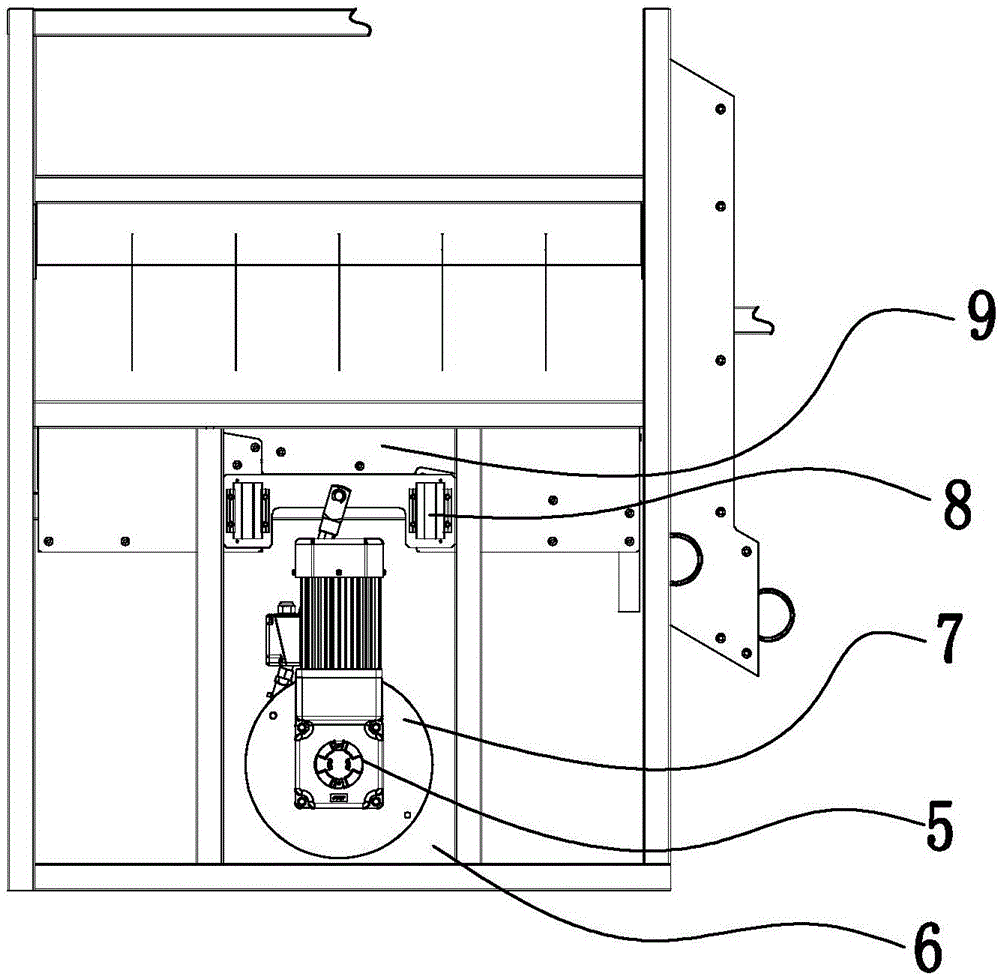

[0031] Embodiment one: if figure 1Shown: a spandex silk paper tube automatic inkjet stacker mainly includes frame I, electric control box II, material distribution module, lifting and inkjet module IV, buffer material channel module V, and vertical cross slide unloading module VI; the frame I is used to install each module, and each module with different functions is assembled into a whole, and the paper tube trolley positioning frame 100 is installed on the outside of the frame 1, thereby constraining the horizontal position of the finished paper tube trolley 101; machine The U-shaped layout on the rack I installs the paper tube distributing module, the lifting and inkjet module IV, the buffer material channel module V and the vertical cross slide unloading module VI in series, and the paper tubes pass through the above modules one by one and finally reach the finished paper tube trolley 101 on the rod 102. The paper tube dispensing module is used to provide paper tubes, and...

Embodiment 2

[0051] Embodiment two: if Figure 8-9As shown: the material distributing module is a paper tube rolling distributing module, and the paper tube rolling distributing module includes a paper tube storage hopper 201, an array type rolling dial 202, a dial mounting seat 203, a second AC gear motor 204, a distributing Material stopper 205, discharge chute 206, discharge lifting stopper 207, conveyor 208, conveyor servo motor 209, cylinder 210, linear bearing 211, optical axis mounting seat 212, optical axis 213, paper tube storage hopper 201 Located on the upper part of the rolling distributing module, it is in the shape of a "V". The lower part of the paper tube storage hopper 201 has an array-type feeding groove. The array-type rolling dial 202 is fixed on the paper tube storage hopper through the dial shaft and the dial mounting seat 203. 201, the dial 202 extends into the inside of the paper tube storage hopper 201 through the arrayed feeding groove, and the second AC decelerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com